Hohenloher Kunststofftechnik is another name for expertise in wire inmoulding. Its product diversity depends on high-quality toolmaking.

Hohenloher Kunststofftechnik GmbH & Co. KG has been a quality-oriented supplier of industrial thermoplastic and thermoset parts since 1952. Under the management of Michael Baum, the Öhringen-based company of Prince Kraft zu Hohenlohe Öhringen concentrates today on its strengths in plastics processing and is at pains to consistently extend manufacturing depth. With its almost 60 employees, HKT aims in this way to become more independent and flexible and boost value added in production. In the toolmaking sector, these steps have already been taken, with a wire EDM machine from Mitsubishi Electric being installed in 2009.

Before installation of the FA10-S Advance, Mitsubishi Electric carried out extensive training so that HKT could start production without delay.

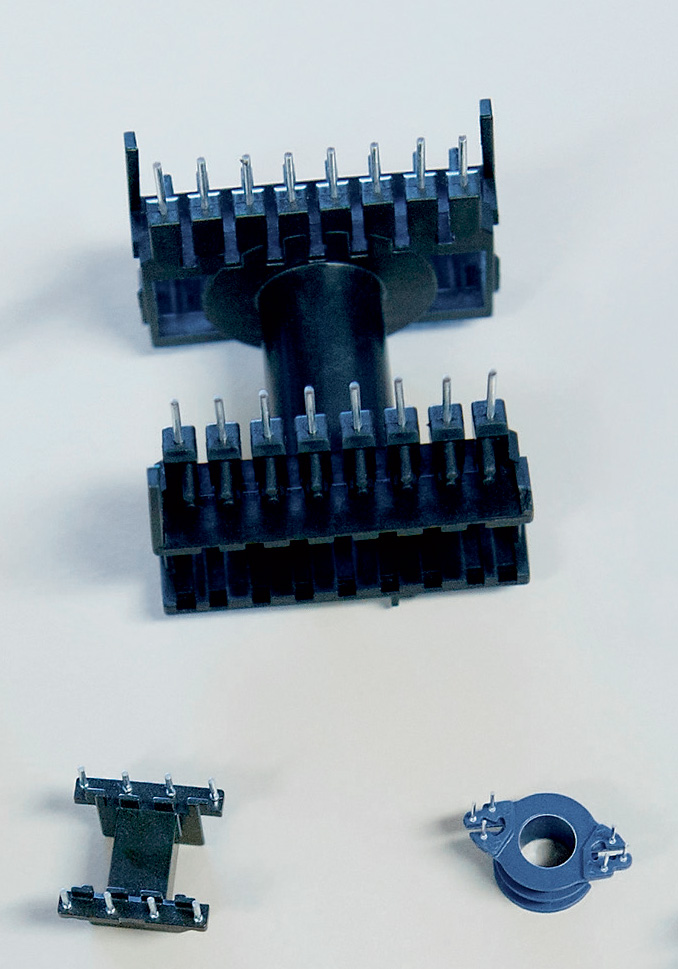

“It’s our goal to perform as many tasks as possible ourselves,” says manager Michael Baum, describing HKT’s policy. The principle is insourcing rather than outsourcing. The company is already a force to be reckoned with in the field of wire and pin inmoulding. These highly specialised industrial thermoplas-

tic and thermoset parts can be found in virtually all sectors of industry where electronics is a prominent feature. Along with the classical electronics industry, HKT also serves the automotive industry and medical technology, to mention just three examples.

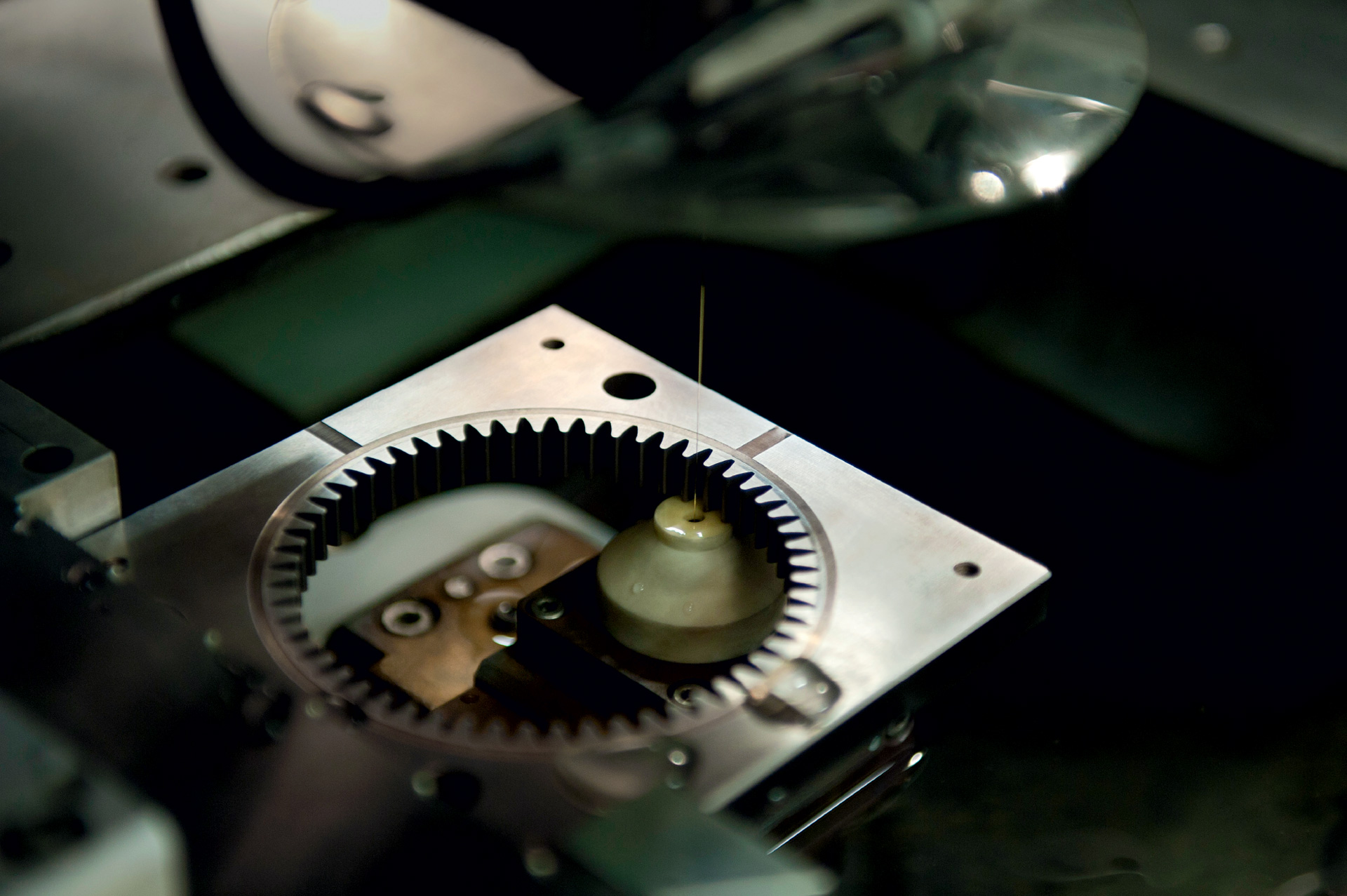

The FA10-S Advance cuts tool components of different kinds – in this case a gearwheel mould. The picture shows the finished injection-moulded plastic gearwheel.

HKT’s diversified products are used in all sectors of industry where electronics is a prominent feature.

“Mitsubishi Electric’s support made a lasting impression on us.”

HKT has many reasons for pursuing its insourcing policy mentioned above, as Michael Baum explains: “First of all, we want to strengthen our independence and become more flexible. In addition, we also want to thus boost our valued added.” His aim with the company is to achieve maximum manufacturing depth. “To this end we shall gradually increase our production area as well as our work-force,” says the manager, outlining his medium- and long-term plans.

The increase in staffing is made possible by consistent initial and further training. “Highly skilled staff are difficult to find in our sector,” says Michael Baum. “That’s why we take the matter into our own hands.” This commitment is tangible, with over ten per cent of employees undergoing initial training. As far as the expansion of production is concerned, a portion of the extended space already benefits toolmaking, where the company went new ways in terms of machinery in 2009 – with a wire erosion machine from Mitsubishi Electric.

Michael Baum has no doubts about the importance of wire-cutting. “Our tools have a very high degree of segmentation. A wire-cut EDM machine is absolutely ideal for us and our way of building complex tools,” he says, giving insight into their approach. The machine they chose is an FA10-S Advance, because the popular model from the Japanese manufacturer fitted perfectly into the reorganised toolshop. The graduate engineer is appreciative not only of the machine parameters: “The equipment is just what we were looking for. In the end, however, it was the overall package that tilted the balance.”

In Michael Baum’s view, the overall package includes not only the high-performance machine but also outstanding service. “Mitsubishi Electric’s competence during initial consultations as well as during training and in recurring support made a lasting impression on us,” the manager recalls. The attractive price also contributed to the purchase decision. The training in the use of the control and of the machine was carried out by Mitsubishi Electric before machine installation, which meant that toolmaking got started at about the same time as production.

Thanks to the FA10-S Advance, the toolshop is now capable of much more than before. While the toolshop used to only handle tool repairs, the wire EDM machine now enables HKT to build entire tools as well. Michael Baum also stresses quality as a factor: “Many tool components call for a level of precision and surface quality that can only be attained with wire erosion – and cost-effectively at the same time.”

With production benefiting from improved flexibility and higher value added,

Michael Baum looks ahead: “Our growth goals can only be achieved with consistent ongoing development in the company.” In other words, innovation is writ large at HKT. “This is just as crucial in our sector as in others and is ultimately expected by our customers as well,” the manager adds.

The restructuring of tooling is just one example of the commitment to innovation at HKT. Another example is the continuous optimisation of production processes in the moulding shop. “Wherever possible and sensible in production, we employ robots in order to automate processes,” says Michael Baum explaining the procedure. This boosts productivity and improves efficiency. The measures taken so far have paid off, so Michael Baum sees no need to depart from this policy: “We’ve still got plenty of potential and want to grow to twice the size in the coming years.”

HKT engages in injection-moulding production with highly advanced equipment and highly optimised processes.

Manager Michael Baum (right) inspects the current project with wire EDM machinist Norbert Trefz.

Name and place of business:

Hohenloher Kunststofftechnik GmbH & Co. KG, Öhringen, Germany

Founding year:

1952

Number of employees:

52

Managing partner:

Prince Kraft zu Hohenlohe-Öhringen

Core business:

Kunststofftechnik

Hohenloher Kunststofftechnik GmbH & Co. KG

Pfaffenmühlweg 82

74613 Öhringen

Germany

Tel +49 . 7941 . 60960

Fax +49 . 7941 . 6096 40

info @ hkt-hohenloher.de

We specialise in the high-precision injection-moulding of thermoplastic and thermoset products in combination with wires, pins and metal inmoulding technology.

As a student in the laboratory for the testing of concrete samples.

Achieving something every day!

We learn from our mistakes and make adjustments faster so that we can continue to pursue our goals.

We aim to continuously and consistently develop personally and technologically and offer the market options in our technology of wire inmoulding in order to grow with it. Expressed in concrete figures, we’d like to see our company double in size within the next five years.

Restructuring the company.

After sport, having a good chat over a glass of beer.

Reliability and trust.

Go your own way and listen to your inner voice!

Imagine casting shapes in lead, but using plastic instead.

Manager

Hohenloher Kunststofftechnik GmbH & Co. KG

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com