High-precision components are standard in medical technology. The 40 employees of RS-technik CAD-CAM GmbH, a component supplier to this and other challenging sectors, are well aware of the high standards expected of components and tools and achieve them with technical proficiency and the latest production equipment. Integrated machining processes have thus become part and parcel of daily operations. In the wire-cutting sector, RS-technik has been a longstanding Mitsubishi Electric customer, and when purchasing the most recent wire EDM machine – an FA20-S Advance – they again trusted in the Japanese manufacturer.

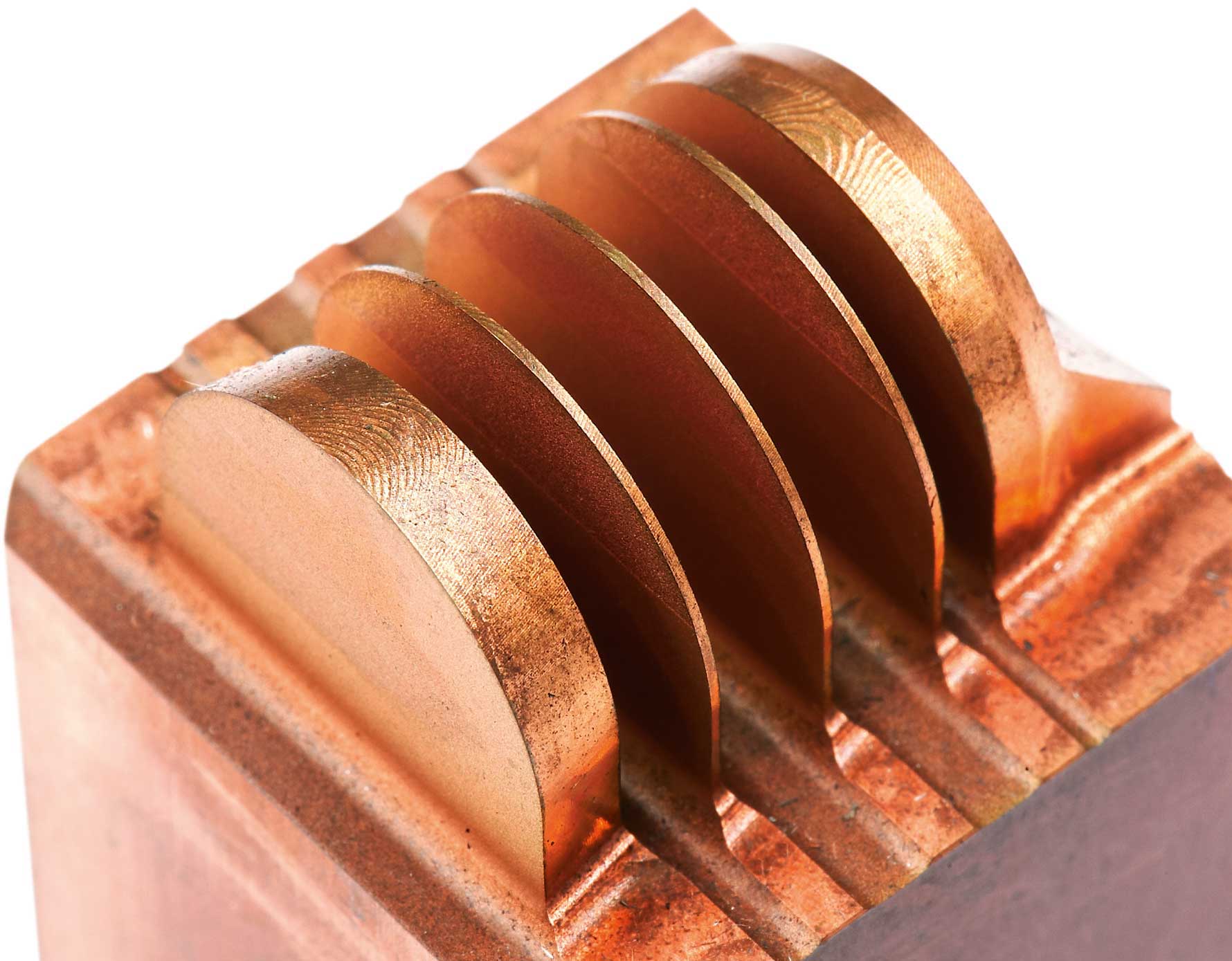

Copper electrode for an injection mould.

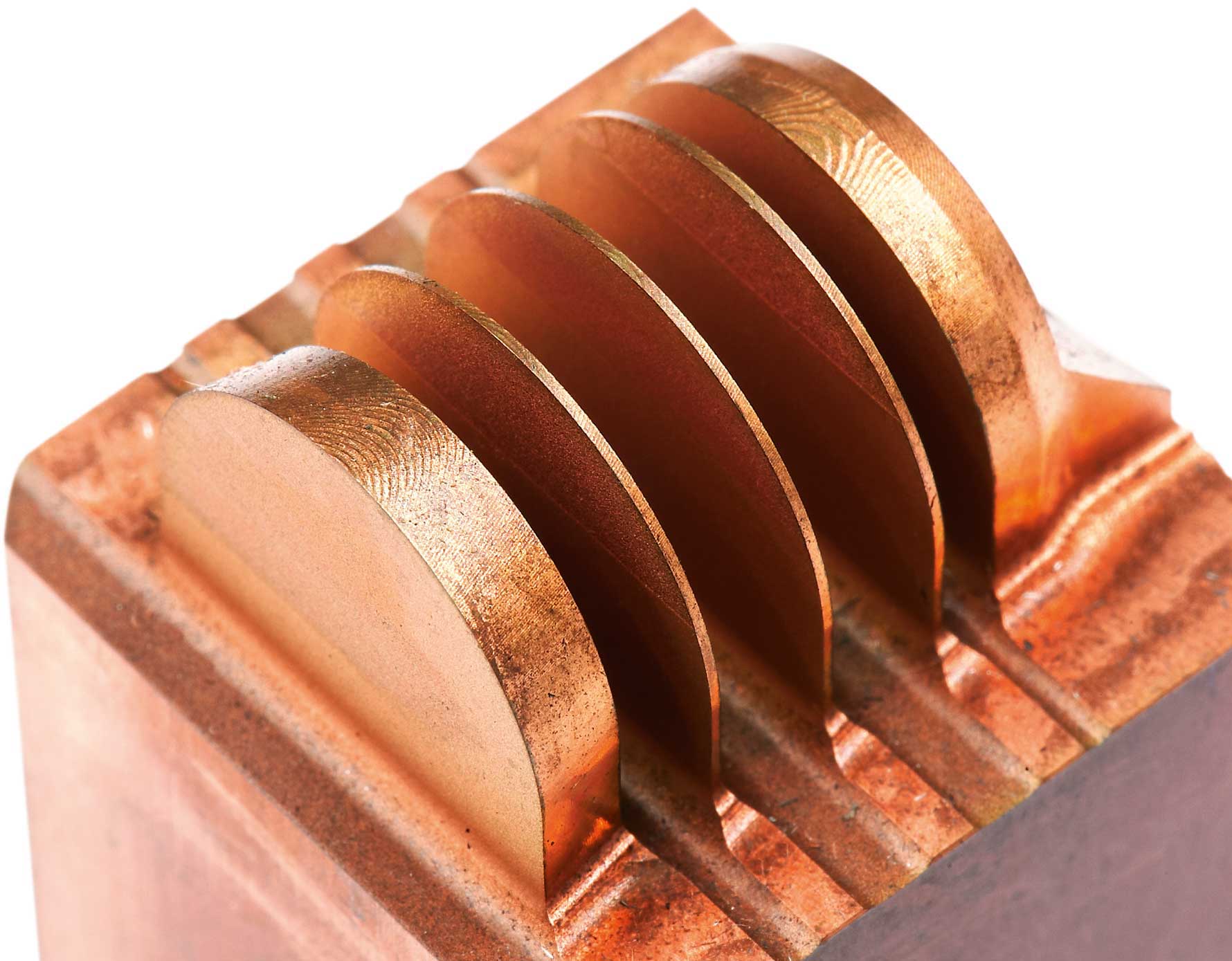

Positive experience with Mitsubishi Electric was reason enough for RS-technik to purchase the most recent model of the FA20 series.

“There’s constant demand for wire erosion in our production activities because this technology is capable of so much more than conventional machining,” says Roland Schafhäutle, founder and managing director of RS-technik, explaining the frequent use of wire-cutting. His statement is illustrated by a number of examples: “There are simply unmillable parts with the tiniest radiuses that only a fine wire can master, and often the required surface quality is so high that processing on the wire erosion machines is the only sensible option.”

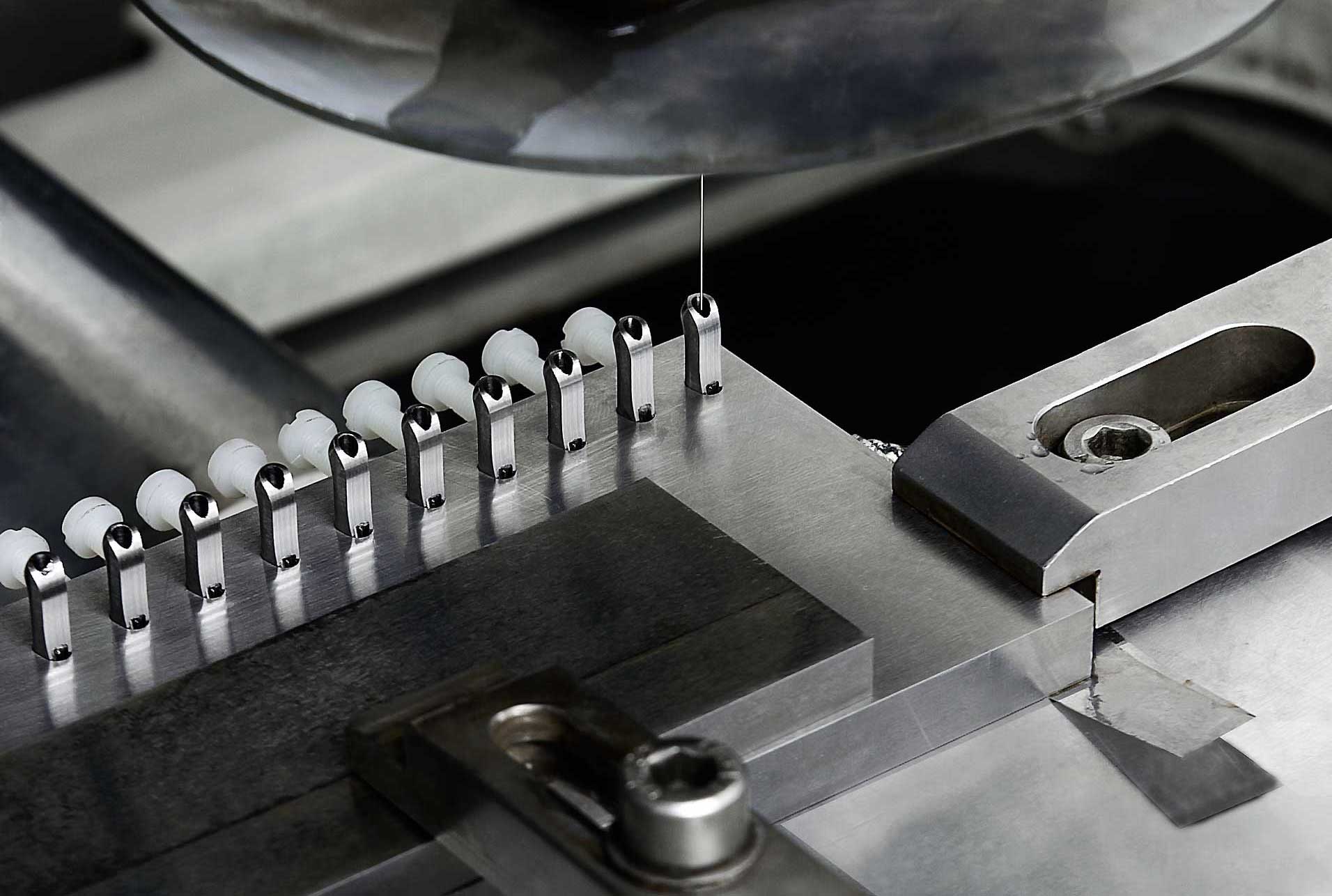

The fine wire of the FA20-S Advance achieves optimal surfaces even in tiny holes.

Meeting such high standards in production has therefore become commonplace for RS-technik. This is due not least to the customers in medical technology who contribute a good 50 per cent of orders. “The sector is very strong in this region,” Roland Schafhäutle adds. This has paid off particularly in the last two years, because steady growth in medical technology protected RS-technik from major business shortfalls. On the contrary: the service provider from Emmingen-Liptingen is aiming for further growth. The products and services of RS-technik described by the managing director are correspondingly wide-ranging: “We satisfy customer wishes for anything from the tiniest part for medical technology to large tools for automotive engineering.”

Many years of experience of Mitsubishi Electric RS-technik’s success is founded on quality consciousness, highly skilled manpower and many years of industrial experience. In addition, the modern machine park also makes a major contribution, Roland Schafhäutle believes: “The more progressive and functional our machines are, the more innovatively and efficiently we can process customer orders.” This applies as much to conventional machining at RS-technikas to wire erosion where machines from Mitsubishi Electric have been in use since the beginning of the Nineties. The latest acquisition is an FA20-S Advance.

Johannes Hense (left) and Andreas Flühs (in charge of programming and wire EDM) discussing the current project.

RS-technik has been gathering experience with the Mitsubishi Electric FA series since 2001. Andreas Flühs, responsible for the wire EDM department, recalls this technological milestone: “At the time, we had one of the first models. Its impressive precision and rapid threading of the wire were pioneering innovations.” A machine of the predecessor series is still in use. The accustomed high precision is now coupled with noticeably higher machining speeds, Andreas Flühs remarks. “We mostly process very fast-running jobs in two shifts, and the machining speed gives an extra bonus of flexibility,” he adds.

The decision to stay with wire EDM machines from Mitsubishi Electric was easily taken by Roland Schafhäutle: “The machines’ precision – an absolute must in our production activities – is just one of the reasons. The FA20-S Advance, like its predecessors, operates absolutely dependably and offers our operators a high degree of user comfort.” In relation to the most recent investment, he means the reorganization of operator control via a straightforward touchscreen. In addition, he continues, we had had years of experience of the control, so the basic course from Mitsubishi Electric was sufficient to train our operators to use the new machine.

Parts are programmed as before with the software from Cimatron. Andreas Flühs sees practical advantages here as well: “The software is well adapted to Mitsubishi Electric, which takes a lot of the effort out of programming.” The process is usually organized in such a way that the customer merely sends us the CAD data, and these are quickly converted at RS-technik into finished programs. “We hardly ever work to classical drawings any more,” the programmer states. The FA20-S Advance pulls out all the stops in practice. Depending on cutting height, a maximum of four cutting operations are necessary in order to achieve immaculate surfaces. “This means that we achieve exceptional quality in the first step of the process chain, as a result of which we also save time and reduce effort in the downstream steps,” Andreas Flühs explains.

A quick response and precision – these are the qualities that the employees of RS-technik have inscribed on their banner. The investment in the new FA20-S Advance was therefore only consistent. Faster wire erosion combined with greater flexibility will have a positive impact on punctual job completion. “Our overriding goal is to supply precision-machined parts on time – this way we can be sure of totally satisfied customers,” says Roland Schafhäutle summing up.

Name and place of business:

RS-technik CAD-CAM GmbH

Germany

Founding year:

1991

Owner:

Roland Schafhäutle

Number of employees:

40

Core business:

Conventional machining and erosion of complex components for medical technology, mechanical engineering, automotive engineering, and tool- and mouldmaking

RS-technik CAD-CAM GmbH

Gehrenstrasse 9

78576 Emmingen-Liptingen

Germany

Tel: +49 (0) 74 65 / 92 94-0

Fax: +49 (0) 74 65 / 92 94-79

info @ rs-technik.com

www.rs-technik.com

Using conventional machining methods and EDM, we fabricate complex components, one-offs and series, made of different materials for medical technology, mechanical engineering, automotive engineering, and tool- and mouldmaking.

I earned my very first money sweeping the road and mowing the lawn.

The pleasure of my work, my enthusiasm for progressive and innovative machining technologies and the finding of solutions for challenging tasks.

We plan further ahead. By building the present production site five years ago, we have been able to optimize all our business processes and have thus achieved greater efficiency.

Reacting swiftly to growing customer requirements by using the latest technologies.

Steady growth since the founding of the company and coming through the uncertainty of 2009 with only a minor drop in business.

Running or jogging in the fresh air with friends.

Top of the list for me are such attributes as ambition, single-mindedness, reliability and honesty in their daily dealings with people.

“You can only hang on to what you’ve actually got in your hands!”

We at RS-technik process highly different materials measuring anything from one millimetre to ten metres on controlled machines.

Owner

RS-technik CAD-CAM GmbH

Andreas Flühs

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com