Anyone committed to a reliable and swift single-source supply of anything from one-off and replacement parts to complete automation systems has to be very cautious in his choice of machining method. As far as Schäfer Feinmechanik in Oberndorf near Salzburg, Austria, is concerned, there’s no serious alternative to electric discharge machining for the execution of complex geometries – particularly if the material is hard.

Focus on precision. EDM is the method of choice for hard materials.

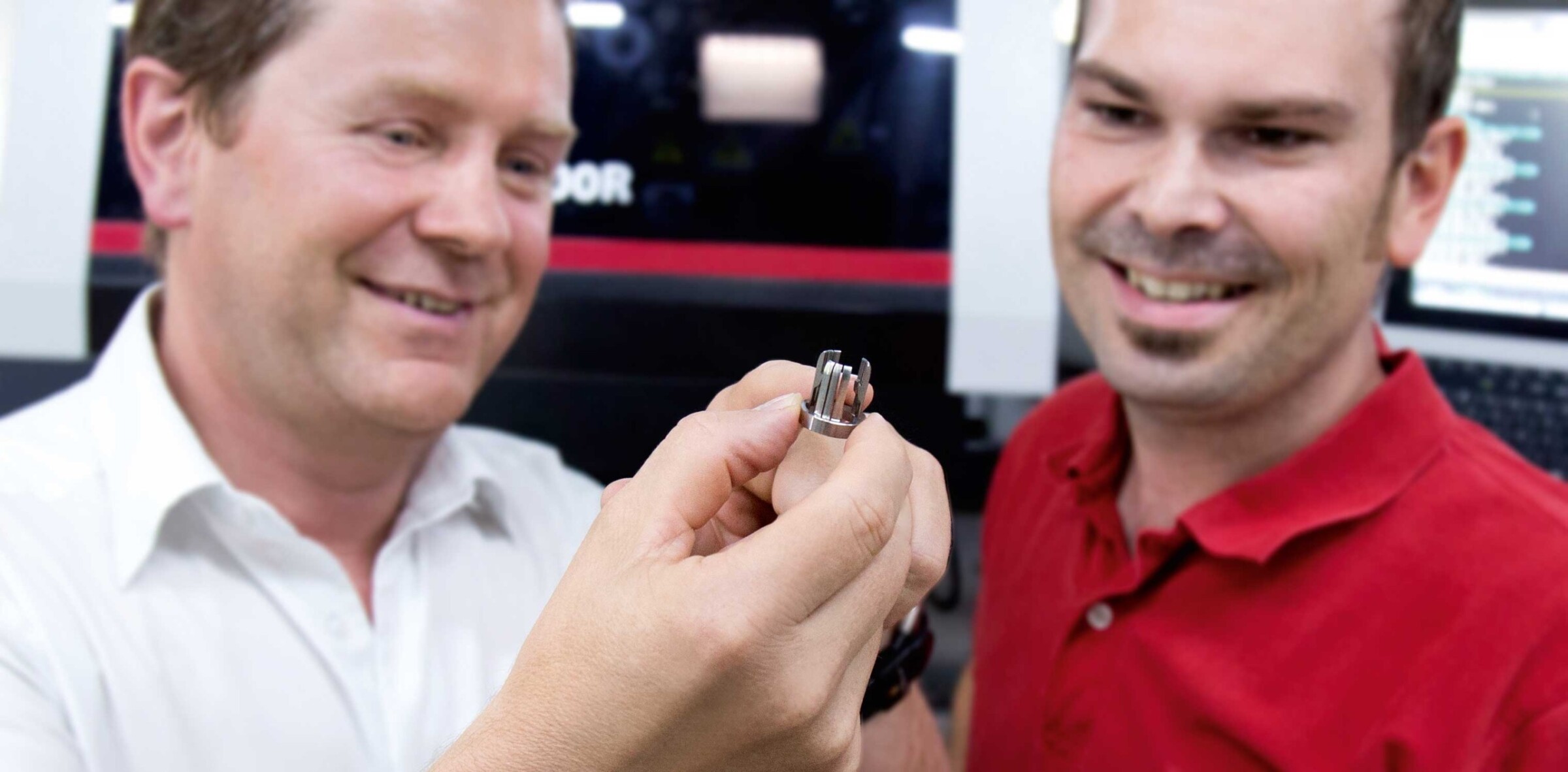

With its current roughly 50-strong workforce, the company in Oberndorf develops and fabricates a very broad range of items – ranging from one-off parts to complete devices and systems – for toolmaking, automation, medical technology and the food industry. Among elite athletes, Schäfer Feinmechanik also enjoys a fine reputation worldwide. Competitive shooters and biathletes appreciate the sports equipment developed and produced in Oberndorf as an assurance of their success. This sports equipment helped to win Gold and Silver at the 2012 London Games and Gold, Silver and Bronze at the 2016 Rio Games. “In our mechanical production department, we process some 6,000 to 7,000 different workpieces each year,” Anton Ensinger, Schäfer’s head of production in Oberndorf, reports. His primary goal is to uphold speed and accuracy in production – an all-important competitive factor for the company. As confirmed by Ensinger, customers today expect ever shorter delivery deadlines, over and above the quality and accuracy of the finished components and systems. “To satisfy these requirements, it is up to us to constantly accelerate throughput in production,” Ensinger adds. This applies just as much to the one-off items and components for the equipment assembled on site as to the workpieces machined under subcontract for customers. The latter include single and replacement parts for injection moulds and punching tools as well as components in small and medium series for automation systems or medical technology.

An assurance of success.

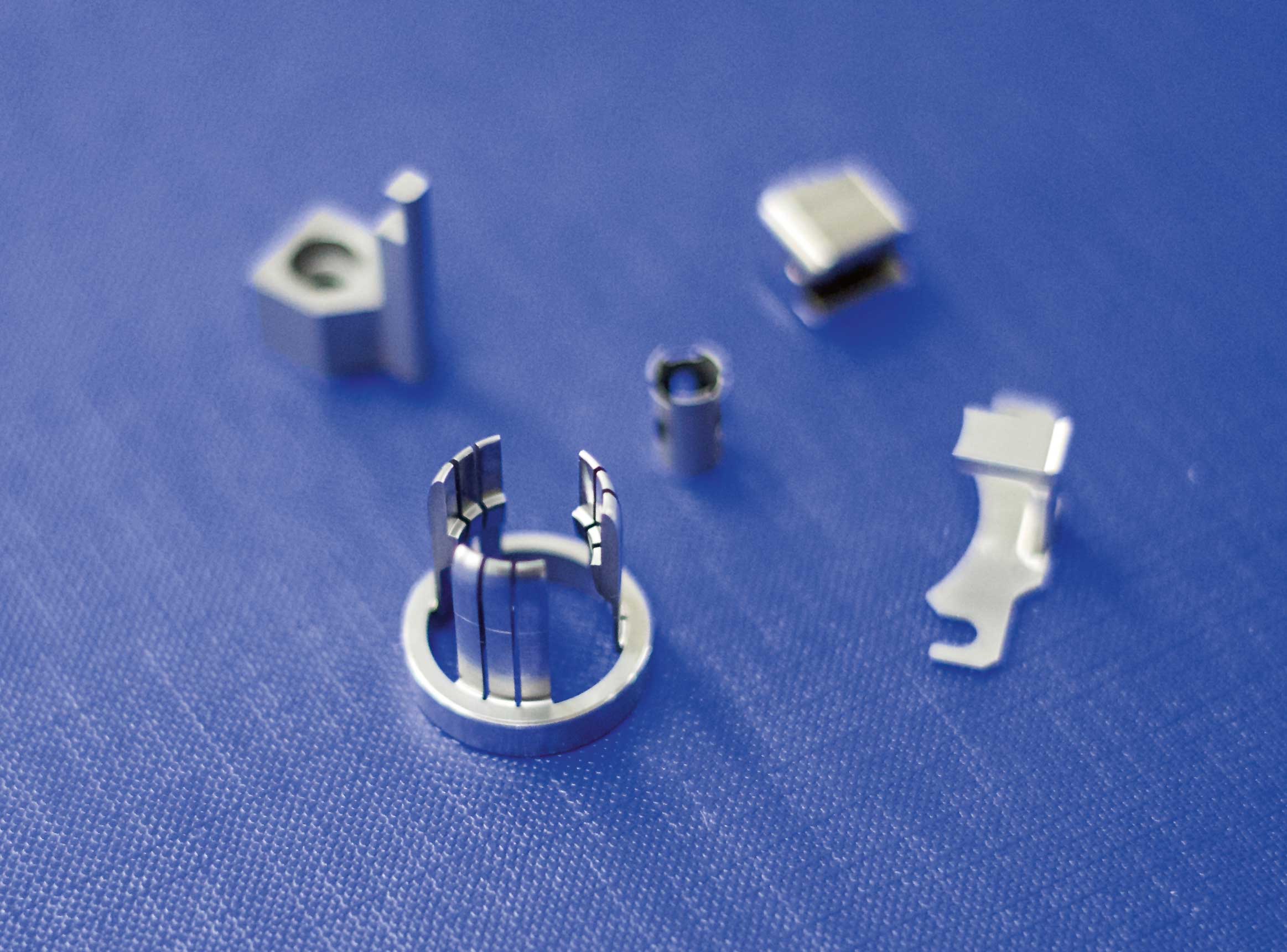

Precision parts made of difficult-to-machine materials are preferentially processed with EDM at Schäfer Feinmechanik.

To ensure rapid throughput and maximum flexibility in the development and manufacture of its own products – anything from automation solutions to gun stocks – Schäfer Feinmechanik has a high degree of vertical integration. Metalworking and welding work for machine frames are performed by the specialists themselves, as is the precision fabrication of small and super-small components for medical technology and tool- and mouldmaking. In addition, Schäfer Feinmechanik has several advanced 3D CAD CAM workstations. This is where the company designs and machines its entire product spectrum, ranging from single parts and subassemblies to entire configurations. The experience derived from this for production-ready design also benefits its subcontracting operations. Ensinger elucidates: “We also make use of our comprehensive design and production expertise to optimise the components machined under subcontract so that we can produce them faster, more efficiently and more reliably.” It often happens that unspectacular improvements in the design of components and subassemblies open up huge opportunities for simplifying and hence accelerating production and assembly to a large degree. And this of course cuts costs for the customer.

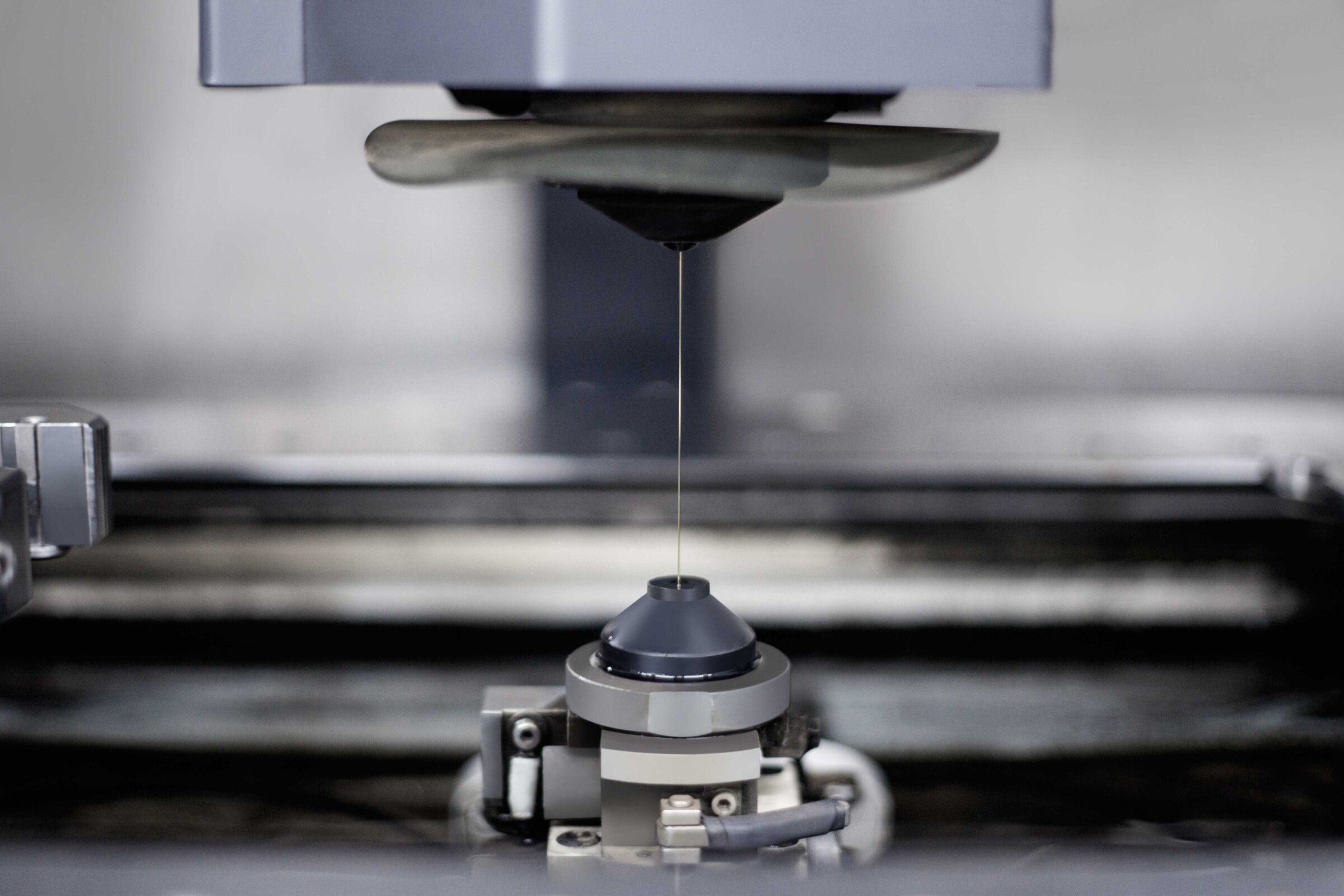

For the machining of precise geometries in hard materials, there’s no alternative at Schäfer Feinmechanik in Oberndorf an der Salzach to wire EDM as a cost-effective and high-accuracy production method.

As Ensinger continues, there was a strong shift towards EDM a few months ago, accompanied by the desire for optimised production processes. “Wire-cutting is practically the only option for some machining operations, although we used to make only limited use of it,” he reports. Previously, it had been reserved solely for the small-scale machining of replacement parts for tool- and mouldmaking and for in-house requirements.

Ensinger: “Thanks to the harmonised system for operation and programming, our skilled staff were able to work productively with die sinking, a technology that was new to us, after only a short time for familiarisation.”

Wire-cutting is practically the only option for some machining operations.

But that changed when Schäfer received a growing number of orders for the production of individual parts for punching tools and injection moulds in small and medium series. In Ensinger’s view, the only suitable machining process for this was EDM, as it is vastly superior to other machining operations, such as hard milling. It is capable of effortlessly and dependably achieving contour accuracies of 3 to 5 µm and surface qualities of Ra 0.3 µm, he stresses. Moreover, EDM is beneficial economically, despite the supposedly slower machining processes. As a mature and reliable production method, unsupervised running is possible in some cases, making multi-machine operation possible. Machining is also possible during entirely unsupervised night shifts. As Ensinger explains, he makes use of this particularly for highly complex components or for machining several components out of a single block.

In the production of intricate parts for tool- and mouldmaking, medical technology and automation equipment, there is no serious alternative to EDM, Ensinger believes.

Maximum flexibility with minimum throughput times

By investing in an EA8S die-sinking machine and an MV1200R wire-cutting machine, Schäfer extended its production capacity a few months ago. The two machines were purchased so that the company can continued to handle the growing number of subcontracted jobs on time. Ensinger aims to build on the production expertise already available at the firm. “Every machining technology available in-house boosts our flexibility and contributes to faster throughput,” he adds. The production technicians opted for the EA8S from Mitsubishi Electric because they were thoroughly impressed by the quality and performance of the FA10S wire EDM. “The FA10S was entirely up to our expectations. So it made sense to invest in a die-sinker from the same manufacturer.” Mitsubishi Electric also made a good impression with its high-grade equipment coupled with unbeatably attractive pricing. The choice of the EA8S was vindicated in only a few weeks. With minimal outlay on instruction and familiarisation, staff were able to work productively on the EA8S only a few days after commissioning, aided in this by their extensive experience of the FA10S wire-cutting machine and the recently commissioned MV1200R.

EDM – proven, process-secure, high-performance and efficient

On Mitsubishi Electric’s machines, the operation and control interfaces are based on a single system. On the EA8S die-sinking machine, ESPERADVANCE dialogue programming with graphic support simplifies and accelerates machine set-up and the machining process considerably. A large number of machining cycles can be selected in a library. The operator and tool setter merely has to add the pairing of electrode and material. Ensinger reports that, for instance, when producing tapered gate bores with diameters of only 0.7 mm, his machinists have managed to cut set-up time by up to 30 per cent thanks to the mature machining cycles. The control automatically selects the matching technology parameters and generates the cutting programs. The tool setter is then assisted by the Auto&Easy Setup system developed exclusively by Mitsubishi Electric. The machine automatically scans the clamped workpiece and the electrode in order to precisely record its position and enter it in the cutting program to determine zero. With the support of this outstandingly simple programming and operation, Ensinger reports, staff took very little time to learn the ropes with the new technology. Thanks to its automatic tool changer for up to 10 electrodes, the EA8S operates particularly cost-effectively and is capable of fully machining complex components in a single operation, working for long periods and in some cases throughout unmanned shifts. Short machining times due to high removal rates are made possible by the IDPM generator technology, which also reduces electrode wear significantly when graphite electrodes are used.

At Schäfer Feinmechanik the EA8S from Mitsubishi Electric proved its worth after only a few months.

Ensinger is also highly appreciative of the MV1200R wire-cutting system purchased a few months ago which machines faster than its predecessor. In tandem with the absolutely dependable automatic wire threader, it boosts the productivity of wire-cutting by up to 30 per cent and is capable of working trouble-free during unsupervised night shifts. The specialists in Oberndorf produce their cutting programs at an external CAD workstation, sending them to the machines via a DNC network. Another benefit of the MV1200R is its high energy efficiency, says Ensinger. Because Schäfer Feinmechanik attaches special importance to conserving natural resources. For example, the company generates the power needed in production with its own fully independent photovoltaic installation on the production building. Given growing production capacity, in-house power generation can only be continued with efficient and energy-saving production equipment. The MV1200R, Ensinger stresses, meets the requirements with its limited power needs.

A preference for machining difficult components

In view of their wide range of advantages, Ensinger relies heavily on EDM technology from Mitsubishi Electric. “EDM is a proven, absolutely process-secure and highly efficient and cost-effective technique,” he explains. “It is particularly suitable for precision components made of difficult materials. We therefore aim to handle difficult workpieces made of hard materials with EDM rather than hard milling, for example.”

Name and place of company:

Schäfer Feinmechanik GmbH

Austria

Founding year:

1984

Founder:

Karl Schäfer

Number of employees:

50

Core business:

Subcontractor for everything from individual and replacement parts for tool- and mouldmaking, medical technology and automation equipment to ready-to-operate systems for automation in mechanical engineering and the food industry

Schäfer Feinmechanik GmbH

Austrasse 1

5110 Oberndorf, Austria

Tel +43 6272 4060

Fax +43 6272 4060-40

office@schaefer-feinmechanik.at

www.schaefer-feinmechanik.at

We design, produce and assemble everything from metalwork to items machined with µm precision.

I put my heart into exploiting new technologies and improving the quality of the items we produce.

Today we work a lot with CAD/CAM systems to accelerate throughput and achieve more stable processes.

The successful adoption of 5-axis technology enabling us to fully machine many components.

I enjoy climbing and skiing in the surrounding mountains.

Frankness and honesty in admitting mistakes for which we can jointly search for a solution.

I’m in charge of production in a mechanical engineering company.

We generate most of the electricity we need ourselves with our own solar cell installation on our production building.

Production Manager

Schäfer Feinmechanik GmbH

Anton Ensinger Production Manager

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com