Flexible and customer-oriented – with an FA10-S Advance from Mitsubishi Electric, Nedo produces complex tools for specialized solutions.

For over a century, Nedo GmbH & Co. KG has been synonymous in the construction industry with high-grade and reliable measuring tools and the associated surveying accessories. Managed by Walter and Gisela Fischer and their sons Frank and Thomas, the family-run company is now in its fourth generation. High quality is a continuous theme throughout the product range and is attributable to integrated manufacture. Virtually all the processing steps are carried out on the premises – from toolmaking through to final assembly.

“There’s a tradition of customer orientation at Nedo,” says Gerhard Hofmann. The graduate engineer was appointed plant manager at the surveying specialists three years ago. In its early years, Nedo acquired the reputation of a pioneer in the field of surveying and measuring and has upheld its high standard of staff skills and innovative capacity through to the present day. Its lavishly equipped plant with the very latest technologies has everything that’s needed for successfully operating on the market.

Gerhard Hofmann sees market trends realistically: “Because of the tough competition, it’s up to us to develop ever better products. At the same time, if we want to maintain our position, we have to achieve high productivity as well.” Therefore, while the designers continually set new standards, it is up to production to convert the ideas into cost-effective reality. “This is why we are constantly optimizing our processes so that our 120 employees can handle increases in demand,” the plant manager continues.

Process optimization at Nedo presupposes a high manufacturing depth. “This is the only way we can respond flexibly without being dependent on outside service providers,” says Gerhard Hofmann, explaining the regular investments in machining centres and key technologies. A recently completed investment project to bolster toolmaking included not only an injection moulding machine but also a new wire-cut EDM machine from Mitsubishi Electric, an FA10-S Advance.

Toolmaking is an existential activity for Nedo. As an important aspect of manufacturing depth, the department creates flexibility towards the customer, as Gerhard Hofmann explains: “Since we are not dependent on outside component suppliers, we are able to react extremely fast, particularly when it comes to customized solutions.” From the point of view of costs, having its own tooling department is important for Nedo. “In our tooling department we have all the necessary technologies and make full use of them. We are thus in a position to produce punching dies and injection moulds on our own premises much less expensively than an external supplier.”

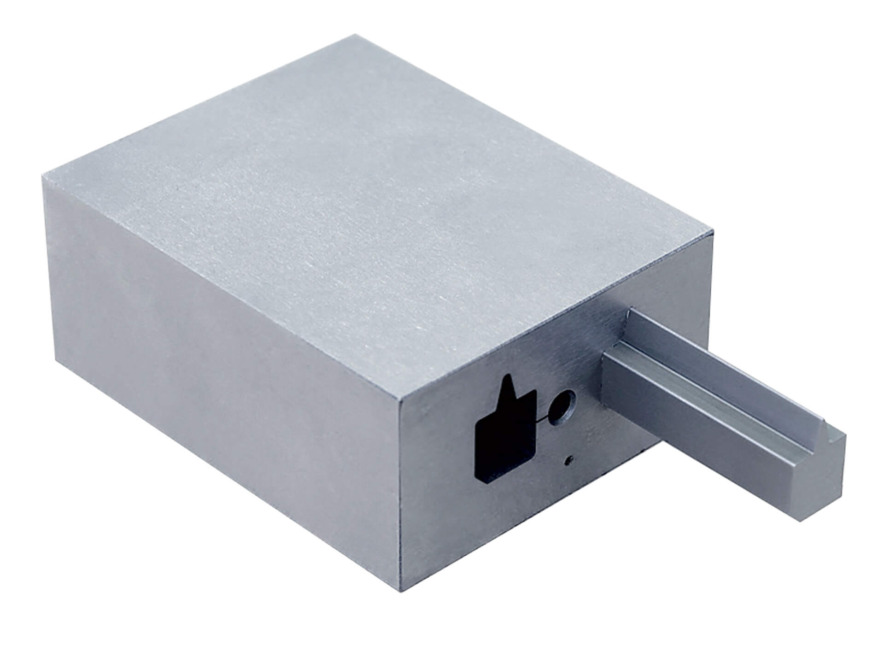

Components of punching and bending tools are also cut with the FA10-S Advance.

„First of all, we have a contact that’s always there for us and can often help over the phone. And, failing that, the after-sales service is quickly here if need be.“

By making its most recent investment in the FA10-S Advance, Nedo has taken another step into its technological future. The modern wire-cut EDM machine was purchased in 2009 to replace a good 15-year-old machine from a different manufacturer. “On the old machine, we were constantly having to deal with wire breakages and weren’t able to run the machine continuously overnight,” Gerhard Hofmann recalls. Wire feed on the new machine is much better by a long chalk, he claims, and should a breakage occur, the wire is automatically rethreaded, day or night.

The machine’s superior wire feed and automatic threading were only two of the crucial points they considered in their search for a new machine. The speed of the FA10-S Advance was also a decisive factor, because: “Our top priority was productivity. Reliability and speed were therefore the most important criteria,” says the plant manager. The machine was impressive in its totality and also featured an unbeatable price/performance ratio.

Since huge importance is attached to staff training at Nedo, there was also strong interest in good training for the new wire erosion machine. “A female employee who already had prior experience of wire-cutting was able to work at the machine after the basic course, while another staff member attended the advanced course as well,” Gerhard Hofmann reports. In the programming field, Nedo had three employees trained by Mitsubishi Electric so that it can always be sure of having sufficient manpower.

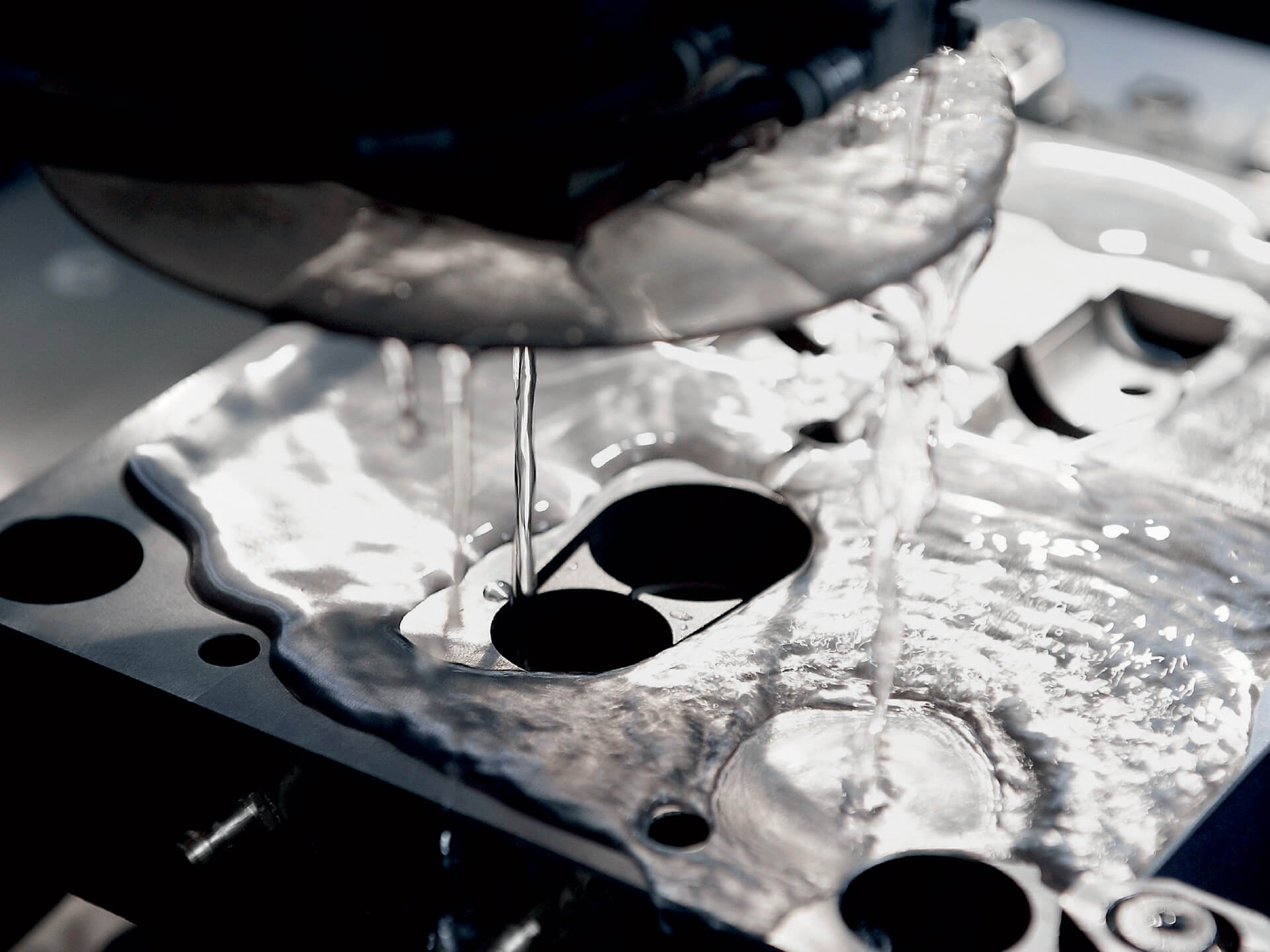

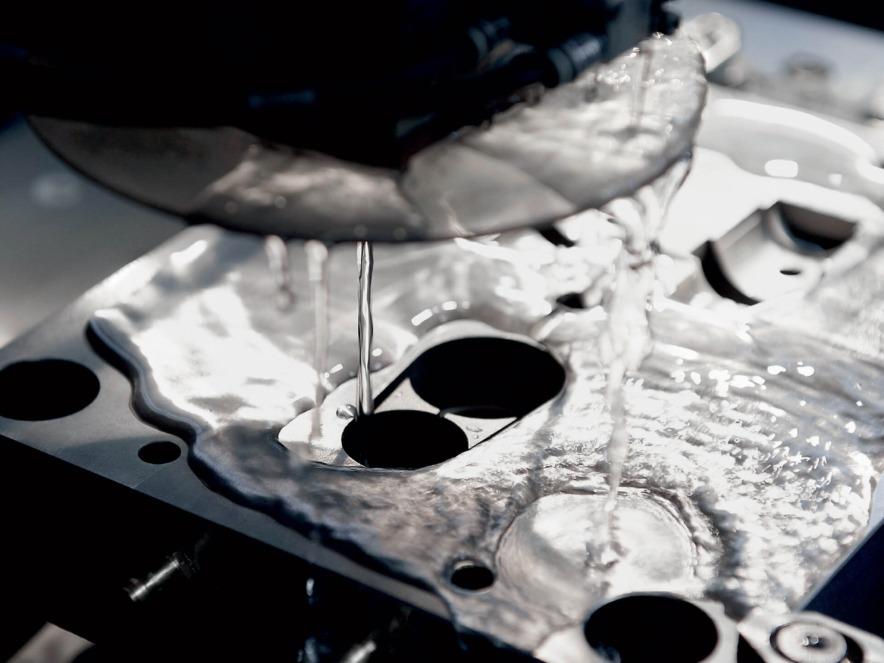

Nedo stands for consummate machining quality. These complex injection moulds are used for producing high-grade plastics mouldings.

Nedo’s pipe laser is designed specifically for tough site conditions.

The plant manager also has words of praise for Mitsubishi Electric’s after-sales service. “First of all, we have a contact that’s always there for us and can often help over the phone. And, failing that, the after-sales service is quickly here if need be.” Compared to those of other suppliers, the service charges are more than reasonable in Gerhard Hofmann’s view.

Thanks to the FA10-S Advance, tool- and mouldmaking in the company have developed into an efficient department that processes even complex jobs quickly and reliably in close cooperation with product development. Gerhard Hofmann regards modern production technologies as a clear competitive advantage for future business development. “We’re dependent on such productive and reliable machines so that we can deliver the quality that Nedo customers are used to and have come to expect.”

Name and place of business:

Nedo GmbH & Co. KG, Dornstetten,

Germany

Founding year: 1901

Number of employees: 120

Managers:

Dipl.-Ing. Walter Fischer,

Gisela Fischer,

Dr.-Ing. Thomas Fischer,

Dipl.-Wirtschaftsing. Frank Fischer

Core business:

Development and production of measuring tools and the associated surveying accessories for the construction industry.

Nedo GmbH & Co. KG

Hochgerichtstrasse 39–43

72280 Dornstetten

Germany

Tel: +49 (0) 74 43 / 24 01-0

Fax: +49 (0) 74 43 / 24 01-45

info@nedo.com www.nedo.com

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com