ProKASRO specialises in customer-driven solutions for sewer rehabilitation and has opted for maximum manufacturing depth – with the aid of wire erosion.

In August 2000, ProKASRO Mechatronik GmbH based in Karlsruhe took over from D.T.I. GmbH, a company that had embarked on the development and production of sewer milling robots back in 1989. Since takeover, ProKASRO has evolved into a full-range supplier in the sewer rehabilitation sector, equipping customers all over the world with its technology. Its product range covers innovative products for sewer rehabilitation, UV liner systems and camera inspection units. As a complete supplier, ProKASRO also operates an integrated production system with every conceivable form of machining. The most recent investment here was in the wire EDM sector. Production has been benefiting from an FA20-S Advance from Mitsubishi Electric since 2011.

Intact sewer systems are an important aspect of urban infrastructure. The quality of drinking water, for

instance, depends among other things on the exclusion of extraneous substances from water mains.

Equally important is that waste water is not allowed to seep into the ground. It is in this context that the regular control and rehabilitation of sewers are so essential. ProKASRO, the German abbreviation for

“progressive sewer rehabilitation robotics”, develops tailor-made solutions for precisely such tasks.

“With the aid of our advanced products, many sewers can be restored to an excellent condition, and this is much simpler and less expensive than laying new pipes,” says Uwe Reinhardt, Managing Director of ProKASRO, explaining the advantages of sewer rehabilitation. The company thus safeguards

underground supply systems and upholds ecological, hygiene and technical standards, he claims.

“The FA20-S Advance has markedly improved our wire erosion work.”

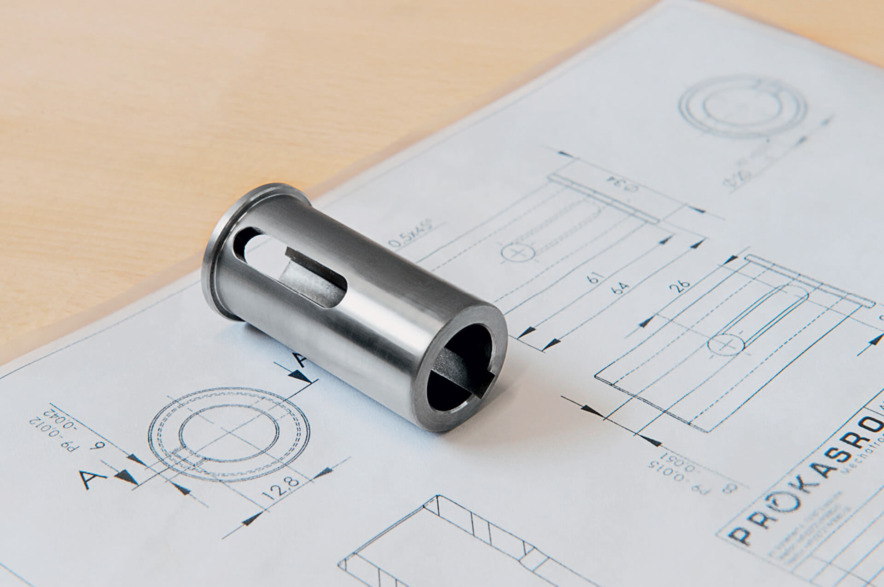

Wire erosion permits superfine cuts and high precision so that even the tiniest grooves of the required quality can be machined into the workpiece.

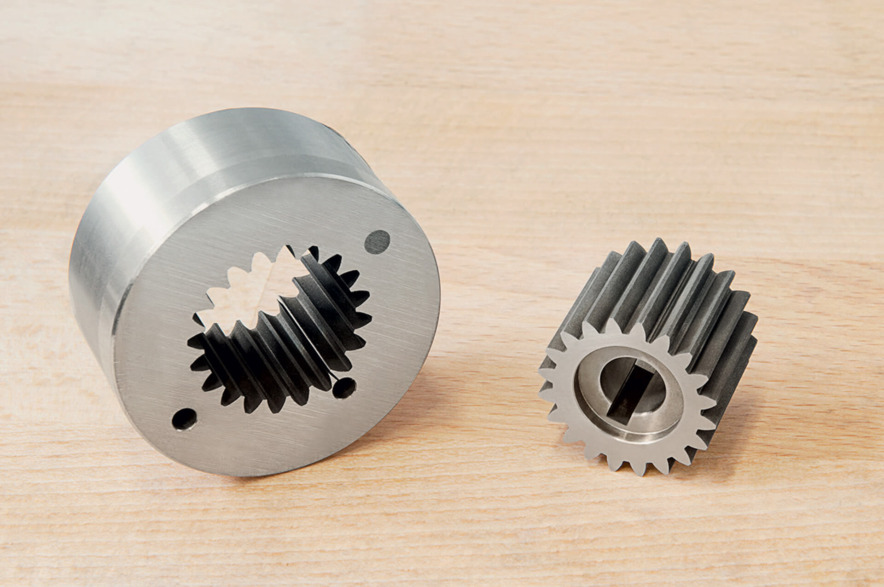

After wire erosion the gearwheel fits tightly into its counterpart.

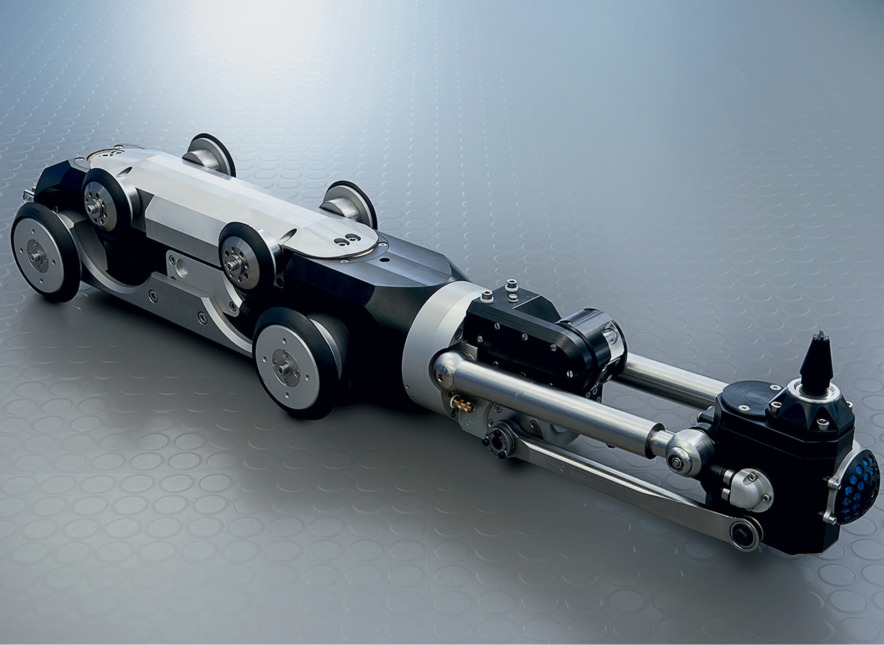

ProKASRO’s equipment comprises sewer robots and UV liner systems whose basic components are mutually compatible and combinable. This means that they can be used in all conceivable sewer systems with nominal widths of DN 100 to DN 1000 in circular or ovoid profiles. The tasks that sewer robots are capable of performing are manifold. They can mill, grind, fill, position balloons and install top hat profiles and liners for house connections, to mention but a few of the tool functions. In addition, UV liner systems and camera

inspection units permit applications ranging from inspection and cleaning to milling work and pipe union rehabilitation.

Since its founding 12 years ago, ProKASRO has become established as the sole full-range supplier in sewer robotics and thus conquered a leading market position. The product range extends from fully equipped vehicles enabling the customer to work independently for several days through to small, mobile robot solutions that have their justification in a city like Strasbourg, as Reinhardt explains: “A large truck simply wouldn’t make it through the narrow streets.” For its various projects, ProKASRO can count fully on the experience and skills of its over 100 employees. “Our spectrum of activities covers everything from development through to product delivery,” says the Managing Director, describing the company’s work. Depending on the complexity and size of the order, delivery within eight weeks is possible.

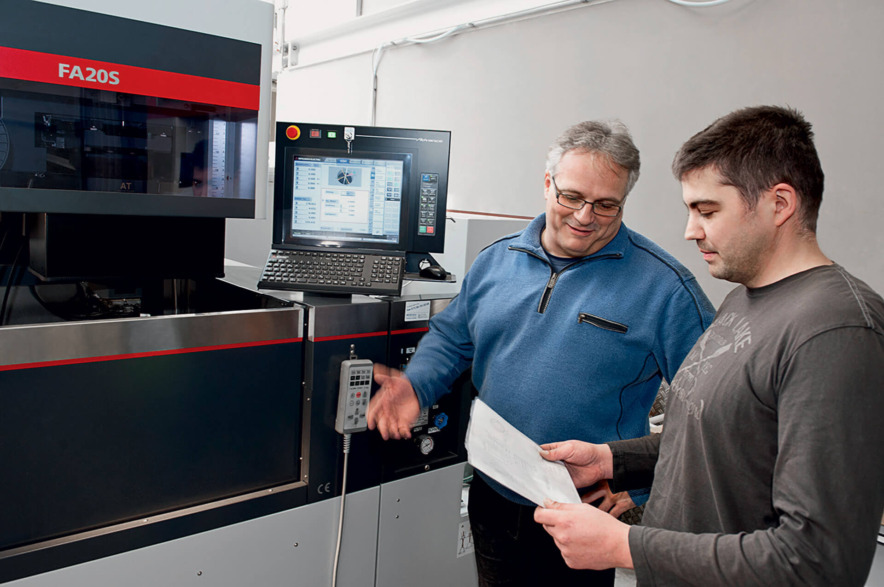

Rolf Dettinger (left), head of production, and Sven Beuchle, his deputy, appreciate the advantages of the FA20-S Advance: “It operates reliably and swiftly, and our flexibility benefits from this.”

Sewer rehabilitation robots are versatile. This one is equipped with a camera and a milling device.

This customer-driven approach is part of ProKASRO’s company philosophy. This is not least because the company has built up an extremely high manufacturing depth over the years. “Farming out our work makes little sense, because we would at best commission small series – for jobbers, this isn’t very attractive, so they’re often unable to react flexibly enough,” says Reinhardt. A multi-faceted assortment of technologies on a single site has huge advantages in this respect. Today, ProKASRO produces practically everything itself, from the robots and cameras to the gear fitted in the vehicles. The very few products bought-in are largely confined to CCD chips for the cameras and the vehicles proper. The technologies mastered by ProKASRO extend from conventional machining to die sinking and wire EDM.

In the wire erosion sector, ProKASRO took a big step forward in 2011, when an old machine was replaced by a modern model from Mitsubishi Electric. “We’re known for our innovative products and therefore also attach importance to progressive production techniques,” says Reinhardt, explaining the purchase. Mitsubishi Electric’s offer was impressive not least for its excellent price/performance ratio. “The FA20-S Advance has markedly improved our wire erosion work.”

The FA20-S Advance from Mitsubishi Electric has been in operation in production at ProKASRO since 2011.

“Automatic wire threading greatly simplifies everyday operations.”

The reasons for the investment in a new wire EDM machine were manifold. Along with extending the companies technological possibilities, the emphasis was on reliability, productivity and user comfort. On the subject of reliability and user comfort, Production Manager Rolf Dettinger highlights the machine’s dependable wire handling. “Automatic wire threading greatly simplifies everyday operations.” Wire breakages have been banished to the past since the FA20-S Advance has been in operation. Productivity has also gone up, a fact attributable to the machine’s powerful generator. “Performance can be adapted to increasing cutting heights so that cutting rate stays at the same high level,” Dettinger adds. ProKASRO benefits from the productivity of the FA20-S Advance not least in terms of flexibility. “We can now handle single parts and small series at very short notice. For larger production volumes, we run the FA20-S Advance unmanned overnight,” says Dettinger explaining how production is organised. If required, special jigs are built so that unconventional workpieces can be efficiently machined. The control of the FA20-S Advance has also proven to be a boon to Dettinger and his colleagues: “The Windows-based software and a user-friendly touchscreen are ideal because anyone can then quickly learn how to operate the machine.” CAM programming is performed centrally in advance at PC workstation.

ProKASRO also handles the complete fitting of vehicles for sewer rehabilitation. The solutions here depend entirely on the customer’s needs.

Business at ProKASRO has grown consistently. From the original 30 employees, the workforce has since grown to over 100. Engineers develop the complex equipment for sewer rehabilitation, and in production and assembly these plans are implemented to a high standard of quality to ensure customer satisfaction.

ProKASRO trains its own junior staff so that it has the capacity to cope with future business growth. Reinhardt views the future with optimism. “Progressive and innovative solutions for sewer rehabilitation are becoming increasingly important – after all, there are plenty of sewer systems in our cities that need regular maintenance.”

Name and place of company:

ProKASRO Mechatronik GmbH,

Karlsruhe, Germany

Founding year:

2000

Management:

Markus Lämmerhirt, Uwe Reinhardt

Number of employees:

Over 100

Core business:

Sewer rehabilitation

ProKASRO Mechatronik GmbH

Im Schlehert 6

76187 Karlsruhe

Germany

Tel +49 . 721 . 95082 0

Fax +49 . 721 . 95082 28

info@prokasro.de

www.prokasro.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com