What is the key to the success of a family-run jobshop? It has to consistently respond to the customer’s wishes and be innovative at the same time. When called upon to fully machine small precision parts for the electronics industry, Huber in Besenbüren in Switzerland extended its production spectrum at short notice by purchasing an MV1200S wire EDM machine with a B axis.

A useful addition. Wire EDM in series production.

Innovative technology for the benefit of our customers.

Felix Huberwho runs Huber Präzisionsmechanik AG is a family man whose business is very much a family affair. He and his wife Olivia and son Daniel together program, operate and load up what are now eleven turning machines. They are joined by a female employee from the neighbourhood for a few hours per week. In a modern, bright shop, Huber machines precision parts mainly for the electronics industry. These are mostly turned parts in batches of between 150 to 500 pieces, usually as repeat orders. The workpieces measure anything from 2 or 3 millimetres to several centimetres in diameter and length and are predominantly machined off the peg on Swiss-style lathes with a multitude of linear tools. Huber now also has modern turning centres with powered tools and milling units. The future second-generation owner and managing director Daniel Huber stresses that he is always interested in the latest technology. “If we want to hold our own on the market, we have to constantly re-examine our current machining methods. This doesn’t mean following every fad or jumping onto every bandwagon. But we keep ourselves abreast of the innovative technologies that we can sensibly put to work for the benefit of our customers,” he continues.

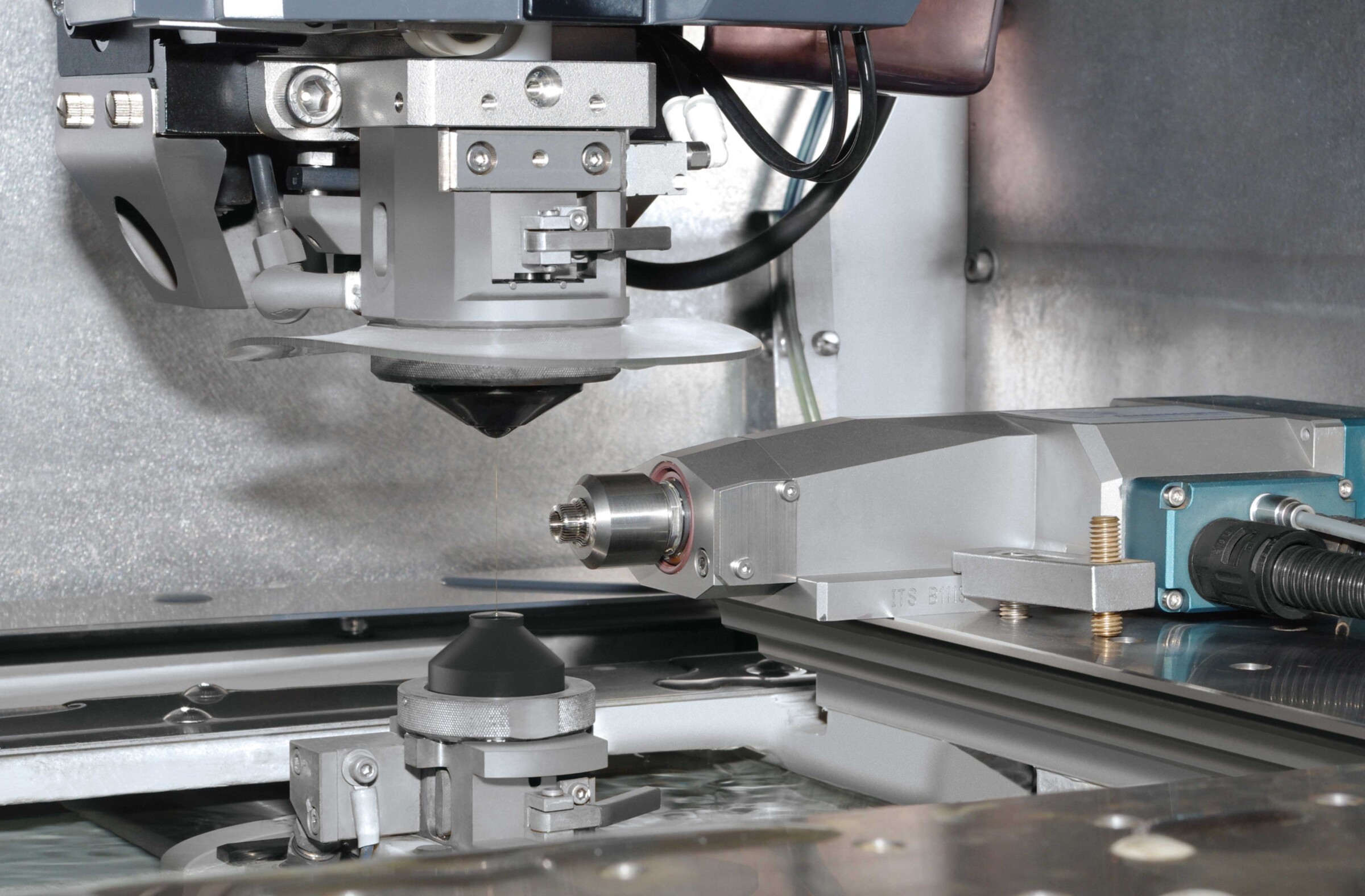

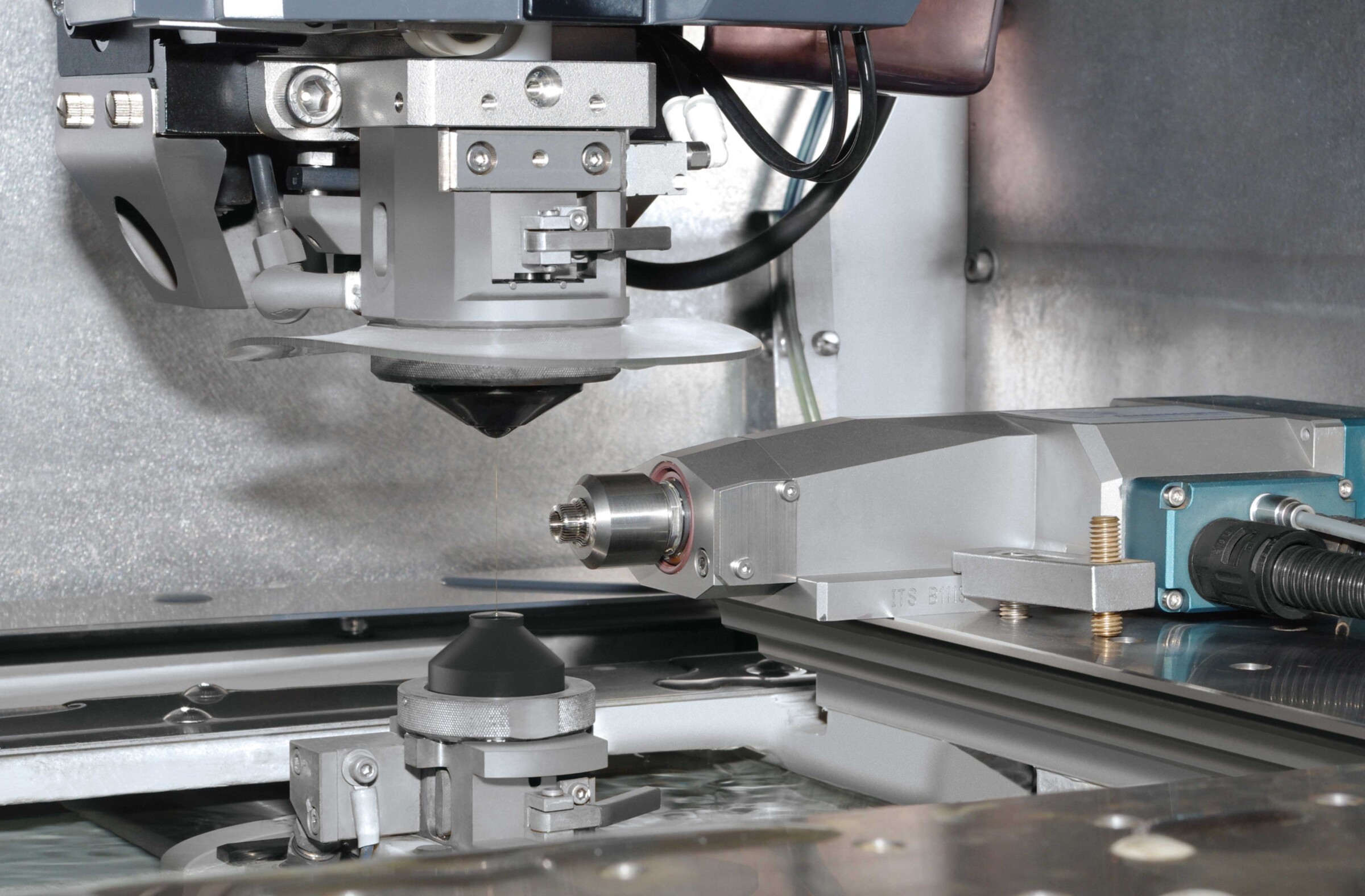

Incremental 10° rotation ofthe component thanks to the sophisticated B axis

It soon became obvious that the machines from Mitsubishi Electric appealed to us most.

And this is how they came to invest in an MV1200S wire-cutting machine with a B axis. For Huber this was at first totally uncharted territory. As a result of requests for precision parts with superfine grooves and high surface qualities, Huber senior reports, the existing technology of the turning centres was soon pushed beyond its limits. But he still wanted to offer his customers a solution. So he and his son put their heads together, investigated the available technologies and immediately arrived at wire-cut EDM. To stay flexible and acquire the necessary expertise, Huber decided to purchase his own wire EDM system. “It soon became obvious that the machines from Mitsubishi Electric appealed to us most,” Huber junior explains.“They’re very solidly built. Consultations and service via the regional distributor quickly established the necessary trust. The software is comfortable to use and easy to learn. We were particularly impressed by the Natural User Interface. In addition, we had no difficulty getting the equipment that we required for the current workpiece. The machining of sample parts confirmed that the machine achieves the accuracy demanded by the customer.”

Felix Huber Managing Director Huber Präzisionsmechanik AG

This success is due in large part to the family focus of our business. Because trust and dependability for us are essential values that also of course apply to all of our business relationships.

As an example of the now highly successful and dependable series production on the MV1200S, Huber shows us an electronic component only about 4 mm in diameter and 3 mm long. The disc is first pre-turned. Then, 36 radial grooves roughly 0.5 mm deep and only 0.3 mm wide have to be cut across the diameter. Thanks to the sophisticated B axis that rotates the component in precise 10° increments for each groove, the MV1200S masters this task with ease. Due to the high rate of erosion, Huber also operates cost-effectively as well and stresses the machine’s dependability. “We cannot afford a failure during the production of a batch of, say, 100 components, as this would jeopardise our entire business strategy. We flexibly and reliably supply our customers with the currently required component batches in the shortest time,” says Felix Huber summing up.

Daniel Huber second-generation Managing Director Huber Präzisionsmechanik AG

With the MV1200S, we were thus able to integrate the technology of wire-cut EDM into our production processes in just four weeks. Since then, we have been operating productively and economically and can offer our customers a much extended range of machining options.

Within just a few months, the selection of successfully wire-cut components has expanded markedly. These include needle-like, cylindrical components about 50 mm long and 5 mm in diameter. On these, one or two rectangular penetrations are wire-cut radially.

Reconciling technology and nature, the Huber family now intends to meet the power requirements of its production shop with a battery-buffered solar cell installation.

New technology rapidly integrated.

Even these relatively complex components were no cause for concern for Daniel Huber even though he was originally unfamiliar with the technology. As he confirms, the training provided by Mitsubishi Electric was very instructive and detailed. In addition, after installation of the wire-cut EDM machine in the shop, all the functions worked precisely and reliably after only a day for commissioning. “After the initial training on the basics of the software and technology, familiarising myself with the specific process features and functions of the systemwas easy. With the MV1200S, we were thus able to integrate the technology of wire-cut EDM into our production processes in just four weeks. Since then, we have been operating productively and economically and can offer our customers a much extended range of machining options. The very user-friendly programming and control software has undoubtedly had a large share in the technology’s rapid and trouble-free integration in our machining environment,” he continues.

At Huber Präzisionsmechanik AG, a family business in Besenbüren, (from right to left) son Daniel, father Felix and mother Olivia and the outside employee are impressed by the quality of the MV1200S wire-cut EDM machine.

Flexible and reliable within tight deadlines.

It all started in 1986. As Huber senior tell us, he simply wanted to be his own boss and started out with two lathes in his garage. His project was encouraged by his boss at the time – Huber was still working as an industrial mechanic at a jig boring machine – who offered him sufficient free time. This is how the young Huber business got going as a part-time jobshop.

We want to stay a family business.

Huber attracted a growing throng of customers. After only five years, the jobber moved into a larger workshop. “It was obvious from the outset that we wanted to be a purely family business,” says Huber. “Our credo has always been to supply quality to the customer’s complete satisfaction. And we’ve achieved this consistently over the years – a success due in large part to the family focus of the business. Because trust and dependability for us are essential values that also of course apply to all of our business relationships,” Huber explains. Huber Präzisionsmechanik AG has thus grown on the strength of customer recommendation alone into today’s force to be reckoned with on the regional level.

Quality for the complete satisfaction of our customers.

The most important innovations in the near future, Huber explains, involve a comprehensive energy strategy for the firm. “We have a strong commitment to the environment and subsequent generations in our home country. This is why we have planned to supply our production shop largely with ’home-grown’ electricity. With the aid of a solar panel installation and the associated control equipment, we will generate most of our electricity ourselves and install a suitably dimensioned power storage module. We also intend to feed any surplus power into the public grid and only draw on the grid to meet our own needs in exceptional cases,” says Huber outlining his plans. The resource-conserving strategy of the advanced wire-cut EDM system from Mitsubishi Electric with its unique Long Life System and integrated energy management are thus fully in line with Huber’s environmental commitment.

Name and place of company:

Huber Präzisionsmechanik AG

Switzerland

Founding year:

1986

Managing Director:

Felix Huber

Employees:

Three family members and one external employee

Core business:

Subcontracted machining of precision parts in small and medium series mainly for the electronics industry

Huber Präzisionsmechanik AG

Chälistrasse 6

5627 Besenbüren

Switzerland

Tel +41 56 6222662

Fax +41 56 6227178

info@hpme.ch

www.hpme.ch

Flexibility for tight delivery deadlines, dependability for lasting confidence, and the superlative quality of the finished components.

Exploiting and making sensible use of current technologies for the benefit of our customers.

We investigate the various technical trends in detail and choose carefully the technologies and machines that seem to be the best and most trustworthy.

The satisfaction of our customers. Good work results in personal recommendation, and this is the best form of marketing.

We want to generate our own power with solar cells and thus make an important contribution to conserving resources and protecting the environment.

We don’t like saying “no”. Even when we’re pretty well booked out, we still want to give our best for our customers.

Alongside the business, we have farmland extensively grazed by suckler cows. Dealing with livestock and nature brings us down to earth.

The second generation in the shape of our son Daniel is already fully integrated, and he intends to run the business along the same lines.

Managing Director

Huber Präzisionsmechanik AG

Felix Huber Managing Director Huber Präzisionsmechanik AG

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com