Alessandro Volta invented the electrical battery and pioneered electricity, with the unit of measurement being named after him. Even today, trailblazing inventions are being developed in the shadow of the Alps.

ASTES4 has developed and globally patented an automation system that goes a long way towards revolutionising production. To work efficiently, laser-cutting systems need a swift supply of material and subsequent sorting. ASTES4’s mastery of this task is second to none, and it has now teamed up with Mitsubishi Electric for the handling of large and extra-large projects. The fact that the systems are in global demand after only a decade and, with their unique capability, often represent the only cost-effective solution shows that Volta has made a lasting mark on the region.

In the wake of the pioneer of electricity and the unit of measurement named after him.

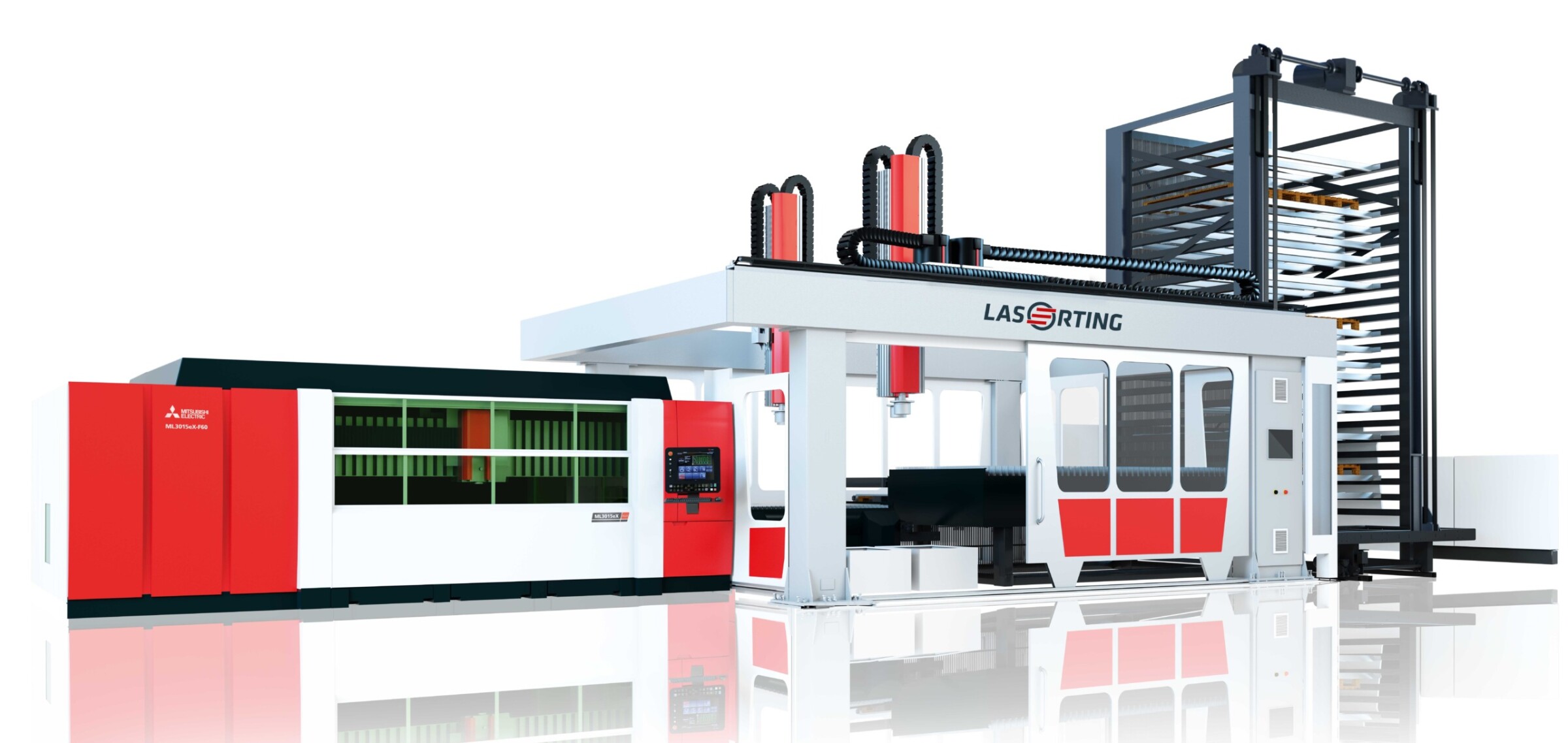

LASORTING redefines the automation strategy in sheet metalworking: its holistic treatment of the process has brought forth a single integrated multifunctional system capable of controlling the entire production process from cutting and sorting through to the storage of the finished parts.

ASTES4 SA

ASTES4 SAThe outcome of cooperation between Mitsubishi Electric and ASTES4 – LASORTING – is the synthesis of the most advanced technologies in 2D laser cutting and flexible automation. A project inspired by the simple idea of increasing the industry’s process efficiency and performance to a new level.

LASORTING ensures continuity of production in terms of laser workload, sorting and storage. Rapid and dependable processes help you stay competitive. With unmanned operations, LASORTING permits operation 24 hours per day, 7 days per week. The result is increased or stabilised output with lower unit wage costs. The employees, so far responsible for physically demanding sorting, can now be entrusted with value-generating activities.

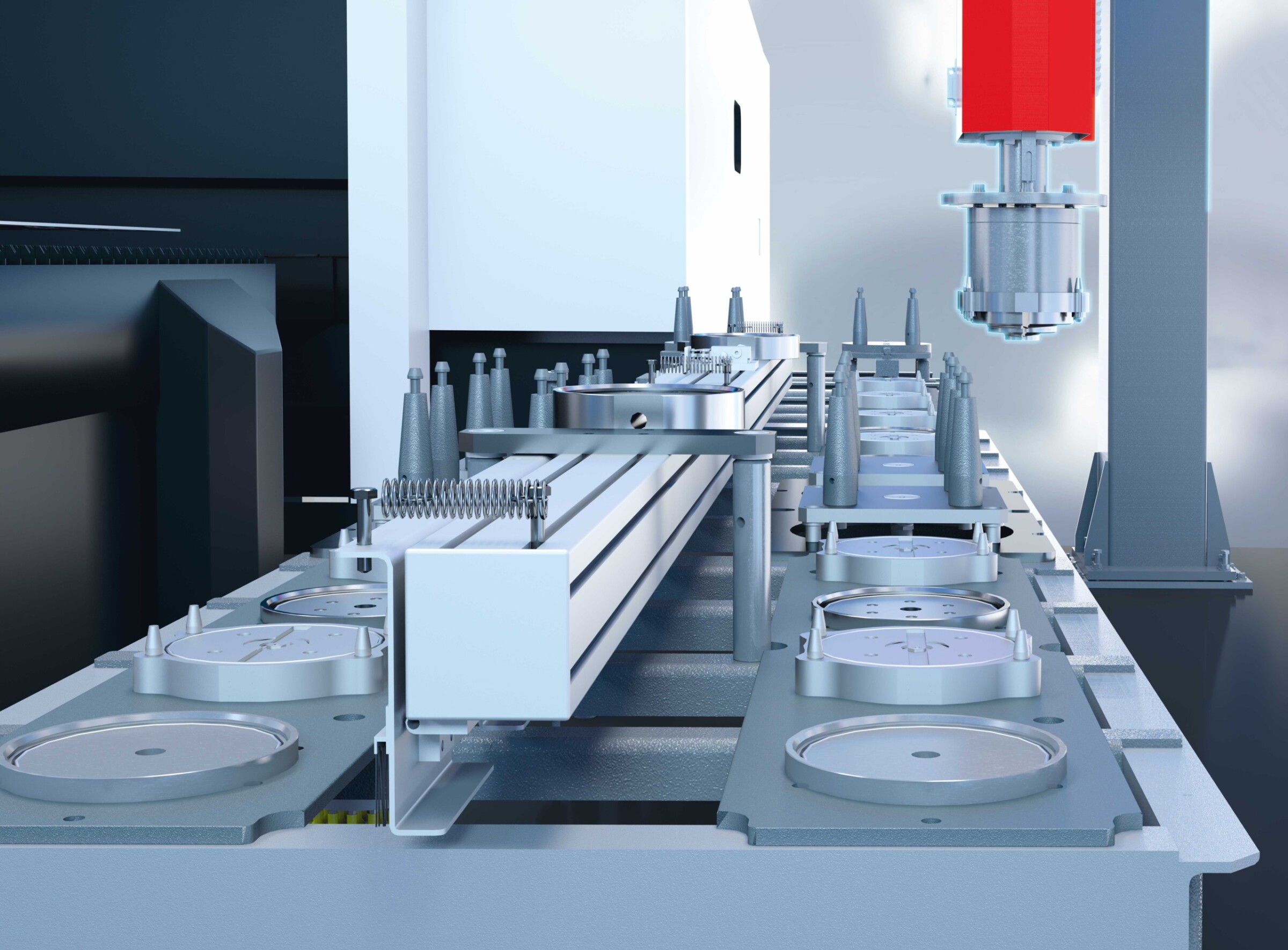

Only when the downstream process steps (such as bending, welding and painting) are taken into account from the outset can work proceed without lost time. ASTES4 ensures precisely this seamless integration into the production process, regardless of whether the downstream process takes place on your own site or elsewhere.

The orders are intelligently processed without jeopardising efficient material utilisation – thus excluding order-picking errors and time lost between the various process steps. All this brings down the costs that would arise due to downstream manual handling.

Synthesis of progressive technologies.

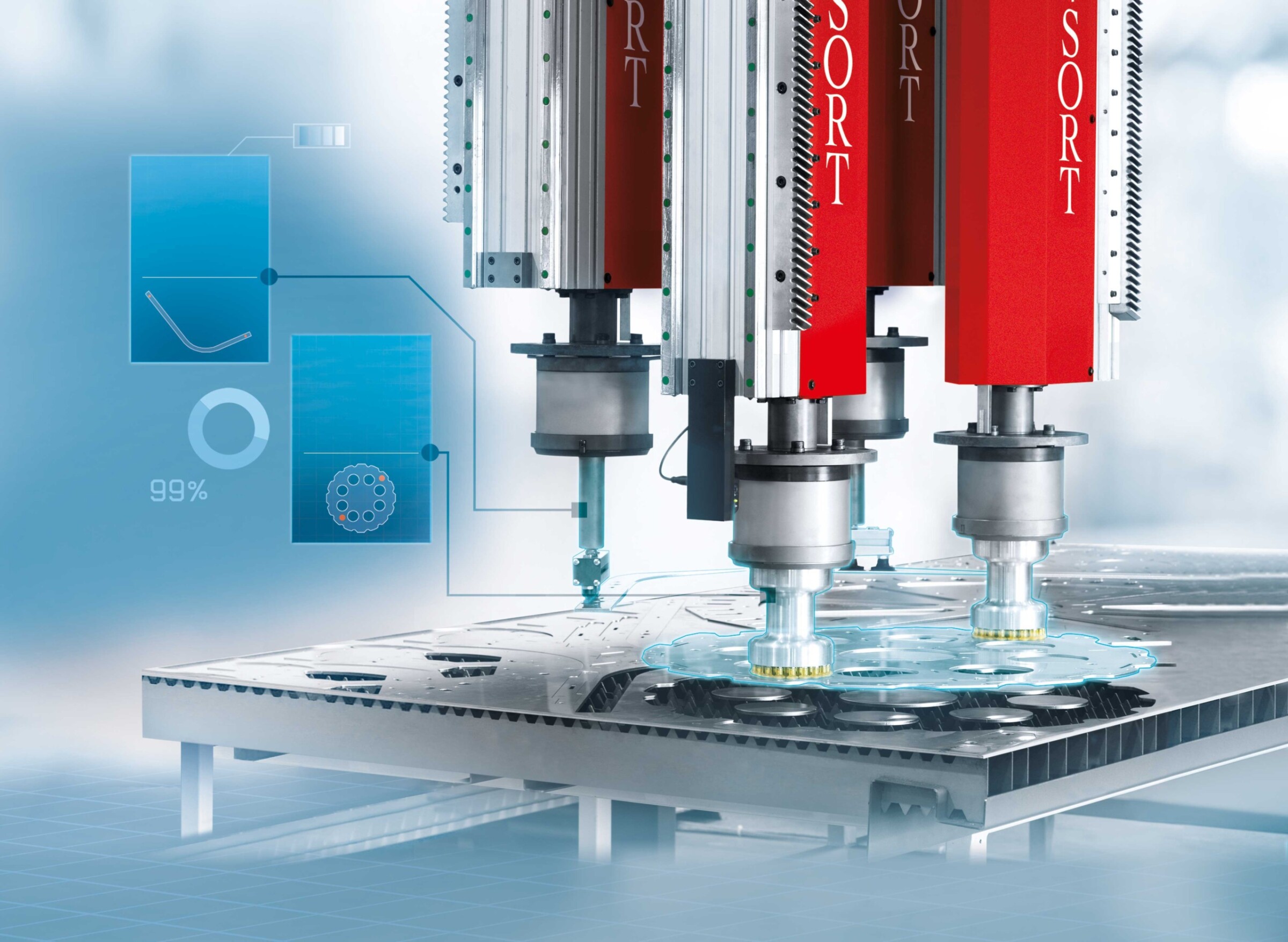

LASORTING features all the benefits of the ASTES4SORT technology developed and patented by ASTES4. All loading, unloading and sorting processes are controlled by 4 Cartesian grippers. A unique system that combines exceptional versatility with remarkable execution speed and manoeuvrability. The system can be seamlessly integrated in ERP and other management systems.

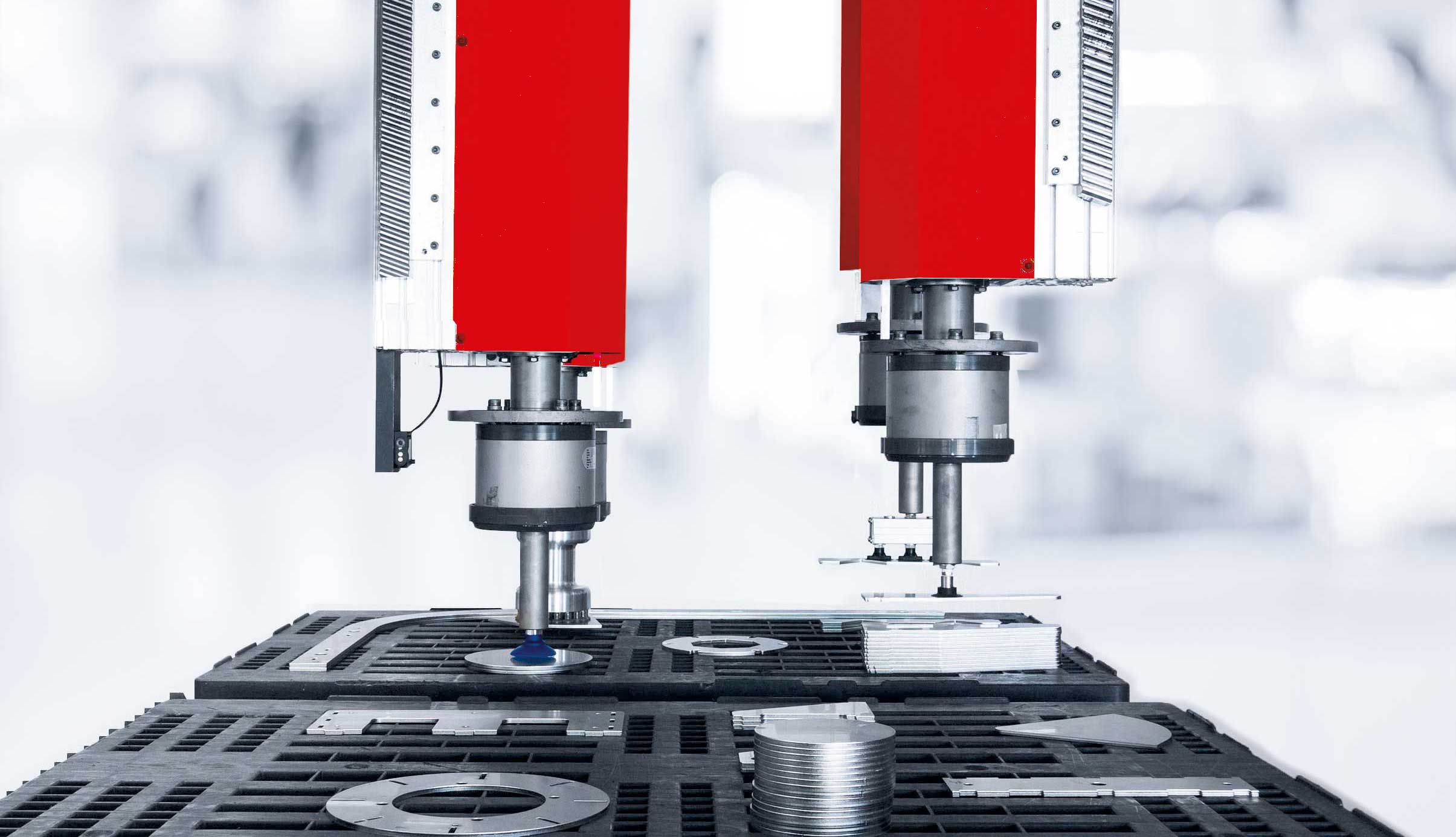

Different sheet thicknesses are prepared as kits for further processing. This saves time and money and ensures that they are accurately positioned on each pallet.

A fully automatic warehouse with a sorting system ensures optimum materials flow and continuous processes. Stocktaking at the press of a button and a complete overview of all critical process data are thus possible.

Fast and reliable processes.

Four grippers are better than one or two, particularly when your laser-cutting process depends on sorting speed. This is precisely where the ASTES4 patent comes into play. Each gripper is capable of using vacuum or magnetic tools in a variety of shapes and sizes. These tools are automatically changed to suit the geometry and weight of the part. The grippers can operate individually or collectively to move large or heavy parts and are thus vastly superior to all conventional laser automation systems in terms of productivity and efficiency.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com