Universal1972 is a company active in the domestic appliance sector but is capable of serving any branch of industry in which sheet metal is worked. The company recently installed a Mitsubishi Electric MV4800 wire-cut EDM system.

The added value of invention.

Universal1972 is a mechanical workshop that specialises in the design and construction of tools for the cold working of any type of sheet metal. The company is located in Suzzara, Italy. The company offers the most progressive techniques available on the market today for any kind of shaping operation: single-stage (deep drawing, punching or bending), stepwise (conveyor belt feed) and transfer machining (automated handling of the product by robots). An integral feature of the company philosophy is continuous investment in equipment ranging from CAD/CAM systems to machine tools. The company also handles the maintenance and repair of existing tools.

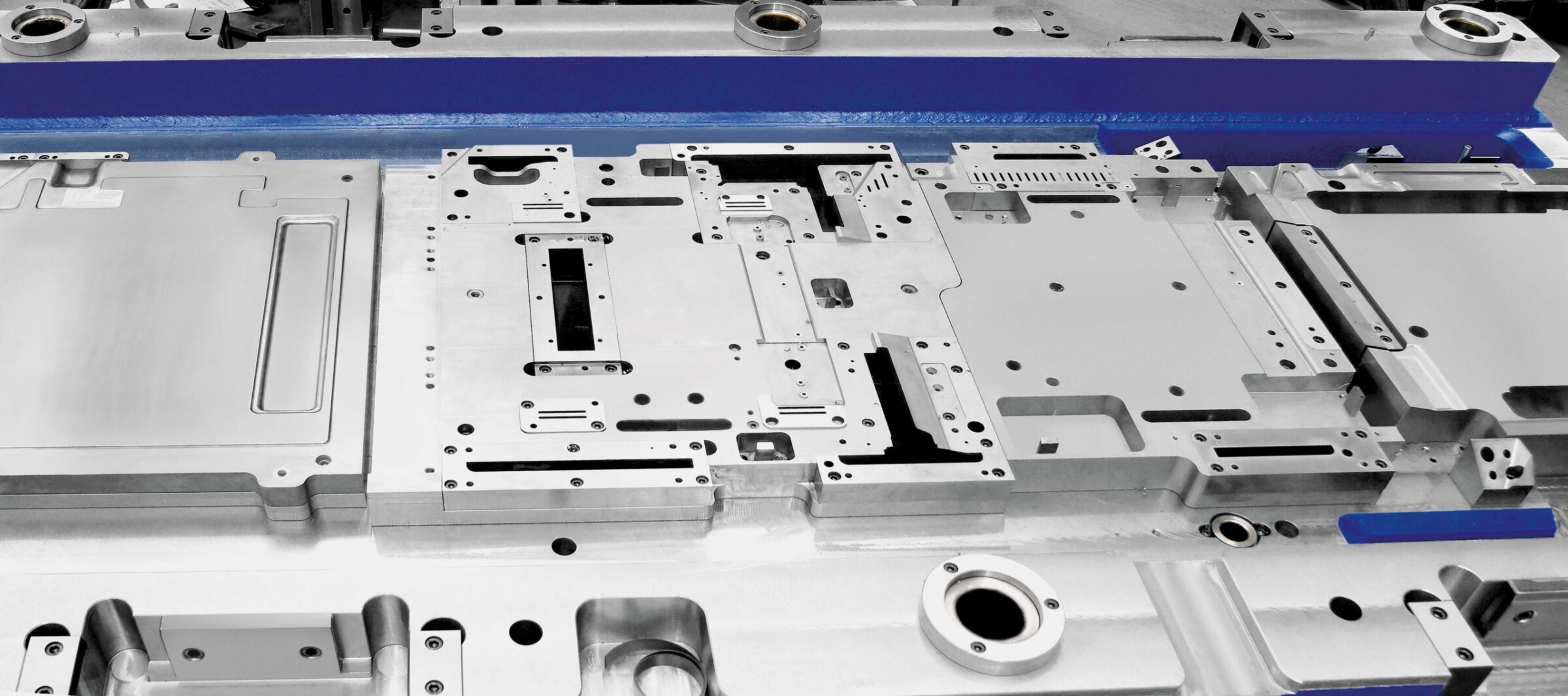

The outstanding precision of Mitsubishi Electric’s EDM equipment ensures a perfect fit between the punch and die on each of the 1260 holes of this tool.

Universal1972 is a classic family-run business, as is often encountered in Italian manufacturing. This is where employees’, and not only the owner’s, exceptional enthusiasm for their own work combines with metalworking skills and an inventiveness that constantly brings forth new solutions. Such companies were able to survive the banking crisis owing to their expertise and establish a reputation of reliability and precision on all foreign markets.

The most progressive technologies on the market.

Alessio Caramaschi, the firm’s managing director, explains: “Our strength is being able to offer the customer a turnkey product. We work directly on the design and production of tools and offer solutions that are capable of actually reducing the cost of shaping. We take active part in the development cycle from the first steps, always study the best solutions until the tools are capable of working faster and thus ensuring high productivity. The tools are tested in our workshop so that the customer receives a finished item of equipment for his production operations.”

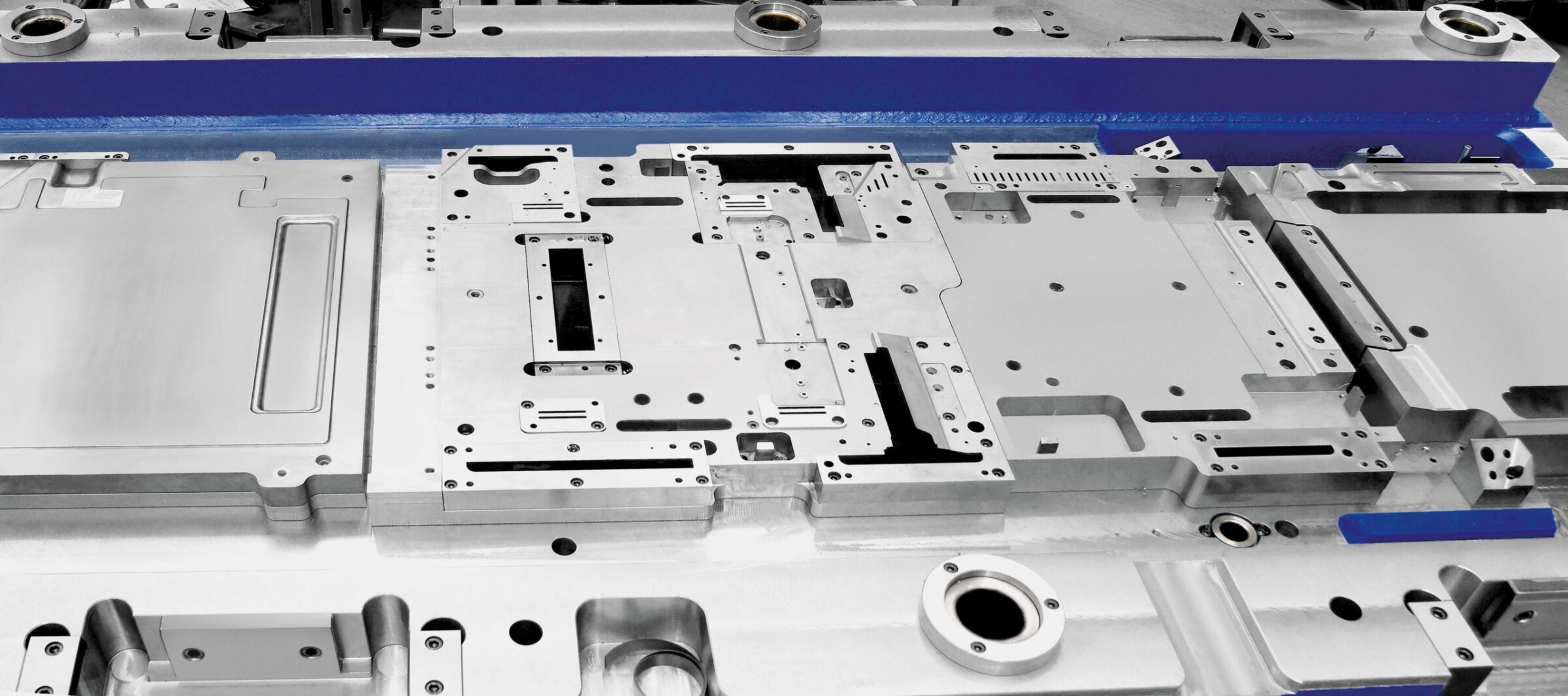

The Mitsubishi Electric MV4800 EDM system installed at Universal1972

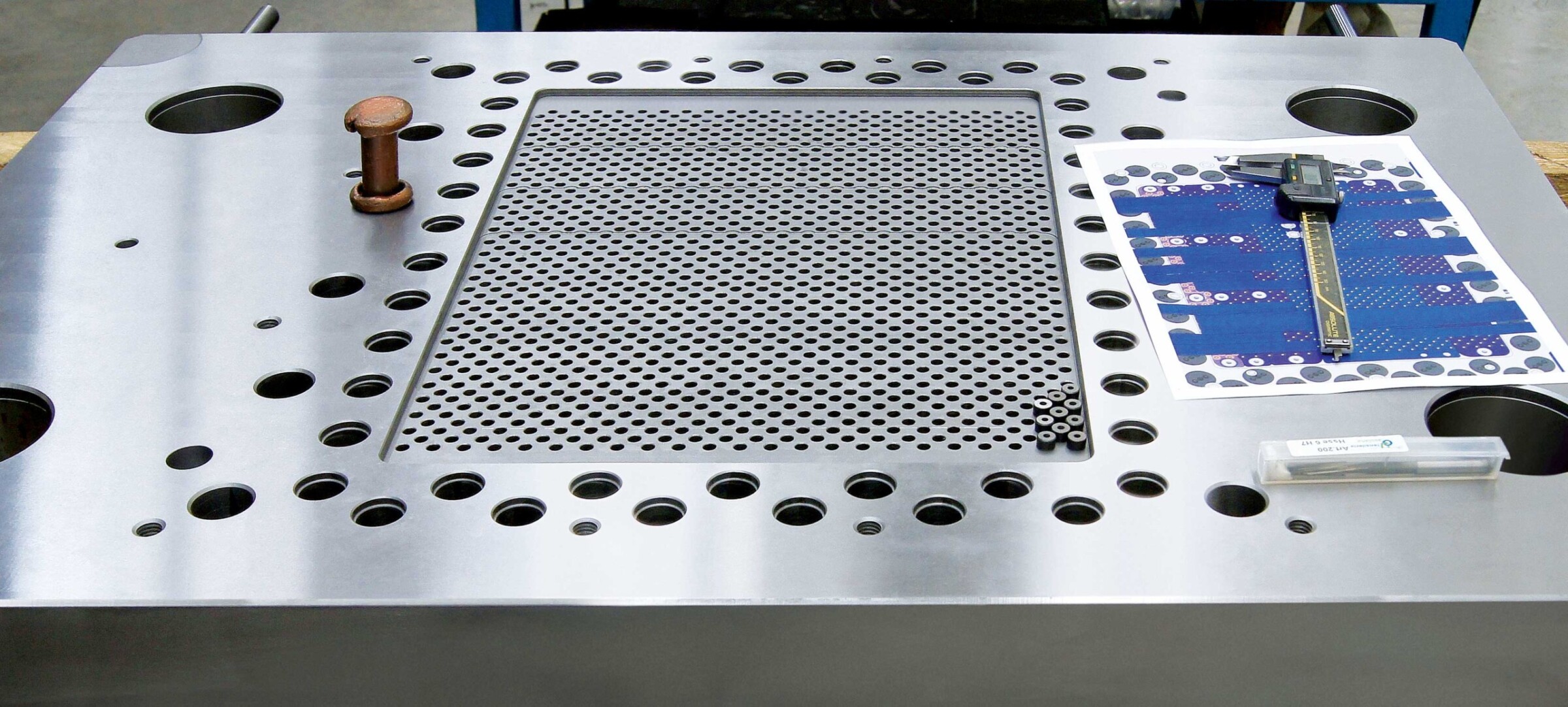

The company’s flagship product is the so-called “tool opener” machines that were developed by the company’s creative founder Armando Camp to overcome the difficulties with the handling of shaping tools, which are usually very heavy and cumbersome. Traditionally, a mobile crane, chains or other gear are required for the handling of these tools. Operating personnel are also exposed to constant danger from the huge suspended loads. With the tool opener machines, on the other hand, all the movements are performed by the machine that opens the tool, tilts it, stops it in any desired position and enables the operator to work at close quarters comfortably and without risk. The company in Lombardy exports these machines worldwide to market-leading businesses engaged in the cold forming of sheet metal. To save time, cut costs and ensure safety, they have meanwhile evolved into indispensable items.

During the financial crisis, many customers turned to China. However, the differences in costs are now minimal, while the quality of goods from East Asia still has to be checked and can never be taken as given. “One of our customers asked us do the design work for a series of tools for a project (the cold forming of washing machine drums), which would then be built in Asia. The tools arrived four months later, but failed to work properly under the presses. We checked them: the tolerances, tightness of fit, closures and values were all anything but accurate. We also discovered that the steel they were made from was too soft and would have worn out long before the envisaged target value of 150,000 items was reached.” In fact, experience, knowledge, skill, inventiveness and human talents are necessary to convert the project on paper into physical reality. “We had to build new tools ourselves and now they work perfectly.”

From the left: Alessio and Armando Caramaschi, two generations at Universal1972. They are both convinced that investment in new equipment is capable of boosting efficiency and stimulating a company’s growth.

Saving time and costs.

“At Universal1972 we are convinced that you have to have the courage to invest continuously so that each department can be regularly upgraded with new machines. Technology is constantly advancing and no one can afford to be left behind.” The Mitsubishi Electric MV4800 wire EDM was recently installed. The nerve centre of this machine is the communication system between the CNC, drives and motors based entirely on optical fibre (ODS). It was delivered to Parma by Overmach, a company group with many years of experience of the sale of new and used CNC machine tools, inclusive of service, maintenance and prototyping. The machine uses revolutionary patented Tubular Shaft Motors. The use of a virtually loss-free circular magnetic field reduces energy consumption, while the contactless power transmission permits constantly stable and precise shaft movement. Mitsubishi Electric has implemented many more innovations, such as a highly efficient wire threading system (Intelligent AT) that can be adapted to working conditions and facilitates a process yielding an optimum surface finish with less reworking. The highly progressive Advance Plus CNC control is equipped with a special user interface that can directly import and manage physical geometries. The new EDM system has already met all expectations: “This is our first machine from Mitsubishi Electric and we are very satisfied with it. We had serious problems with the unreliability of the previous manufacturer and are happy that we have now turned to one of the industry’s leading companies. We also built up excellent relations with the supplier Overmach and were impressed by its rapid installation and set-up of the machine. We only needed to switch it on to start production. We appreciate its exceptional accuracy, a factor that is of fundamental importance for us. We cannot afford any deviation, even if it’s only one per cent. For instance, on one of our punching tools there are 1260 holes (this tool punches holes in a metal strip from which the drum of a washing machine is later produced). If only one of them is less than perfect, the punch will no longer fit in the die and the punch will be ruined owing to the high speed of cold forming.”

The machine known as the tool opener is an invention of Universal1972, the company’s flagship product. It makes it possible to handle tools safely.

The tools produced by the Lombard company are truly mechanical, with stations, slides and sequentially performed motions. The difficulty here is to imagine and build a mechanism that is capable of converting a metal strip into a finished object with a minimal number of preferably automated steps. It is precisely here that inventiveness and knowledge can give the customer a competitive edge. The more logical a tool’s design, the greater the efficiency that the customer can achieve with it. “In a factory in Poland, we noticed that baking sheets were being produced in a huge 6 m long press with four tools – an incredible waste of resources. We studied the live process and soon came up with a different and much more functional way of performing the task. So we approached the plant manager and told him we would be able to build him a much smaller tool that can be used on a much slimmer and significantly less expensive press. We were awarded the job on the spot. Only a short while later, we had built six units of the same type. This freed up the larger machine for other tasks and the firm was able to boost its cold forming output to a million items per month.”

The finished tools are supplied to all the big names in domestic appliance manufacture.

Genuine competitive edge.

This is the added value of invention, which creates satisfied customers and gives them a genuine competitive advantage. Universal1972 helps companies that produce domestic appliances to innovate: with a single tool, a simple mechanical press can be used instead of an expensive electronic “intelligent” device. The workpiece is moved between the stations by a pneumatic robot system. The knurling of the tray is one of the most difficult work steps. We have developed a motion by which the metal coils itself up, literally in the air, without causing any metal waste. The stations are integrated in the tool, and their maintenance is very straightforward compared to the traditional method, as they are easy to detach.

At Universal1972 all tools are thoroughly tested on completion.

After almost half a century of producing tools for the domestic appliance industry under contract, Universal1972 sought a new challenge and decided to manufacture and market a product of its own. Made entirely of sheet metal, of course – of stainless steel in fact. The product is the Grilioo, a revolutionary and brilliantly conceived barbecue, hard-wearing and efficient, a high-grade product. “For a company like us it would have been insane to come up with such a product unless it is highly innovative, as we wouldn’t be able to compete with mass-produced items that only cost a few hundred euros. What makes our barbecue special is that it works practically by itself, without generating smoke. The rack tilts and turns and ensures almost automatic uniform cooking; it can move closer to the heat source (high-grade vertical ceramic burner) while the water at the bottom catches the fat and prevents smoke being emitted into the environment. For instant cleaning, the water drains off and the rack can be washed in the dishwasher. The barbecue designed with a CAD program permits a truly environment-friendly cooking process. Market research has shown that demand for it is particularly high in the United States and Australia. It offers many functions that other products of this kind don’t have. All parts are produced with moulds generated at least partly by EDM.”

After almost half a century of producing tools for the domestic appliance industry under contract, Universal1972 sought a new challenge and decided to manufacture and market a product of its own. Made entirely of sheet metal, of course – of stainless steel in fact. The product is the Grilioo, a revolutionary and brilliantly conceived barbecue, hard-wearing and efficient, a high-grade product. “For a company like us it would have been insane to come up with such a product unless it is highly innovative, as we wouldn’t be able to compete with mass-produced items that only cost a few hundred euros. What makes our barbecue special is that it works practically by itself, without generating smoke. The rack tilts and turns and ensures almost automatic uniform cooking; it can move closer to the heat source (high-grade vertical ceramic burner) while the water at the bottom catches the fat and prevents smoke being emitted into the environment. For instant cleaning, the water drains off and the rack can be washed in the dishwasher. The barbecue designed with a CAD program permits a truly environment-friendly cooking process. Market research has shown that demand for it is particularly high in the United States and Australia. It offers many functions that other products of this kind don’t have. All parts are produced with moulds generated at least partly by EDM.”

Universal1972

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com