The Plastics Centre in Leipzig makes its mark in research with its expertise, creativity and a wide range of technologies.

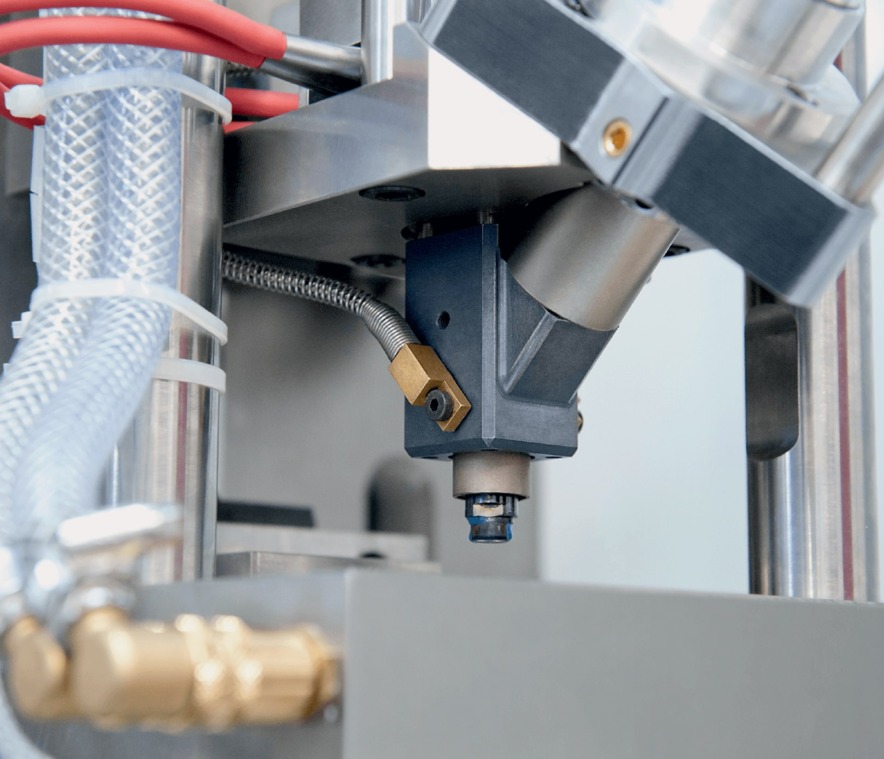

Compared to an old machine, die-sinking with the new machine offers the staff of the Plastics Centre entirely new opportunities.

With over 50 years’ experience of plastics technology, Kunststoff-Zentrum in Leipzig gGmbH (Plastics Centre) develops innovative processing solutions for this widely used material. The success of its research projects with companies from industry is made possible by its scientific knowledge and technical skills. Technologically, the Plastics Centre is excellently equipped with hypermodern laboratories and a high manufacturing depth in all areas. The tooling department has been recently supplemented with a die-sinking EDM machine from Mitsubishi Electric as an extension to its range of machining methods.

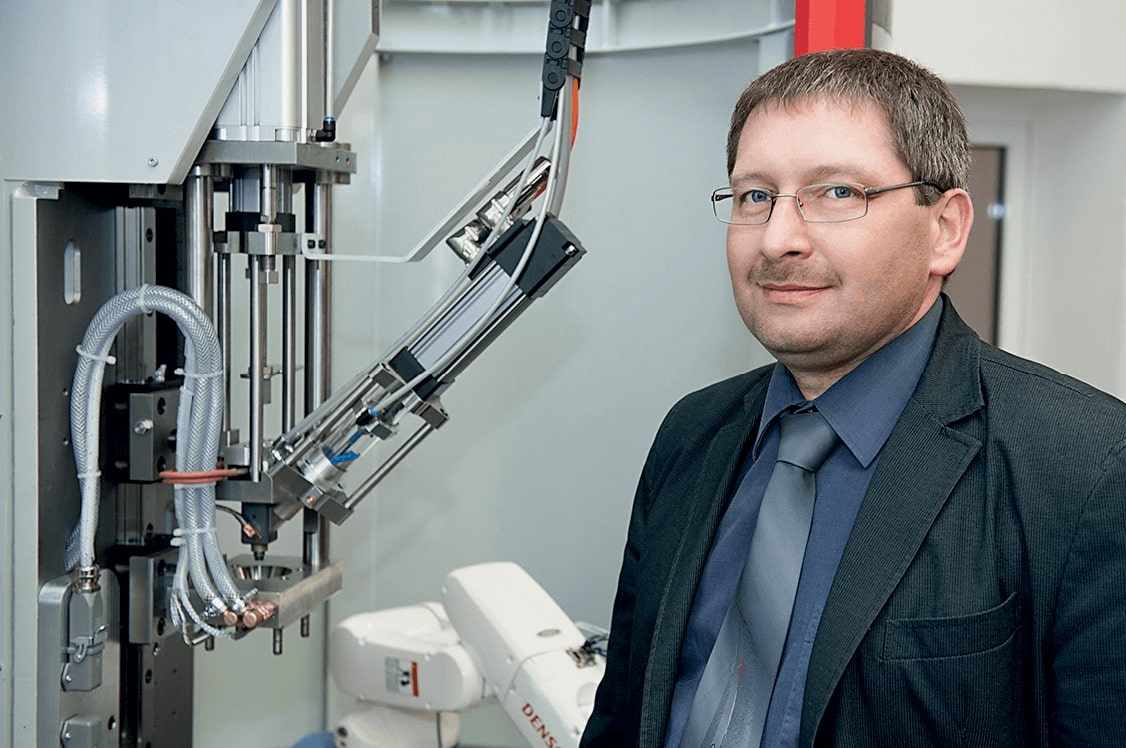

“Plastics can be found in all areas of modern life. Today, they enjoy the status of high-tech materials whose development and processing are spurred on by innovation,” says Jörg Michaelis, explaining what his work is all about. As the head of Tooling and Joining Techniques, he is responsible at the Plastics Centre in Leipzig for research projects that bring forth just such innovation. “In this context, we see ourselves as problem-solvers for industry.” The Plastics Centre works on solutions facilitating the cost-effective realisation of new applications in plastics processing.

The Plastics Centre is broken down into four departments. Along with the areas that Michaelis is responsible for, Tooling and Joining Techniques, there are Processing and Testing. 40 scientific and 20 technical employees work hand in glove in meeting the needs of clients from industry. “We go in for research cooperation and work very closely with the companies that come to us for advice,” says Michaelis, outlining the Plastics Centre philosophy. He also stresses the win-win situation for everyone concerned: “In

these projects, we have the very latest technologies and laboratories at our disposal so that we can perform all of our tasks flexibly and without outside assistance.” Along with funding from the German Ministries of Industry & Technology and Education & Research and Saxony’s Reconstruction Bank (SAB), the projects, he claims, are a cornerstone of the non-profit organisation’s business success. “60 per cent of our costs are covered by the ministries and the SAB, and the rest comes from projects from industry and from training courses,” says Michaelis, explaining how the Plastics Centre obtains its income.

The customers of the Plastics Centre also benefit from the wealth of experience gradually accumulated since its founding in 1960. After reunification, the then “Central Laboratory for Plastics Processing” ventured into the uncharted territory of the free market economy, says Michaelis looking back. “So that we could operate as a non-profit ‘GmbH’, we needed a supporting body.” This when they managed to attract such big names as Arburg GmbH & Co. KG and Bayer MaterialScience AG. The supporting body today has 84 members. Over the years, the focuses of the Plastics Centre’s work have gradually taken definite shape. “Our core competences are polyurethane processing, joining techniques and particularly ultrasonic welding, and injection moulding with a focus on micro-injection moulding.”

Micro-injection moulding is a good example of the Plastics Centre’s engineering expertise. In this process, tiny parts in the milligram range are produced. Fine structures measuring micrometres are generated in this process. “When shot weights of less than 200 mg are injected for the production of micro-parts, conventional machines with a screw-type plunger run up against their limits,” Michaelis explains. For this purpose, the Plastics Centre has developed a micro-injection moulding machine with plunger premelting and plunger injection. The engineer refers in this connection to the importance of the centre’s clients: “As researchers, we’re not a in a position to establish new products on the market because we lack the necessary service structures, among other things.” In this particular case, a company called Desma Tec markets the machine under the name of ‘formica Plast’.

Jörg Michaelis and Reiner Kluge (right), Workshop Manager, appreciate the flexibility of the EA12-V Advance.

To efficiently handle 25 to 30 research projects per year, a high degree of flexibility is called for. And this is one good reason why the Plastics Centre aims for a high manufacturing depth in all areas. “It is simpler for us to handle complex tasks ourselves than to farm out work of this kind to subcontractors who don’t have the same in-depth knowledge of the project as we do,” says Michaelis, explaining this policy. A toolmaker by training, he turns to the centre’s own toolmaking activities: “Even if we don’t earn money directly with this department, it is still an essential means to an end.” Along with milling and turning machines, the machine park has also been home to a die-sinking EDM machine from Mitsubishi Electric since 2010. In the metalworking sector, the new machine offers the Plastics Centre “entirely new possibilities”, as Michaelis puts it, compared to an older machine.

The EA12-V Advance was ultimately chosen for a number of different reasons, Michaelis recalls: “It was the combination of good advice given to us by the distributor R+H Erodier-Technik and the technical features of the sinker EDM machine.” In the end, the machine’s excellent price/performance ratio tipped the scales in its favour. The compact model from Mitsubishi Electric is the perfect addition to the Plastic Centre’s tooling department and offers a huge diversity of machining options. While the electrodes and workpieces for micro-injection moulding are relatively small, the EA12-V Advance is also capable of processing larger parts weighing up to 700 kilos. The machining range on the X, Y and Z axes is sufficiently large at 400 x 300 x 300 mm. The maximum electrode weight is 50 kg.

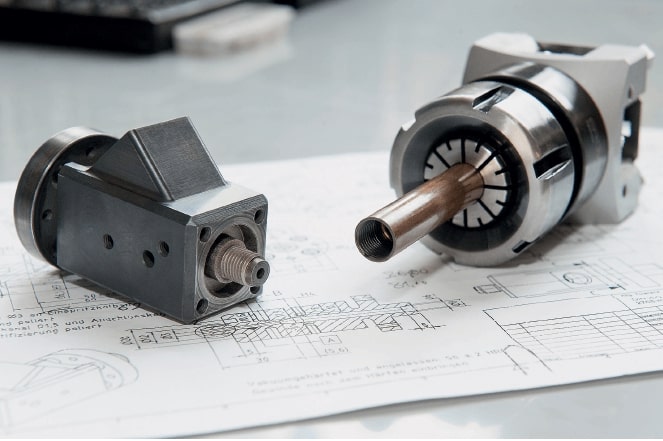

The electrode (right) with an inner thread erodes the thread of the two-stage injection cylinder. Conventional thread-cutting requires an undercut that impairs the strength of the thread.

The plastics parts produced in the micro-injection moulding machine weigh only a few milligrams, yet their complexity is exception- ally high.

“Even if we don’t have to achieve the same rate of productivity as job shops, the machine’s process security nevertheless enables us to stay sufficiently flexible.” The hotline is a big help if required, he says, and Michaelis views the future with confidence. He’s equally optimistic about the machine’s operating comfort: “The user-friendly control and touchscreen enable staff to familiarise themselves quickly.” This is an important factor, as Michaelis would like to have two operators available for each technology.

Installed in the micro-injection moulding machine, a machine nozzle is mounted on the thread of the two-stage injection cylinder.

“Workpiece precision can be measured in thousandths, and the complexity is very high as a rule.”

There are plans to expand the various technologies at the Plastics Centre. After the encouraging experience with Mitsubishi Electric, Michaelis is now also considering branching out into wire EDM: “With this process,

we would again have an extra range of options for our tasks – tasks that at present are either impossible or can only be mastered in a roundabout way.” Research at the Plastics Centre in the quest for practical solutions means solving problems with creativity and passion. “In those areas where we really excel, we want to stay ahead with intelligent solutions. After all, innovation is our motivation and that’s how things should stay.”

Name and place of company:

Kunststoff-Zentrum in Leipzig gGmbH,

Germany

Founding year:

1960

Managing Director:

Dr. Peter Bloss

Number of employees:

60

Core business:

Research and development in plastics technology with focuses on polyurethane processing, joining techniques and micro-injection moulding

Kunststoff-Zentrum

in Leipzig gGmbH

Erich-Zeigner-Allee 44

04229 Leipzig

Germany

Tel +49 . 341 . 4941 500

Fax +49 . 341 . 4941 555

info @ kuz-leipzig.de

www.kuz-leipzig.de

We do research and development in the field of plastics technology.

As a toolmaker.

The fact that we’re given interesting and diversified tasks and solve problems for our clients.

Not much. It’s still important for me to have a good team around me.

We want to continue concentrating on our core competences: injection moulding with the focus on micro-injection moulding, polyurethane processing and joining techniques.

Firstly, before I joined the company, the Plastics Centre in Leipzig successfully survived the period after German reunification; and secondly, we have achieved a stable position on the market with good staff and a number of patents.

Honesty, the ability to work in a team, and helpfulness.

One must never get into a panic, but deal with a problem calmly and with composure. Also, one should always be able to stand by one’s decisions.

We deal with plastics parts, ranging from Lego bricks to hearing aids.

Kunststoff-Zentrum in Leipzig gGmbH

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com