What has Sogameca got to do with the 24 Hours of Le Mans race? Firstly, the specialist in cutting tools and turnkey single-purpose machines is located within the race circuit. And secondly, speed and precision are two of its key quality attributes.

Lionel Bézannier, Sales Manager for single-purpose machines at Sogameca in Mulsanne, France, unfolds a map of the almost 14 kilometre long Circuit des 24 Heures and puts his finger on his company’s location. “The high speeds that make motor racing so exciting are reflected in our machining and delivery times. In addition, we’re also known for our high-precision products with superlative surface quality and can look back on over 40 years’ experience. These are advantages that keep us ahead of the field.”

The user-specific single-purpose machines are an important source of business of the customer oriented engineering company that, together with its Polish sister company, belongs to the French SERFRA holding company. So far, Sogameca has sold some 800 of these machines worldwide, which are supplied turnkey and hence ready to go in manual and semi-automatic versions. The company sees its main target groups in the automotive and aerospace industries, cosmetics manufacturers and general industry. If higher output is called for, the machines are integrated in production cells in which robots do the handling. An example of this is packaging machines for perfume samples.

With his right thumb, Gérôme Lenoir, in charge of machining parts to customer drawings, traces the complex cuts of a cutting tool that his department has developed and produced. “These tools are mainly used in the food industry for the manufacture of plastics packages and also for the production of cheque cards. They’ve enabled us to tap another source of business and also put ourselves in a unique position. The exceptional precision of such components made mainly of steel and stainless steel can only be achieved with wire erosion.”

This is why the company certified to ISO 9001, which operates 20 hours a day, six days a week, and achieved sales of EUR 9 million in 2011, has invested in two FA30-S Advance wire EDM machines and an EA28-V Advance die sinker machine from Mitsubishi Electric. In February 2011 and January and April 2012, these replaced older machines from a different manufacturer. These systems were supplied by Delta Machines, Mitsubishi Electric Europe’s French distributor located in Morangis.

The EA28-V Advance can automatically replace its starting electrode with up to 19 other electrodes and thus also operate unmanned.

According to Sogameca, a high-precision erosion machine is not enough. You need a skilled operator as well.

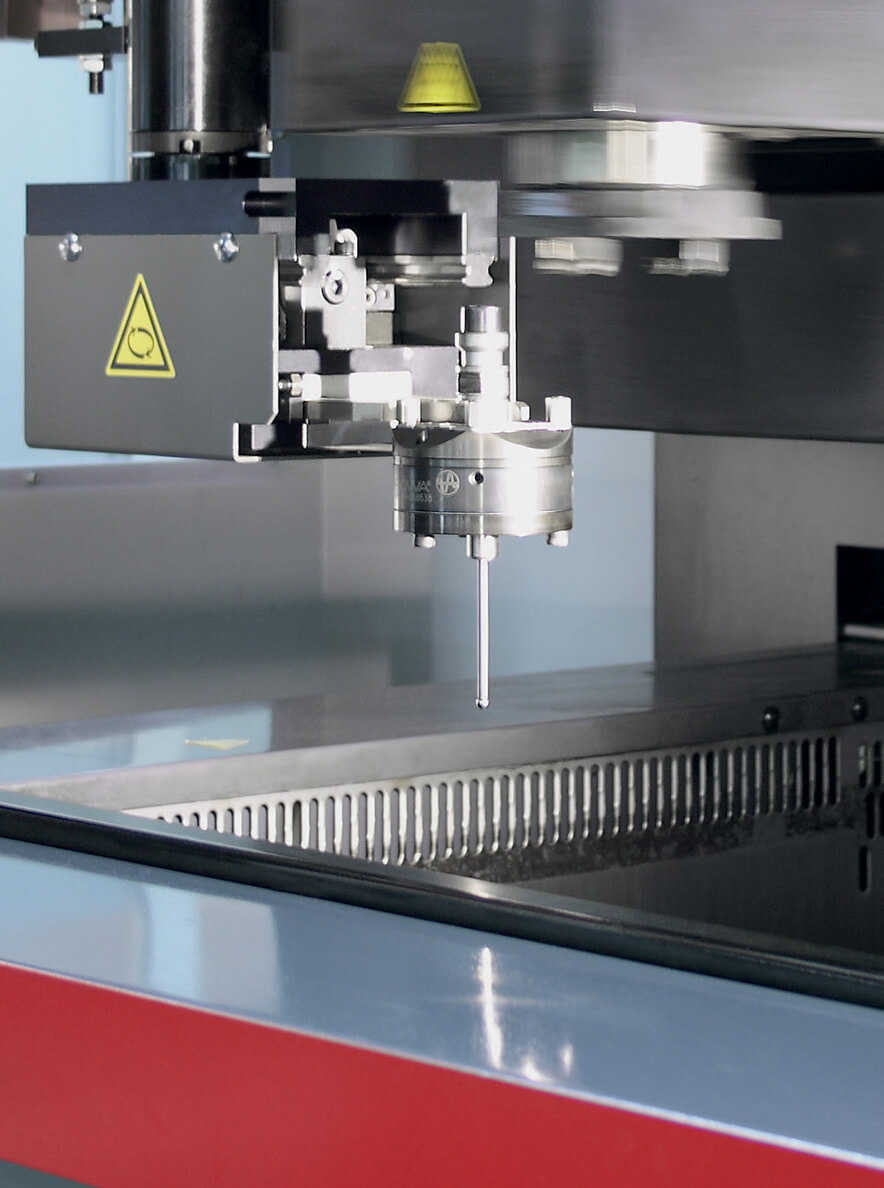

During his tour of the business, Lenoir stops at a FA30-S Advance, which is equipped as standard with a high-speed generator. The erosion machine cuts the material with 0.25 mm diameter wire and achieves parallelism and precision of less than 2 µm and surface quality of 0.4 to 0.8 µm Ra. “Here again, it’s all about speed,” says Lenoir, stressing an attribute shared with motor racing. “This is where we can really put our foot down. The operator can set up the machine more easily and faster because the door to the tank can be lowered and he has unrestricted access to the work space.

“The machines are simple to operate and offer easy access.”

In view of our workpieces with footprints ranging from 400 x 220 to 1300 x 1000 mm, we wouldn’t want to be without this feature.”

As can be seen from the example of the retractable door, Mitsubishi Electric takes account of the factor of time in the development of its EDM machines. This also applies to the automatic wire threader of the FA30-S Advance. Lenoir opens the machine’s side door and points to the 20 kilo wire spool. “With this in reserve and the automatic threader, which can be relied on to do its job in only 10 seconds, we can run the machines unmanned at night and at the weekends.”

Sogameca produces most parts by get- ting the desired workpiece into shape initially with die sinking and then cutting the material with wire EDM.

“A high-precision erosion machine is not enough. You need a skilled operator as well. And the service you provide also has to be good.”

On a wall board in the conference room, Lenoir sketches a die sinking process to illustrate what moved Sogameca to invest in two machines using different processes. “We produce most parts by getting the desired workpiece into shape initially with die sinking and then cutting the material with wire EDM. The EA28-V Advance can automatically replace its starting electrode with up to 19 other electrodes and thus also operate unmanned.”

Electrode replacement is indispensable for two reasons. Firstly, because the eroded surface of the workpiece has to be finished with a fresh electrode after the first machining step; and secondly, because of the wear that occurs on the electrode. Replacement is also executed smoothly in unmanned operation. As an electrode has a known service life, it is possible to program the replacement times. The user monitors these phases with the aid of Mitsubishi Electric’s intelligent remote contact function that enables the machines to send test messages to selected phone numbers. It is ultimately in these ghost assignments that the company builds up a strong lead, to borrow a phrase from motor racing.

Patrice Jacquelin, Production Manager at Sogameca, calls up a page of test results on his laptop. “The EDM machines from Mitsubishi Electric came off better than the machines from two rival manufacturers, as they meet our expectations in terms of quality, reproducibility and price/performance ratio. The precision with which the workpiece can be positioned on the clamping table also satisfies our requirements. In addition to all this, the machines are simple to operate and offer easy access.” The employees therefore soon got the hang of the control and user interface. The CAD data for wire EDM are produced by the company’s own design office. The operators then transfer the data from the company network straight onto the control of the FA30-S Advance. For the EA28-V Advance, the employee generates the CAD data himself.

Lionel Bézannier sees the machines as only one of the prerequisites for immaculate production results. “A high-precision erosion machine is not enough. You need a skilled operator as well. And the service you provide also has to be good.” Bézannier can rely on this, because when the machine comes off the production circuit for a ‘pit stop’, the service from Delta Machines fully meets the operator’s needs. This also applies to operator training, which is also performed by Delta Machines.

Serge Hessemans, Sogameca President, opens up a folder and shows us a document. “As soon as a job is completed, we ask the customer to rate his satisfaction. We’ve produced this document for this and appointed a quality officer.” The company evaluates each document and takes any appropriate remedial action. Ultimately, it’s a question of producing high-quality turnkey machines with a fully integrated strategy and getting them up and running smoothly. And, as in the 24 Hours of Le Mans, as quickly as possible.

Name and place of company:

Sogameca, Mulsanne, France

Founding year:

1970

President:

Serge Hessemans

Number of employees:

80

Core business:

Design and production of tooling and single-purpose machines

Sogameca

L’Ancien Moulin – Mulsanne BP50017

72231 Arnage

France

Tel +33 . 243 . 2138 38

Fax +33 . 243 . 2138 39

sogameca @ sogameca.fr

www.sogameca.fr

Gérôme Lenoir: We’re on the fast track for high precision.

Lionel Bézannier: During a holiday job in a foundry.

Lionel Bézannier: Inquiries from customers.

Lionel Bézannier: With the aid of our customer satisfaction questionnaire, we give greater attention to new technologies for the customer’s benefit. And we’ve taken on an employee who’s concerned solely with research and development.

Lionel Bézannier: We’d like to make greater inroads into certain markets – in the health sector, food industry and aeronautics, for instance.

Gérôme Lenoir: With sport.

Lionel Bézannier: Honesty and professionalism.

Sogameca

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com