The subcontractor Raditek in Markdorf on Lake Constance has expanded its range of machining processes to include wire-cut EDM. For the company this opens up additional opportunities to supply even complex components from a single source.

Easily grasped. Component suppliers benefit from simple programming and operation.

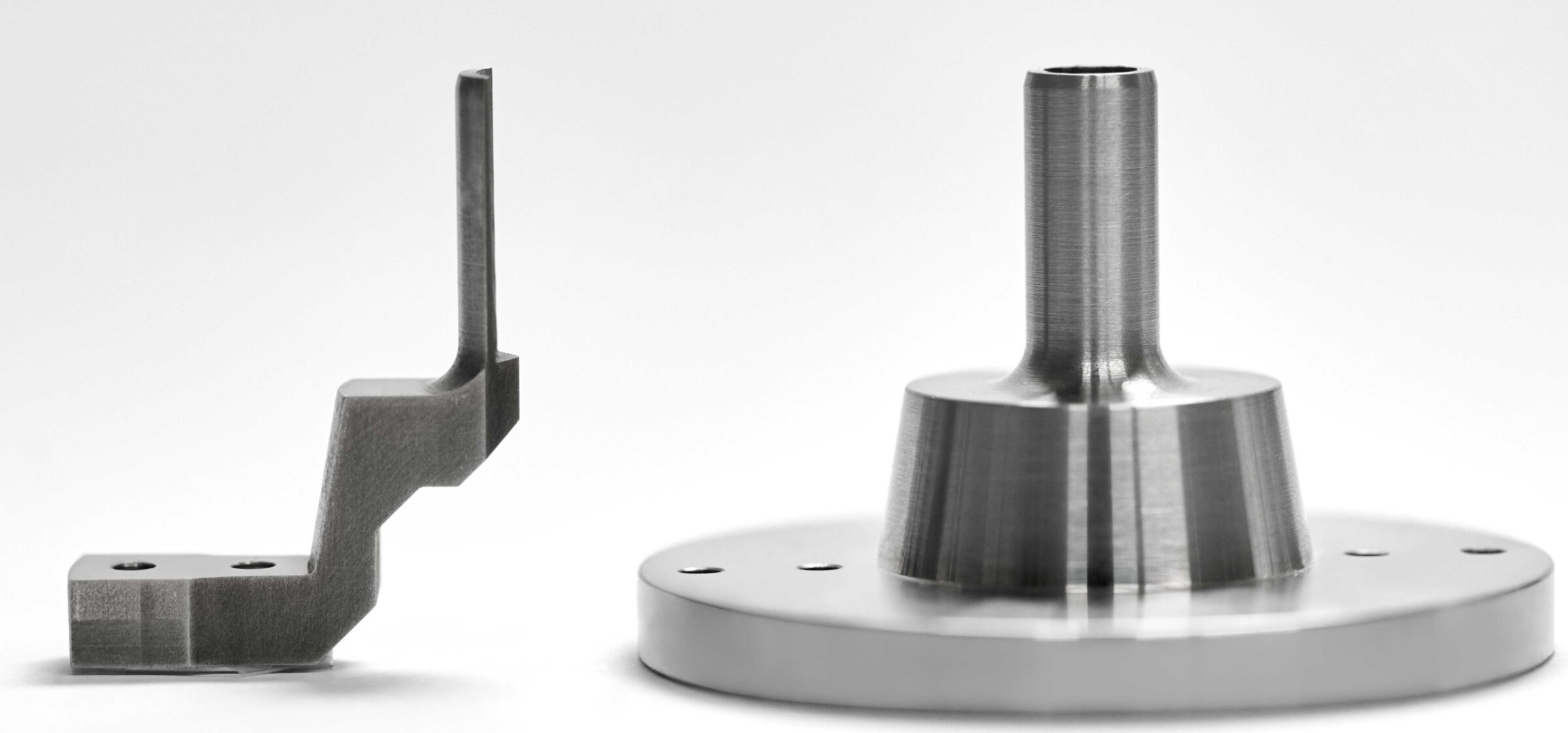

Founded in 1998, Raditek CNC-Technik in Markdorf, Germany, now has nine employees and works flexibly and at short notice, mainly for regional customers. Its product range includes customer-specific components for jigs and fixtures, for assembly and packaging systems and for automation technology. Most of its orders come from industrial companies working in the aerospace, food and beverage, and pharmaceutical industries in the surrounding Lake Constance region. Most jobs, second-generation owner and Managing Director Jasmir Dzidic explains, are for single items or at best tiny series up to about five identical components. To produce workpiece grippers and carriers, drive levers, guide rails and similar parts from sketches, customer drawings or data, for example, the subcontractor in Markdorf has at its disposal all the usual machining technologies, such as drilling, turning, milling and now also grinding.

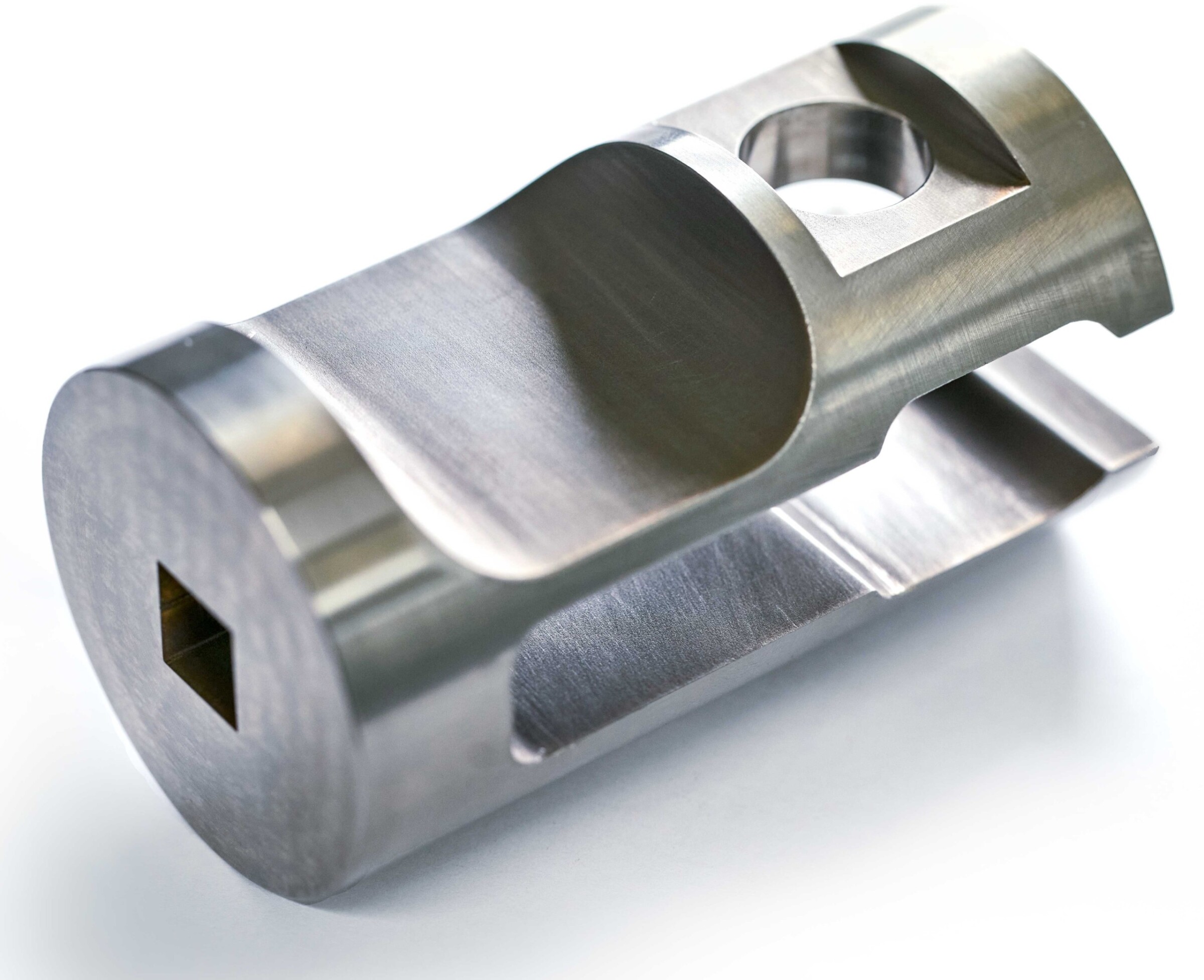

The subcontractor machines complex structures in hard materials faster and more economically with wire EDM – more easily than by turning and milling.

Thanks to the high quality of the components produced and to the company’s flexible processing of orders to tight deadlines, there have recently been an increasing number of enquiries, even extending to complex workpieces, Dzidic continues. This also includes components with special geometries, such as gearing, and workpieces made of extremely hard materials and hardened steels. “A few months ago, we received orders to machine components with internal gearings. Customers also asked whether we could produce nozzles with conical inlet funnels. The latter are made of a pre-pressed sintered ceramic, so-called green bodies. Such components cannot be milled or turned, or only with extreme effort and very long machining times. That was the reason for me to take a closer look at wire EDM machining,” says Dzidic.

The choice is yours: the MV2400S NewGen can be operated either like a smartphone with an app structure and graphic support or with classic G-code programming.

Nearly all of those we talked to recommended the machines from Mitsubishi Electric. These, they claimed, are equipped with the latest technology …

Jasmir Dzidic, Managing director

Together with his father Razim, who still works for the company, Dzidic first gathered information at a trade fair in December 2019 and then interviewed employees of other manufacturing companies, including those of his customers. The latter use wire EDM technology mainly for the machining of their product range. “It soon became evident that wire EDM is just the right machining technology for our extended range of components. Hard materials, difficult contours with very small radii, and even very narrow grooves – anything that cannot be milled or only with great difficulty can be accomplished effortlessly by using wire EDM,” says Dzidic, summing up his conversations. Now it was a matter of finding the machine that was best suited to the needs of a small, inexperienced jobshop. “Here, too, the information from neighbouring businesses soon gave us the necessary clarity. Nearly all of those we talked to recommended the machines from Mitsubishi Electric. These, they claimed, are equipped with the latest technology and can be programmed and operated easily and unproblematically, which makes them particularly suitable for ‘beginners’. The advice, training for programmers and operators, and the after-sales service at Mitsubishi Electric were also considered outstanding and highly rated,” says Dzidic recalling his conversations. All the interviewed users of these wire EDM machines also spoke approvingly of the cost-benefit ratio.

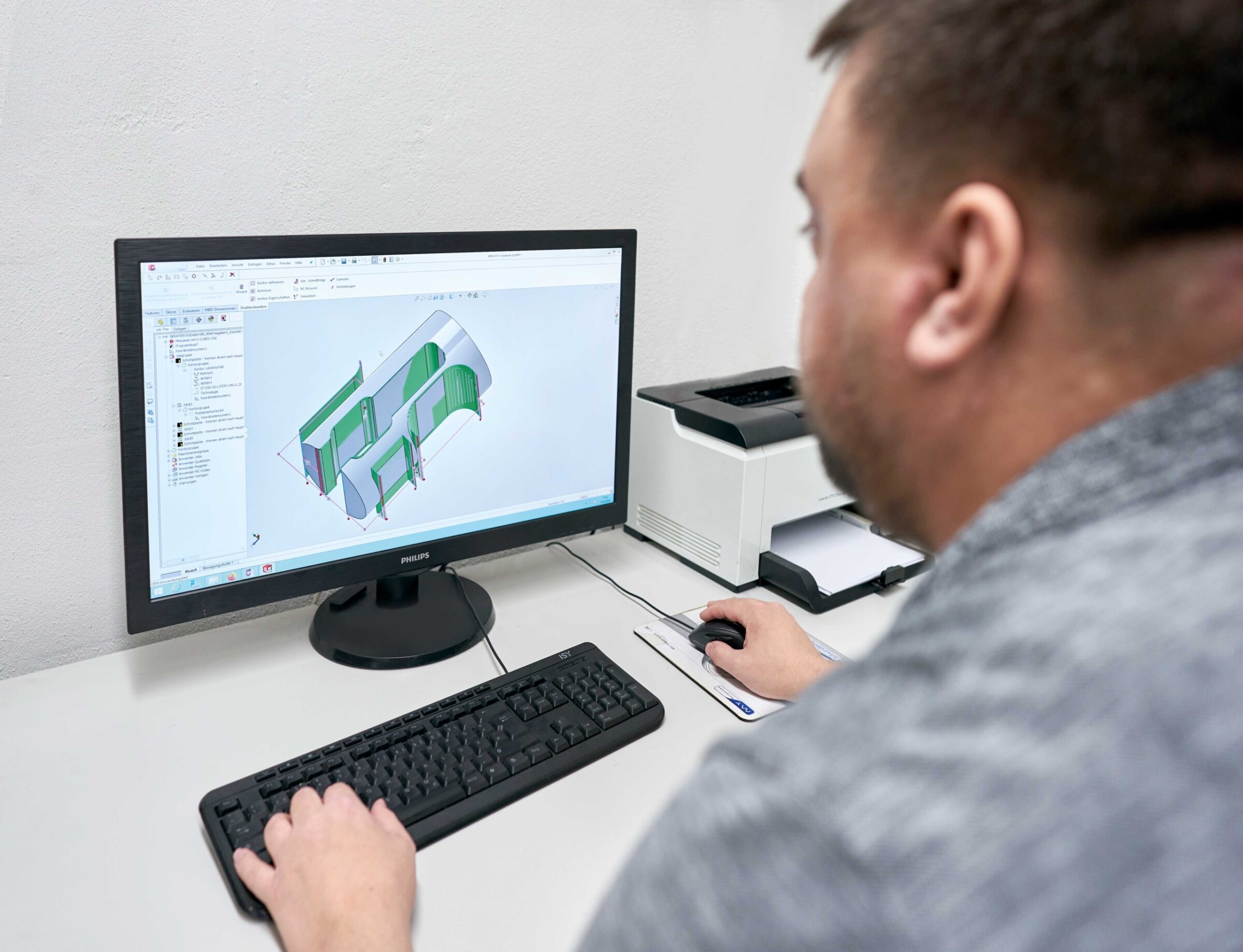

The datasets of NC programs for wire EDM are generated at the programming station from 3D models.

On the basis of these recommendations, Raditek invested in an MV2400S NewGen wire EDM machine. After only a few months of practical experience, Dzidic says that all the claimed features and advantages of this machine described by his fellow professionals have been vindicated. The advice and service supporting the commissioning process were excellent, he adds. Within a few days, the skilled applications technicians in Ratingen explained to him the functions and working methods in such detail and with such proficiency that he took only little time to produce the first workpieces from drawings.

Razim Dzidic flexibly produces customised clamping fixtures for a wide variety of components.

Dzidic considers the workspace to be large and very accessible. He can easily insert and clamp even bulky workpieces, he confirms. He finds special praise for the current D-CUBES control generation. “The touch panel with its control panels and functions – comparable to today’s smartphone apps – is naturally fully in line with the way younger employees work,” says Dzidic, and by this he also means himself. The functions selected on the large screen are self-explanatory and guide the user systematically and intuitively through the various dialogues for parameter input. Nevertheless, experienced specialists can also draw on their technical knowledge from other, proven NC manufacturing technologies. As an alternative to the graphically supported functions, they can also select a programming function with classic G and M codes. Dzidic is convinced this would be very helpful to his father, for example.

The best-suited machine.

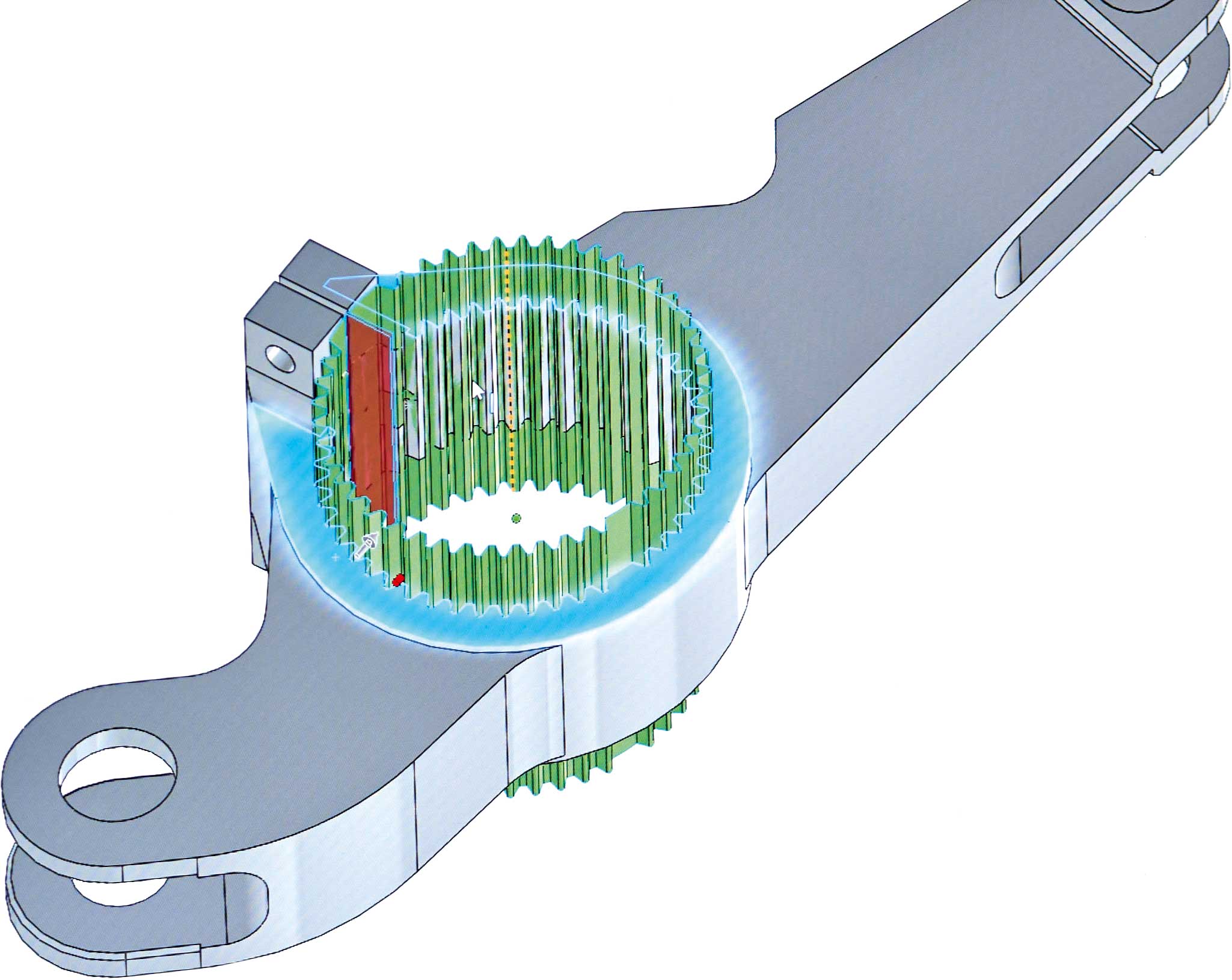

At Raditek, most of the components destined for wire-cutting are first transferred in data form to an external CAD/CAM system from DCAM. This is where the NC programs for wire EDM are generated. This external programming is particularly useful for complicated contours such as internal gears, Dzidic reports. After programming, the machining process can be simulated on the screen. In this way, possible collisions or geometric errors are revealed in advance, thus subsequently accelerating throughput, since this approach eliminates aborted machining processes, expensive scrap and the protracted reworking of workpieces. A special advantage is that the MV2400S NewGen controller stores proven parameters for commonly used materials. This means that inexperienced users can simply adopt the data and machine efficiently with them.

Internally and externally, wire EDM can be used for finishing intricate components made of hard materials in a single pass.

Wire EDM technology has now enabled Dzidic to machine difficult contours and geometries in-house. This has increased his flexibility in the handling of changing production orders at short notice. He has also come up with his own ideas for innovatively, quickly and accurately machining workpieces by adopting unusual processes. He explains an example: “We had to manufacture housing components using structural steel plate up to 170 mm thick. The usual production steps – first flame-cutting the rough geometry, cleaning the edges with an angle grinder and then milling them to the exact dimensions – were in my view laborious and complicated. So we simply put the plate directly onto the EDM system and wire-cut the final geometry in a single pass.” EDMing with wire initially requires longer processing. But with a 10 kg wire spool, the machine can machine such workpieces unsupervised for up to 30 hours. Thanks to the reliable wire threader, it runs smoothly and productively over the entire period. This machining process, Dzidic confirms, is more cost-effective overall, since lengthy and elaborate transfers between processes, idle times, multiple clamping and reclamping, expensive tools and special clamping devices for the milling machine are no longer required. “With the MV2400S NewGen wire EDM machine we have gathered excellent experience in just a few months. We were able to familiarise ourselves quickly, Mitsubishi Electric’s service department provided us with excellent advice and support, we have managed to expand our range of services considerably, and we have achieved greater flexibility because we can now machine a wider range of components entirely in-house,” says Dzidic summing up.

Optimal machining: wire-cutting the internal gearing on a lever

Enhanced flexibility thanks to wire EDM.

Realising ideas with more flexible and faster machining

Working flexibly and at short notice for regional customers.

Jasmir Dzidic, Managing director

[…] the MV2400S NewGen wire eroding machine, so we see ourselves well equipped to master difficult situations even for several months.

Name and place of company:

Raditek CNC-Technik

Germany

Founding year:

1998

Managing director:

Jasmir Dzidic

Employees:

9

Core business:

Flexible and fast machining of customer-specific components for jigs and fixtures, automation and assembly systems and for operating equipment in general as one-offs and multiples from hard and hardened materials on the basis of drawings, samples and graphic data

Raditek CNC-Technik

Bergheimer Str. 28

88677 Markdorf

Germany

Tel +49 7544-741097

Fax +49 7544-741098

info@raditek.de

www.raditek.de

We are currently experiencing an approximately 20 per cent decline in incoming orders. We produce special and replacement parts for plant construction and for plant operators. As long as these plants continue to operate – in the food and beverage and pharmaceutical industries, for example – wear and replacement parts will certainly be needed. For this reason, the situation is likely to stabilise for us at the current level.

Obviously, we hope that the restrictions will soon come to an end and that the economy in general will then pick up again. As a result of the financial crisis ten years ago and my joining our company’s operational business, we are already well set-up for the long term. We have streamlined our internal processes. Likewise, in recent years, which have been marked by growth and sound financial management, we have invested repeatedly in new machines and also in forward-looking technologies. The most recent example is our investment in the MV2400S NewGen wire eroding machine, so we see ourselves well equipped to master difficult situations even for several months.

Following the financial crisis in 2009/2010, we gradually drew up contingency plans, which we can now use as a guide. This gives us the certainty that, in conversation with customers and also with the banks, we will be able to cope well with the current adversities. We have also certified our company to ISO 9001. As a result, we are perceived as a competent and capable supplier, even in times of economic crisis, by our considerably larger customers. This will continue to safeguard sufficient orders so that we can survive financially.

Managing director

Raditek CNC-Technik

Jasmir Dzidic, Managing director

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com