In its initial and further vocational training, Fohnsdorf training centre (Schulungszentrum Fohnsdorf = SZF) in Austria is keen to keep pace with current technologies and the needs of industry, craft enterprises and trade. In the metalworking department, there were compelling reasons to invest in an EA12S die-sinking machine from Mitsubishi Electric.

Training for industry.

Skilled manpower for industry.

An open, bright foyer with a coffee bar and comfortable seating is a pleasant place for relaxing. This is how Fohnsdorf training centre presents itself to visitors. As Heimo Gladik, in overall charge of training, reports, this open and inviting atmosphere is part of the centre’s concept. “We want to welcome motivated participants to our initial and further training. And that’s why we organise our training centre in such a way that participants feel at home and take genuine pleasure in studying hard.” The training centre works on behalf of the job centre, i.e. the state-organised system of helping people who are out of work temporarily or long-term to find new employment. “However, with the training that we’ve designed, we differ markedly from what is otherwise available. Anyone who comes to us must demonstrate his genuine interest with an application and in a detailed interview,” Gladik explains.

Not a token commitment: Thanks to the experienced full-time instructors, numerous women also gain a sound training qualification in typical “male” professions at the centre.

Always technologically state-of-the-art.

In return, course participants are given unusually broad initial and further training. The curriculum is carefully balanced to the needs of industry, craft enterprises and the economy, says Gladik. The roughly 170 highly skilled, full-time instructors teach not only technical content, but also social skills. This includes comprehensive factual knowledge as well as abilities that can be put to practical use in the metalworking, electrical engineering, tourism and office/IT sectors. “We also teach broadly-based knowledge and skills in the interdisciplinary fields of CAD, languages, transport and logistics,” Gladik adds. Some 400 participants come to Fohnsdorf every day, and each year about 1500 leave with a certificate documenting successful completion of their initial and further training courses. In doing so, they benefit firstly from the modern furnishings and equipment of the training and seminar rooms and secondly from the large workshops packed with the latest technology. Unlike comparable institutions elsewhere, the participants attend initial and further training lessons tailored to their personal needs. In Fohnsdorf there are no fixed groups or classes and no strictly timed courses. In accordance with their prior knowledge and expectations of themselves and of the initial and further training, each participant is given a personally structured training package. “We’ve been highly successful with this approach. Each year, about 150 participants take a final training exam. About half pass with distinction or a good grade,” says Gladik. He’s proud to note that over 60 per cent of qualified trainees find employment in positions appropriate to their skills within three months of completing their initial or further training.

Group learning: The instructors at the centre attach a lot of importance to social skills.

Particularly in the present situation in which craft businesses, industry and trade urgently need highly skilled manpower, the strategy of Fohnsdorf training centre is proving to be highly relevant to needs in industry. In consultation with company managers, the centre also offers further training geared to the specific needs of certain companies. It also assists firms with a comprehensive service in the search, selection and upskilling of currently needed and suitable specialist employees.

To uphold the exceptionally high quality of initial and further training, the instructors and students work of course with the very latest technologies, machines and equipment. As metalworking instructor Robert Wallner reports, this also applies to the machines for metalworking. “We carry out training so that our students can afterwards immediately find appropriate employment. This is why our course participants, and particularly those in further and advanced training, work on top-level production machines. The same applies, for example, for CAD/CAM systems. We are always state-of-the-art here.”

The EA12S die-sinking machine is a current technology.

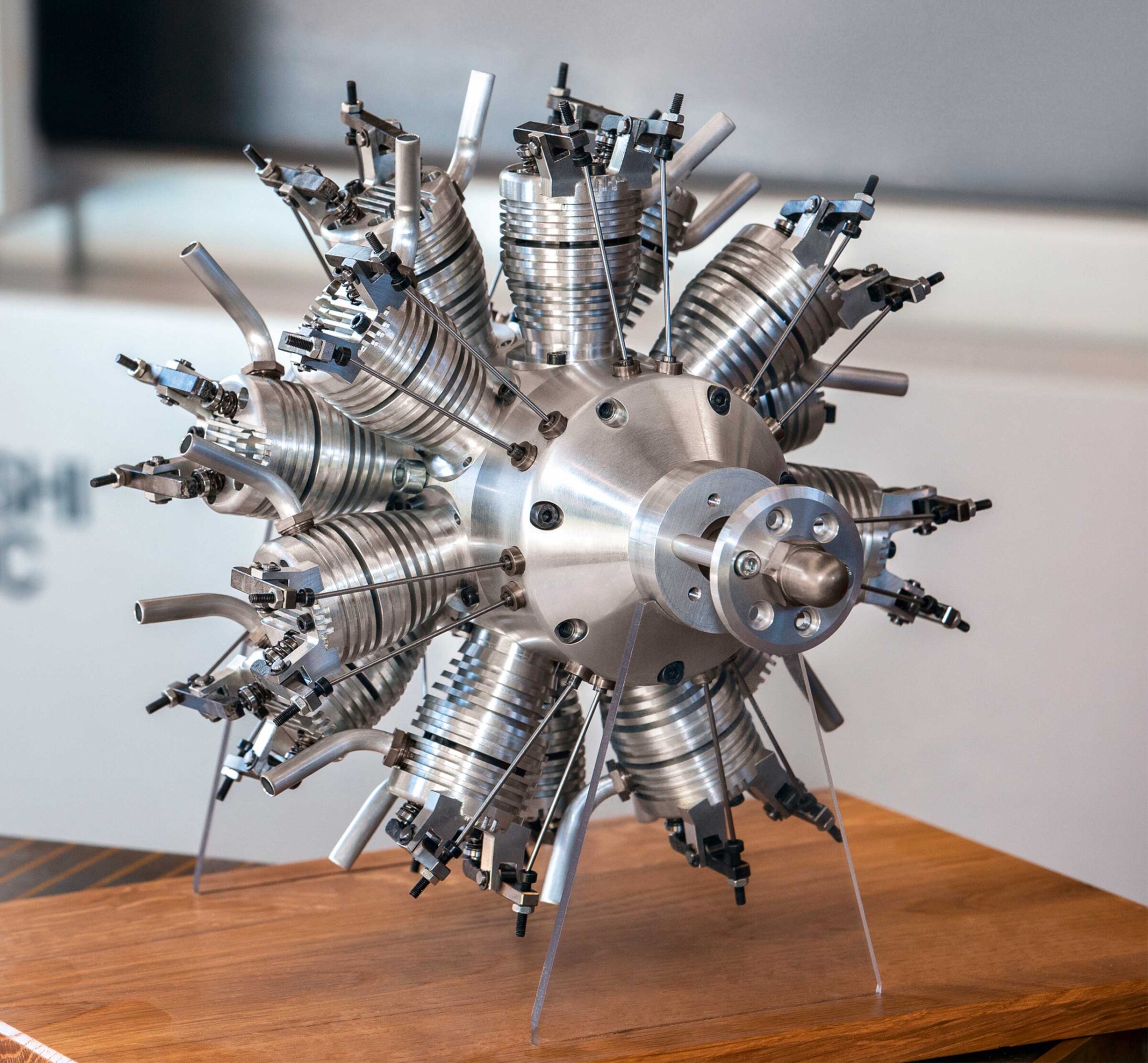

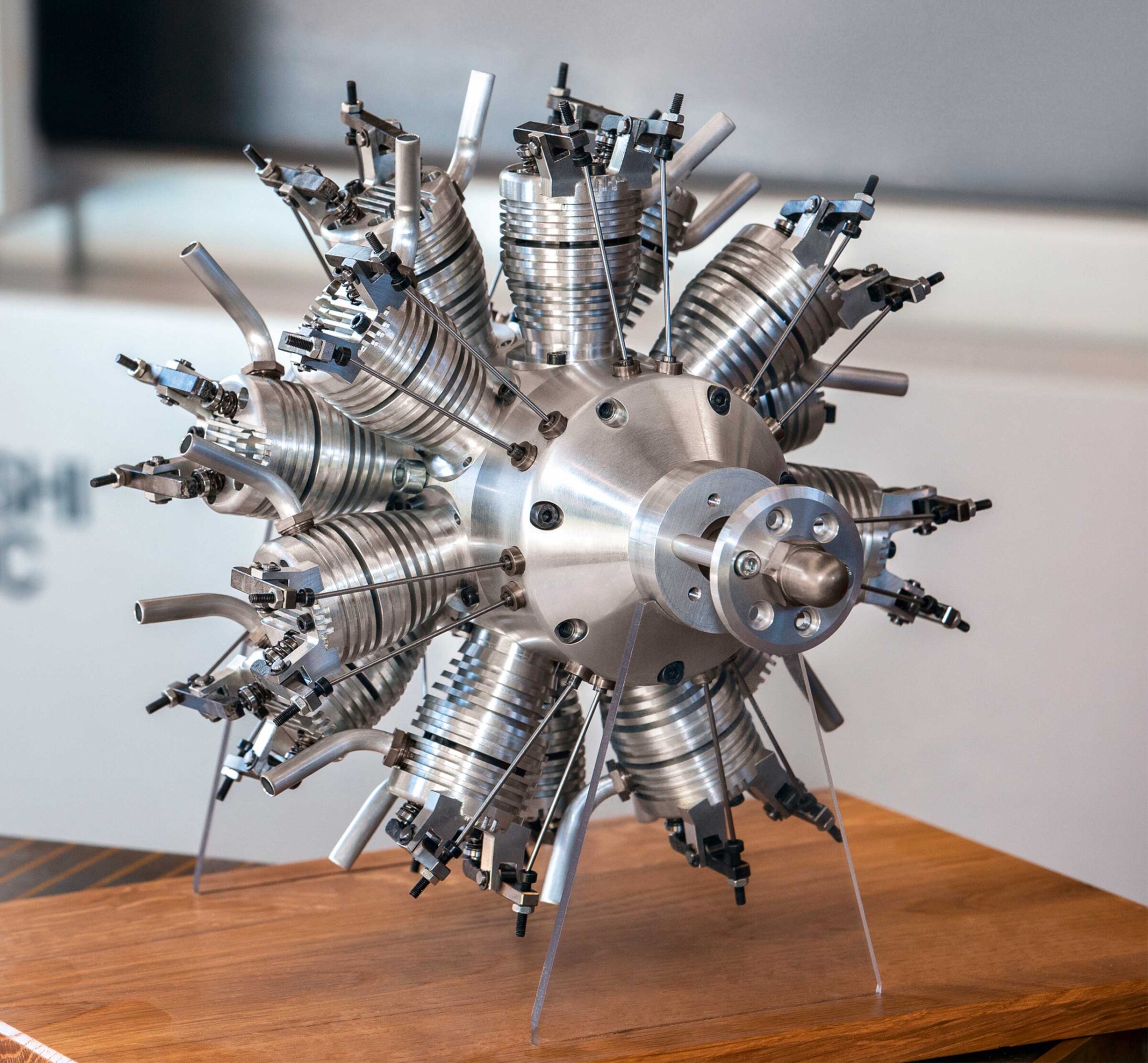

He furnishes immediate proof of this on a tour of the initial and further training workshop for metalworking. This is where there are, among other things, high-grade 3- and 5-axis machining centres for HSC machining that are equipped with all the control and drive technologies currently widespread in industrial practice. In addition, there is an EA12S die-sinking machine from Mitsubishi Electric. “By using this EDM system, we can teach not only EDM itself but also, in combination with the machining centres and milling machines, the entire process in tool- and mouldmaking from CAD to the finished punching die or injection mould ready for use in production,” Wallner explains.

Precision in all areas: At Fohnsdorf training centre, the advisers and instructors adapt the curriculum to the specific needs of students and companies.

Outstanding cost/benefit ratio.

Current equipment with the best cost/benefit ratio

Manager and Training Director Gladik adds: “We consciously chose a machine from Mitsubishi Electric, as it reflects perfectly the current state of technology. It also offers an outstanding ratio of performance to investment and operating costs.” In addition, Wallner continues, the machine’s dependability and the quality of Mitsubishi Electric after-sales service also contributed to this investment decision. “Training for the instructors is also excellently organised. Our specialist employees receive at short notice the necessary training in the current control technology and, in the event of updates, in machine functions,” Wallner adds.

Heimo Gladik (left) and Robert Wallner

We carry out training so that our students can afterwards immediately find appropriate employment.

Robert Wallner, metalworking instructor at Fohnsdorf training centre

Teaching employees can thus base the content of their initial and further training courses on current practice in industry and on the latest technologies – such as current digitisation. “That’s one of the main bonuses of our strategy. We are always technologically at the cutting edge. Students who attend our courses can go straight into appropriate positions in industry, crafts and trade,” says Gladik summing up. This is entirely in line with Fohnsdorf training centre’s own motto: “We train skilled manpower for industry!”

Name and place of company:

SZF Schulungszentrum Fohnsdorf

Austria

Founding year:

1975

Managing Director:

Edmund Müller

Employees:

150

Core business:

Specialised and interdisciplinary initial and further training in the latest technologies, individually tailored to the interests of trainees and companies, in the fields of metalworking, electrical engineering, tourism and office/IT

SZF

Schulungszentrum Fohnsdorf

Hauptstrasse 69

8753 Fohnsdorf / Austria

Tel +43 3573 6060

Fax +43 3573 6060 1009

office@szf.at

www.szf.at

Back in the late 1960s, the regional mining of lignite was increasingly proving to be uneconomic. The coal mined underground was heavily contaminated with sulphur, and because rock had to be cleared away, mining was highly unprofitable. Over the years, many people lost their jobs and were unable to find new ways of earning a living. The surrounding municipalities, together with a private sponsor, therefore decided to found an initial and further training centre.

The first courses and lessons for mature working people who had previously been employed in mining were then held here at the Fohnsdorf site in 1975. The aim was to enable them to take a new career path in tool- and mouldmaking or woodworking and earn their own living. It was not only purely factual information that was to be taught, but also social skills to enable them to work in groups and be able to find their feet in a rapidly changing technical environment. Within a few years, the training proved to be highly successful. Today’s Fohnsdorf training centre has evolved out of this. We now have a branch in Fürstenfeld where, working to the same principles, we are highly successful in giving people with varied interests initial and further training.

The vast majority of participants of our training are sent by the job centre. Some come on their own initiative and about 20 per cent of trainees we obtain through direct cooperation with regional companies. These companies contact us to jointly devise programmes of further training for their employees. This applies, for example, to companies that are introducing new technologies or are restructuring, causing numerous employees to change to different positions and areas in the company.

We do not see ourselves as the administrators of a social problem, i.e. unemployment. We focus instead on individually devised initial and further training geared to the interests of participants and commercial enterprises in our area. This means, for example, that we hold detailed interviews with each individual on prior training, interests and personal goals. We tailor personalised training programmes for each participant. This also means that we offer inexpensive accommodation on our premises for the duration of training. As a result we can also take in trainees from further afield and whose economic circumstances would otherwise prevent them from attending the course.

This is another area in which we want to offer more than other initial and further training centres. We design our courses so that they are always attuned to current technologies and the interests of industry. In the EDM sector, we realised in consultation with nearby production firms that this technology tends to be neglected in training for the metalworking trades. This is why we have included a die-sinking machine in our metalworking shop. We can thus give trainees in-depth experience of EDM while also explaining the overall processes in tool- and mouldmaking across the whole spectrum of production technologies.

We opted specifically for the die-sinking machine from Mitsubishi Electric because it reflects current technology with a particularly attractive price/performance ratio and because you can rely on the after-sales service.

Manager and Training Director

SZF Schulungszentrum

Heimo Gladik Manager and Training Director

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com