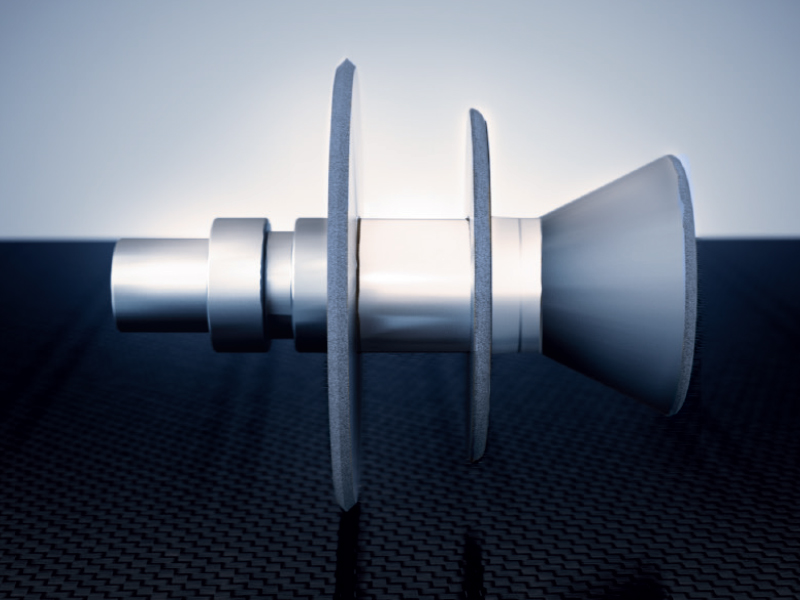

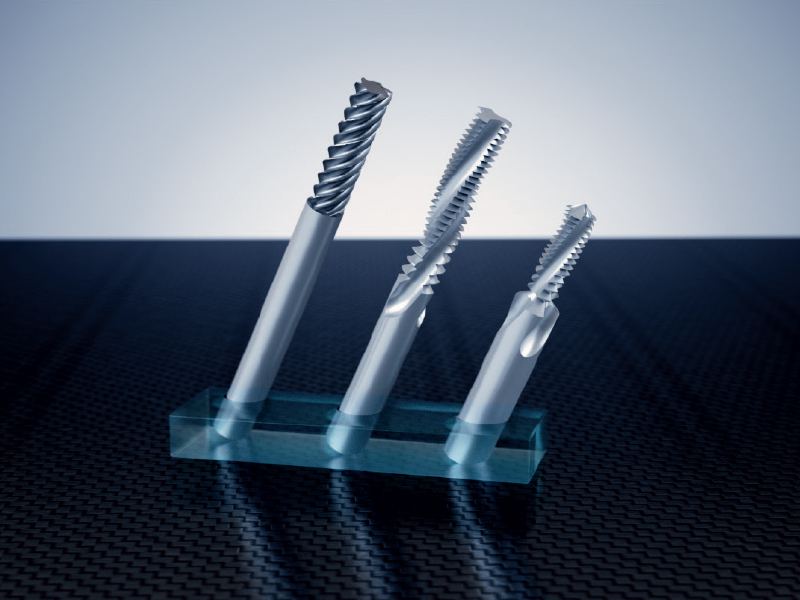

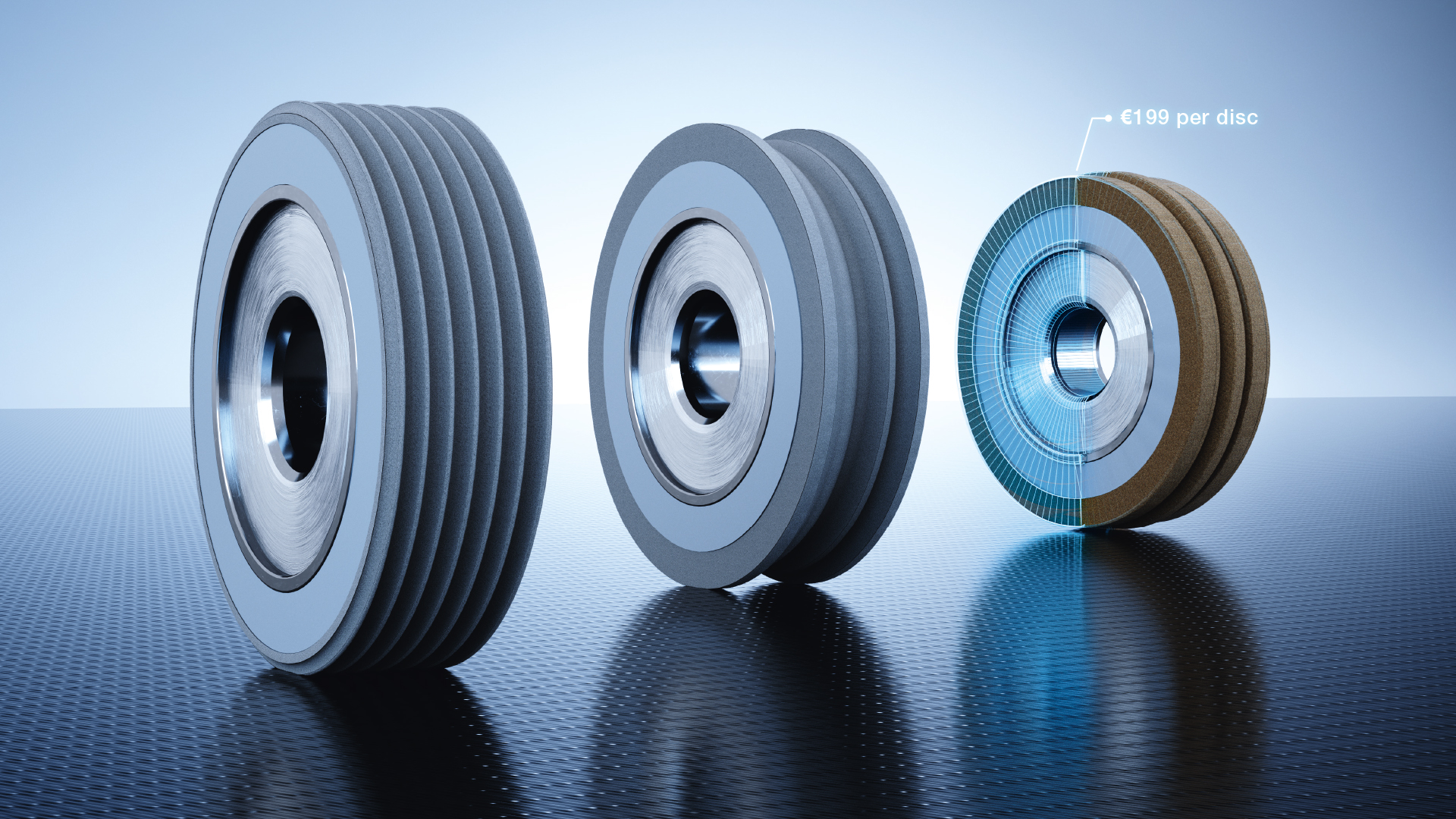

Exploit the advantages of metal-bonded grinding wheels in the grinding process

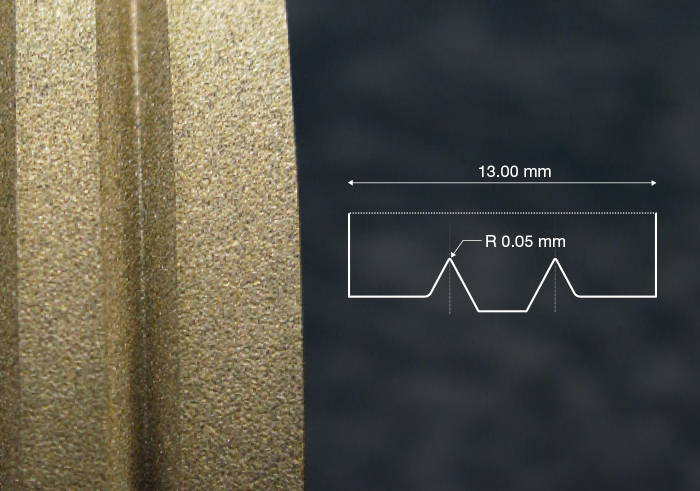

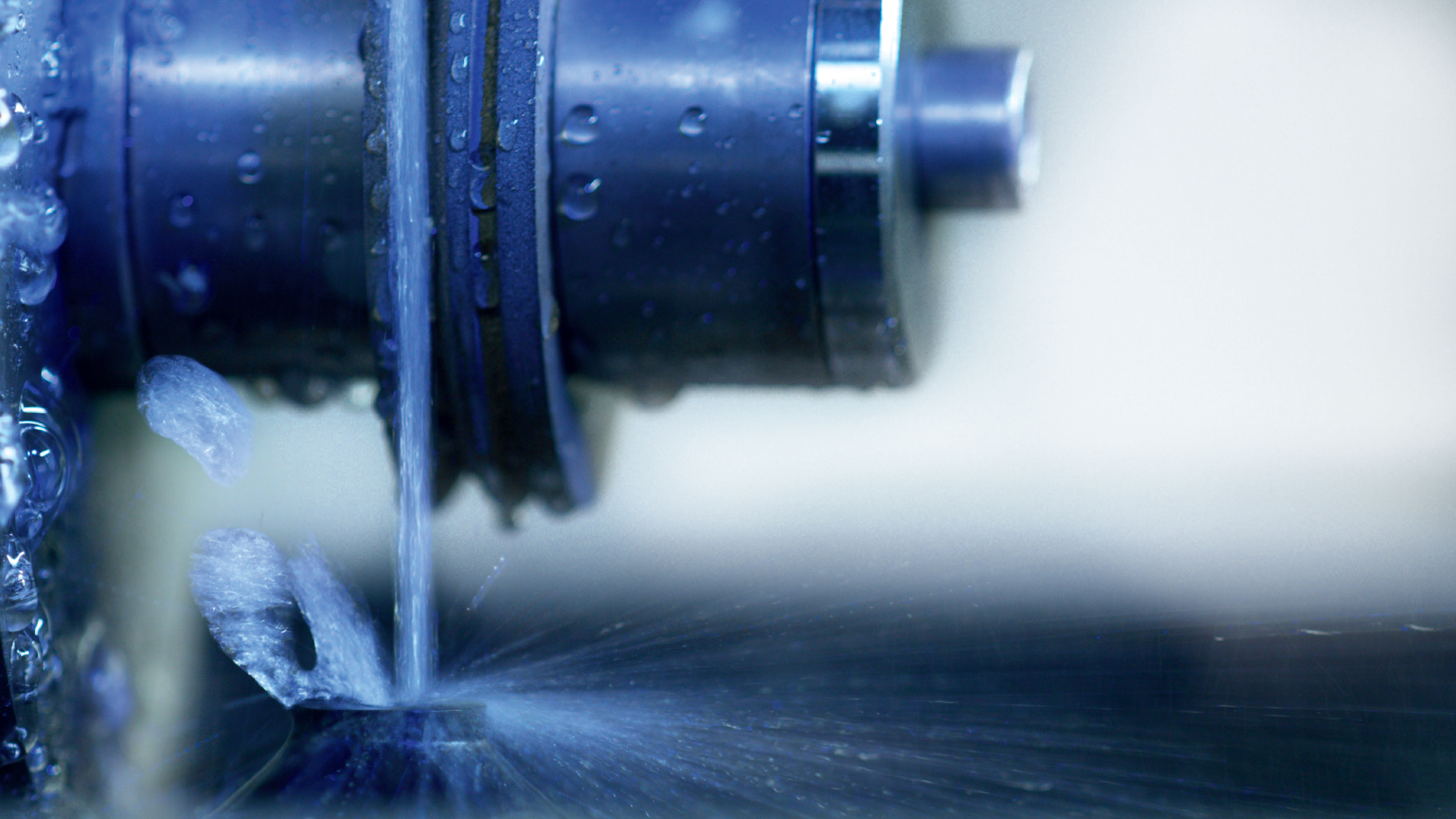

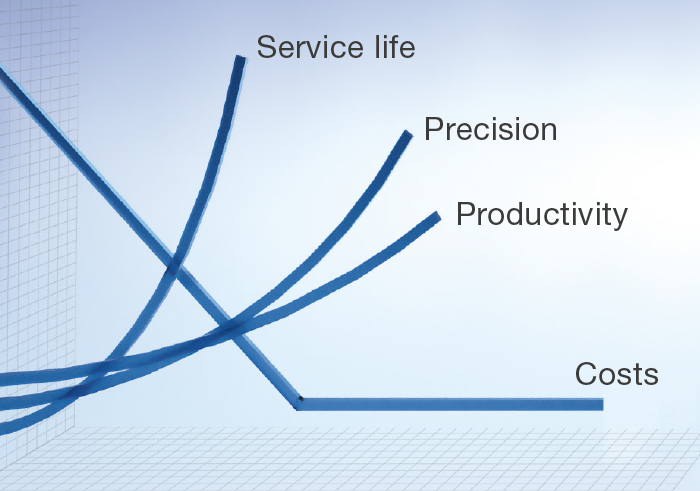

In the grinding of tungsten carbide, ceramics and hardened steels, metal-bonded grinding wheels have huge advantages over the grinding wheels with synthetic resin bonds currently in frequent use. They are much more dimensionally stable and permit significantly higher grinding feed rates – for previously unattained productivity.

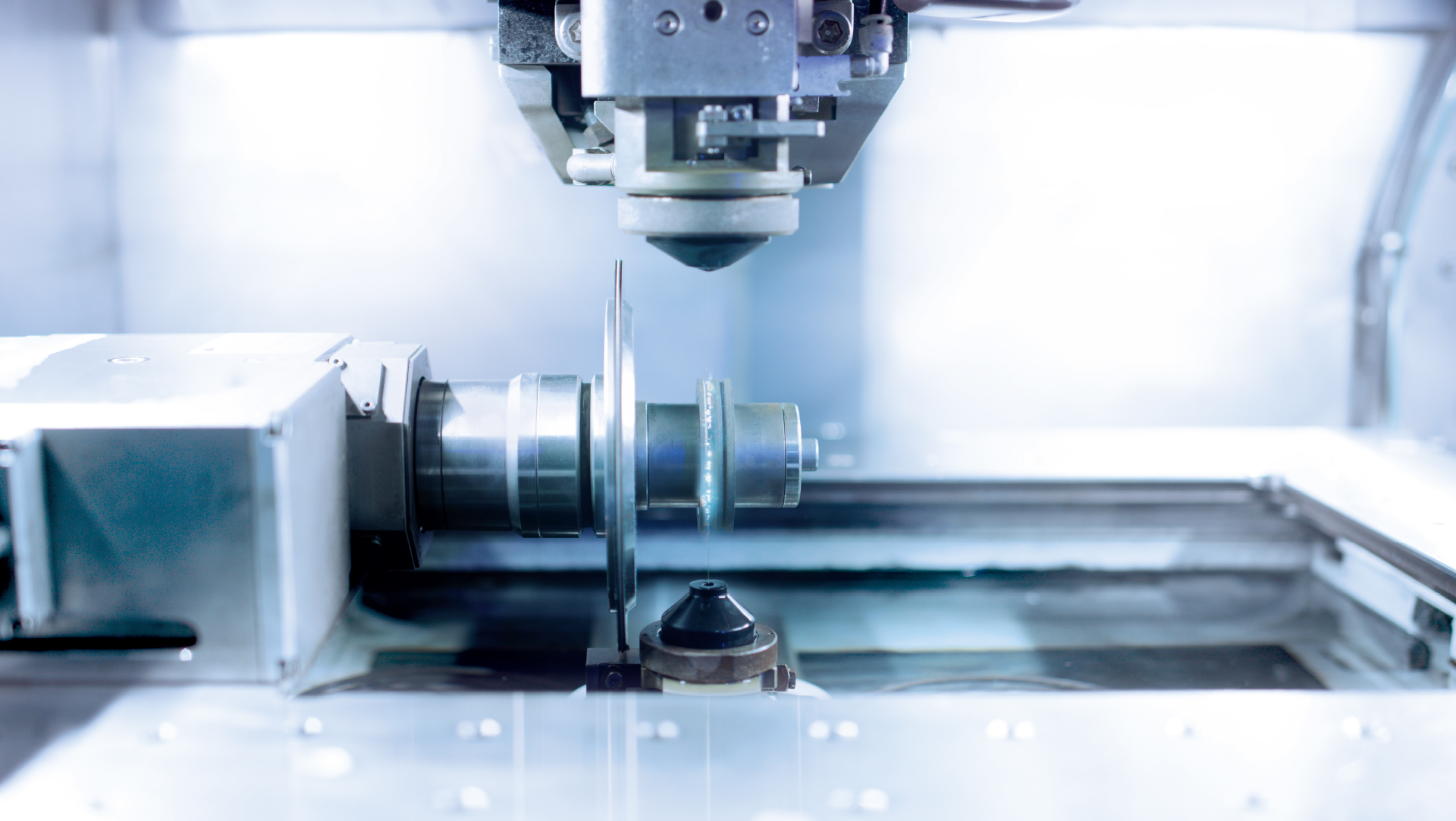

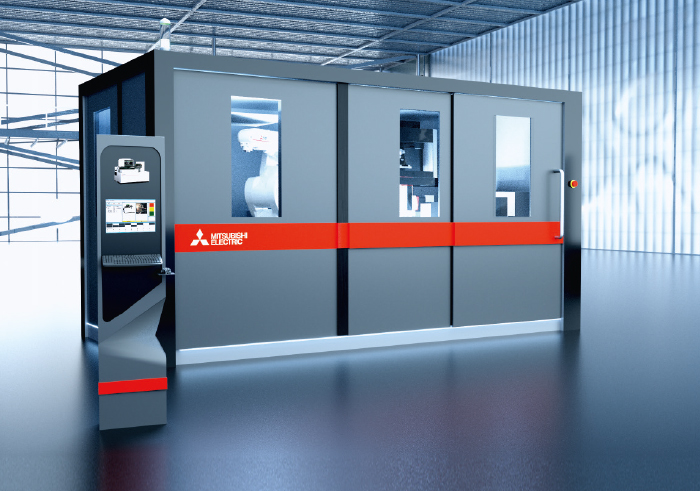

The constant challenge of boosting precision and effectiveness while reducing costs can be achieved with metal-bonded grinding wheels. The previously highly elaborate dressing process can now be superseded by wire EDM systems with the V350 generator from Mitsubishi Electric.

Welcome to our quick navigation. Here you can directly select a topic that you are particularly interested in. You will then be directed to this topic.

Mitsubishi Electric has been a partner of the Formula 1® team for many years, and over 26,400 workpieces are machined on Mitsubishi Electric EDM systems each season.

For Alfa Romeo Racing, every millisecond of lap time counts, and the demands on precision and performance are extreme.

Why shouldn’t you benefit?

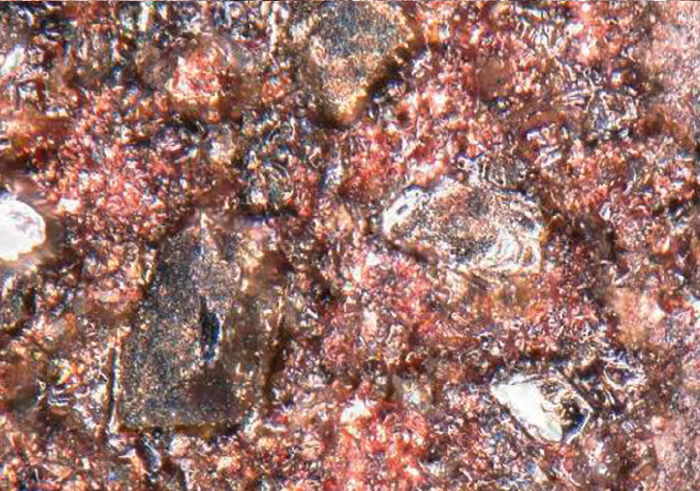

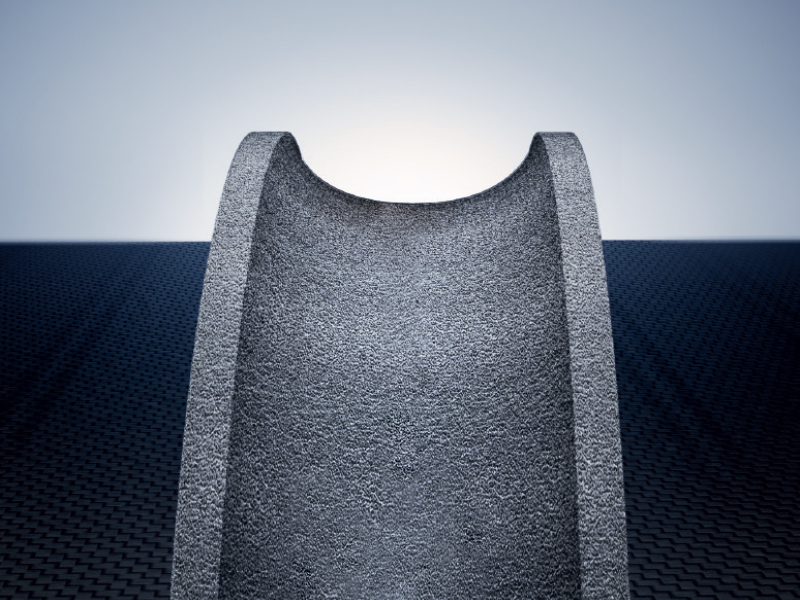

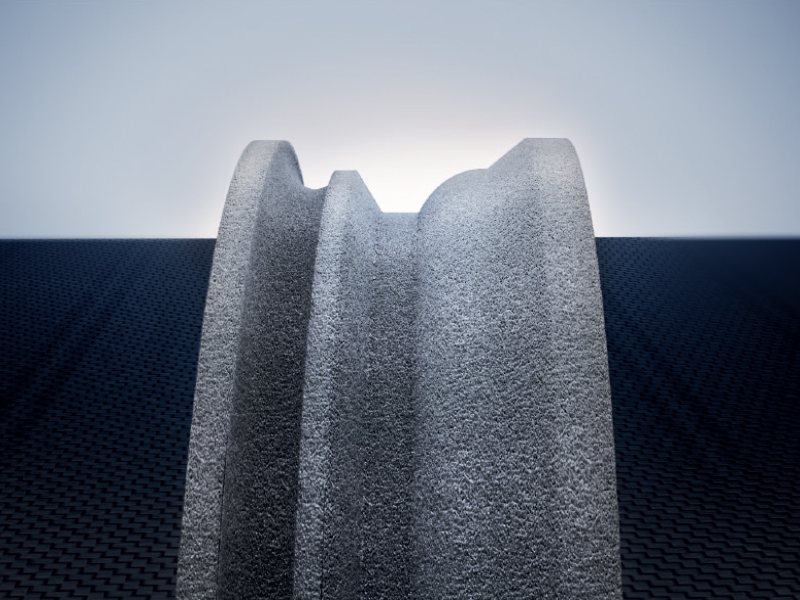

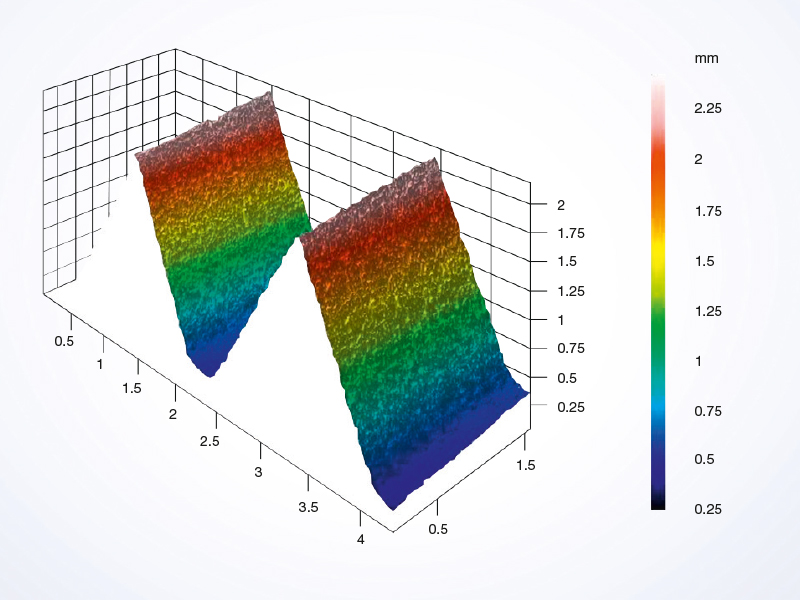

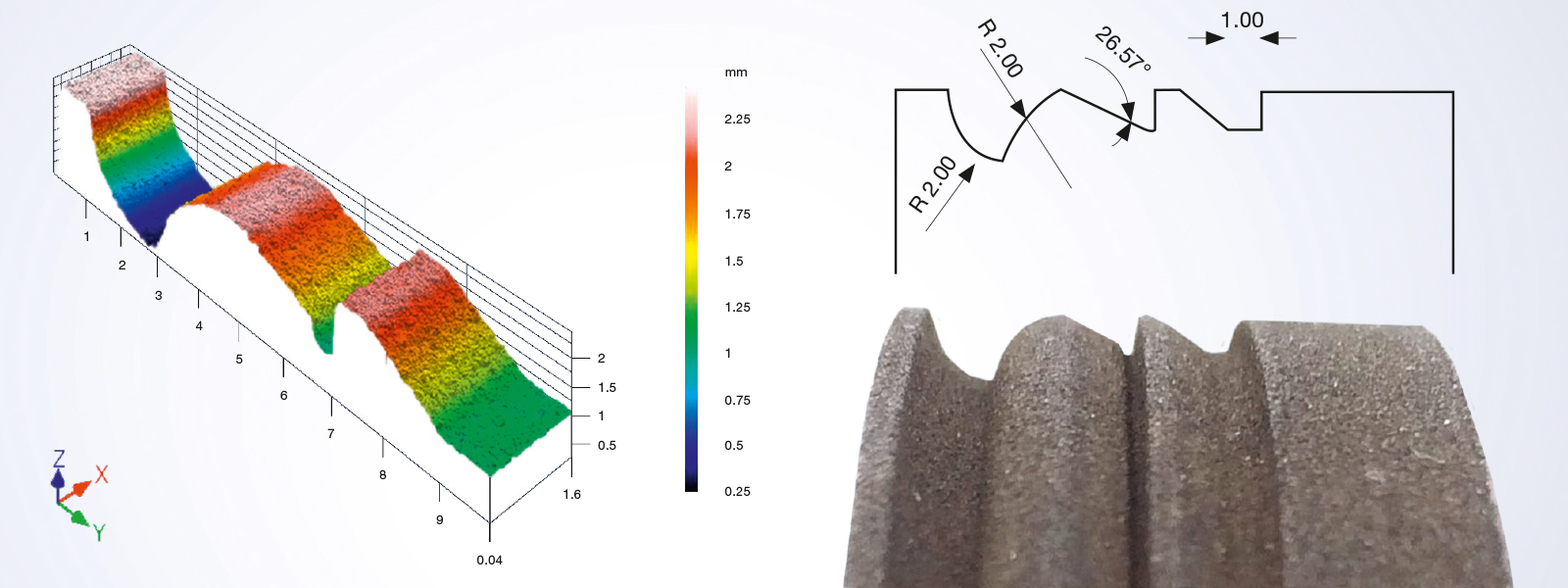

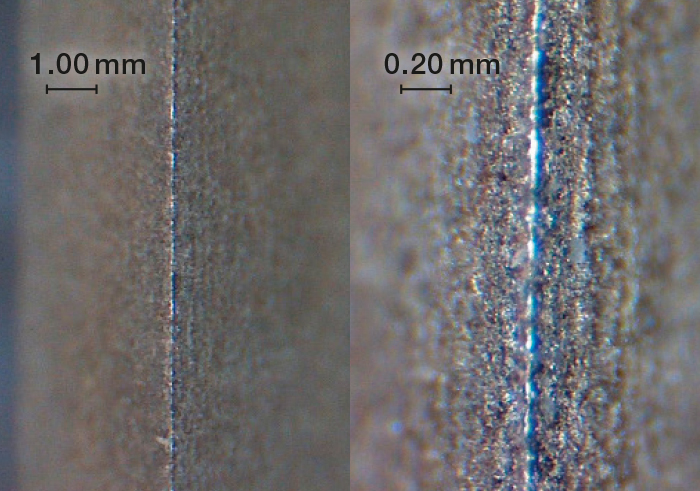

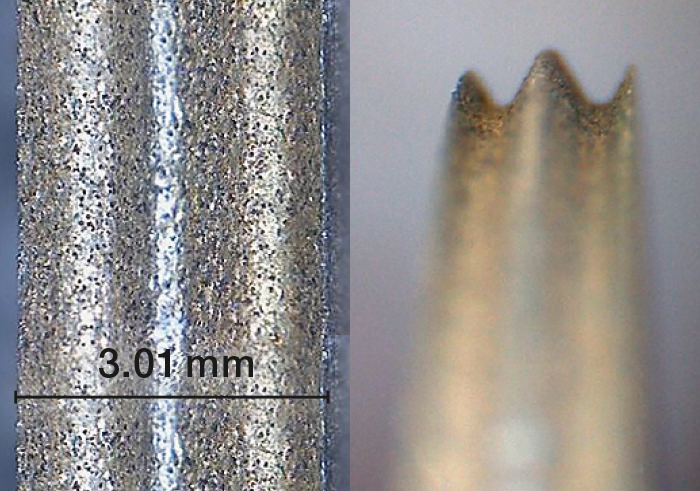

As a result the remaining structure of the grinding wheel is characterised by protruding, sharp exposed abrasive grains creating greater chip clearance and performance.

This significantly improves grinding performance, i.e. grinding feed rate, and grinding burn is avoided. At the same time, the service life of the grinding wheel is extended several times due to the considerably reduced mechanical and thermal stressing.

The grinding wheel is profiled to your wishes. Test the feed rates and service life on the real-life job. You’ll be delighted with the superior productivity and potential for savings.

For only €199 per disc – the offer is limited to one grinding disc, max. diameter 150 mm, per customer.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com