For decades wire-cutting has been synonymous with the efficient, high-precision machining of electrically conductive materials. Machine manufacturers regularly introduce innovative refinements such as automatic wire threading and the Tubular Shaft Motor. However, no less important for cost-effective eroding processes are suitable software solutions. Only with highly evolved software is it possible to make efficient use of a wire EDM system’s hardware. The Berlin software company DCAM provides users with a tool that is easy and quick to program even for complex workpieces, ensures maximum process security and permits unsupervised machining over long periods.

An underestimated product factor. A software solution for process optimisation.

Wire EDM systems operate with extreme precision, with tolerances of a few thousandths of a millimetre. They generate outstanding finishes, operate with high process security and create the ideal conditions for unsupervised machining for long periods – advantages marginally offset by the longer machining times. What is obvious is that makers of tools and moulds need cost-effective systems. And this is where wire-cutting machines with intelligent software come into their own.

At its modern training centre, DCAM attaches great importance to practical training.

A software company that has been concentrating entirely on wire EDM for almost 30 years is DCAM GmbH domiciled in Berlin. Managing Director Jens Franke is convinced that “for companies that don’t constantly use their machines and only cut the simplest contours with them, the software solutions supplied by the machine manufacturer are sufficient. But the more complex the task, the more difficult it becomes to operate profitably with bottom-of-the-range CAM solutions.” DCAM has therefore developed an ingenious CAM solution that delivers a number of advantages. Its DCAMCUT software runs with precision, is quick and easy to use and ensures maximum process security.

The ideal partners for long-term unsupervised operation – DCAMCUT and the rotating/pivoting axis

Less programming effort thanks to templates

When preparing each job, users of most systems have to newly assign the contour characteristics, select the surface finish and enter all production-related parameters. DCAMCUT, on the other hand, operates with templates. With this technology, all machining processes can be stored in catalogued form and can be re-used for different geometries as required. This reduces the programming effort by 60 to 70 % and cuts the error rate.

Marcel Schilsky sets up the EDM system for the next training session.

These days, most workpieces are designed with 3D CAD programs, but the machine data are often still generated on the dual-level principle. Two levels, an upper and a lower, are generated and averages between them are calculated. This is where Franke sees a definite advantage of his software: “DCAMCUT works directly with the data of the 3D model, in other words on the original faces of the design.” This way it is easy to determine early on, during data input, whether a workpiece can be wire-cut or changes to the design are necessary. It is no longer necessary to derive contours with sections through the component, and this saves a good deal of time for the user. In addition, all the workpiece geometries can be reliably checked before the workpiece is loaded onto the machine. DCAMCUT also identifies minimal deviations and alerts the user so that he can decide whether they are intended or have been overlooked by the engineer. Workpieces programmed with DCAMCUT are thus produced without any deviations as they are based directly on the 3D model.

Jens Franke, Managing Director DCAM GmbH

Cooperation with Mitsubishi Electric works very smoothly.

Many users use their experience to compensate for these deviations. They are aware of numerous geometries that can give rise to deviations and attempt to offset them. They are often successful, but the user only obtains certainty on the measuring machine. And by this time, several hours of machining have already been invested. “This can be really expensive,” says Franke. “And process security is something else. In practice, such deviations are happily attributed to the machine’s shortcomings although they are obviously programming errors that DCAMCUT rules out.”

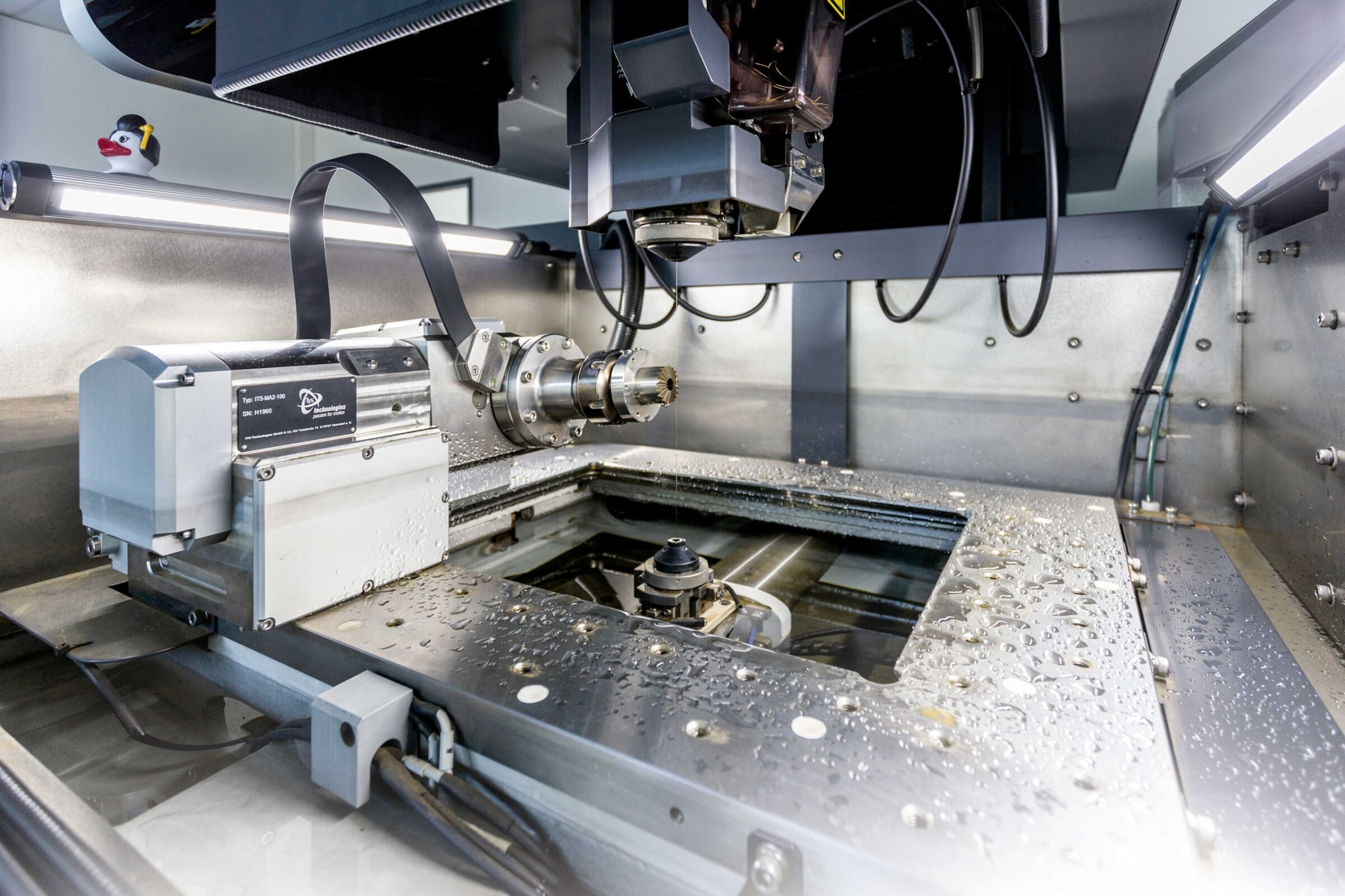

For practical training a Mitsubishi Electric MV1200R Connect is installed.

Wire cutting is not always the fastest machining method in tool- and mould-making, but it does offer high process security and the possibility of unsupervised machining for long periods. And this makes it highly cost-effective. DCAM has optimised the wire EDM process by introducing new features. These include, for example, 4-axis clearing on any geometry. Cut-outs must not be allowed to drop into the machine in an uncontrolled fashion. They either have to be removed from the machine by the operator by hand or tacked with the new Mitsubishi Electric technology. The first method is labour-intensive, and the second calls for reworking.

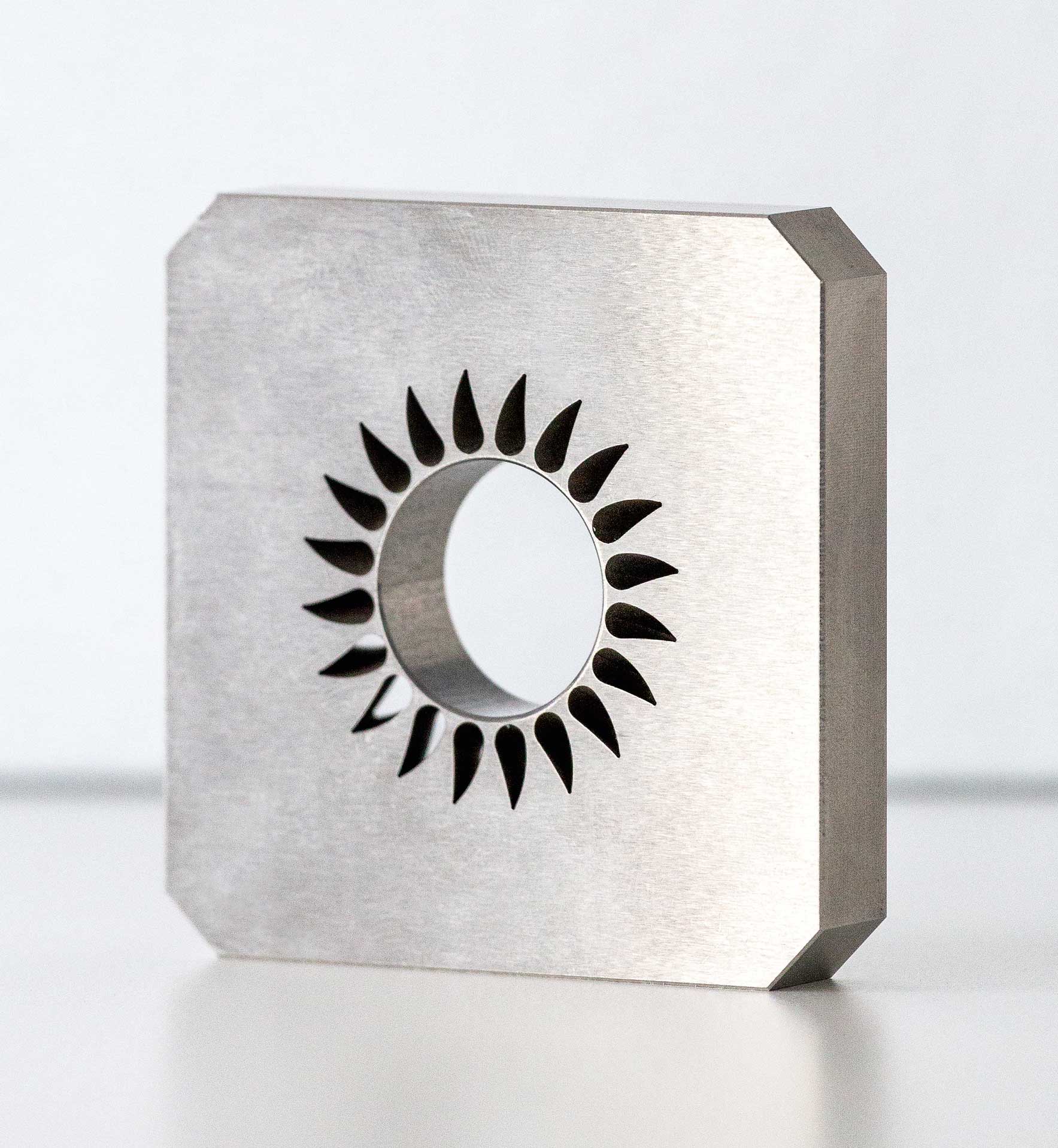

With multi-axis technologies combined with complex clearing strategies, DCAMCUT permits highly intricate machining.

To make these steps more economic, DCAM has redesigned the 4-axis clearing process from the bottom up and focuses particularly on the machining of tiny geometries. In the clearing cycle, the material is ‘destroyed’ rather than cut out. “This is often cheaper than cutting out the material,” Franke explains. Because such processes require much less supervision than processes with dropping parts. Profitability depends also on the geometry.

Standard programs operate with a postprocessor that converts the data into the machine code. DCAMCUT, on the other hand, has an NC processor that generates the data in the machine code itself without going via a postprocessor. The user benefits directly from this procedure, as data conversion is more exact and at the same time faster. If during programming, the geometry is distorted by the offset, for example, DCAMCUT immediately issues a fault message. With standard programs, the error only becomes apparent when the data are transferred to the machine. Downtime and machine stoppages then make themselves felt.

Maximum process security and unsupervised machining over long periods.

“When we demonstrate our software to the customer,” Franke explains, “we ask the customer to give us the data of a current production workpiece that has caused difficulties. On the basis of this workpiece, we show DCAMCUT’s features and how it works. We generate the machining data in the customer’s presence and then ask him to transfer them to the machine and test them. He can then see how quickly and easily his machine can be programmed with our software.”

An ingenious CAM solution that offers a multitude of benefits.

“My solution works, so why should I waste my time trying others?” This is something that DCAM’s sales employees hear on a daily basis. For Franke, there’s only one answer: cost. “What could you save if you compared them? This question has to be asked repeatedly in order to arrive at the most cost-effective solution.” Franke is convinced that the wire-cutting processes in many companies can be accelerated significantly with DCAMCUT and that process security will be improved as well.”

Precise and at the same time fast data implementation.

DCAM attaches great importance to practical training. At its Teltow Training Centre, the company has installed a wire-cutting machine from Mitsubishi Electric, an MV1200R Connect. This is where training participants can obtain their first experience with DCAMCUT at the machine. “Our cooperation with Mitsubishi Electric is going very smoothly,” says Franke. “Mitsubishi Electric involves its cooperation partners very early on in reporting improvements in the control and programming. This way we can respond in good time and always modify our solutions appropriately.” Mitsubishi Electric thus ensures that the machines are launched simultaneously with the new software.

DCAM headquarters in Teltow

DCAMCUT is available for wire-cutting machines from all manufacturers. It has a modular structure and can be adapted to any task. As a solo version, it offers an almost fully fledged CAD system. DCAMCUT is capable of integration into the CAD environments of Solidworks and Autodesk Inventor.

With limited features, the software can be tested free of charge for 30 days or, on request, with all functions for a limited period.

Name and place of company:

DCAM GmbH

Germany

Founding year:

1990

Managing Director:

Jens Franke

Core business:

Software development for wire EDM

DCAM GmbH

Potsdamer Strasse 12B

14513 Teltow / Germany

Tel +49 (0) 89-81803-1501

Fax +49 (0) 89-81803-1519

info@dcam.de

www.dcam.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com