Simple wire-cutting was yesterday. With its B-axis and “column-up” option, Lüntech GmbH also offers its customers out-of-the-ordinary solutions.

By taking over a small one-man business, Karen and Jörg Lünstedt founded Lüntech GmbH in 2000 in order to establish themselves in the EDM metalworking sector. The first two wire-cut EDM machines from Mitsubishi Electric – a FA20-S and a RA90 – were installed in 2001. Impressed by their quality and performance, the master toolmaker invested in further machines of the FA series and rounded off his machine park in 2009 with a “column-up” FA20-S Advance V and a FA20-S Advance with an integrated B-axis. With four employees, Lüntech in Werther in Westphalia, Germany, today serves some 140 customers within and outside the region.

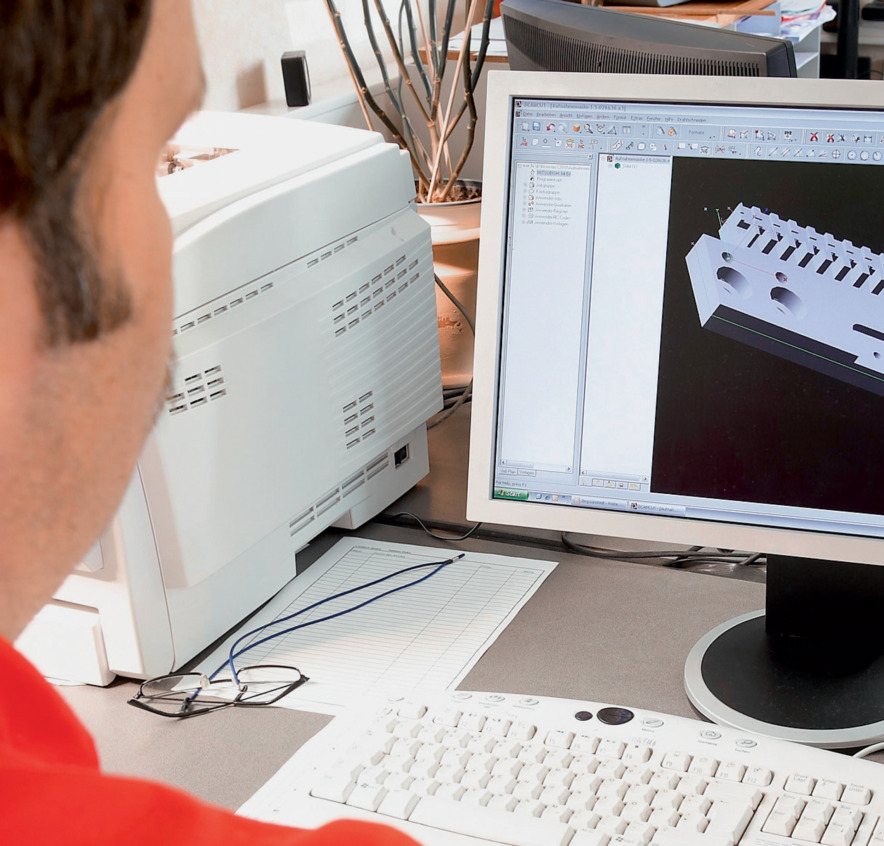

High-precision wire EDM calls for a trained eye.

“After last year, staffing and output are now back to the high 2008 levels,” says Jörg Lünstedt, optimistically summing up his company’s current situation. What has remained unchanged is the huge deadline pressure. Jokingly, he adds: “Ordered yesterday, supplied the day before.” However, their flexible way of working enables the team to respond appropriately – naturally always with the intention of producing top quality.

As a company specializing in wire-cut EDM, Lüntech benefits from being able to run its machines at night unmanned. “At about 4 o’clock in the afternoon, we see what has to be clamped on the machine,” says Jörg Lünstedt, outlining the procedure. Not only long-running jobs are handled at night, but short ones as well. “Our freedom of choice is so large because we use a clamping system from Erowa and can clamp several workpieces at the same time.” The managing director makes use of the installed VPN link to monitor the machines from home. “Access to the machines, modifications to the programs – everything can be controlled with this, including a machine restart,” Jörg Lünstedt adds.

Jörg Lünstedt also owes the company’s flexibility to its machine park. He has been working with wire-cut EDM machines from Mitsubishi Electric since 2001. “A wire EDM friend had switched to Mitsubishi Electric and was very happy with it. At the EMO trade fair in Hannover, we then followed suit,” Jörg Lünstedt recalls. He now has four models in operation. What impressed the master toolmaker at the time was the speed of the wire EDM machines from Japan. “The current generation is of course much faster still and,

more importantly, more precise.” Far fewer downstream cuts are now necessary in order to achieve dimensions in the µm range. Lüntech’s performance spectrum additionally comprises die-sinking EDM and laser welding, which means that customers can avail themselves of a wide range of services.

Business relations with Mitsubishi were for Jörg Lünstedt a very positive experience right from the outset. “As a newcomer to wire EDM, I was taken seriously by the salesmen from the beginning – contrary to my experience with other manufacturers.” What’s more, he was made to feel one of the family. “The service alone is extremely helpful – if anything goes wrong, then mostly Friday evening at around seven.” In 80 per cent of cases, the assistance via the hotline is sufficient and production can resume, he says.

Last year, Jörg Lünstedt modernized his machine park. In part-exchange for an older model from Mitsubishi Electric, he purchases the FA20-S Advance V. “We chose the version with the ‘column-up’ option so that we can machine a larger product range,” says Jörg Lünstedt, explaining the purchase. The decision in favour of the V-generator was taken for similar reasons. “On taller components, the superior cutting performance makes an appreciable difference.” The timing of the investment was also favourable – despite or perhaps because of the economic crisis, as Jörg Lünstedt believes. “Now that order levels are so good again, we are perfectly equipped and are ready for anything.”

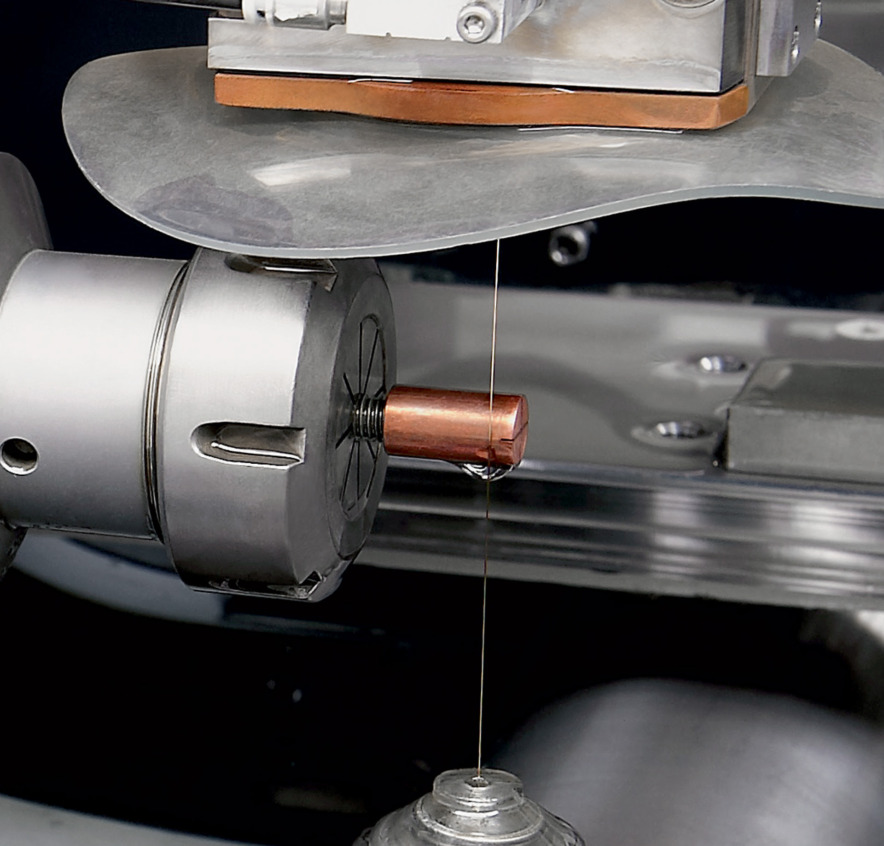

At the same time as the “column-up” FA20-S Advance V, Jörg Lünstedt bought a B-axis for rotationally sym-

metrical wire-cut EDM so as to extend his range of services still further. “However, we installed this on a one-year-older FA20-S Advance, because this makes us more flexible,” the managing director explains. Because of the possible height of the components, he in fact has to reckon with longer machining times on the more recent machine. Jörg Lünstedt has one more option for the future: “Should the need arise, we can quickly retrofit the B-axis on the ‘column-up’ machine as well by additionally installing an axis amplifier.”

Complex and intricate tasks are the bread-and-butter of the EDM job shop.

“The service alone is extremely helpful – if anything goes wrong, then mostly Friday evening at around seven.”

Jörg Lünstedt sees big potential in rotationally symmetrical wire-cut EDM. “So far this has accounted for only a smallproportion of our jobs, but design engineers are gradually recognizing the new possibilities.” It is therefore his goal to push ahead with this technology and firmly establish it in Lüntech’s everyday production operations. In rotationally symmetrical wire EDM, the jobber’s staff can exploit their full range of skills.“ 3D programming is our strength and an appealing challenge again and again,” says Jörg Lünstedt. Customers are thoroughly satisfied with the immaculate fruits of the service provider’s labours.

Design and programming are mainly carried out in 3D.

Lüntech has long been regarded as a specialist in wire erosion. With the raised column on one machine and the B-axis on the other, it will consolidate its position in the long term because the team of staff can also realize complex designs. Jörg Lünstedt hopes to expand his business in the future. “With further investments in wire EDM and 3D laser ablation, we shall expand our production capacity and extend our range of services.”

Rotationally symmetrical wire-cut EDM opens up new opportunities for designers.

Name and place of business:

Lüntech GmbH, Werther, Germany

Founding year: 2000

Number of employees: 6

Managing director:

Jörg Lünstedt

Core business: EDM metalworking and laser welding

Lüntech GmbH

Erodiertechnik

Dammstrasse 23

33824 Werther/Westfalen

Germany

Tel: +49 (0) 52 03 / 91 90 84

Fax: +49 (0) 52 03 / 91 90 85

info@luentech.de

We’re the extended work bench for customers in the EDM sector.

Doing a newspaper round in Schleswig-Holstein.

Our willingness to serve and the new challenge every day of fulfilling the customer’s wishes.

We approach a job with greater deliberation in order to exploit the best possibilities.

We shall continue to grow and occupy new premises.

We managed to survive 2009 and restore staffing to the previous level.

On extended motorbiking tours.

Reliability, punctuality and honesty.

From my wife, to set up my own business.

What a locksmith achieves with millimetre precision in wood with a belt saw we cut with our electrically charged wire in the micrometre range.

Managing director

Lüntech GmbH

Jörg Lünstedt (2nd from the left), his wife Karen Lünstedt and the four-man team.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com