With superlative-quality tools and moulds fabricated by its skilled staff, AWEBA has advanced to become one of the shining lights of the industry. In the wire EDM sector, they trust among other things in two NA2400 Essences from Mitsubishi Electric.

Even Thomas Schlemmbach, in charge of production at the company in Saxony, is surprised by the sudden encounter with the heavy, packaged load suspended on a hook from a gantry crane. “Our second wire EDM machine from Mitsubishi Electric is just arriving. We’ve again chosen an NA2400 Essence.”

The importance of wire cutting for AWEBA can be seen from the fact that the time-honoured company uses a

total of 18 wire erosion machines. Heiko Koller, production foreman, pages through a list: “We clock up 330,000 production hours each year in three shifts, and wire EDM accounts for 96,000 and hence almost 30 per cent of this.”

AWEBA, one of the biggest independent toolmakers in Europe, expects modern spark erosion machines to achieve extreme precision, surface quality, parallelism and contour trueness. The core competences of the company based in Saxony are in forming tools and die-casting moulds for the power train – products whose purchasers demand top quality. Suppliers to the automotive industry use the moulds for the production of sheet metal parts for transmissions, differential gears and generators and for internal combustion engines and electric motors. AWEBA, which works together with researchers in research institutes, universities and industry, is happy to take on such challenging jobs. Examples of this are combined forming and precision blanking in a mould set and the integral casting of inserts in the die-casting moulds needed for

high-precision transmission components.

“Compared to the competition, Mitsubishi Electric came out best in all tests.”

“Against this background, we spared no effort and exhaustively tested two NA2400 Essences in parallel for a good six months.” To underline this, Thomas Schlemmbach taps the frame of a wire EDM machine. “Mitsubishi Electric installed one of the machines in September 2011 so that we could test it in real-life conditions at any time until we decided to buy it in April 2012. The other one was in Ratingen. We achieved precision of less than three micrometres with both of them. This meant that we could precisely assemble our parts eroded for electric motor moulds (cemented carbide dies on one machine and cemented carbide punches and dies on the other). This suited us down to the ground, as we wanted to invest in two identical systems with the same high precision.” This precision is due in large part to the load-free tubular direct drive of the energy-efficient NA2400 Essence, which communicates with ultra-fast optics between the control, axis amplifiers and drives. An advantage resulting from the drives’ highly dynamic response which, combined with its proven cast-metal construction, yields exceptional workpiece precision.

Exclusively employing skilled workers like Bernd Kehrer is one thing that makes AWEBA unique.

To stress component quality, Schlemmbach runs his fingertips over the surface of a component. “Compared to the competition, Mitsubishi Electric came out best in all tests. For instance, in terms of the minimum time that the NA2400 Essence takes to achieve the desired results.” The operator benefits from the machine’s impressive machining speed mainly when the customer demands high surface quality, as this calls for more

subsequent cuts.

Schlemmbach and Koller refer to a car body to illustrate just how varied the parts are that are produced with moulds from AWEBA. “Along with the power train, we’ve also made a name for ourselves with tools for other vehicle components,” explains Koller. “And right across the range of possible types of tools and moulds. These include cutting and precision blanking tools, follow-on composite tools, transfer and progressive press tools, and complex diecasting moulds inclusive of burring. “The components that we produce with them include air conditioners, exhaust gas systems, filters, pumps, electronics housings, mirrors and brakes. In view of this application-specific performance spectrum, it’s no surprise that the automotive supply industry purchases 90 per cent of our tools and moulds. The remaining 10 per cent mainly goes to the electrical industry. For this sector, AWEBA has a long tradition of producing cutting tools and die-casting moulds

for stators and rotors used in electric motors of all kinds, from the smallest motors to large-scale generators.

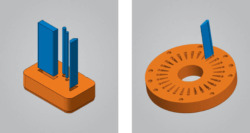

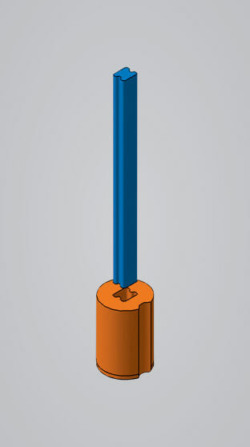

Replacement cutting punch. Reproducible tolerance 0.005 mm.

Gearing die and punch. Precision ± 0.004 mm.

Cutting punch. Height 125 mm, parallelism less than 0.008 mm.

Schlemmbach and Koller take us through a high-tech machine park comprising 150 tool systems of all kinds and also into air-conditioned measuring and production rooms designed for high-precision processes with temperatures controllable between 20 and 22 °C. Then we continue past high-performance presses into the company’s own hardening shop. Like its tool and mould diversity and the principle of employing

only skilled staff, this is something that makes the globally operating company unique. “Thanks to our equipment and the comprehensive expertise of our work-force, we create a positive environment for the construction of high-precision moulds and tools with long service lives,” says Schlemmbach. “Since we have

all the machining technologies available on our own site, we can offer our customers high flexibility, fast delivery times and complete quality components from a single source.”

Steel parts.

Cemented carbide punch with parallelism of 0.003 mm.

AWEBA, which is certified to ISO 9001 and by leading European steelmakers, also awards a replacement part guarantee for each tool, covering its entire working life. This ensures that the replacement parts are identical to the original components – and this even though they produce roughly 50,000 one-offs each year.

At the NA2400 Essence, Koller watches the operator change the 20 kilo wire reel so that the reliable AT4 wire threader can automatically thread the new wire in just 10 to 15 seconds. “The wire-threading system is essential for unmanned operation and hence indispensable for us. In addition, I’d also like to mention the machine’s operating comfort and ergonomics. These are points that are just as important to us as the machine’s easy integration into the live production process.” AWEBA optionally uses not only the larger wire station, but also the Telecontact monitoring function that makes it possible for the NA2400 Essence to send text messages to any phone number.

The newly arrived NA2400 Essence has now reached its future workplace. Liberated from its packing, it awaits customer service, which is scheduled to arrive tomorrow. Looking at the new wire erosion machine, Schlemmbach discloses another reason for choosing Mitsubishi Electric as a supplier: “The man from Mitsubishi customer service served us competently and extremely trustingly from our very first contacts. By this I mean that he carried out a large number of tests for us over a period of five to six years without any

assurance that we’d place the order.”

Andreas Lange benefits from the operating comfort and ergonomics of the NA2400 Essence.

Name and place of company:

AWEBA Werkzeugbau GmbH, Aue (Erzgebirge), Germany

Founding year:

1882 as a special factory for cutting

and punching tools

Managers:

Udo Binder, Chairman of the Management, Rüdiger Drewes, Commercial Manager

Number of employees:

Over 400

Core business:

Toolmaking, precision parts

AWEBA Werkzeugbau GmbH

Damaschkestr. 7

08280 Aue

Germany

Tel +49 . 3771. 273 0

Fax +49 . 3771. 273 353

info @ aweba.de

www.aweba.de

Our core competences are in forming tools and die-casting moulds for the power train.

During my school days in the holidays at AWEBA.

I have a strong interest in helping the company advance because I owe AWEBA a great deal in terms of my career.

Not much. I still feel it’s important to have a good team around me.

We’d like to have developed an extra source of business by then.

That we as a former East German firm today rank among Europe’s biggest independent toolmaking companies.

Sailing.

Loyalty, a sense of duty, honesty and ambition.

in charge of production

AWEBA Werkzeugbau GmbH

Thomas Schlemmbach, in charge of production. Also in the picture Heiko Koller, production foreman (left)

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com