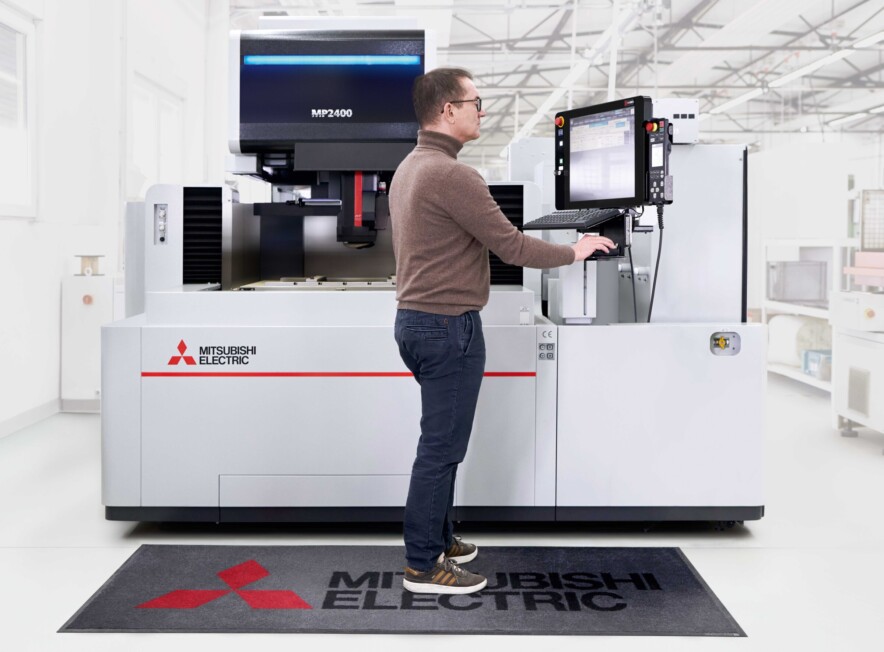

The Vogt & Käfer GmbH toolmaking and punching shop in Esslingen machines the cutting edges of its punching tools for thin foils and sheets with high precision on an MP2400 Connect wire-cut EDM system.

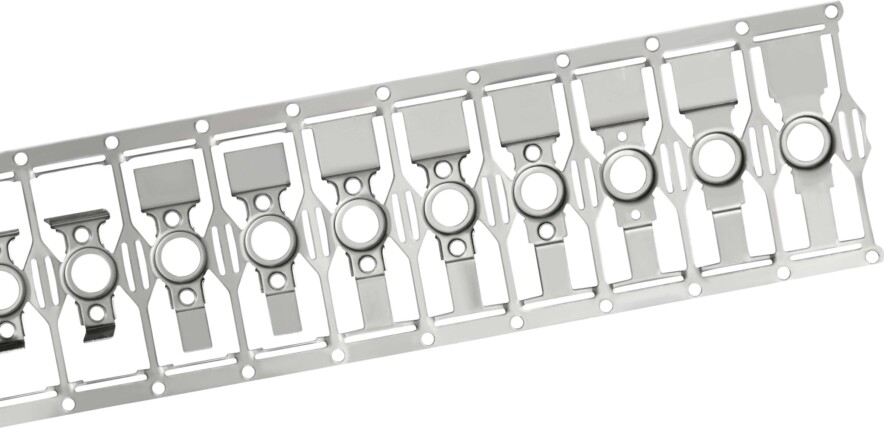

For the automotive industry, manufacturers of electrical and domestic appliances, and suppliers to the electronics industry in the Swabian region, the Vogt & Käfer GmbH toolmaking and punching shop produces precision parts in large series mainly from thin and super-thin sheet metal. These can be electrical contacts and terminals as well as spring circuit boards, for example.

In its punching shop, Vogt & Käfer produces sheet metal parts in large series for the automotive industry and for electrical and household appliances.

As Managing Partner Mike Kuhlmann reports, his company firstly designs and produces the necessary progressive dies on the basis of the client’s component drawings. In addition, the Esslingen-based firm has a number of high-productivity punching presses on which it punches and forms the required sheet metal parts in large series from the strip. He can thus flexibly provide each of his customers with the optimum service, he says.

From the component drawing to the punching tool

The toolmakers in Esslingen usually design progressive dies to their clients’ component drawings. “In addition, we also advise our customers so that we can produce the desired components in the best possible way,” Kuhlmann adds. “Sometimes even minimal adjustments to the geometries of the punched parts can help to make the punching tools much simpler. The result is that the punching tools can be made more economically and work more reliably on the presses. With this advice, we support our customers so that they can realise the optimal design of their tools and their punched parts,” Kuhlmann explains. The company’s technical contact is Rainer Hägele.

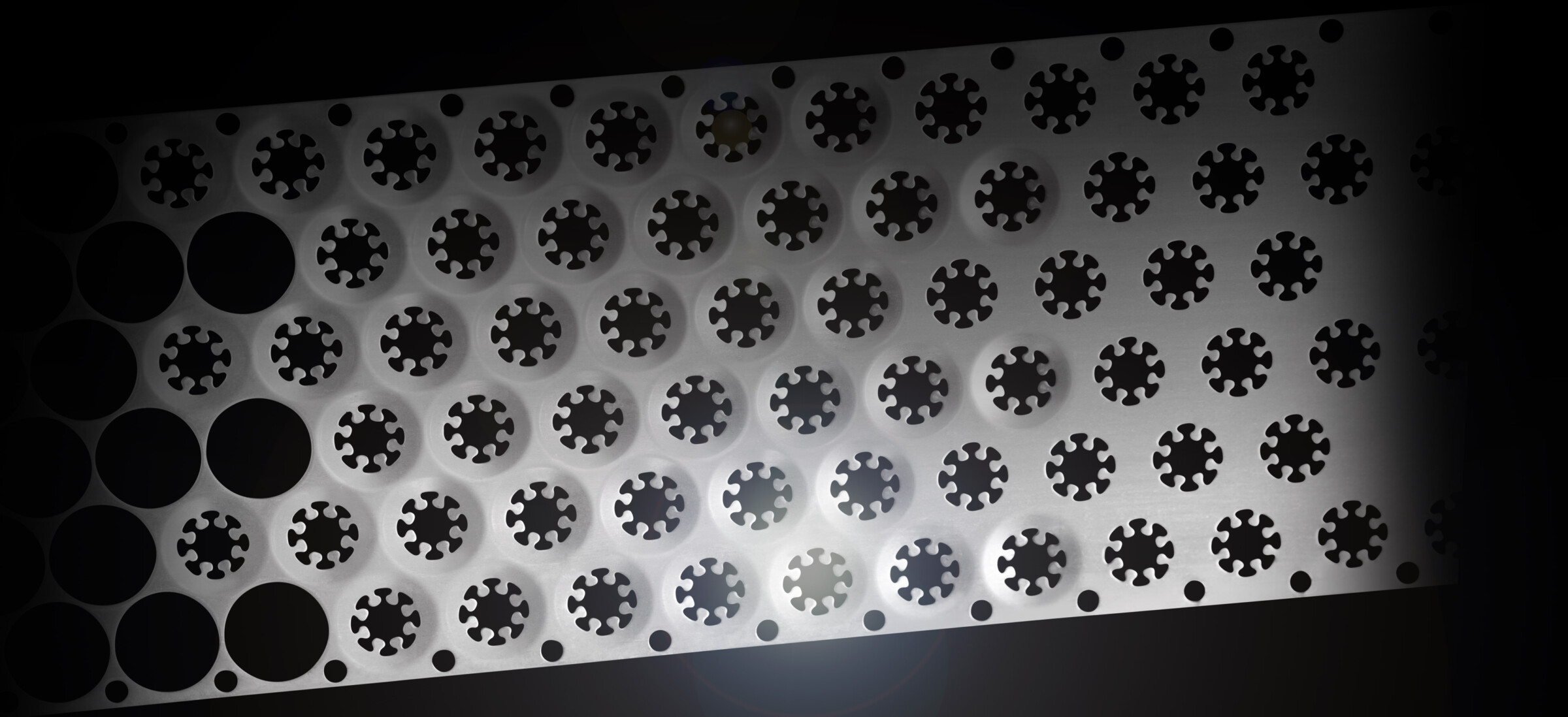

Vogt & Käfer specialises in highly intricate punched parts made of thin steel, copper and aluminium sheet.

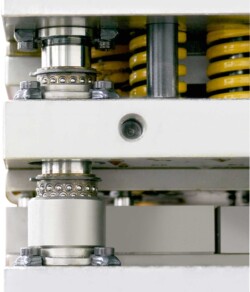

The specialists design and build reliable progressive dies even for highly complex components. Integrated into these tools are not only cutting and progressive forming – bending, piercing and drawing – but also joining techniques, such as the riveting of contacts. The type of components requiring punching imposes special demands on the design and on toolmaking, Kuhlmann continues. “In electronics and for sensor applications in particular, but also for food packaging, very thin sheets and foils often have to be punched. This calls for special technologies in the internal feed of the punching strips in the progressive dies. In addition, the cutting and forming parts of the punching tools have to be produced with great precision and to a very high surface quality,” he adds.

The tool and die makers produce high-precision progressive dies for use by customers and in the in-house punching shop.

The toolmakers in Esslingen can machine the cutting and forming parts of the punching tools to the required accuracies by wire EDM alone. Although they have had the right machines for this for many years, due to the growing volume of orders, they decided to expand production capacity in 2021. Kuhlmann explains: “We already had two wire EDMs and some experience of this machining technology. However, we were now looking for wire EDM machines that would perform significantly better in certain important respects. That’s when we came across the machines from Mitsubishi Electric.”

After the demonstrations by the Japanese manufacturer in Ratingen, the toolmakers were soon won over and invested in an MP2400 wire-cut EDM machine in July 2021. “That proved to be the absolutely right decision. This machine comes with a number of special advantages. Thanks to its height-adjustable tank, its workspace is highly accessible. Even heavy, relatively large steel plate can be easily and comfortably inserted and clamped in the workspace,” Kuhlmann continues.

A few days of training in Ratingen were sufficient to get the new MP2400 working productively.

The Esslingen toolmakers were also thoroughly impressed by the accuracy and reliability of the MP2400. Thanks to thin wires, they can cut even the tiniest geometries and sharp corners on cutting parts – punches and dies – to the highest accuracy in kerfs only a few hundredths of a millimetre wide. This is where the automatic wire threader has proven particularly reliable. “We have no worries about running the machine with a multiple clamping during unattended shifts and can be sure the components are cut error-free,” Kuhlmann elaborates.

As an extra bonus, it turns out that the MP2400 cuts significantly faster and thus with higher productivity than the wire EDMs of other manufacturers. The toolmakers use it to machine not only individual parts for newly designed tools, but also replacement parts for worn-out punching tools. Thanks to the MP2400’s dependability and high productivity, it does so quickly and highly flexibly. In this way, with the aid of the MP2400 wire-cut EDM machine, the toolmakers can minimise unproductive downtime in the punching shop.

The MP2400 was the perfect choice, because this wire EDM machine delivers an outstanding price-performance ratio across the board.

In its punching shop, Vogt & Käfer produces sheet metal parts in large series for the automotive industry and for electrical and household appliances.

Efficiently organised training and after-sales service

“During the installation and commissioning of the MP2400, we were particularly impressed by Mitsubishi Electric’s after-sales service,” Kuhlmann admits. In just one week of training in Ratingen, the programmers and machine operators of the Esslingen-based toolmaker gathered all the important data they needed for productive operations on the MP2400. Using a PEPS programming system they write the NC programs for the components they want to cut. In their view, setting up the MP2400 and programming it with the required parameters is particularly easy. Operation of the current software with large buttons on the touchscreen is particularly straightforward and quick to learn, they confirm.

Thanks to their wire EDM experience, the toolmakers in Esslingen can adapt the parameters specified by Mitsubishi Electric to their individual requirements and optimise them to obtain the best surface quality and accuracy. The MP2400 wire-cut EDM system is particularly reliable, Kuhlmann affirms. “In our experience, the hotline at Mitsubishi Electric is also very well organised. If we have questions, regarding certain parameters or special functions, for example, a competent contact person is always available at very short notice, who immediately provides expert advice and instructs our specialists at the machine,” Kuhlmann continues. This clearly sets the Japanese machine manufacturer with its specialists in Ratingen apart from other machine manufacturers. “The MP2400 was the perfect choice, because this wire EDM machine delivers an outstanding price-performance ratio across the board,” says Kuhlmann summing up his experience.

Since 1926, Vogt & Käfer has been producing cutting and drawing tools and progressive dies for the regional automotive industry, electrical appliance manufacturers and machine manufacturers, and the electronics and sensor industries. As a punching firm, Vogt & Käfer is also a reliable supplier to industry. From design, toolmaking and punching through to quality assurance, the Esslingen-based specialists cover the entire spectrum from a single source.

Name and place of company:

Vogt & Käfer GmbH toolmaking and punching shop

Germany

Founding year:

Founded by Georg Vogt and Karl Käfer in 1926

Management:

Mike Kuhlmann, Rainer Hägele

Employees:

19 overall, 8 of them toolmakers

Business fields:

Design and production of high-quality punching, drawing and forming tools and progressive dies, and production of small precision parts in large series from thin sheet metal

Vogt & Käfer GmbH toolmaking and punching shop

AlleenStrasse 25

73730 Esslingen am Neckar

Germany

Tel +49 711 3100933-0

Fax +49 711 3100933-99

info@vogtundkaefer.de

www.vogtundkaefer.com

We have experienced considerable declines in incoming orders and orders on hand. The business strategy of just-in-time procurement is now proving to be highly critical. Just as we are expected to deliver at short notice, we are now losing orders at very short notice, sometimes within a matter of days. This, of course, puts a strain on planning or even makes it impossible.

We’re confronted with mostly rising costs that change on a daily basis. In addition, it is becoming more difficult to procure sheet steel in sufficient quantities, at least a far as selected materials and steel grades are concerned.

We shall continue to diversify our business. We want to be less dependent on the automotive industry, so we are looking for more customers in the electrical appliance and domestic appliance industries, for example, but also in precision mechanics and apparatus engineering in general.

Managing Partner at Vogt and Käfer

Vogt & Käfer GmbH toolmaking and punching shop

Mike Kuhlmann, Managing Partner at Vogt and Käfer

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com