The German Branch of Mitsubishi Electric celebrated its 40th anniversary on 19 October 2018. Based in Ratingen near Düsseldorf, the company has been supplying its customers with high-quality products and solutions in the fields of transportation, air conditioning and heating technology, automotive, communications, semiconductors and automation for four decades now.

40 employees of Mitsubishi Electric’s German branch making the key visual for the company’s 40th anniversary.

Its customers are not only located in Germany and other European countries, but also in the Middle East and Africa. Accordingly, the company is positioned internationally. Its employees come from 26 different nations.

Andreas Wagner, President of the German Branch

Since its foundation, the German Branch has been an essential part of Mitsubishi Electric’s European business. We owe our great achievements and constant success to our committed employees as well as to our business partners and customers.

After its foundation in 1978, the German Branch developed rapidly. Initially, the focus was on the sale of consumer products, but business activities were continuously expanded. In the 1980s, the company recorded enormous growth and extended the activities of the German branch to other product areas. The investment in and the move to a new, ultra-modern office building in Ratingen-Ost symbolise the Japanese parent company‘s deep attachment to Germany as a business location, as the German branch is one of our most important locations outside Japan. The company regularly demonstrates this clear commitment to its location with social and cultural engagement.

Magnificent achievements and continuous success.

In addition to the Branch at Mitsubishi Electric-Platz in Ratingen, there are now 16 other sales companies, 12 production facilities and two research and development centres in Europe.

40 years of technological experience.

Mitsubishi Electric is active in Europe in areas such as information processing, communications, semiconductors, automotive, industrial technology, energy, transportation, building management, and air conditioning and heating technology. However, rather than stress developments in and the prospects of individual business areas, the company prefers to focus on the overall strategy. “It is one of our strengths to think in terms of solutions that include many industries and technologies. By dissolving the boundaries of individual business areas, we will create sustainable potential for the further positive business development of our German subsidiary,“ Andreas Wagner stresses. “We still have a lot to do in the coming decades.”

Wherever you look, Mitsubishi Electric is there. Everything from trains and lifts carrying you from A to B through to satellites keeping us globally connected – Mitsubishi Electric is changing and improving the world with innovation.

Amazing what we’re capable of!

Mitsubishi Electric is one of the world’s leading names in the manufacture and sale of electrical and electronic products and systems used in a broad range of fields and applications. In Europe Mitsubishi Electric is active in the fields of information processing and communications, automotive, industrial technology, energy, transportation and building equipment, and air conditioning and heating technology.

Thanks to its broad range of innovative products and services, the Ratinger company offers not only single products, but also the key to intelligent complete solutions. By intelligently combining various products and cross-divisional projects, Mitsubishi Electric is able to offer customers entirely new opportunities. Complete data centres, for example, work faster thanks to Mitsubishi Electric‘s 10 Gbit/s and 25 Gbit/s laser diodes.

Part of your life.

In doing so, Mitsubishi Electric has a clear goal in mind: the holistic conception of complete solutions in the market. The following five areas of technology that are crucial for present and future living have been identified: Transportation, Building, Communication, Energy and Automation. Mitsubishi Electric impresses with precisely adapted products, intelligent comprehensive solutions and first-class service, for example in residential and building construction. Mitsubishi Electric is thus making the five-star lifestyle of the luxurious Mainport Hotel even more comfortable. All rooms are equipped with high-class entertainment electronics. To adhere to the construction period of less than a year. it was decided to install a Mitsubishi Electric heat pump system to make heating and cooling possible at the same time. Elevators from Mitsubishi Electric transport guests quickly and safely to their floors.

The new German Branch of Mitsubishi Electric in Ratingen is also a fine example of the use of the company’s various products. Thanks to the City Multi VRF-R2 system the energy consumption is reduced by 40 per cent in the new building.

„We want to be perceived homogeneously as a single coherent company in different market segments. We focus on the future and present solution strategies that help us to master the technical and social challenges of tomorrow,“ explains Andreas Wagner, President of the German Branch of Mitsubishi Electric Europe.

Exploring the universe with radio-telescopes, networking the sky with communication technology and monitoring our environment with observation technology, Mitsubishi Electric makes use of its unique strengths in the design and production of satellites in ushering in a new era in space applications.

Circling the globe.

Image quality is the reason why customers all over the world are turning to Mitsubishi Electric when it comes to the most advanced visual information systems – everything from giant displays like the Ultra HD at Times Square in New York or in stadia, and large-format LED screens to display walls. Our technologies cut costs thanks to their innovative properties and high energy efficiency and set new standards of image brightness and reliability.

Times Square New York. 23.8 million pixels, 4064″ screen diagonal.

Displays of the superlatives.

More than 10,000 servers are often installed in modern computer centres. 70 % of the communication arising in a data centre takes place within the computer centre itself, so it needs high-performance fibre optic transmission links. With its 10 Gbit/s and 25 Gbit/s laser diodes, Mitsubishi Electric supplies key top-quality components for this, making the company a reliable and efficient supplier to industry.

High-speed computer centres with Mitsubishi Electric

The Lanxess Arena in Cologne is a breath-taking events venue. It has 18,000 seats, 83,700 m² of floor space, 1000 employees, large screens for direct video transmission, a restaurant, bistro, bars, shops and much more besides. As Germany’s biggest events venue, it sets new standards – and this now also applies to its video cube. What is probably the world’s biggest indoor video cube impresses thousands of spectators day after day with its brilliant pictures.

20 tonnes of high tech hovers magically above the playing area.

Lifts and escalators bring people swiftly, safely and comfortably to their destinations. Today, our high-speed lifts are making the construction of ever-higher skyscrapers practicable, while spiral escalators are creating new opportunities in the design of public spaces. Energy-efficient air conditioning systems and heat pumps ensure a pleasant indoor atmosphere and the highest possible comfort in public and private buildings.

The world’s fastest lift.

Mitsubishi Electric has received a contract to supply two lifts designed for a maximum travel speed of 600 m/min. After their installation in the LCT Landmark Tower in Haeundae, Busan, they should then be – according to Mitsubishi Electric’s research – the fastest lifts in operation in South Korea.

The two lifts will propel passengers from the ground floor to the 100th floor in about 52 seconds. The distance of 383.5 m will be the longest that a lift has ever covered in South Korea.

Thanks to Mitsubishi Electric’s trailblazing innovations in ultra-fast elevators – in drive and control technology, aerodynamically designed cabin covers, active roller guides and various safety features, for example – the elevators offer outstanding travel comfort and maximum safety coupled with low-noise operation.

Building technology.

New buildings with exciting hotel strategies can be seen going up in many towns. The buildings of the Prizeotel signature brand hotels, for example, offer exclusive interior design with the charm of a private hotel, combining high-grade styling and low room prices in a consistent strategy. The investor is equally consistent in the building services sector where intelligent VRF R2 heat pump technology is being put to use. This technology exploits excess energy in the building so that heating and hot water preparation are inexpensive and environment-friendly. In the hotel with high design aspirations, we keep energy costs low.

By Prizeotel Management Group. Design by Karmin Rashid Inc. & Photo by Eric Laignel

The Prizeotel strategy is distinguished by its combination of low prices and exceptional design. The hotel brand founded by hotelier Marco Nussbaum and property economist Dr Matthias Zimmermann in 2006 succeeded in exclusively contracting international designer Karim Rashid in New York for the development of their hotels in Germany. The first Prizeotel opened in Bremen in only 2009. With its 127 rooms, it is now successfully established on the market. It was followed by the second Prizeotel in Hamburg, now with 2016 rooms, in 2014 and the Prizeotel in Hannover with 220 rooms in 2015. In Hamburg, a second Prizeotel has subsequently opened near the well-known Reeperbahn – further Prizeotels in other cities are in the pipeline.

The VRF R2 heat pump system is the world’s only 2-pipe system for simultaneous cooling and heating with heat recovery. The energy extracted from rooms being cooled is not released into the ambient air, but is used to heat the rooms that require heat.

The hand of the designer Rashid is visible in all the budget design hotels – from the styling of the individual rooms and corridors through to the lounge/lobby area. Treating the hotel as an integrated design object has permitted the creative unfolding of a strategy that is best described as intelligent, pleasant and sensually inspiring as well as cost-effective. The combination of comfort and profitability is of special importance for the group of owners. However, it is not a question of generating rapid extra value from a cost-optimised investment, but of including running costs in the overall business strategy and keeping them low, as expected in the present day.

It is widely known that outlay for the operation of a hotel is composed of many items. In addition to manpower, expenditure on building services, such as the heating and air conditioning of a building, is critical for a property’s economically sustainable and healthy development. The objective has to be to lower variable costs with a lasting reduction in overall energy consumption in the building. And this applies all the more in times of highly volatile but essentially rising energy prices.

Made for major challenges.

After initial experience at the Bremen Prizeotel with chiller units to air condition the property, the investor went a step further in the Hamburg project and had a modern VRF air conditioning system with heat recovery function installed. This refrigerant-based system exploits the heat energy extracted from rooms with cooling needs. Within the closed system, this heat energy is fed in just 2 pipes to where heat is needed. This contributes not only to greater comfort, but also to considerable savings. With its extremely high energy efficiency and highly flexible heating and cooling, the VRF R2 heat pump system is absolutely ideal for use in the hotel.

Since building regulations prevent the installation of outdoor units on the roof of the Hamburg Prizeotel, the building utilises a solution with water-cooled VRF outdoor units that are installed in an interior plant room on the sixth floor of the hotel. Overall, the 17 compressor units achieve cooling output of approx. 290 kW. The VRF R2 heat pump system from the City Multi series from Mitsubishi Electric was developed for large and challenging buildings in need of customised solutions. It is particularly suitable for use in hotels, large public buildings and office blocks. Like their air-cooled counterparts, the units of the R2 series with water-cooled heat exchangers are distinguished by their extremely high efficiency when cooling and heating. The installation in Hamburg has now been in successful operation for roughly four years, and the energy consumption figures speak for themselves. “The initially computed energy savings of between 30 and 40 % have been achieved,” explains Michael Lechte, Product Manager at Mitsubishi Electric.

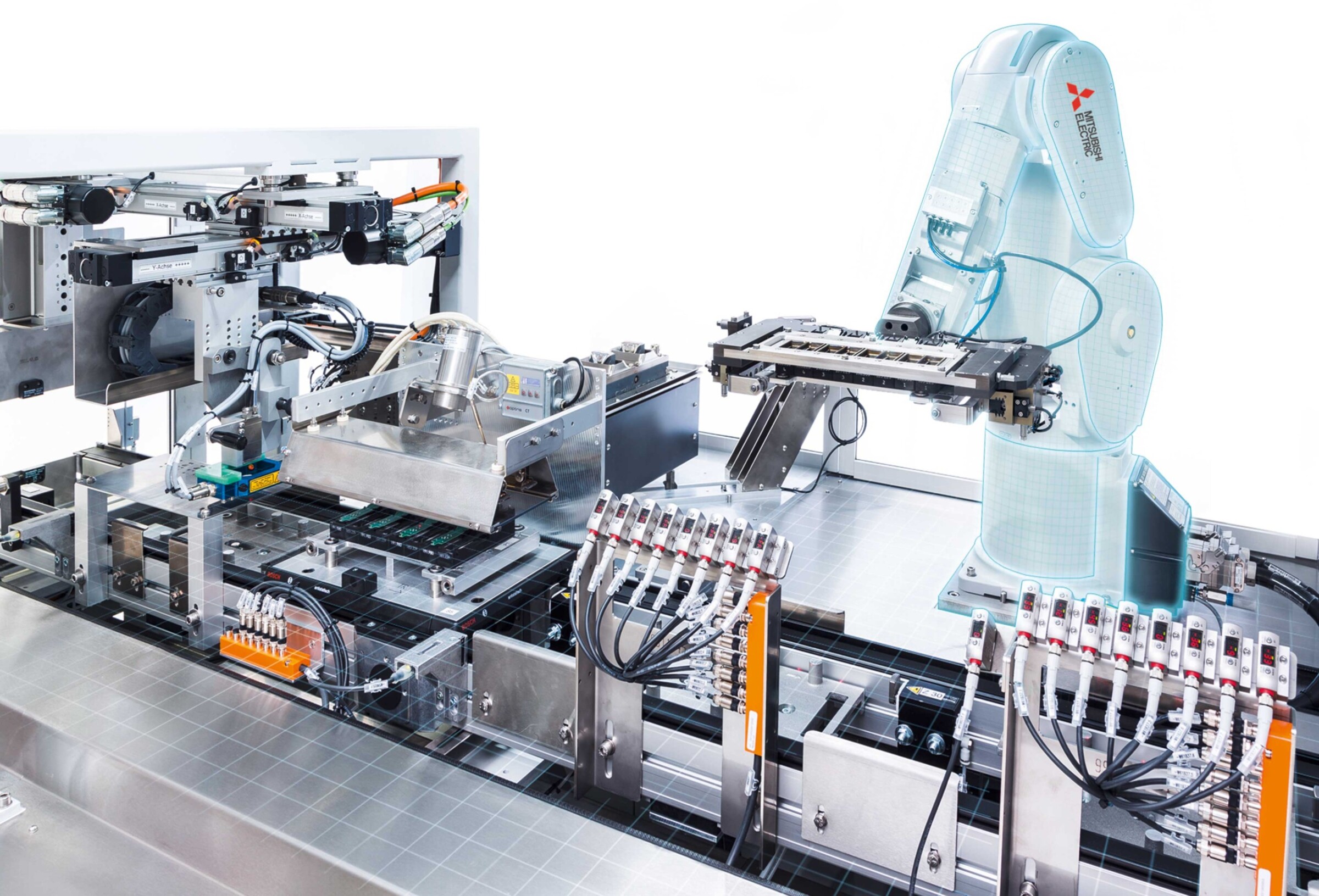

Eutect, a manufacturer of electronics soldering systems, is turning increasingly to 6-axis robots from Mitsubishi Electric for its automation cells. This type of robot is not only capable of performing more complicated tasks than conventional 3-axis kinematics, but is also even faster and exceptionally undemanding as far as its footprint is concerned. The advantages for Eutect’s customers are higher process integration, greater flexibility, shorter set-up and cycle times, and savings of space and a reduction in the cost of investment. In addition, the use of robots offers a degree of security for the future which is difficult to quantify but would appear to be more important than ever.

Our robot takes 4.5 s of cycle time to solder a circuit board.

Founded in 1996, Eutect has specialised in modular automation solutions for soldering applications in mini-wave soldering, laser soldering, induction soldering, iron soldering, thermode soldering and lift/dip soldering for computer circuit boards. In 2008, junior boss Matthias Fehrenbach invested in a used 6-axis MELFA robot from Mitsubishi Electric to try out a new idea. The robot was to be fitted inverted in a compact automation cell in order to make space underneath for further processes. The possibilities offered by this arrangement were exhaustively tested, and it was possible to restrict the machine’s footprint to 2 m². Since the first customer project in 2009, Eutect has developed and supplied many highly specialised robot cells to German vehicle makers and manufacturers of electronics components.

A robot cell with an RV-4FLM articulated robot has been built for drive manufacturer Faulhaber, for example. The cell with an upright robot processes tiny electric motors. Unlike the kinematics of rival makes, the robots from Mitsubishi Electric can be set up without modification on the floor, overhead on the ceiling or also on the wall, so the configuration can be adapted for efficient use of space in the application in question. The RV-4FLM 6-axis articulated robot with a loading capacity of up to 4 kg and a range of 649 mm displays high mobility and flexibility in all tasks. Processes are reliably executed with a repeat accuracy of ±0.02 mm. Cables and compressed air hoses for electric and pneumatic gripper subassemblies have been transferred to the interior of the robot arm so that its room for manoeuvre is not limited. This is also enhanced by the robot’s ability to fully fold down into a flat pack so that its six degrees of freedom can be fully exploited. All robots of the RV-F series are supplied in IP67 and can be ordered in a cleanroom version if required.

Everyone involved agrees that small, lightweight articulated robots such as those from Mitsubishi Electric not only boost the efficiency of production machines, but are also capable of cutting development costs and optimising the available installation space.

A sound investment in the future.

In addition, the MELFA controllers are already generously equipped with interfacing for applications of Industry 4.0 and the Internet of Things, which makes the systems a sustainable and sound investment in the future.

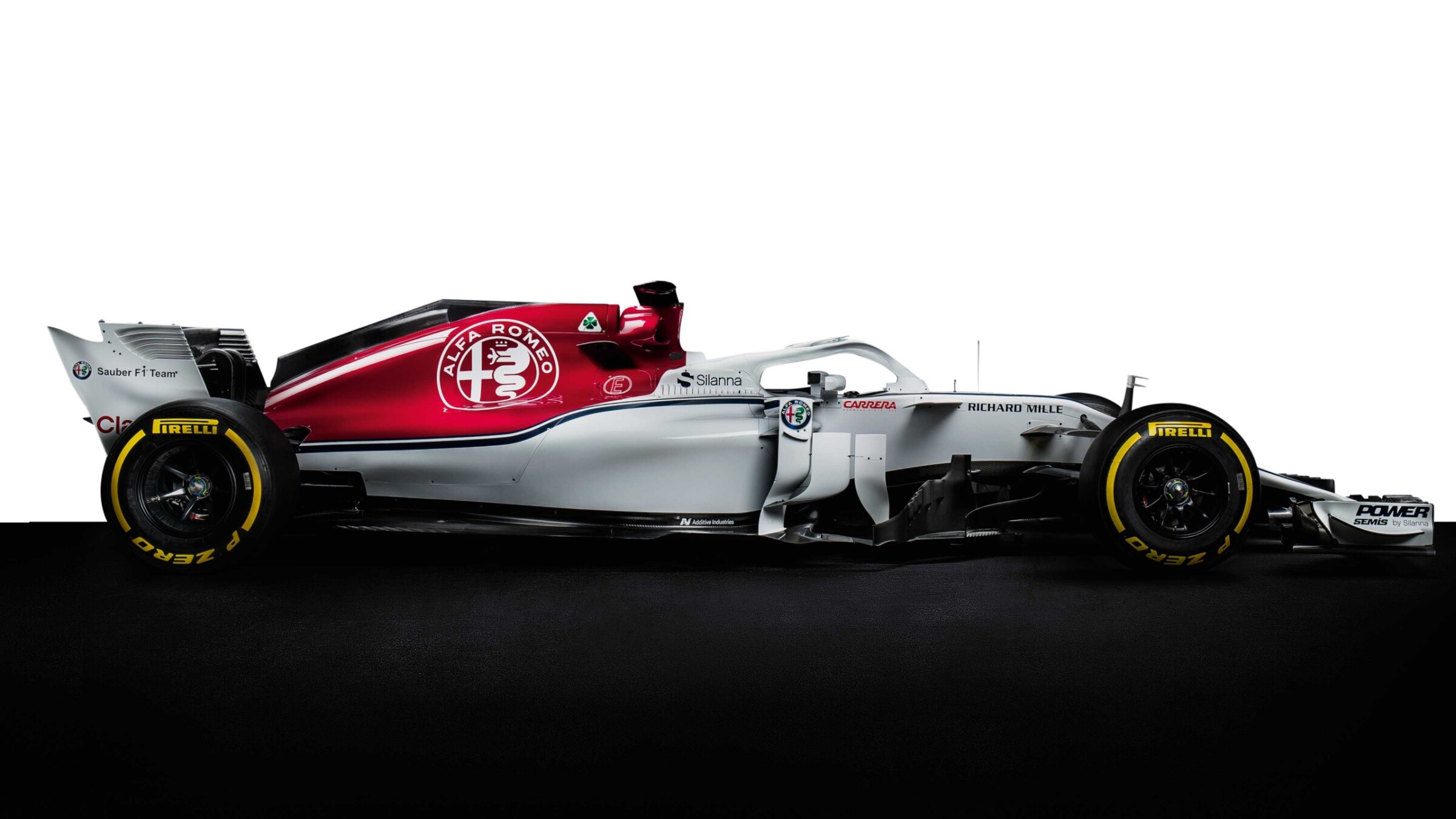

On the race circuit every millisecond counts – and in production every µm. World market leader with wire EDM systems, Mitsubishi Electric has been supporting Formula One for more than a decade.

Sauber C37-Ferrari – the 2018 Alfa Romeo Sauber F1® Team vehicle.

World market leader.

From the technical point of view, the philosophy of the C37 was new, as its aerodynamics differs from that of its predecessor model, the Sauber C36-Ferrari. The C37 is equipped with new and improved aerodynamic parts, responding to the changes in the rules for 2018 involving the elimination of the shark fin and T-wings, for example. What’s more, the C37 is equipped for this year’s season with the current 2018 Ferrari engine, which has had a positive impact on performance. Simone Resta, Technical Director, puts it as follows: “As we have seen, the new strategy has offered us new opportunities and helped us to achieve improvements in the course of the season. In terms of performance, we have also benefited from the 2018 Ferrari engine.”

26,400 workpieces are machined each year on Mitsubishi Electric EDM systems at a single Formula One team.

Mitsubishi Electric actively assists its customers with the development and integration of components into the overall vehicle strategy – and with outstanding success. The vehicle equipment technologies from Mitsubishi Electric are, and will remain, essential features of many conventional, hybrid and electric vehicles of the world’s biggest car makers. Mitsubishi Electric not only supplies main units (the nerve centres of any vehicle equipment), alternators, starters, electric steering systems and multimedia equipment, but also a multitude of innovative and high-grade electric and electromechanical vehicle components for greater comfort, maximum safety and environment-friendly motoring.

Driving safely with Mitsubishi Electric.

Mitsubishi Electric’s Mobile Mapping System uses a combination of sensors, cameras and lasers that are mounted on the vehicle roof and collect data in real time to create three-dimensional maps accurate to the centimetre.

Under the motto “Feeling with you; convenient, safe and comfortable for each one”, the development of the new concept car has been based on three specific areas of research: electrification, autonomous driving and networking. The EMIRAI 4 comes with next-generation driver assistance technologies such as human-machine interfaces, driver condition monitoring and a lighting system.

Safer and more comfortable driving.

Our equipment is being used in the future Rhine-Ruhr Express – and in many other rail projects in Europe. Mitsubishi Electric is not only one of the leading suppliers of air conditioning systems to railways on the Japanese market, but is also supplying these systems to the Rhine-Ruhr Express. And has since been on course for success in Germany and Europe. The RRX runs smoothly – with our air conditioning equipment.

Drive systems for 118 trains of the Dutch railways

Mitsubishi Electric is supplying high-tech drive systems for 118 trains of the Sprinter New Generation (SNG) of Nederlandse Spoorwegen (Dutch railways). The project awarded by the Spanish railway vehicle manufacturer CAF (Construcciones y Auxiliar de Ferrocarriles, S.A.) is regarded as one of the biggest supply contracts in European rail transport and is being executed in cooperation with the Italian branch of Mitsubishi Electric Europe.

Global traveller.

Deutsche Bahn AG has contracted Mitsubishi Electric to modernise the drives of 46 high-speed trains of the Intercity Express 2. The DB Group is a major rail transport operator with one of the longest rail networks in Europe. The high-speed train of Deutsche Bahn’s ICE 2 series went into operation in 1996. Mitsubishi Electric first supplied railway equipment to Europe in 1967. Over the years, the company has consistently expanded its commitment on the European railway market.

Modernisation of Deutsche Bahn

Continuous further development and modern production facilities are key factors in the high quality of our high-performance modules. Semiconductors are indispensable components of products that are increasingly more efficient. They are the raw material of the future. Mitsubishi Electric is a worldwide leader in the semiconductor industry. Innovative thinking, modern production lines and high-capacity research and development are the key factors in maintaining this leading position. Customers benefit from comprehensive technical services as well as a widespread sales and distribution network.

More than 30 years of expertise in power modules.

The German headquarters of Mitsubishi Electric are in Ratingen, North-Rhine/Westphalia. It is responsible for carrying out technical service, sales and marketing activities and also export activities for Europe, Russia and South Africa.

The ongoing success of our power semiconductor technology is based on extensive expertise in four product fields: high frequency, opto electronics, power semiconductors and TFT-LCD modules. In line with our key values of quality and reliability, Mitsubishi Electric Europe B.V. has continuously complied with the strict ISO 9001 and 14001 certification rules. It is no wonder that Mitsubishi Electric is a leading manufacturer of power semiconductors.

Our power semiconductors have a broad spectrum of application fields including high-voltage direct-current transmission, railway technology, regenerative energies, motor control, uninterruptible power supply (UPS), white goods, medical technology, elevators, escalators, welding and pumps. The concept of the intelligent power module (IPM) forms the basis for current switching, current management and current flow. For example, our integrated intelligent modules reduce the development time and cost of frequency inverters for driver, monitor and control circuits. The necessary peripheral electronics is always integrated.

The power semiconductor devices started from the current-controlled GTO (Gate Turn-off Thyristor) and bipolar Darlington transistor (all current controlled) developed by Mitsubishi Electric to the first voltage-controlled IGBT modules. Their compact form offers distinct advantages for rough environmental conditions such as in the drive technology. Further advantages of the IGBTs compared to predecessor technologies are higher switching frequencies, lower switching losses as well as substantial cost savings due to a simple control mechanism.

Leading manufacturer of power semiconductor modules

Name of company:

Mitsubishi Electric

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com