In Linz in Austria, the Business Development Institute (WIFI) of Upper Austria’s Chamber of Industry runs a regional centre for initial and further vocational training. It is here that basic technical and commercial training is available in all craft, service and industrial trades. Skilled staff can also obtain further training here, e.g. to become master craftsmen. The training of skilled EDM staff on modern machines was also launched there a few months ago.

The Training Centre of Upper Austria’s Chamber of Industry promotes the regional economy and industry with hands-on initial and further training in all craft, service and industrial trades.

The region around Linz in Upper Austria ranks as one of the foremost industrial centres of the Alpine republic. Alongside globally renowned and important large enterprises, e.g. steel mills, there is an abundance of small and medium-size businesses here, including jobshops as well as tool- and mouldmakers. In Austria, too, these firms are aware of the looming shortage of well-trained and qualified specialised staff. To counteract this, the Training Centre in Linz supports the regional economy and industry with a broad spectrum of training and courses. Erich Döberl, Director of the Metalworking and CNC Technology Department, reports: “Initial and further training in industrial trades is an immensely important economic factor and encourages the ongoing development of the industrial region around Linz. With our range of training opportunities, we play a key role in laying the foundations for the region’s future.”

Angel Muñoz, Regional Sales Manager EDM of Mitsubishi Electric Europe; and Erich Döberl, Director of the Metalworking and CNC Technology Department at WIFI in Linz, see the benefit of investment in modern EDM technology in improving the skills of specialist employees of tool- and mouldmaking businesses. This investment also supports Mitsubishi Electric’s regional sales activities.

A broad range of training and courses

Overall, some 80,000 people make use of the varied offering of courses of WIFI in Linz and are trained by 2,200 instructors in all craft, service and industrial trades. This makes this initial and further training centre about twice the size of comparable institutions in other cities and regions of Austria.

As Döberl explains further, some 1200 apprentices attend courses of basic training in a broad variety of metalworking trades each year. Over 80 examiners serve these young people on their way to their final exams. In addition, about 350 lathe and milling machine operators take advantage each year of industry-wide training to update and build on their knowledge and skills. Furthermore, over 400 apprentices and 200 skilled hands from industry are given special training in CNC technology. More recently, there has been a drive to interest women in technical professions and in the associated training. Offering attractive courses for women, the Training Centre in Linz introduces them among other things to CAD/CAM and CNC programming. Döberl explains: “Our curriculum is targeted at both young people and mature individuals who wish to obtain vocational qualifications. Our training is geared to the field, and the knowledge and skills acquired by course participants enable them to go straight into production in craft and industrial businesses. With our drive to offer women further training in technical professions, we are also actively engaged in mitigating the shortage of skilled staff.”

Detlef M. Büll, Managing Director of dealer Büll & Strunz and regional representative for Mitsubishi Electric in Austria.

Laying the foundations for the region’s future

Demand for specialists in tool- and mouldmaking

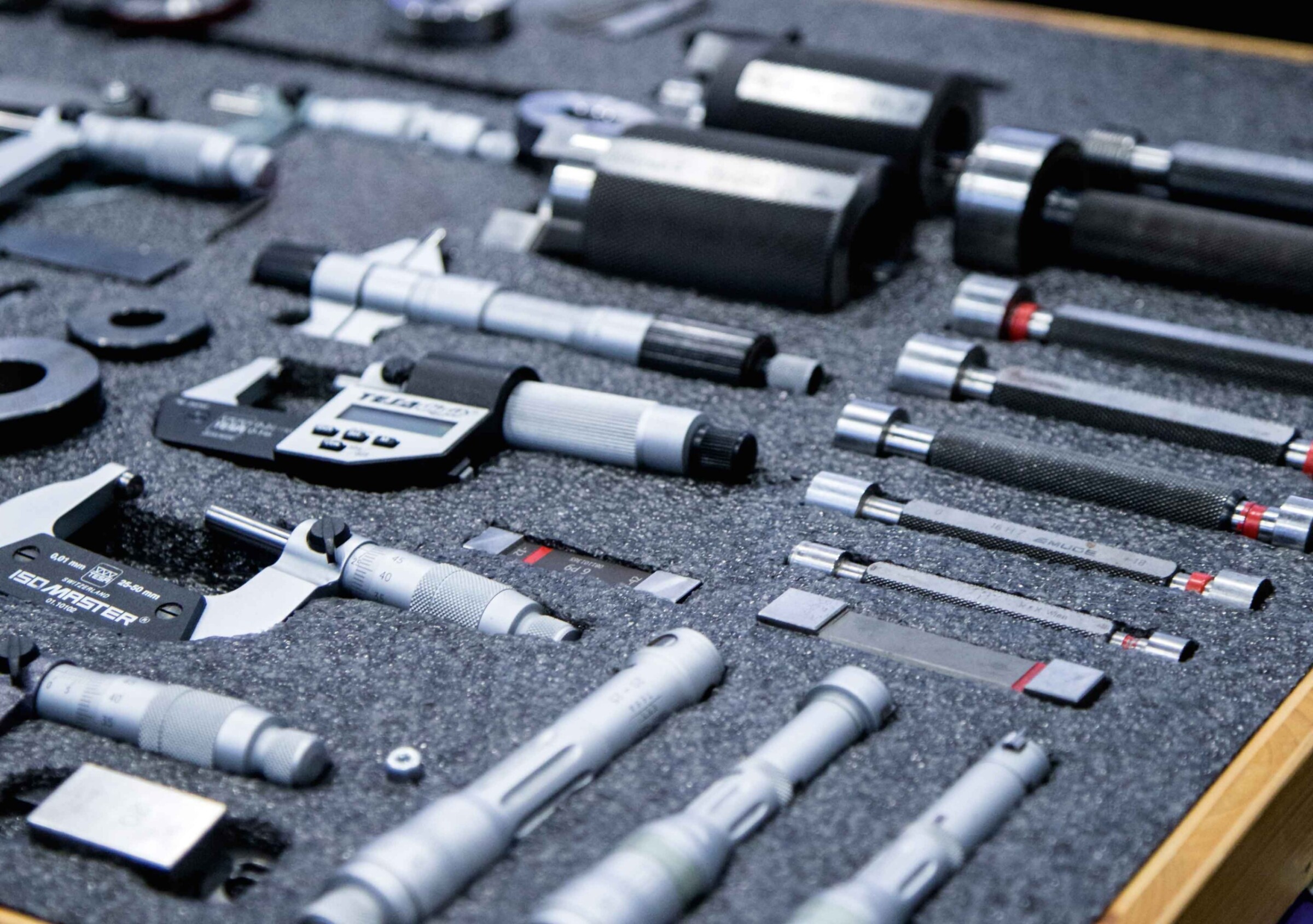

Numerous tool- and mouldmaking businesses are concentrated within a radius of some 200 km from Linz and these are dependent on highly skilled staff. Only with them can they meet today’s standards of quality and flexibility. As Döberl has repeatedly learned from these firms, there is big demand for well-trained staff. This applies not only to specialists in turning, milling and grinding, but also experts in wire cutting and die sinking. The last-named technologies are indispensable in tool- and mouldmaking, although they are considered more of a technological niche than conventional machining methods. Even in the usual training of tool- and mouldmakers, this technology is only covered as a side-line, so there is special demand for regular further training in die sinking and wire cutting on current machines and equipment.

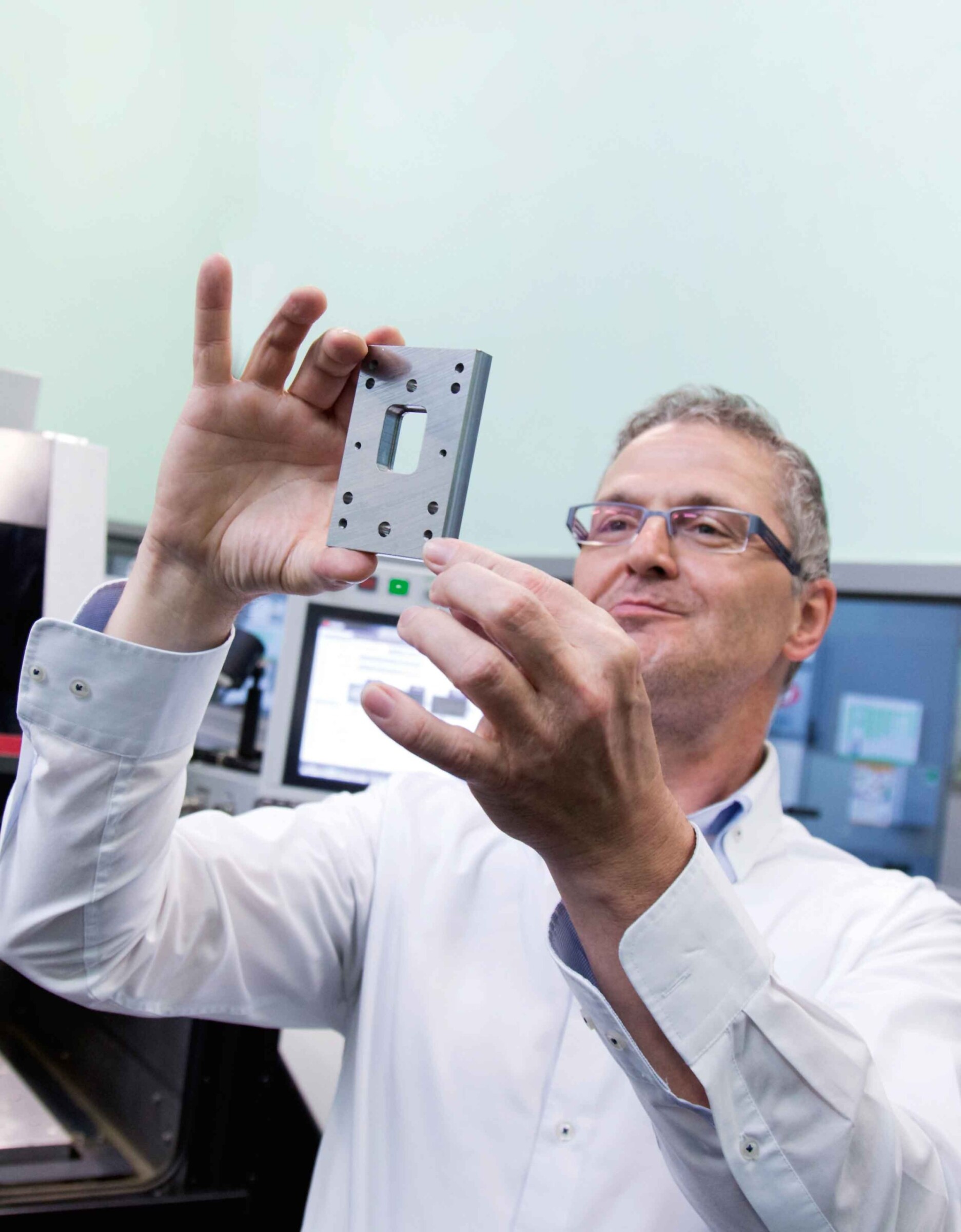

By investing in the EA8S die-sinking machine and the MV1200R wire-cutting machine from Mitsubishi Electric, WIFI in Linz is excellently equipped for the sound basic and advanced training of skilled staff in industry.

To satisfy regional demand for training, the specialists at WIFI’s Training Centre in Linz invested a few months ago in an EA8S die-sinking machine and an MV1200R wire-cutting machine. Notwithstanding its compact design, the EA8S is a fully equipped unit and comes with an automatic tool changer and a C-axis with an attachment for Erowa pallets. With the current Advance Control, it offers all the prerequisites for sound basic training in die sinking. The MV1200R wire-cutting machine is equipped with the optional fine-finishing generator to achieve surface quality within the Ra 0.1 µm range. It is thus capable of producing high-grade components that meet industry’s practical requirements.

Erich Döberl, Director of the Metalworking and CNC Technology Department: “At the Training Centre in Linz we provide basic courses and advanced training in current production technologies for skilled staff in the metalworking sector.” “Practical training on modern die-sinking and wire-cutting machines from Mitsubishi Electric goes a long way towards enabling regional tool- and mouldmaking in one of Austria’s leading industrial regions to stay competitive.”

For initial and further training, two external trainers are available, both of them employed as skilled staff in tool- and mouldmaking. This means that the course has a strong practical basis in the long term. As Döberl explains, course participants can benefit from this as well as actual and potential customers in the region. “With the machines from Mitsubishi Electric, trainers at WIFI can practically communicate the special advantages of current EDM technology and its benefits for manufacturing businesses,” he adds.

Erich Döberl, Director of the Metalworking and CNC Technology Department

A strong practical basis in the long term

Mitsubishi Electric’s regional agent in Austria profits additionally from cooperation with WIFI. Detlef Büll reports: “We can use the EA8S die-sinking machine and the MV1200R wire-cutting machine at WIFI in Linz for demonstrations and test machinings. For our customers in this important industrial region, this means they don’t have to travel far. This makes us flexible in addition, so that we can respond at short notice to inquiries and requests.” Büll is the Managing Director of Büll & Strunz Ges. m. b. H., Wiener Neudorf, a trading company that has been acting as the regional agent for Mitsubishi Electric in Austria since April 2016. In cooperation with WIFI, the specialists of Büll & Strunz also organise after-sales service for Mitsubishi Electric EDM machines for customers in Linz and environs.

Erich Döberl, Director of the Metalworking and CNC Technology Department

Döberl and Büll are unanimous in their conviction that the purchase of EDMs from Mitsubishi Electric has paid off in every respect. In their view, it can serve as a model for similar cooperation with institutions for initial and further vocational training elsewhere.

Erich Döberl, Director of the Metalworking and CNC Technology Department

A strong practical basis in the long term

WIFI OÖ GmbH

Name and place of company:

WIFI OÖ GmbH

Austria

Built in:

1966

Extended in:

1985, 2001, 2010

Managing Director:

Mag. Harald Wolfslehner

Number of employees:

5

Core business:

Information, advice and support, and especially initial and further training (4,228 training places)

WIFI OÖ GmbH

Wirtschaftsförderungsinstitut der Wirtschaftskammer Österreich

Wiener Strasse 150

4021 Linz, Austria

Tel +43 05 7000-77

Fax +43 05 7000-7609

kundenservice@wifi-ooe.at

www.wifi-ooe.at

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com