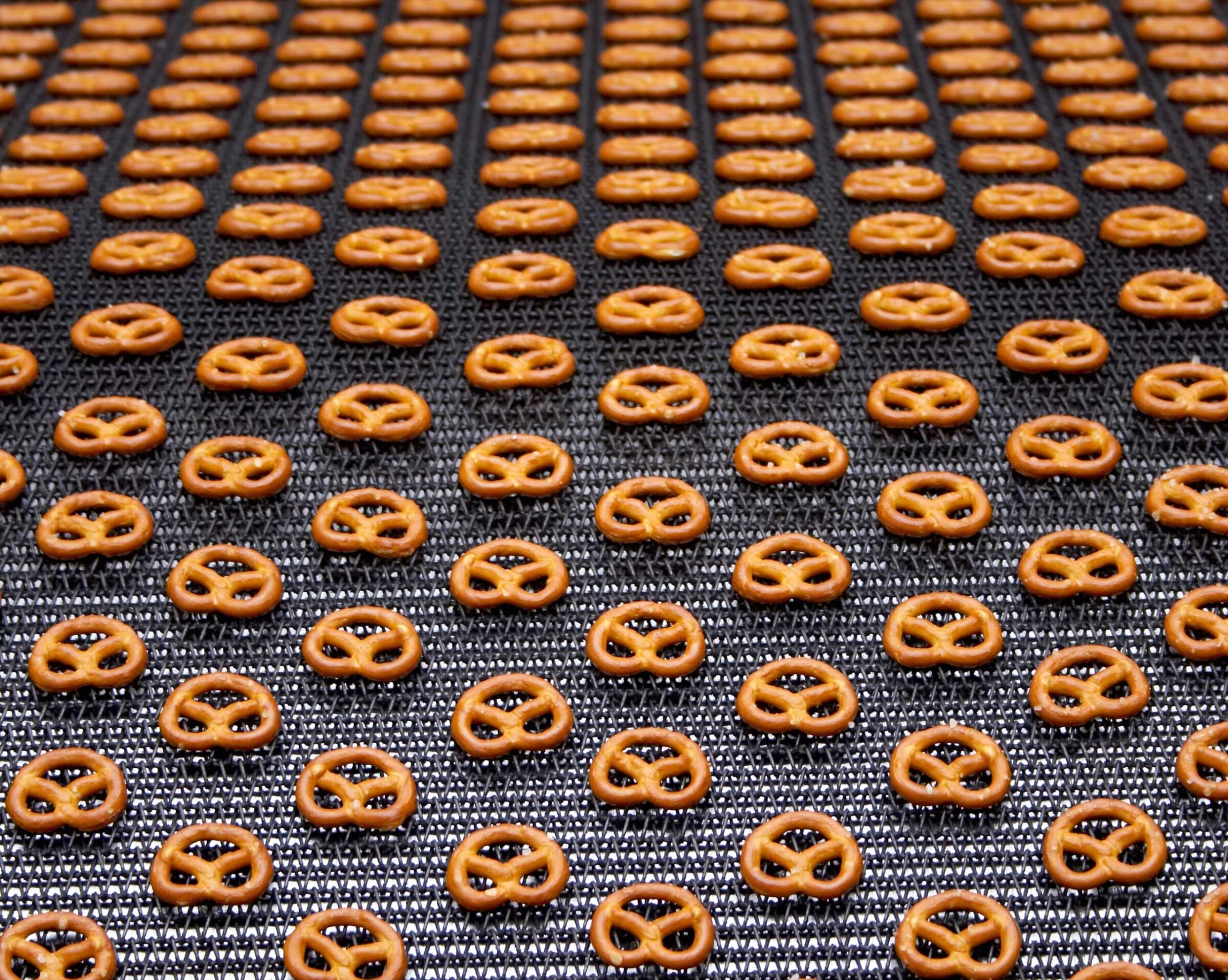

Designer food is a big talking point. To be able to productively manufacture meat, sausage and and dough products with imaginative shapes, Albert Handtmann Maschinenfabrik in Biberach, Swabia, develops and builds automated filling, portioning and packaging machines. Wire erosion is indispensable for producing the complex geometries and contours of the shaping tools.

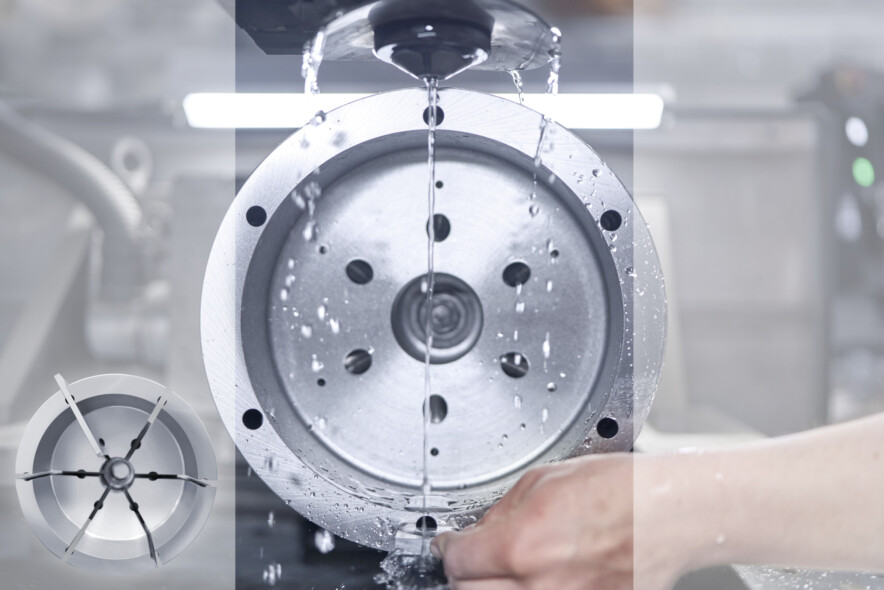

In stainless steel alloy pump rotors, 2 to 4 mm narrow grooves up to 120 mm deep can be cut with the wire alone.

Albert Handtmann Maschinenfabrik GmbH & Co. KG in Biberach an der Riss ranks as the world’s leading manufacturer of advanced machines for meat and dough processing. As Georg Briegel, Production Manager in Biberach, proudly reports, Handtmann machines perform outstandingly every day all over the world in the production of sausage and dough products: “From small rural butchers and bakers to nationwide meat factories and bakeries, a multitude of companies in the food industry use our modular machines, which can be flexibly configured to individual requirements and needs. Pet food is also produced on our machines.”

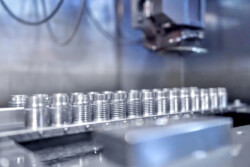

For the automated feed, portioning, dosing, filling and packaging of dough and sausage mixes, Handtmann builds modular machines.

He goes on to explain what the machines do: “It’s always about feeding, dosing, portioning, wrapping and finally packaging pasty foods, such as bread and pizza dough, and meat and sausage mixes.” Machine manufacturer Handtmann focuses primarily on largely automated processes with high productivity. This is the only way to produce food in the large quantities required today economically and at sufficient speed. As an example, Briegel cites smoked sausage, which is sold among other things in discount markets and at petrol stations. “Stuffing the sausage casings with precisely metered mix, sealing the ends of the sausage and packaging the sausages attractively, either one or several at a time, cannot be done manually in quantities of several hundred thousand sausages a day. Only our sophisticated, interlinked machines are capable of this.” Handtmann’s highly innovative technology also ensures that sausage manufacturers can stuff, seal and package up to 3,600 per minute of the ‘Wienerle’ sausages very popular in Germany, with 0.5 g accuracy.

According to Joachim Haller, head of toolmaking and prototypes at Handtmann, food processing machines require a large number of components made of highly chemically resistant materials. These are primarily high-alloy and corrosion-resistant steels, but also nickel castings. The task involves fabricating a variety of components, each of which is fitted in the filling, portioning and cutting machines. “We can machine numerous parts exclusively with wire erosion. These include, for example, so-called forks for our wire cutting stations. We have to cut deep holes with diameters of only 0.3 to 0.6 mm in steel parts hardened to 60 HRC,” says Fabian Ruf, NC programmer at Handtmann in Biberach. He also shows us pump rotors for vane cell pumps. These components have a diameter of around 200 to 300 mm, depending on the variant. Radial star-shaped grooves up to 120 mm deep and only about 4 to 8 mm in diameter have to be machined into certain rotary parts.

High-productivity and automated processes.

The pump rotors are made of a stainless steel alloy, e.g. grade 1.4301. The vanes slide in the grooves and, in conjunction with the drive and the non-circular pump housing, ensure that the pasty sausage or dough mixes are fed by changing the volume of the various pump chambers. As Rudolf Renz, senior toolmaker at Handtmann, confirms, such geometries can only be produced by wire EDM.

Machining up to 30 workpieces unattended overnight

Milling or grinding geometries with these extremely large depth-to-width ratios, especially in hard or hardened materials, simply isn’t on. “That’s why we invested in an FA20 wire-cut EDM machine from Mitsubishi Electric back in 2012,” he explains. Previously, the Biberach-based machine builders had collaborated with a subcontractor specialising in EDM. “In the long term,” Briegel explains, “we lacked the flexibility so important for us and we often had to wait unnecessarily long for individual components. We were no longer willing to accept the resulting delays in delivery times for our machines, which is why we brought the wire EDM technology in-house and acquired the necessary expertise ourselves.” “The FA20 machine has proven itself very well,” Renz adds. “It’s easy to program and extremely reliable.” Since the demand for complex components has steadily increased, the Biberach machine manufacturers opted to invest in another wire EDM machine in 2021.

The toolmakers at Handtmann use wire-cut EDM machining mainly because of its technological advantages. It can be used to produce a huge range of component geometries. In addition, the machines operate reliably unattended for long periods of time and are therefore cost-effective – despite long machining times.

Many function-critical components for our filling and portioning machines can only

be produced by wire EDM.

Fabian Ruf, NC programmer at Handtmann.

“Since we wire-cut about six to ten components for each of our filling and portioning machines, we’ve supplemented our existing FA20 with an MV4800R wire EDM system. In its large workspace, we can not only cut large components, but also several smaller components from a larger block or plate. This makes our work much more flexible,” Renz continues. In this way, the specialists in Biberach manage to machine up to 30 workpieces in a multiple clamping overnight without an operator. To make this possible, the MV4800R has a wire station for the supply of wire extended to accommodate 20 kg reels. The automatic wire threader of the MV4800R has proven to be extremely useful in unmanned production. “Even up to 120 mm deep in the water tank, the machine reliably rethreads the wire straight into the kerf after a break. This has a large hand in our ability to produce the required components highly flexibly and economically,” Haller explains.

Flexible and cost-effective production.

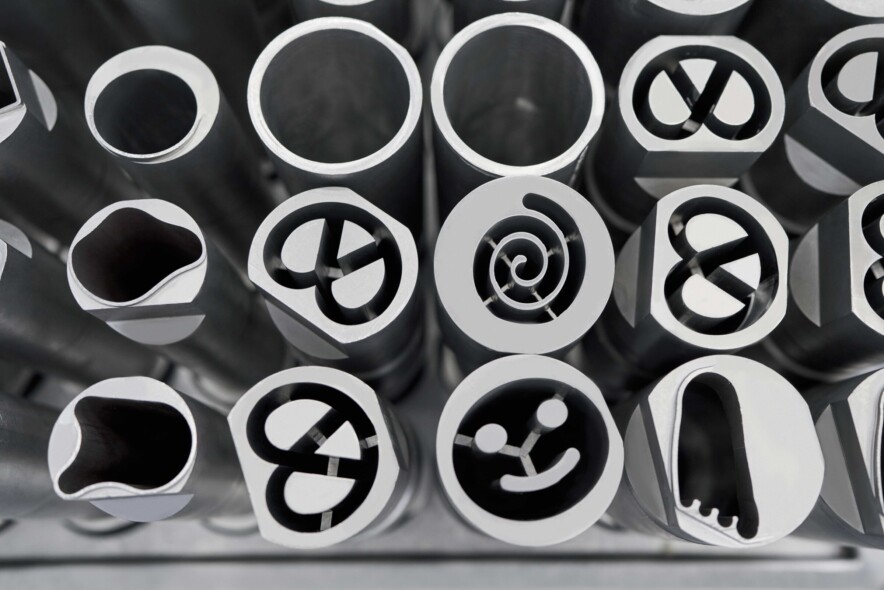

The machine manufacturers in Biberach are increasingly benefiting meanwhile from the wide-ranging, universal machining capabilities of the MV4800R wire-cut EDM machine. The machine is equipped with a sturdy and large B-axis (dividing head). “This enables us to act at very short notice in following a current trend in the food industry. Many traders currently want to market original and creative designer food products. These include sausage and and dough products with symbolic geometries, such as in the shape of a heart, star or pretzel, or as a stylised Christmas tree,” says Production Manager Briegel.

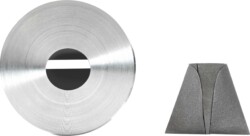

Forks of hardened steel (60 HRC)

The moulds required for shaping the sausage and also dough are produced on the MV4800R. A conical inner geometry is cut from round rods up to 120 mm long. This transitions from a cylindrical hole at one end of the round rod to the desired geometry – a pretzel, star or heart shape for example – at the other end of the rod. On the portioning machines, via these shaped tubes, the sausage and dough mixes are fed, cut and discharged as a strand. Fabian Ruf points out that the specialists in Biberach have meanwhile acquired the necessary expertise for this. “Above all, arranging the position and sequence of the wire cuts so that the waste pieces (slugs) drop out of the shaped tubes, whose inner contours are cut conically with changing geometries, always requires considerable spatial imagination and very skilful NC programming,” Ruf adds. He has been working with an external NX-CAM NC programming system for the last two years, and a special postprocessor is available for this. This means he can even program free-form surfaces and complex geometries, such as the contour transitions in the shaped tubes, without any problems.

Mould for sausage and also dough. A conical inner geometry is cut from round rods up to 120 mm long. This merges into the desired geometry of a cylindrical hole at the end of the rod.

When machining the contours on the shaping tools, wire eroding on the MV4800R wire EDM system offers further benefits. Renz says: “We need a high surface quality so that not only do the sausage and dough mixes slide well, but the components of the machines can also be hygienically cleaned with ease. On the MV4800R, we achieve roughness of Rz 2 µm. After blasting the eroded contours – with glass beads, for example – we produce high-quality surfaces that meet all requirements without any further finishing.”

Mitsubishi Electric has impressed us all round with its rapid delivery times and always available, highly professional service. Joachim Haller, head of toolmaking and prototypes at Handtmann.

Designer food – original and creative.

For NC programmer Ruf, the control system technology has proven to be particularly beneficial. “The current programming and user interface with a touchscreen was quick and easy to grasp and learn. It is useful to be able to switch between the conventional and innovative interfaces,” he reports. Due to a lack of electronic components, the touchscreen envisaged by Mitsubishi Electric was initially not available. The specialists in Ratingen therefore fitted an alternative screen so that the production technicians in Biberach were supplied their MV4800R on time and were able to get straight to work.

Haller stresses: “This is just one example of the excellent and professional service provided by Mitsubishi Electric for wire EDM machines. You get practical support and in-depth information and detailed answers to all your questions from skilled specialists.”

The bell founder and master mechanic Christoph Albert Handtmann founded a brass foundry in Biberach in 1873. From 1954, the newly founded machine factory produced the first portioning, filling and linking machines for sausages.

FA20-S Advance and MV4800R Connect working side by side in harmony.

Ruf confirms this: “Especially because of the special geometries of our shaped tubes, we learn something new almost every day with the support of the Mitsubishi Electric service in Ratingen. Starting with the standard parameters provided by the control system, we are constantly optimising the EDM processes. In conjunction with the high reliability of the wire EDM machines, this puts us in an ideal position to cost-effectively and efficiently fabricate the wide range of different components for our filling and portioning machines.”

The bell founder and master mechanic Christoph Albert Handtmann founded a brass foundry in Biberach in 1873. From 1954, the newly founded machine factory produced the first portioning, filling and linking machines for sausages.

Name and place of company:

Handtmann Maschinenfabrik

GmbH & Co. KG

Germany

Founding year:

1954

Managers:

Harald Suchanka (CEO),

Dr. Mark Betzold,

Valentin Ulrich

Core business:

Manufacturer of vacuum fillers and portioning systems for the food industry

Handtmann Maschinenfabrik

GmbH & Co. KG

Hubertus-Liebrecht-Strasse 10–12

88400 Biberach a. d. Riss

Germany

Tel +49 7351 45 0

Fax +49 7351 45 1599

info.machines@handtmann.de

www.handtmann.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com