Scientists at the Goethe University benefit from the high manufacturing depth of their workshop. The latest addition to the machine park is an EA12-V Advance from Mitsubishi Electric.

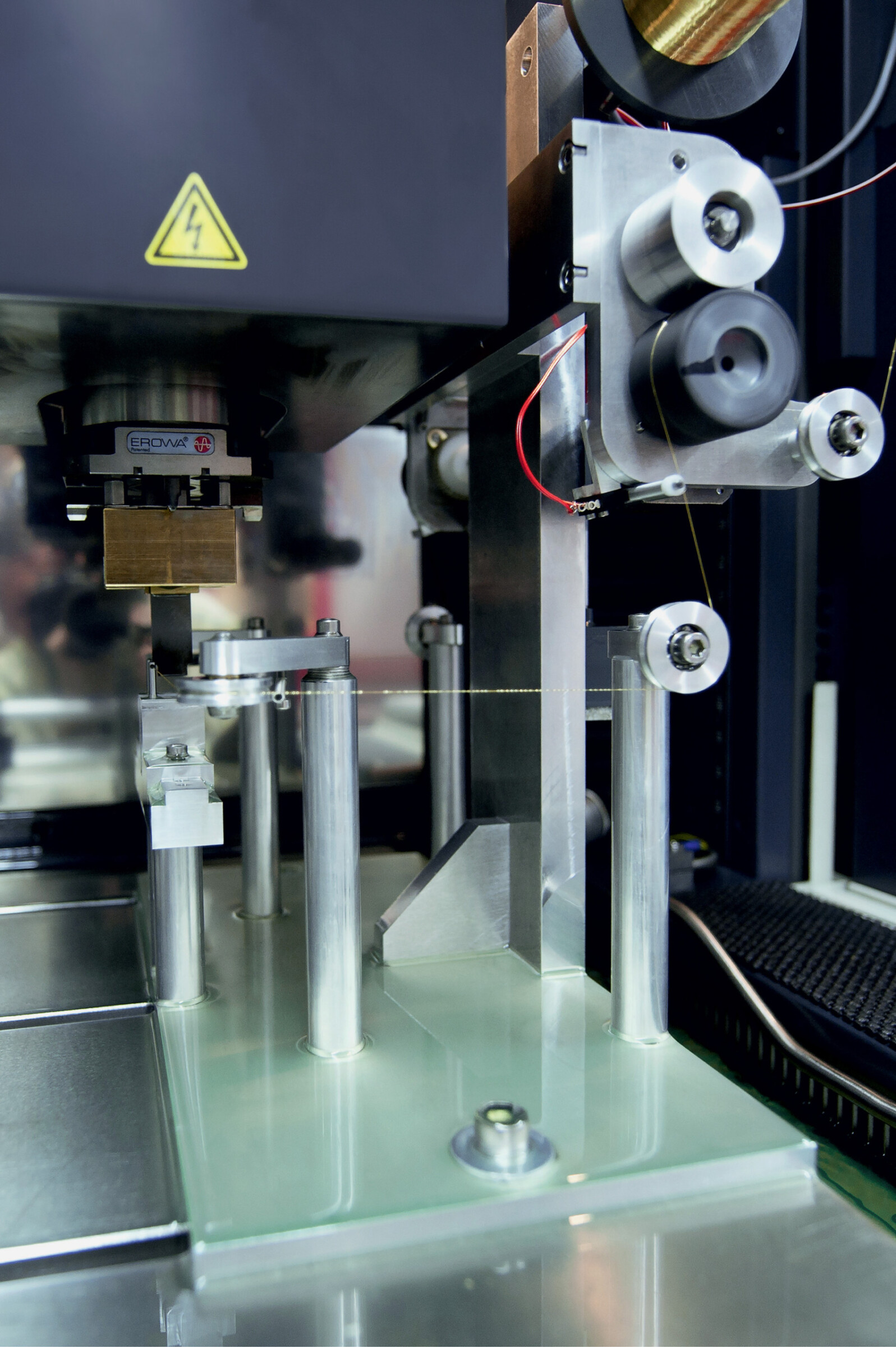

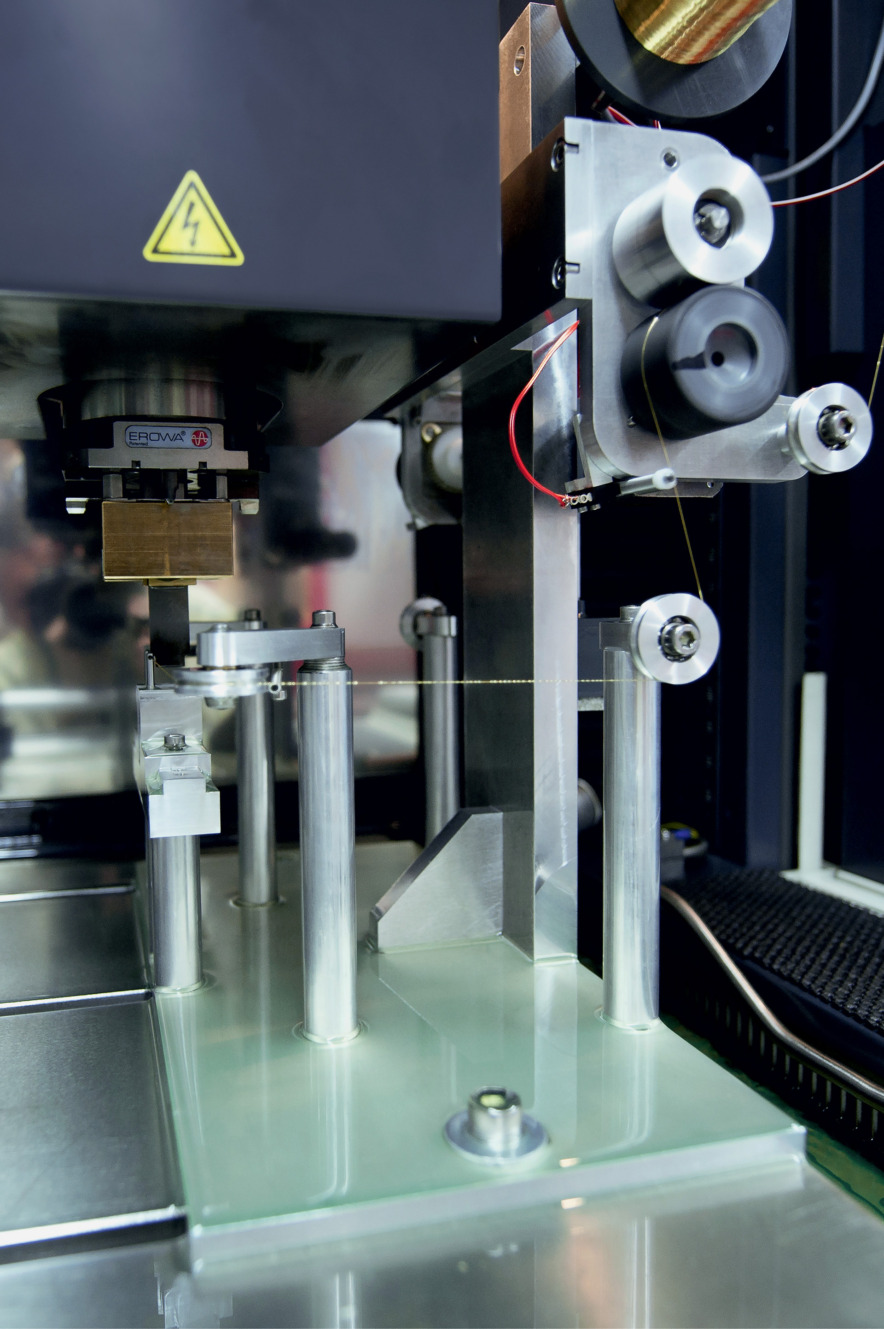

With a device developed in the workshop, they can also perform simpler wire-cutting tasks on the EA12-V Advance.

The multipole at the right-hand end of the component consists of two elements inserted into one another. Sinker erosion is necessary to achieve the narrow gap dimensions.

The Central Scientific Workshop of the Goethe University of Frankfurt am Main has an entirely practical purpose in the context of what is often theoretical research. Experts in industrial and fine mechanics, the workshop’s employees build apparatus that plays a central role in research projects. The innovative components are produced with the very latest production technology. The range of machining methods extends from conventional machining to die-sinking EDM. The latter has been possible since the installation of an EA12-V Advance from Mitsubishi Electric in 2009.

The Institute of Physical and Theoretical Chemistry at the Goethe University concentrates on “investigating microkinetics, molecular dynamics and the structure of biomolecules and model systems,”

as it says on the institute’s website. This may seem theoretical at first sight, but the scientists are dependent on entirely practical instruments for their research. This is where the Central Scientific Workshop takes its cue: “We support the work groups by building apparatus enabling them to reliably perform their tests,” explains workshop manager Helmut Jäger. The Central Scientific Workshop of the Goethe University is of key importance for research. Production orders are not awarded to industry, because of its lack of the requisite expertise and because of the excessive cost. “We produce almost exclusively prototypes. This has a lot to do with basic research, and it often takes several attempts to obtain the desired result,” says Helmut Jäger describing everyday workshop activities. The professors are also highly appreciative of their efforts, because close cooperation with the workshops not only yields better results, but also accelerates research. The timely publication of findings is in the interests of everyone concerned because of the high value of research project grants. It is against this background that the Central Scientific Workshop was thoroughly modernised in 2009.

Markus van Tankeren, fine mechanic in the central workshop, makes full use of the scope offered by the EA12-V Advance.

“I would never have thought that we would make so much use of it.”

Although the workshop isn’t located in industry, it does benefit from a high manufacturing depth enabling it to respond quickly and flexibly to the needs of the work groups. Realising this, Prof. Thomas Prisner, head of one of the work groups at the Institute of Physical and Theoretical Chemistry, advocated the purchase of a die-sinking erosion machine in 2009. Helmut Jäger remembers the reason: “With conventional machining, we eventually reached our limits where high precision or extremely fine cuts were concerned.” Inviting

tenders for the new machine was therefore a logical step, since awarding jobs to outside service providers wasn’t a feasible option for the reasons mentioned above.

Since this was the first die-sinking EDM machine that the workshop had ever purchased, Helmut Jäger was not biased by previous machine experience. One of the offers in response to the request for tenders came from Mitsubishi Electric. “In the end, the EA12-V Advance impressed us most with its operation and control.” The die-sinking EDM machine from the Japanese manufacturer is also a model of versatility.

This applies as much to workpiece size – the machining range is 400 x 300 x 400 mm – as to workpiece material. The latter is a crucial factor in research, because the workshop team sometimes has to process materials that are very difficult to machine. “Many components are made of copper, silver or cemented carbide,” the workshop manager adds. The machine’s performance in this area is made possible by the FP120V generator.

The functions of the EA12-V Advance, a versatile machine as it is, have been extended by the staff of the Central Scientific Workshop, as Helmut Jäger explains: “With a device that we have developed ourselves, we can also use the machine for wire-cutting on a limited scale, which helps us a great deal in electrode production.” Such tasks are often impossible with conventional means. The multipole of an ion mass spectrometer serves here as a suitable example: “The various comb bars are so close together that they can only be machined with a suitable electrode by sinker EDM. The slots of 0.08 to 0.4 mm, on the other hand, can only be wire-cut.”

Unlike users in industry, the Central Scientific Workshop doesn’t generate any income with its die-sinking EDM machine from Mitsubishi Electric. Nor does it aspire to achieve maximum machine capacity utilisation or continuously improve productivity. Instead, the goal here is to produce components that help the work groups of the institute to achieve their research breakthroughs. “The technology of sinker EDM has given us a powerful boost in this area, because we have retained our independence and have become more versatile into the bargain,” is Helmut Jäger’s assessment of the benefits of the EA12-V Advance. As far as capacity utilisation of the die-sinking EDM machine is concerned, the workshop manager expresses his positive surprise two years after installation: “I would never have thought that we would make so much use of it.” The machine has already paid its way “because the Institute of Physical and Theoretical Chemistry are not alone in benefiting from the purchase,” Helmut Jäger remarks. Since all institutes have access to the EA12-V Advance, the Central Scientific Workshop today covers an extremely broad spectrum of components. This is just one of several reasons why the workshop manager views the future with optimism: “If new investments become necessary and are approved, I could well imagine the machine park being extended in the wire-cut or sinker EDM fields as well.”

Helmut Jäger (centre), manager of the Central Scientific Workshop, and his colleagues Markus van Tankeren (left) and Christoph Langer (right), in charge of the machine and of programming and design.

Name and place of business:

Goethe University, Frankfurt am Main, Germany

Founding year:

1914

President:

Werner Müller-Esterl

Number of employees:

Roughly 4,600

Core business:

Research and teaching

Goethe University

Senckenberganlage 31

60325 Frankfurt am Main

Germany

Tel +49 . 69 . 798 0

Fax +49 . 69 . 798 28383

praesident @ uni-frankfurt.de

We support the research projects of the Goethe University by producing components for scientific apparatus by conventional machining and by wire and sinker EDM.

Training as a fine mechanic.

Working in research at the university, I’m free to take decisions and contribute my own ideas.

We do more work at the computer.

Work will be dominated even more by controlled machines.

The planning and realisation of the Central Scientific Workshop newly established in 2009.

Listening to music.

Competence, honesty and creativity.

For scientists we produce apparatus that’s not available on the market.

manager of the Central Scientific Workshop

Goethe University

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com