Life is not easy and this is never ignored at Tek-Moulds in Malta. Hard work and determination are the combined driving force of this success story.

Kevin Busuttil is in charge, a precision engineer by trade and a man with a vision. He guides this company in a complex and exciting market, where challenges are met with determination and the correct approach.

Toolmaking is based upon good design, good practices and motivation. In this company people are proud to deliver tools that fulfil their customers’ requirements and also set standards in product presentation. This attitude and philosophy shape every tool manufactured at TEK-Moulds.

Tek-Moulds has changed the toolmaking scene in Malta. Established in November 2003, Kevin Busuttil ventured on a project that very few could really understand. Way back then Malta’s toolmaking industry was only present within established multinationals. From development and a repair service available on the island, Tek-Moulds moved a step ahead of its competition by producing tool parts like inserts, cores and sliders. The quality of the work provided instilled confidence in the market. Suddenly Tek-Moulds were faced with a new challenge – that of producing their first small tools with their own signature.

Tek-Moulds Precision Engineering

Customers started to realise that quality tools were now available a few doors down at the industrial park. This was brought in by Busuttil’s experience in the toolmaking sector. Being a well-travelled engineer, he managed to learn and bring home with him some of the best practices he had encountered on his journeys.

Tek-Moulds made the correct decision by trusting in Mitsubishi Electric as its main machine supplier in the EDM sector. From the beginning, the company enjoyed exceptional support in both application and service. This put minds at rest at the Bulebel plant by ensuring efficiency and facilitating deadline compliance.

This company prides itself in giving to its customers the TEK experience; Kevin’s philosophy towards product quality inspires the shop floor with a natural aptitude to discipline that makes their products achieve high standards and economic viability.

Tek-Moulds started up by investing in an EA8 die-sinker and an FX 20 wire-cutting EDM. The collaboration with Mitsubishi jump-started the firm’s business projections and by the following year an FX 10 wirecutting-EDM was added to the machine park. Encouraged by the results of the end products, the return on investment, and visits to the Mitsubishi Electric Europe showroom in Ratingen in 2010, Tek-Moulds decided to buy a top-of-the-range EA 12V Advance die-sinker. Mr Busuttil insists that, “There is no match for the speed, accuracy and surface output finishing of this machine with minimum wear.”

“There is no match for the speed, accuracy and surface output finishing of this machine with minimum wear.”

Soon after that, Tek-Mould’s natural progression encouraged Kevin to endow his company with two BA24s with fine machining cutting. Again these machines excelled in speed, quality, turnover time and quick response. Busuttil realised that he had discovered the way forward. “It has an astonishing automatic wire threader, which increases efficiency and maintains uninterrupted processes, especially when running a ghost tool room.”

Building up moulds that inject two-coloured components was set to be a challenge! Three-coloured moulds are still an experience, although one must say that at Tek-Moulds these moulds are done with considerable ease. And after building four-coloured moulds, Kevin exclaimed in precisely these words: “I think we have become one of the top players in the industry.”

The boss and his employee showing full concentration.

Kevin Busuttil at his EA12V Advance.

His workforce consisting of twelve hard-working individuals and seven machines solely supplied by Mitsubishi produce an average of 50 to 60 injection moulding tools and progressive press tools a year. There can be no doubt that in the foreseeable future Tek-Moulds will feeling the need to acquire an EA28V advance die-sinker together with two more FA20-S Advance wire EDMs. The need for more precision machinery is prompted by the demand for Tek-Moulds’ products within the sector. The discipline, attention and dedication of Kevin’s crew are what this enterprise is famous for. This energy is channelled into the product itself and, together with skilled management, local and foreign customers appreciate Tek-Moulds’ effort, competence and commitment. Time has proven Kevin Busuttil right. Dedication and tireless effort is what this man is all about. Customers that choose Tek-Moulds are after this kind of attitude, especially when requesting jobs.

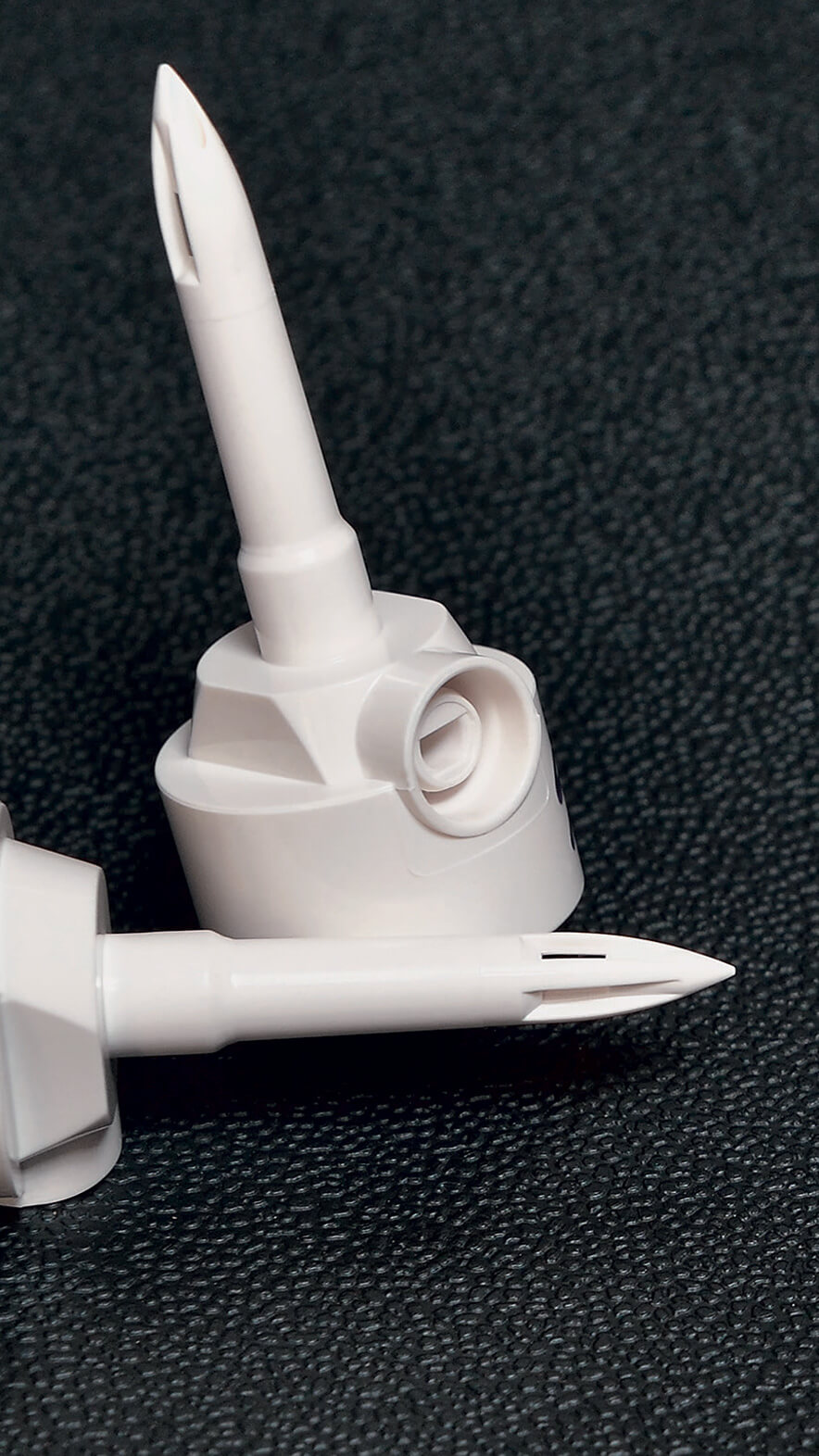

Tek-Moulds is also at home in medical technology.

Tiny feathers for Playmobil Indians.

The machinery available at Tek-Moulds works in tandem with Kevin Busuttil’s set programme of work, with the result that 85 per cent of the machine park operates on an impressive number of unmanned hours including weekends, therefore achieving a 24/7 optimisation level. Tek-Moulds prides itself on motivating and developing unmatched product quality, whilst taking the human element into consideration.

Name and place of company:

Tek-Moulds Precision Engineering Ltd., Malta

Founding year:

2003

Managing director:

Kevin Busuttil

Number of employees:

14

Core business:

Multi-coloured moulds, insert moulding and progressive stamp tools.

Tek-Moulds Precision

Engineering Ltd.

B12A, Bulebel Industrial Estate

Zejtun. ZTN 3000 Malta

Tel +356 . 21808712

info @ tek-moulds.com

www.tek-moulds.com

A unique company in the heart of the Mediterranean offering superb quality and ensuring deadline compliance – competent engineers capable of providing high-end products at the competitive prices found on mainland Europe. Our goal is to manufacture each and every mould so that it surpasses the customer’s expectations.

Repairing a tool whilst a machine was being installed, quite an easy job at the time and never got paid for it.

Being present at every tool trail and seeing the satisfied smile on the customer’s face.

After tripling the size of our premises and employing 14 toolmakers, one thing remains constant. I still emphasise a hands-on approach to the job and making sure that everything runs like clockwork.

Expanding further into the European mainland market whilst providing our customers with high-end tools that ensure stable productivity.

Easy … playing rugby.

Staying calm in emergencies.

Managing director

Tek-Moulds Precision Engineering Ltd.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com