Specialists in EDM evolve into full-range suppliers of medical instruments.

Wire erosion – an essential technology.

Friedrich Daniels Medical GmbH has been operating in the Swabian town of Aldingen for a few months now. In the medical technology sector, this has been for many years a familiar name from a company based in Solingen, and this is something entrepreneurs Robert Keller and Andreas Wenzler wanted to exploit. As Keller reports, the participation of the Solingen medical technology manufacturer in the recently founded company has opened up direct access to customers. “Via our head office in Solingen, we are already listed as a qualified supplier for many potential customers. And this greatly simplifies access to the market we focus on,” he adds.

Part of the product range of Friedrich Daniels Medical GmbH

Easy access to the market.

Friedrich Daniels Medical

An ideal team.

Specialists in EDM evolve into full-range suppliers of medical instruments

Productivity, high precision and dependability.

Keller and Wenzler moved into the modern new building in Aldingen in spring 2019 after only six months for construction. It provides over 1,000 m² of space for production and 250 m² for administration. Within a very short time, production capacity utilisation was high. The company had previously been based in Gosheim for more than two years, but the production site there did not offer any scope for expansion. Keller says: “We’re obviously the ideal team for persuading customers of our comprehensive services, and this is probably why our company has grown so quickly and successfully.” He and his partner started in 2017 by themselves, and today they already employ 15 specialists. The two of them met at handball – a real team sport. Keller had already had several decades of experience of EDM and had been highly successful with his old company Keller Erodiertechnik in neighbouring Gosheim. The other, Andreas Wenzler, had been a technical business economist specialising in medical technology for several years. So that he could embark on his own career, he refused to take over a long-established family business as planned, deciding instead to start something of his own with his newly found partner. With their previous knowledge and excellent contacts in the industry coupled with their new location in the southwest German medical technology region around Tuttlingen, the two team players see themselves well positioned.

This wire EDM machine is highly productive, accurate and dependable. Robert Keller, Manager at Friedrich Daniels Medical

At their newly founded business, they have all the machining processes at their disposal – turning, drilling, milling, grinding and eroding. More than 20 machines are already in operation in the new production building in Aldingen, along with several skilled design engineers and CAM programmers. Keller and Wenzler thus see themselves well equipped to act increasingly as full-range suppliers of medical instruments. Wenzler is familiar with the demands and wishes of medical professionals and manufacturers who have been established in medical technology for many years in Tuttlingen. He has excellent contacts with the specialists, which allows him to participate in innovative projects from the idea through to the finished product. The company mainly focuses on instruments for surgical procedures and orthopaedic treatment of the spine. As a specialist in machining and specifically in EDM processes, Keller uses his comprehensive knowledge to ensure that the company can also cost-effectively manufacture difficult parts and components for medical instruments with high productivity.

Cutting punch for toolmaking

Keller regards the wire EDM production process as one of the business’s essential core competences. “This is the only way to produce the intricate and sometimes complex contours required especially for components for instruments and accessories in medical technology,” he explains, adding: “This also applies particularly to the corrosion-resistant and high-tensile steel alloys used in medical technology.” In Aldingen, the experts produce numerous components for medical instruments, using such materials as steel grade 1.4307, a corrosion-resistant chromium-nickel alloy.

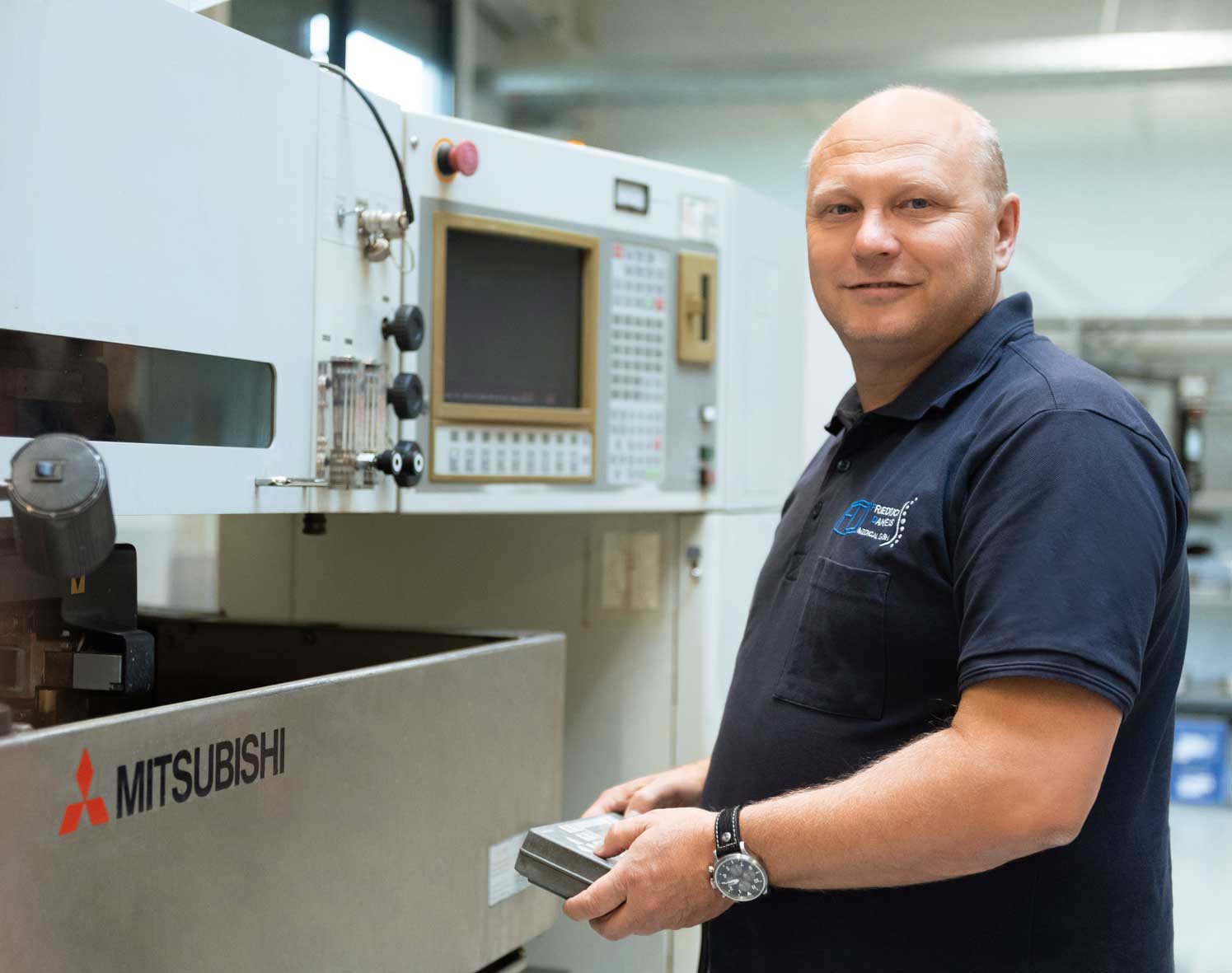

His excellent experience with Mitsubishi Electric wire EDM machines at his old company specialising in spark erosion goes back to 2003. He has experience of the FA10, FA20 and BA8 machines. These, he confirms, have proven themselves over many years. “These machines have always been robust and reliable. I was also impressed by the comprehensive advice provided by the eroding specialists at Mitsubishi Electric. The competent and always accessible service was another reason why I consistently chose machines from the Japanese manufacturer.” Keller proudly shows one of his trusty wire EDM machines, an SX20. “Since its initial installation and commissioning in 1996, it has been working dependably and with high precision. It has survived the move to today’s production site without any problems and will hopefully continue to perform well for a few more years”, Keller stresses. “That says a lot about the outstanding quality of these machines, I believe.”

Robert Keller proudly presents his SX20 wire EDM system.

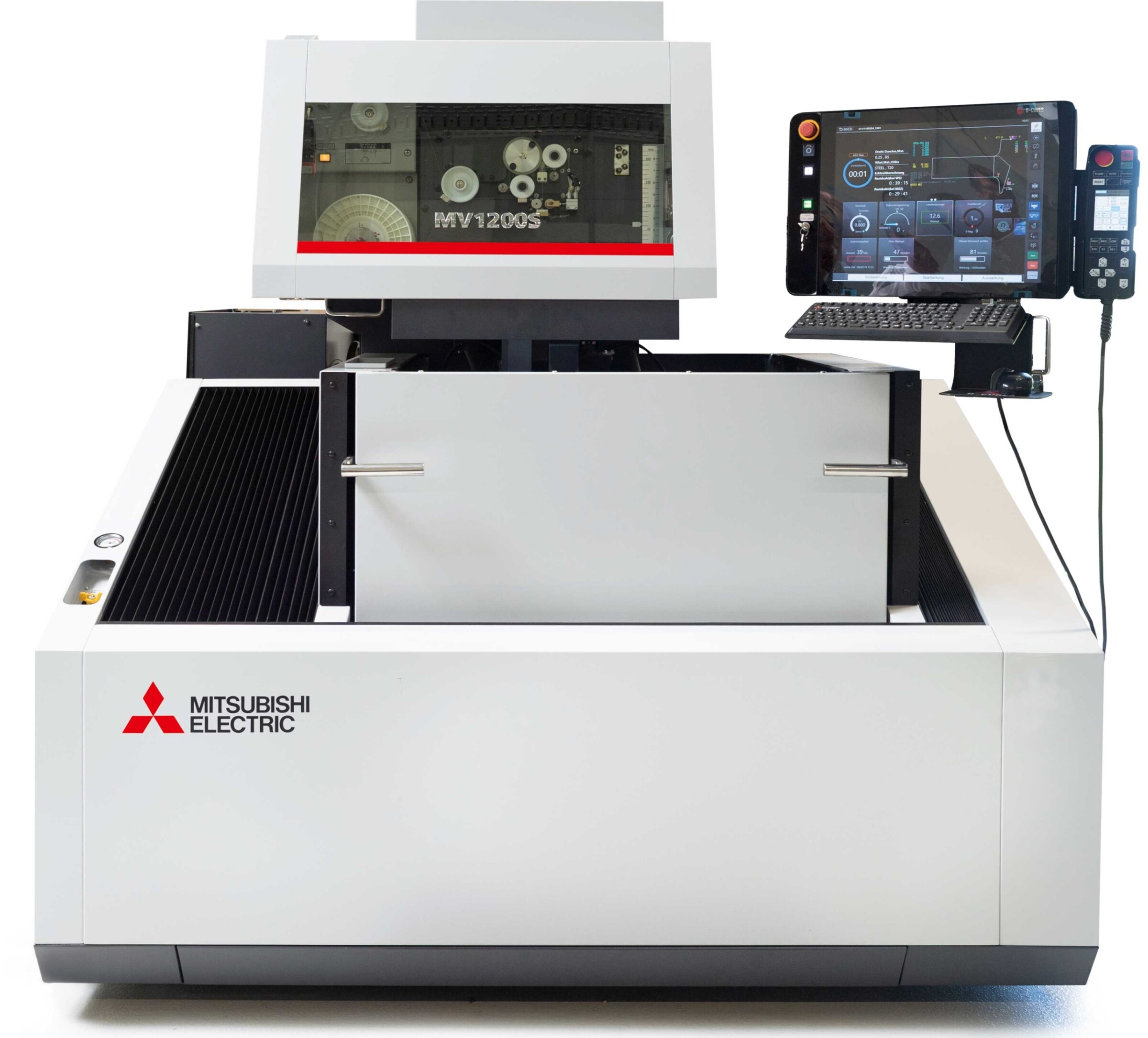

Keller has based his decision for further investments on this positive experience. To expand production capacity, he purchased a MV1200S NewGen wire EDM with its state-of-the-art D-CUBES CNC control in May 2019. The programmers and machine operators took only little time to familiarise themselves with the innovative technology, Keller reports. The app-like operating and programming interface on the touch screen is much appreciated particularly by young professionals who are already familiar with this operating philosophy from their smartphones and tablet PCs. They appreciate the intuitive and simple operation. “However, it is also possible to select the user interface of the previous Advance Plus control system, which allows the new MV1200S NewGen to operate very flexibly. Existing CNC programs can also be used on the MV1200S NewGen by operators who previously worked exclusively at the proven machines,” says Keller. The fourth, rotary axis also contributes to the flexible use of the MV1200S NewGen, enabling it to fully machine all conceivable geometrical details on a workpiece in several planes.

In the quest for µm precision

Programming in Aldingen is conducted almost exclusively at CAM workstations from DCAM. The data is digitally transmitted straight to the EDM systems via the company network. The newly founded business is well on its way to Industry 4.0, Keller notes. The new building offers ideal conditions for directly networking all machines, CAD-CAM systems, and production planning and monitoring. It goes without saying that the processes in production are validated and largely certified. “This is the only way can we become a competent component supplier to medical technology. The components and instruments we develop and manufacture are approved for use in medicine – in surgery, for example,” says Keller.

Learning the ropes the fast way with the new D-CUBES control

With his comprehensive array of EDM systems, Keller intends to continue the contract manufacturing of customer-specific components, making a further commitment to this with the recently purchased MV1200S NewGen. “This wire EDM machine is highly productive, accurate and dependable,” he says. The company in Aldingen therefore has sufficient capacity to punctually complete outside contracts at short notice.

The modern new building in the Swabian town of Aldingen was moved into in spring 2019.

Robert Keller, one of the current managers of Friedrich Daniels Medical GmbH in Aldingen, has followed the technology of eroding from the very beginning. He first came into contact with the process in the 1980s during his training as a toolmaker at a Black Forest watchmaker’s. Later, he worked in stamping and toolmaking and was able to significantly expand his knowledge of sinker and wire EDM. At his design office for toolmaking and at his later company Keller Erodiertechnik, he was also mainly concerned with this specific machining process. He is keen to point out that he is largely self-taught. He has also attended numerous further training courses at industrial institutions and machine manufacturers and finally passed the examination to become an industrial foreman. Throughout his professional career, Keller has seen himself as a practitioner. Even today, he says, he enjoys working at the machine. In this way, he can maintain and further develop a feeling for which workpieces can be produced under which conditions – using wire EDM, for example.

Name and place of company:

Friedrich Daniels Medical GmbH

Laubbühl 2

78554 Aldingen, Germany

Founding year:

2018

Managers:

Robert Keller,

Andreas Wenzler

Employees:

15

Core business:

Development and production of medical instruments and devices as a certified full-range supplier as well as EDM services on a contract basis

Friedrich Daniels Medical GmbH

Laubbühl 2

78554 Aldingen, Germany

Tel +49 74 24 97514-0

Fax +49 74 24 97514-99

info@daniels-medical.de

www.daniels-medical.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com