Mitsubishi Electric, one of the true laser pioneers, is now launching the internationally successful ML3015LVP laser-cutting system in Europe.

Mitsubishi Electric Europe

10,000 laser systems sold, 40 years of experience Mitsubishi Electric initiated laser technology research and development back in the Nineteen Sixties. The first laser system for industrial use was introduced in 1979. The strategic development of business with laser systems, first in Japan and then in the rest of Asia and America as well, has made Mitsubishi Electric one of the world market leaders with over 10,000 laser-cutting systems sold worldwide. Now that the severe economic crisis is largely behind us, Mitsubishi Electric feels the time is ripe to serve the European market with laser-cutting systems as well.

With all its products in the fields of electrical and electronic components, subassemblies and machine tools, Mitsubishi Electric positions itself in the premium segment – and laser-cutting systems are no exception. They satisfy the highest quality standards of the customer as well as its own commitment to supply products and technologies with a superlative price/performance ratio.

10,000 laser systems sold, 40 years of experience

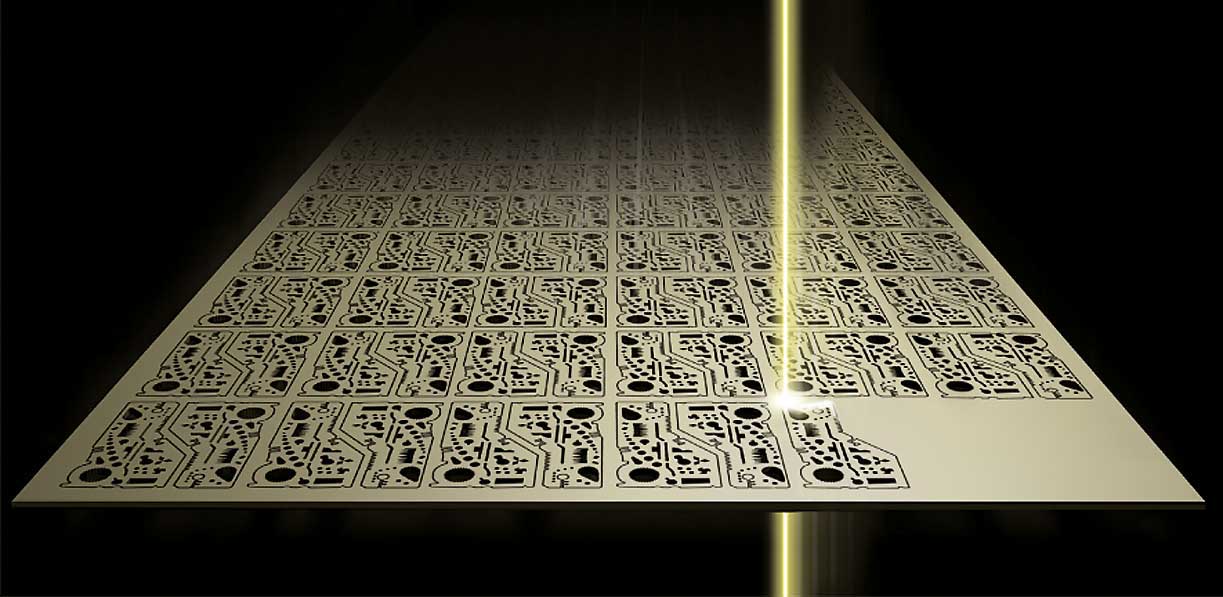

The laser-cutting system ML3015LVP – the first for the European market – covers a large proportion of the application spectrum with its machining range of 3,100 x 1,550 mm (X / Y). The system is designed for consummate precision at high cutting speeds. Thanks to Plasma Guard, corners and intricate geometric structures can be machined with unprecedented quality on components up to 25 mm high – Plasma Guard monitors and controls plasma arising during the cutting process and thus enhances the quality and stability of the process enormously. Unchanging cutting results throughout the machining range are a clear goal. To achieve it, the system brings a variety of technologies with it, e.g. the Beam Stabilizer technology that keeps the beam length constant and thus ensures that the beam parameters remain the same over the entire machining range.

Vision 2021 – for gentle treatment of the environment

With its Brilliantcut, the ML3015LVP also has a technology making it possible to cut stainless steel to a standard of quality that often makes secondary cutting superfluous – again a contribution to lower unit costs and the optimization of overall unit costs in production. Significantly improved surface qualities, reduced effects on the marginal zone and a virtually uniform cutting groove are the key features of Brilliantcut technology.

Mitsubishi Electric has committed itself to treating the environment as gently as possible with its own Vision 2021 strategy. Across the board – from development and manufacture through to product use – the company aims to keep CO2 output as low as possible in the context of this strategy. The agreeable side-effect for customers is that the environment-friendliness of the systems has a direct impact on costs. Reducing energy and laser gas costs cuts the overall cost of operating the systems.

Brilliantcut – saves time and money

This is aided by two key features integrated in the laser-cutting systems. Firstly, there’s the just-on-time discharge technology that dramatically reduces “Beam Off” energy consumption. This technology has far-reaching effects when one considers that in normal operation only about 50 per cent of operating time is active cutting time. In addition, Mitsubishi Electric has developed for its resonators a solution for the reuse of the laser gas. To this end the gas is reused for 24 hours and only then replaced, thus inevitably diminishing gas consumption considerably. Taken together, the two technologies significantly reduce not only carbon emissions, but also operating costs.

Solid machine design, the exclusive use of high-quality components and all the electronic systems produced in-house – all these are an assurance of the precision, durability and maximum dependability of the laser-cutting systems from Mitsubishi Electric. The company’s own CNC control leaves nothing to be desired, drives and control systems from its own production promote total integration, and the resonator developed and manufactured in-house yields superlative cutting results. All the core components come from Mitsubishi Electric.

The ML3015LVP laser-cutting system serves a machining range of 3,100 x 1,550 mm.

The dependability of the systems is underpinned at Mitsubishi Electric by the reliability of a big corporation. The company’s own after-sales service, customer support worthy of the name and a skilled team for everything to do with laser cutting make investing in a Mitsubishi Electric system a sound investment in one’s own future.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com