Instead of tedious and laborious milling, turning, grinding, lapping and polishing, Winkler Präzisionswerkzeuge GmbH in Lauffen am Neckar exploits the potential of wire-cut EDM production engineering. On an MP1200 Connect, the specialists produce backlash-free mating slides for grippers and clamping systems with micrometre precision.

Grinding and honing are so 2017. All in one go with the MP1200 Connect.

Since its takeover by Schunk GmbH & Co. KG, a neighbouring specialist in gripping and clamping technology, Winkler’s subcontracting business has been thriving. Using all the usual machining processes, such as drilling, turning, milling, grinding, honing and lapping, the company specialises in producing precision components to order for the general machine building sector and the automotive industry. This mainly involves customised special components from drawings, such as for jigs and fixtures, clamping devices and robot grippers. Demand for precision components has improved significantly, largely due to recently redoubled efforts to expand automation in the machine manufacture sector. Patryk Hoff, authorised signatory and plant manager in Lauffen, says: “Our success is mainly due to our exceptional high vertical integration. Customers appreciate that they can get fully machined workpieces ready for installation from a single source.” The Lauffen job shop also flexibly organises the hardening and coating of the finished components at short notice in close cooperation with neighbouring companies.

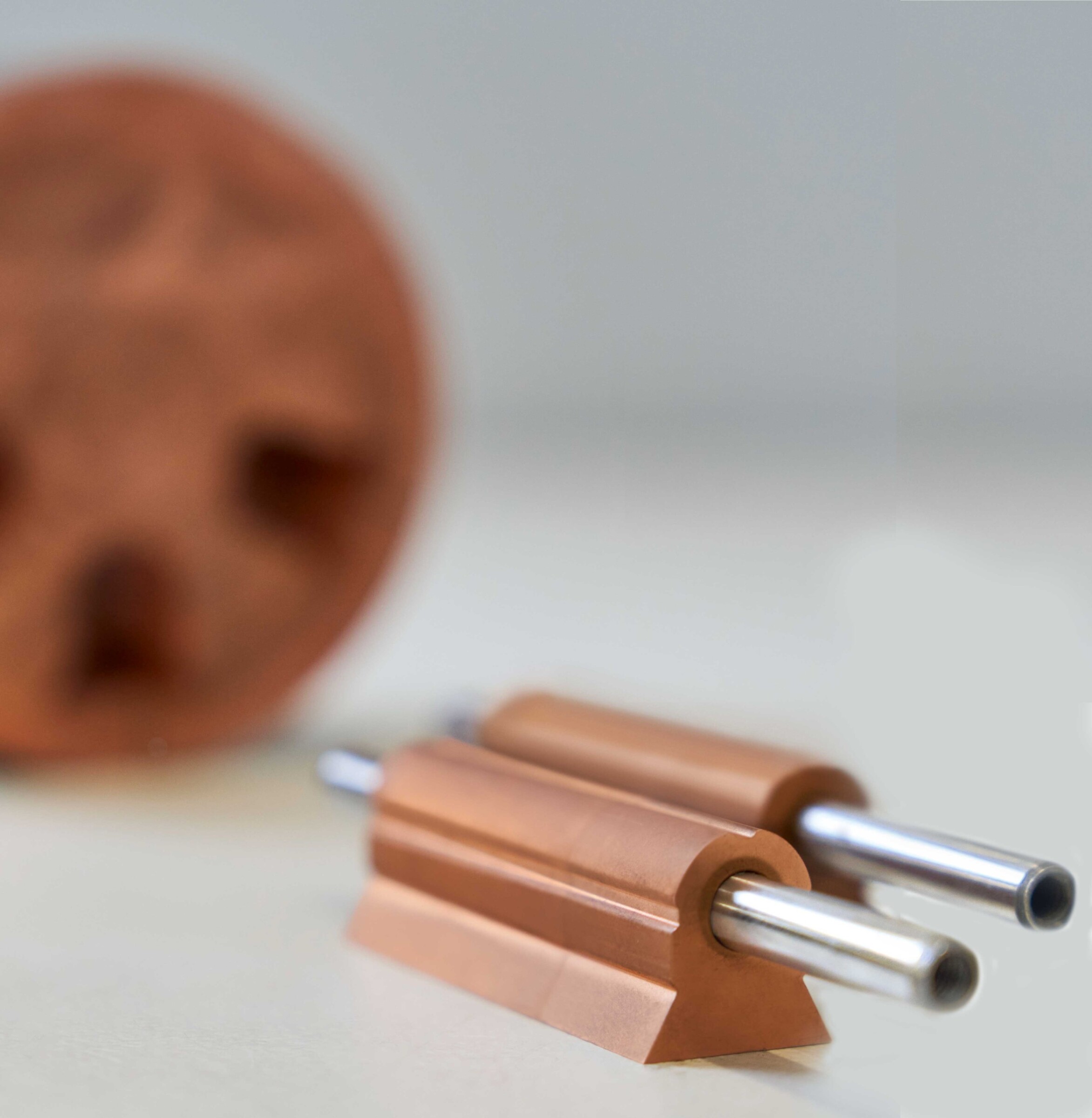

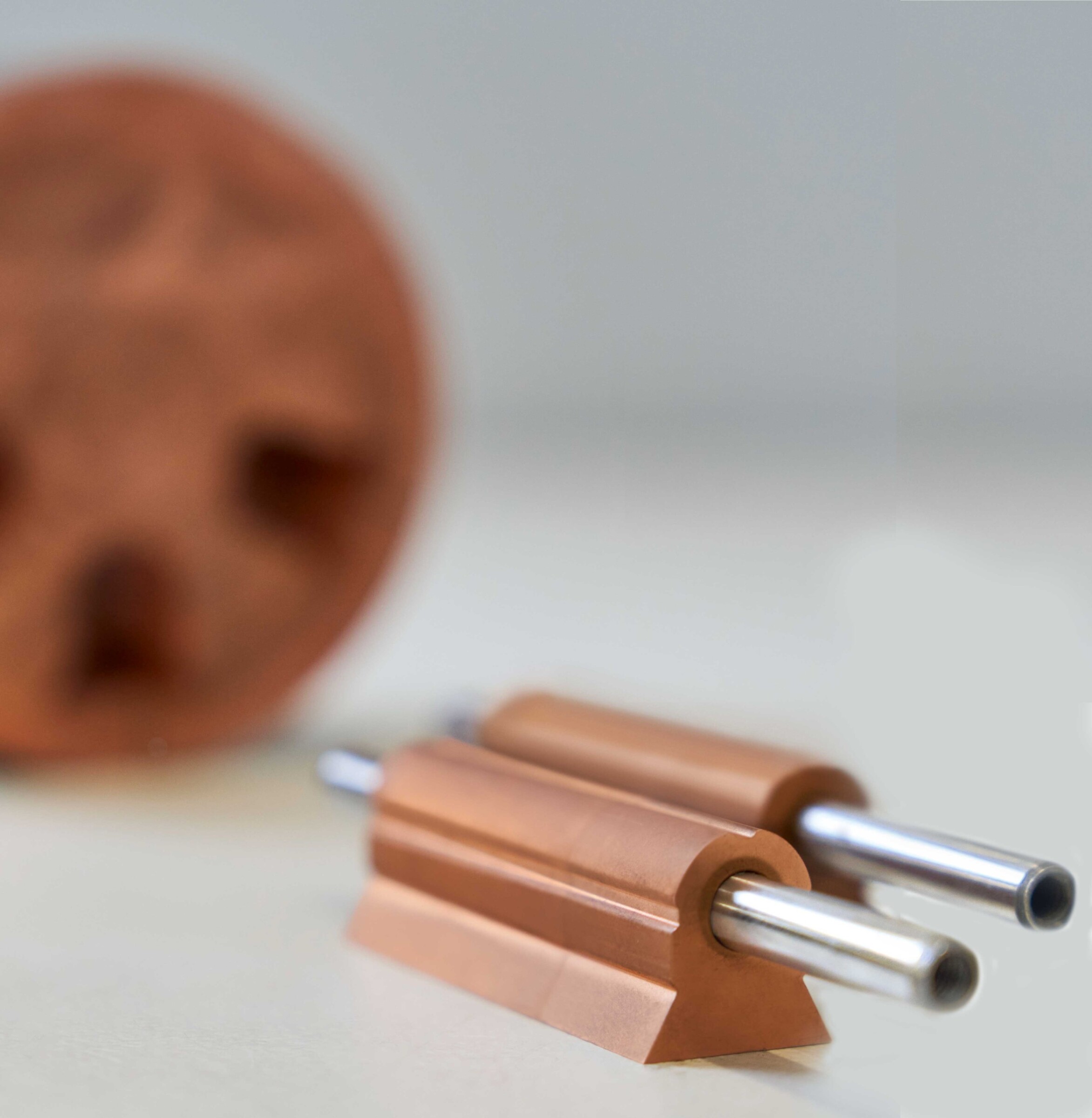

Precision without reworking: With the MP1200 Connect, sliding fits can be wire-cut to an accuracy of 1 μm.

Winkler mainly manufactures one-off items and small series. “We also produce a few selected components in larger series amounting to several thousand workpieces per year,” Hoff adds. In addition, Winkler also builds complete assemblies from various components. The contract manufacturer often cooperates with the client right from the development and design stage. This way, they can use their extensive experience in manufacturing to optimise the components, to enable them to be produced much more economically, for example.

Huge boost in demand.

In 2017, the subcontractor was completely taken over by gripper and clamping equipment specialist Schunk. However, Hoff tells us, the company has remained largely independent and self-sufficient in terms of its customers and contractors. This means that it is still able to work on a contract basis for all companies in the machine construction sector. “Contrary to initial fears,” Hoff continues, “being part of a large parent company has proven to be a huge blessing. We are now in a much better shape financially and have been able to invest heavily over the past three years.” During this period, the job shop purchased an MP1200 Connect wire-cut EDM machine. This has firstly expanded existing production capacity. “In addition, we are now capable of machining precision parts with high accuracy at very low cost,” Hoff adds. He cites a mating slide with a design similar to a dovetail joint. Using wire EDM alone, the specialists in Lauffen machined both the convex and concave profiles to an accuracy of roughly 1 µm. The profiles mate exactly without play and can still be pushed over each other easily and almost without force. “Manufacturing these profiles by milling, grinding and lapping would be far too time-consuming and labour-intensive,” says Hoff. That’s why he and his skilled workers machined the profiles on the MP1200 Connect wire EDM system. “We managed to do this effortlessly with micrometre accuracy. The profiles are perfectly aligned and mate without any reworking, thus underline the high machining accuracy of the wire EDM machine from Mitsubishi Electric,” Hoff stresses. This level of accuracy would not be possible on rival machines. “That tipped the scales in favour of Mitsubishi Electric and the MP1200 Connect.” On the MP Connect, the SD-FS digital fine finishing generator is also always available.

Patryk Hoff, authorised signatory and plant manager at Winkler Präzisionswerkzeuge GmbH

Manufacturing these profiles by milling, grinding and lapping would be far too time-consuming and labour-intensive […] We managed to do this effortlessly with micrometre accuracy. […] This underlines the high machining accuracy of the wire-cutting machine from Mitsubishi Electric.

The MP1200 Connect has thus expanded the contract manufacturers’ capacity not only in terms of the quantity of components machined, but also in terms of the type of precision parts. It is now possible, says Hoff, to reliably produce high-precision parts with difficult, complex geometries with rapid throughput and, more importantly, mostly with low staffing levels. “This brings us additional jobs, especially from our parent company, and lays the foundations for further growth,” he adds.

Patryk Hoff, authorised signatory and plant manager at Winkler Präzisionswerkzeuge GmbH

In comparative tests, this wire-cut EDM system proved to be the only one capable of meeting our demands for high-precision machining to roughly 1 µm.

In the few months since the MP1200 Connect has been running in Lauffen, numerous other advantages of the wire EDM technology from Mitsubishi Electric have revealed themselves. For example, the job shop technicians are highly satisfied with the reliable wire threading, as it enables them to arrange multiple workpieces on larger fixtures and have them fully machined in unmanned night shifts. Thanks to the innovative Tubular Shaft Motor technology, this can be done even faster than on rival wire-cut EDM machines, Hoff confirms. In addition, the spacious workspace is very accessible thanks to the fully lowerable tank. It is possible to fully open the housing and lower the table, allowing machine operators to comfortably reach into the workspace from three sides, quickly load the machine with heavy plates with ease and remove the finished components.

High machining accuracy.

Hoff also appreciates the advantages of the MP1200 Connect in terms of its operational strategy. He notes that younger operators in particular appreciate the graphic user interface, comparable to the look and feel of a current smartphone. “Thanks to the large touch screen and the arrangement of the operating elements as APP graphics, it didn’t take us long to learn how to programme the machine correctly and use it productively,” says Hoff. The workpieces are usually programmed on an external Solidworks CAD/CAM system and the CNC programs are generated with the CAM Works software. The programs are transferred to the MP1200 Connect via data line. There, the operator adds the optimal working parameters and starts the production process. Since the wire-cut EDM machine is extremely reliable, it can also operate unsupervised into the night. For longer operation, it has an additional wire station for 20 kg wire spools.

Optimal working parameters.

Hoff sums up his positive experience: “The MP1200 Connect machines with the high accuracy we demand and meets our requirements downs to the ground. It has demonstrated its dependability and is easy and reliable to program and operate. It’s really brilliant. We have chosen precisely the right wire EDM machine and we couldn’t be happier with it.”

Name and place of company:

Winkler Präzisionswerkzeuge GmbH

Germany

Founding year:

1976

Managing director:

Jochen Ehmer

Employees:

45

Core business:

Production of steel and aluminium precision parts for jigs & fixtures, clamping and gripping equipment, and for general automation in machine construction and the automotive industry

Winkler Präzisionswerkzeuge GmbH

Im Brühl 64

74348 Lauffen am Neckar, Germany

Tel +49 7133 – 974400

Fax +49 7133 – 9744099

post@winkler-gmbh.de

www.winkler-gmbh.de

In 2020, there was indeed an initial decline in incoming orders. But the situation had recovered appreciably by November. We are evidently benefiting from the fact that businesses are investing in automation even under difficult conditions.

We are continuing to build on our company’s unique selling propositions. We aspire to top quality and precision and are convinced that this will enable us to set ourselves apart even in difficult times and to stay one step ahead of the competition. Our investment in the MP1200 Connect from Mitsubishi Electric underlines our strategy. In comparative tests, this wire-cut EDM system proved to be the only one capable of meeting our demands for high-precision machining to roughly 1 µm.

We will always be a reliable partner to the local precision engineering industry in particular. In close cooperation, we can provide our customers with expert support in the realisation of precision parts, from development and design through to production and assembly. We maintain contact with companies in the region and are available at short notice. We are also convinced that there will be above-average demand for high-quality machines and automation technology in Asia and especially China. High-tech from Germany is appreciated there. We see this as a solid basis for successfully developing our business in the coming years.

Authorised signatory and plant manager

Winkler Präzisionswerkzeuge GmbH

Patryk Hoff, authorised signatory and plant manager at Winkler Präzisionswerkzeuge GmbH

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com