What has AI got to do with me as a machine operator? Probably much more than you suspect… Mitsubishi Electric has filed more than 380 patents for AI in machines, systems and vehicles in the last 6 years.

Many people still associate Artificial Intelligence with the supercomputer Deep Blue, the first chess computer to beat a world champion in 1997. The 480 processors were capable of calculating around 200 million moves per second. Compact AI with little computing power will change the world in a big way. Mitsubishi Electric has made AI so compact that it can be used on almost any device and make anything more intelligent.

Maisart® is Mitsubishi Electric’s brand of AI technology.

The name stands for “Mitsubishi Electric’s AI creates the State-of-the-ART in technology.”

AI, or Artificial Intelligence, is a technology that uses computers to perform intellectual functions like logical inference or learning from experience, just as humans do. AI has evolved rapidly in recent years as computing devices have reached higher levels of performance. Nowadays, AI is an important technology supporting our society. Machine learning is one field of AI, and deep learning is one type of machine learning. Deep learning is based on neural networks, which reproduce the network of human brain neurons as a mathematical model. A neural network is composed of three kinds of layers; the input layer, the hidden layer and the output layer. By processing information in multiple layers, neural networks are capable of high-level recognition, identification, analysis, etc. There is a great expectation that this technology will make computers more like humans.

Strengths of Mitsubishi Electric – dramatically less calculation for the same inferential accuracy

There are several issues that need to be addressed for deep learning to become more widespread. One such issue is the great amount of calculation. It can be a challenge to equip factory automation, automobiles, and other equipment with deep learning because it is so hard to fit high-performance computing devices and high-capacity memories in small devices. Mitsubishi Electric has developed a proprietary algorithm that greatly reduces the amount of calculation while maintaining a high level of inferential accuracy. The input, hidden and output layers of a neural network connect to each other in complex ways, like tree branches spreading out. A massive amount of calculation is required to process data this way.

The neural network

Drawing on our machinery knowledge built up over many years, we successfully compressed the amount of calculation to just 1/30 to 1/100 the original amount by “cutting the branches” that are less essential. This makes it possible to implement deep learning in a wide range of devices and further expands the potential of AI.

Reinforcement learning is a type of AI machine learning. Computers usually act following a human-created program. With reinforcement learning, however, a computer can understand the current situation by itself, set its own rules and determine what action to take. Humans do not need to set the rules with a program. For a computer to determine what action to take next, it needs a lot of experience, including the experience of failure, just as humans do.

The branches have been reduced by Deep Learning to only 1/30 to 1/100 of their previous total number.

When we teach a robot some action, tightening a screw, for example, we make it try that action again and again. This is how it learns. During reinforcement learning, a computer makes repeated attempts at actions and is evaluated (rewarded) based on how well it achieved the objective. It revises its action to get a higher evaluation, gradually getting closer and closer to the objective. Reinforcement learning is the part of AI that learns through the principle of “practice makes perfect.” It is the part of AI that finds success from failure.

With the SG series, it is possible to make production processes significantly more economic and time-saving.

Reinforcement learning does not require a human to set rules with a program. However, learning can take a lot of time because a huge number of trials are needed for pre-learning. Mitsubishi Electric has developed proprietary technology that reduces the number of trials to about 1/50 the conventional total. Conventional reinforcement learning senses trial results and sets control parameters based on evaluation of the same.

In addition to that, Mitsubishi Electric’s technology uses knowledge of the machinery that incorporates the AI to estimate the degree of success of trial results and sends feedback to the AI on what motions would get the equipment close to the target state faster. Control parameters are then set accordingly. This allows learning with fewer trials, making it possible to greatly reduce the time and cost of implementing AI.

The “brain” of the Mitsubishi Electric EDM and laser-cutting systems is the Maisart artificial neural network technology developed by the Japanese manufacturer, which imitates the neurons of the human brain and is also used in automobiles for accident prevention. Used in production installations, this revolutionary innovation opens up totally new possibilities.

The SG series – Artificial Intelligence in die sinking

A characteristic feature of the die-sinking systems from Mitsubishi Electric is their ease of operation and programming. They allow the operator time for what matters, i.e. the sensible planning of the various EDM tasks. The D-CUBES control generation of the SG series shines with the Artificial Intelligence developed by Mitsubishi Electric.

The outcome:

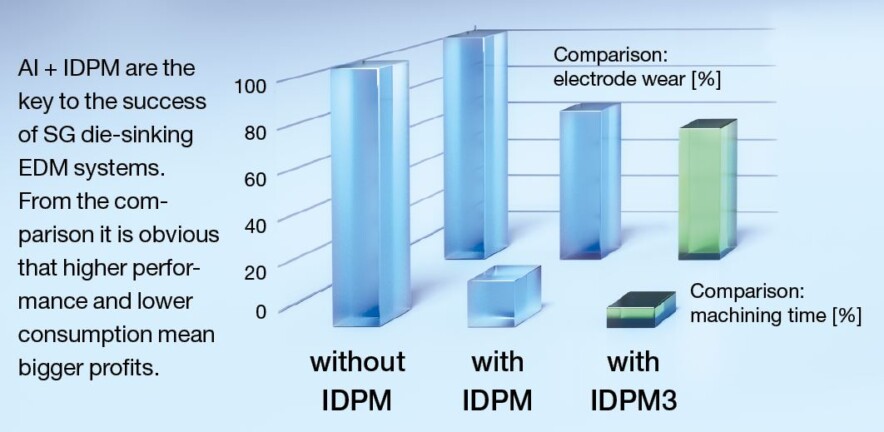

Conclusion: higher productivity, less wear … EDM can be so simple.

The digital Power Master IDPM guided by Artificial Intelligence

With the die-sinking systems of the SG series, it is possible to calculate machining time in advance. Thanks to new algorithms and Artificial Intelligence, machining times can now be calculated much better in advance and processes planned and optimised more effectively. The control system “learns” continuously during the various machining operations and thus steadily improves the accuracy of the machining times calculated in advance. Production processes can thus be made significantly more efficient and time-saving.

The digital Power Master IDPM guided by Artificial Intelligence is the key to the SG-R’s outstanding performance. Minimal wear of the graphite electrodes combined with high removal rates is visibly supported by this technology. The formation of deep ribs with a uniform surface structure is another feature of the new IDPM with AI. The IDPM’s performance is available not only for the machining of steel but also of carbide. Significant improvement of the removal rate over conventional machines: up to 40 % higher machining speed can be achieved with carbide – thanks to the new IDPM. The use of copper-infiltrated graphite significantly increases the removal rate. The finish with tungsten copper electrodes compensates for slightly higher wear – performance and precision combined. Also in carbide.

On top of this, the die-sinking systems of the SG series come with a wide range of tools for intelligent data analysis, such as prediction of erosion times, complete production data analysis and support for external data processing right through to job costing. All thanks to Artificial Intelligence.

Mitsubishi Electric ZoomHead – stepless laser beam adjustment faster than a pit stop Mitsubishi Electric’s proprietary optical system features

The over 18,000 laser-cutting systems supplied so far demonstrate the experience of Mitsubishi Electric as a global player. This is also reflected in the current models. Maisart is the basis of the GX-F series and forms a laser system for maximum productivity and process stability.

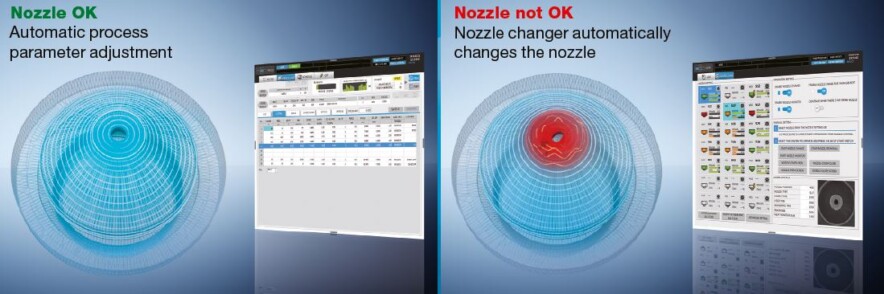

Using audio and light sensors, the cutting process is monitored in real time and parameters are automatically adjusted to optimise cutting performance. If the process is sufficiently stable, AI-Assist even increases the cutting speed. This raises output to the next level and also significantly improves process stability. Irregularities are detected immediately. Parameters are automatically adjusted and damaged nozzles are replaced, thus ensuring unbeatable results.

AI nozzle monitor – intelligent support

Audio and light sensors monitor the cutting process in real time and automatically adjust parameters to ensure a stable process and optimise cutting performance. When a poor cut is detected, the Artificial Intelligence makes the necessary adjustments to improve or restore the cut. The system is also able to optimise cutting speed.

The AI nozzle monitor uses a camera system to monitor the condition of the nozzles. If no damage to nozzles is detected during the check, the process parameters are automatically adjusted. Faulty nozzles detected by the AI nozzle monitor are automatically replaced with back-up nozzles to ensure continuous, long-term production.

AI diagnostics – for better results

Mitsubishi Electric’s proprietary optical system features optimal control of the beam to suit the material and material thickness. The ZoomHead delivers quality, speed and flexibility by automatically modifying the beam diameter, beam shape and focal point for each material. It also accommodates a wide range of material thicknesses.

With the SG series, it is possible to make production processes significantly more economic and time-saving. The control “learns” continuously during the various machining operations and thus steadily improves the accuracy of the machining times calculated in advance.

Since it is not necessary to change the machining lens according to thickness and material, set-up time is significantly reduced. The operator can therefore switch between different material thicknesses without affecting cutting quality, and even without contact. The optional nozzle changer automatically cleans, calibrates and changes the nozzles between the different material types, thus saving time spent on set-up.

Name and place of company:

Mitsubishi Electric

Founding year:

1921

Managing Director:

Kei Uruma

Employees:

146,500

Core business:

Production of electronic devices, e.g. EDM systems, laser cutting systems, CNC controls and drives, industrial robots, air conditioning systems, semiconductor equipment and much more besides

Mitsubishi Electric

Mitsubishi Electric Europe B.V. Mitsubishi-Electric-Platz 1

40882 Ratingen

Germany

Tel +49 (0) 2102-486-0

edm.sales@meg.mee.com

www.mitsubishielectric.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com