Making decisions, acting on his own responsibility and enjoying his work – it was with this positive attitude that Berthold Ortmann started his own business in 2018 as a contract manufacturer for electrical discharge machining. He can now look back on more than 35 years of professional experience in EDM. He has bought two machines from Mitsubishi Electric, although he had no previous experience of this manufacturer’s eroding equipment.

A flight of steps from the conservatory to the workshop.

Ortmann only fulfilled his life-long dream of setting up his own business in middle age. At the age of 55 he finally plucked up the courage to put his long-cherished desire for independence into practice. Since June 2018, the qualified toolmaker has been working in the spacious garage of his detached house, which he has now converted into a workshop.

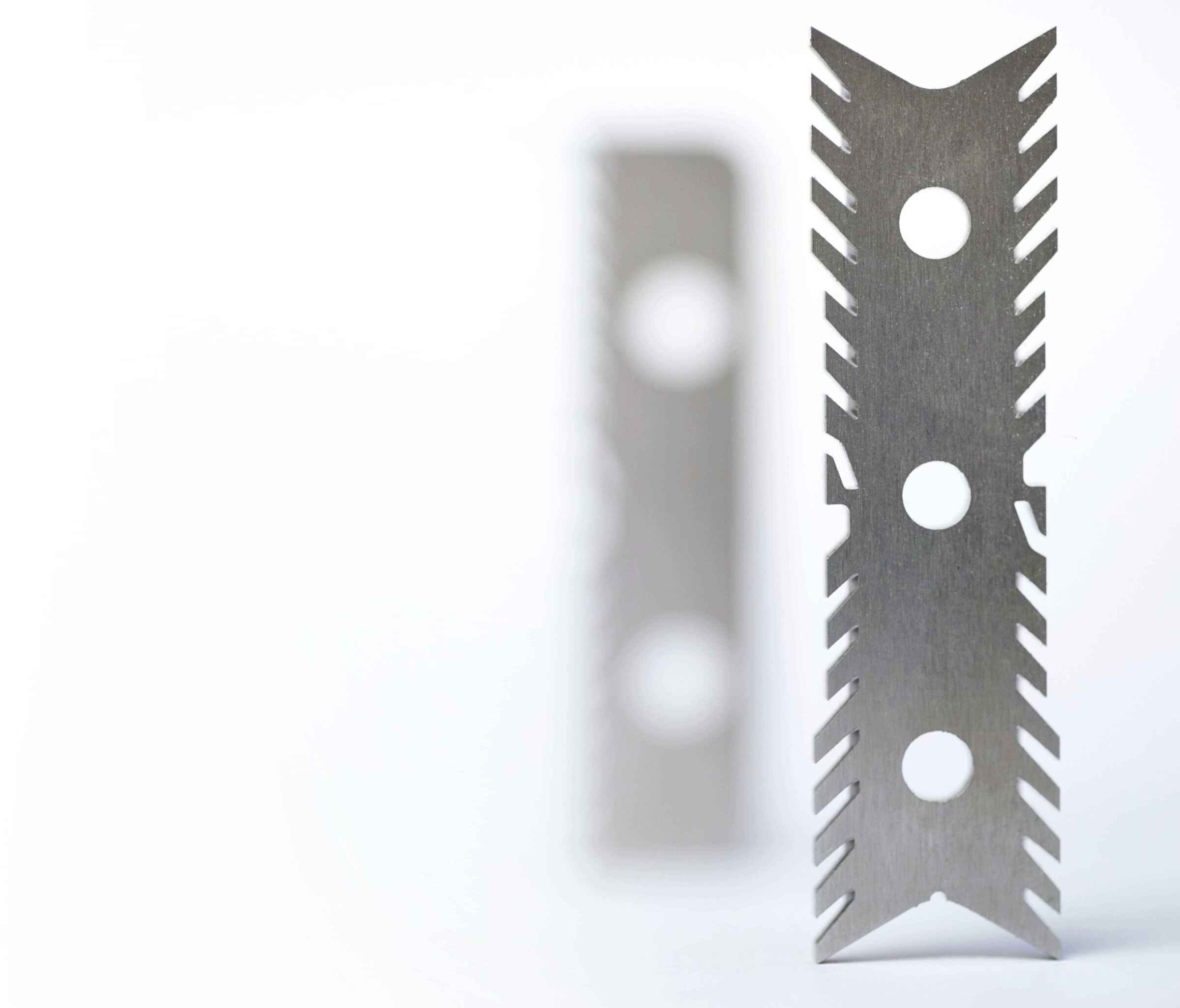

Contour insert for injection mould

In April 2018, Mitsubishi Electric punctually delivered the machines: a MV1200S NewGen wire EDM machine and a Start 43Z start-hole drilling machine. The man from the Allgäu in southern Germany laughs: “I’d never worked on a Mitsubishi Electric in my previous positions, but always heard a lot of good things about it. Of course, during the preparation phase I had also looked at machines of other manufacturers and compared offers. But Mitsubishi Electric’s were unbeatable value for money and I was swayed by the advice I was given during my visit to the technology centre.”

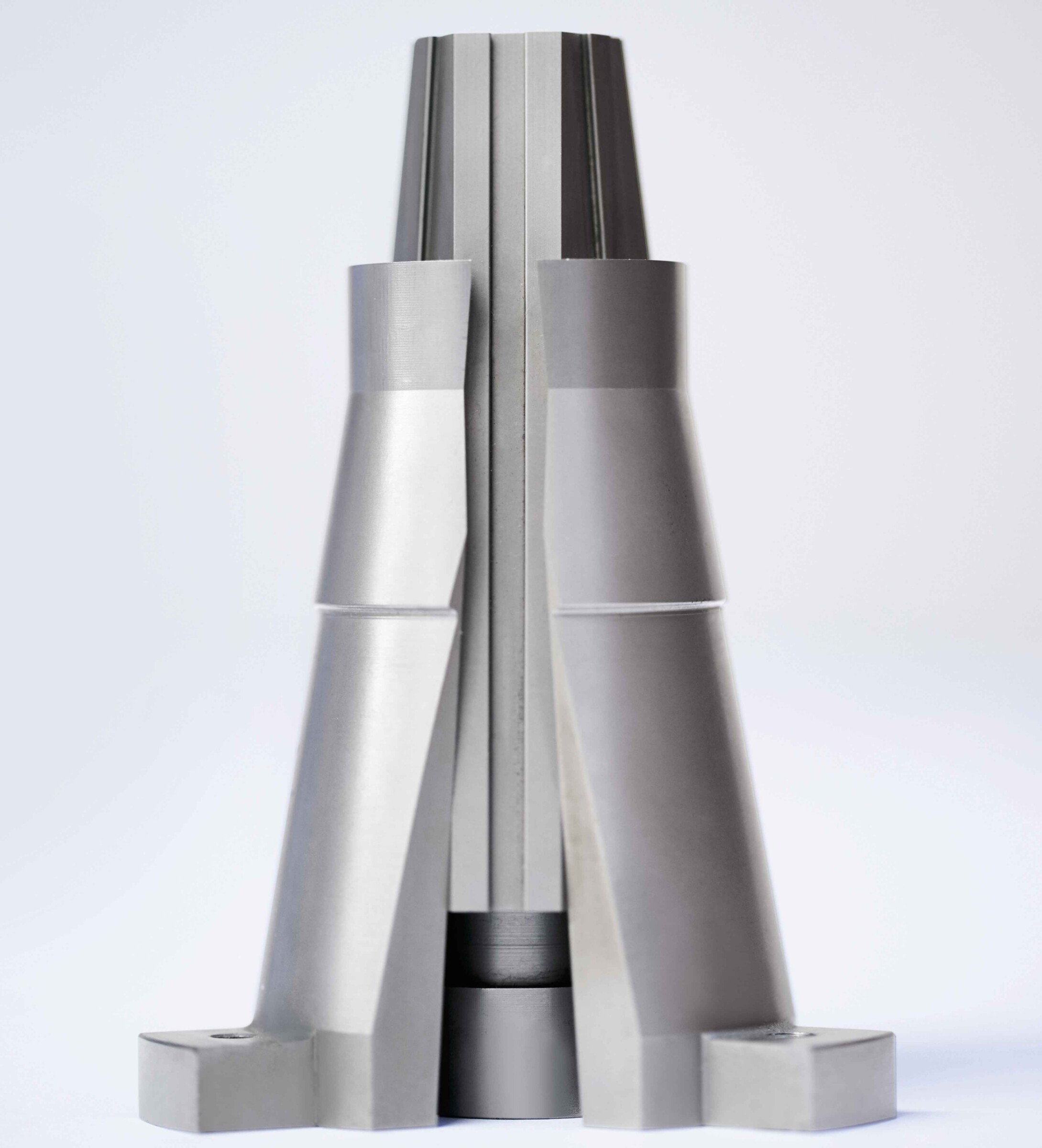

Folding core for injection mould

Ortmann specialises in the manufacture of tools and moulds used in the automotive component supply industry, injection moulding and medical technology, for example. He is not restricted to any particular industry. He has also modified tools and moulds. His customers supply the 3D CAD data for the tool shape, and Ortmann is then responsible for the execution of the order with his high level of expertise. With his many years of experience as a master toolmaker and his extensive know-how as head of EDM in various companies, he’s not easily ruffled.

Berthold Ortmann, subcontractor Managing Director of Ortmann Erodiertechnik

I haven’t regretted for a second opting for the MV1200S NewGen wire EDM machine from Mitsubishi Electric. I am impressed by the overall machine strategy.

“What makes me unique is that, as a one-man subcontractor, I can quickly take decisions and flexibly organise my working hours,” Ortmann enthuses. “For me, personal responsibility means accepting an urgent assignment on a Friday afternoon and completing it by Saturday.” The Allgäuer has no problem with that, because his workplace couldn’t be closer to home: his workshop is only a flight of steps away from his living quarters. He’s also aware that the Mitsubishi Electric system can be relied on to do its job. “I used to have to drive back to the firm in the evening and see what was going on, but it’s all much more relaxed now.” His reward is the pleasure he derives from his work, and he also appreciates the positive feedback from regular customers and, of course, the flexibility. “I’m happy to take the risk of being self-employed. Because now I’m my own boss and have the decision-making authority and responsibility for my business – that’s something I attach a lot of importance to. It feels good, and I appreciate this new quality of life compared to working for someone else.”

Jobshop in the Allgäu.

Customer base built up with quality and service

Since starting up in June 2018, Ortmann Erodiertechnik has been working consistently for six regular customers as well as for the same number of customers with intermittent jobs. “The regulars know me and can rely on getting their tools quickly and in excellent quality,” says Ortmann. “If jobs come in on Friday, I handle urgent repairs by Saturday or Monday.” Sometimes even delivery service is included. Since its foundation, the contract manufacturer has experienced steady growth in work, and he regularly receives new jobs. And all this without advertising.

Continuous clamping system – start-hole drilling machine for wire-cutting machine

Since going into business, the company has been able to increase its planned turnover every month, even in the traditionally quieter January. “I never dreamt things would go this well.”

Start 43Z start-hole drilling machine

Berthold Ortmann, subcontractor in the Allgäu region

Name and place of company:

Erodiertechnik Ortmann

Germany

Founding year:

2018

Managing Director:

Berthold Ortmann

Employees:

1

Core business:

Subcontracting – wire-cutting and die-sinking for tools and moulds in different industries Tool and mould modification jobs – contoured inserts for plastics injection moulds, tools for the automotive industry, tools for the medical sector – silicone processing Workpieces for custom machine manufacture, one-off jobs in prototype construction

Erodiertechnik Ortmann

Unterharprechts 3

88260 Argenbühl

Germany

Tel +49 (0) 75 66 490

info@ortmann-erodiertechnik.de

www.ortmann-erodiertechnik.de

Enjoying my work – that’s my goal. With the two machines from Mitsubishi Electric I have created a really solid basis for myself. They run reliably and efficiently – machines that are based on a mature manufacturing concept. The biggest advantage for me is the automated threading, which works 99.9 % perfectly. I’m astonished by it every time. In addition, the machines’ high availability, tolerances and dimensional accuracy suit my business strategy and the workshop conditions in my garage.

Yes, even though I first came into contact with EDM more than 35 years ago. That was when training as a toolmaker. But I heard a lot of good things about Mitsubishi Electric over the years. What I particularly appreciate is that the machine user has the same sales staff as contact persons for many years in order to build up a trusting relationship. The service and maintenance services provided by Mitsubishi Electric were also decisive factors in my decision, because I as a one-man show still get support even on Friday afternoons.

After their delivery, I attended a one-week training course at the training centre, which was very well organised and prepared. The trainers provided a lot of theoretical and practical input and addressed numerous issues. I quickly found my bearings with the straightforward operation and control system. At home I only actually took three days to test what I had learned and try out different jobs. By then I’d got the knack of it.

Managing Director

Erodiertechnik Ortmann

Berthold Ortmann Managing Director

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com