With an advanced high-tech machine park, Falk Lange has made K-L Präzision a trendsetter in the region. Its demanding customers benefit from the extraordinary quality of its machined products.

If you want high quality, you need high-tech production.

A pronounced commitment to quality.

In picturesque Nideggen, Lange inaugurated his new production shop in 2014. The Eifel National Park and the High Fens are within easy reach. “Here we’ve got everything we value,” says Lange summing up, “– a central location between Cologne and Aachen, a high-speed Internet connection and an idyllic landscape as well.”

The new building with its light-flooded production shop is working to high capacity only a year after the firm moved in. Some 900 m² of space is available for production and 100 m² each for offices and staff rooms. Armed with a wealth of expertise, a pronounced commitment to quality and, above all, a clear understanding of the needs of his customers, Lange took the leap in setting up his own business in 1998. Today, a total of nine employees work for his firm, all of them specialists who have a complete mastery of their respective trades and are able to machine with micrometre precision. One of them is Felix Lange, the founder’s son. The tool mechanic by training is ensuring second-generation continuity in the family business. “One of our strengths is undoubtedly the business’s high manufacturing depth,” Lange explains. “With the exception of hardening, we perform all the jobs on the premises and can therefore respond very quickly and flexibly to customer requests.” On the basis of his many years of experience, Falk Lange can also realistically assess the feasibility of more extravagant customer requests. “If a customer comes along with his drawings and instructions, we consult with him in detail and conscientiously examine the required work steps in advance,” Lange reports. “When we then confirm the job and give our okay, the customer can rely 100 per cent on getting precisely the tool he’s ordered.”

Before a workpiece goes to the measuring room, it has to withstand close scrutiny from Viktor Voth.

One of our strengths is undoubtedly the business’s high manufacturing depth.

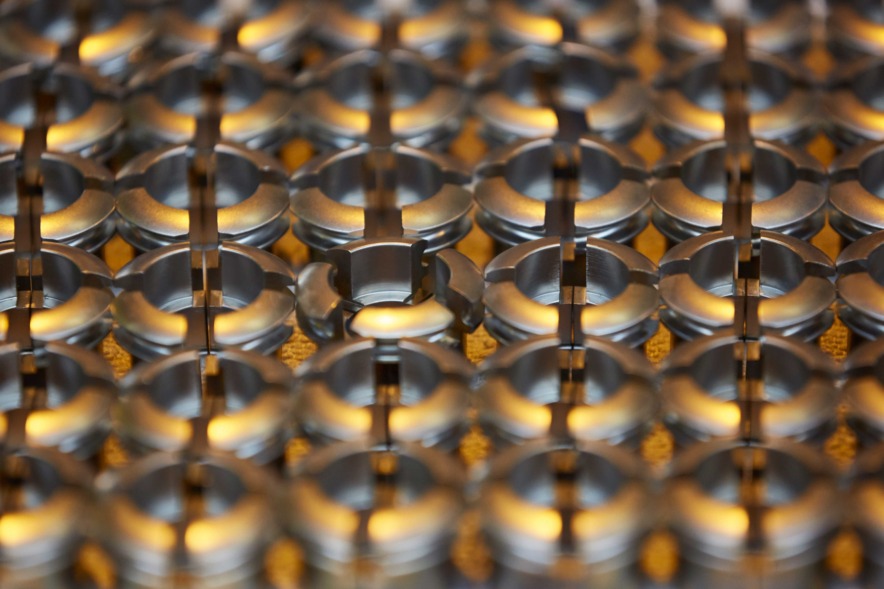

Lange has always been fascinated by high tech and aspires to always be one step ahead of the competition. So it’s hardly surprising that his machines always keep pace with technological progress. The advanced machine park of K-L Präzision is in every respect state-of-the-art and comprises not only electric discharge machines, but also machining centres, surface and cylindrical grinders, lathes and, last but not least, professional measuring equipment. With its ambitious aspirations, the company has acquired a unique position for itself in the region. “Being just one of the crowd is not my thing,” is how Lange explains his philosophy. “We may not always be the cheapest operator, but our customers acknowledge the quality of our work and have realised that our strength lies in the dependable execution of challenging tasks,” he adds.

The modern machine park is state-of-the-art.

Lange works alongside his team in production at the machines. He attaches great importance to personal relationships with his employees for he knows that high employee satisfaction has a positive impact on quality and productivity. He is not only ready to help his staff with his technical expertise, but also always has an ear for organisational and even personal concerns.

When cutting special electrodes, the five standard axes of the Mitsubishi Electric EDMs are not always sufficient. This is when a rotary axis comes into play at K-L Präzision. “Of course it’s also possible to cut these special electrodes in segments without an additional axis,” Lange admits. “But that’s time-consuming and the surface quality falls a long way short of the demanded standard. For medical technology applications in the USA, we’ve produced injection moulds, for example, and performed the die sinking with our immaculately cut electrodes. The customer was so impressed by the outstanding quality that he awarded us follow-up orders,” says an enthusiastic Lange. Mitsubishi Electric makes it easy for users to integrate rotary and articulation axes. The controls of the more recent EDMs are designed for the integration of extra axes and also make it possible to control additional axes simultaneously.

With its light-flooded new building, Falk Lange has paved the way for his business’s successful future.

Lange gathered his first experience with the machines from Mitsubishi Electric back in 1986, many years before going it alone. “My workmate, who at the time was responsible for wire-cutting, left the firm at short notice. So I had to stand in for him and was really thrown into the deep end. But it didn’t take long for me to feel at home on the DWC 90,” Lange recalls, laughing. Today, a total of nine machines from Mitsubishi Electric are in operation in Nideggen – four die-sinking and five wire-cutting machines. When setting up his own business, Lange opted exclusively for EDMs from the Japanese manufacturer. Two factors were critical for this decision: first, their innovative technology; and, second, the excellent service and support. “I’ve always studied what’s on the market thoroughly. Technological advances like the Tubular Shaft Motor, automatic wire threading and the new generator technology are outstanding features. What counts for me ultimately, however, is the overall package of technology, service and price. And Mitsubishi has always had the best offer so far,” says Lange justifying his choice.

Background information on the precision specialists.

A particular strength of Mitsubishi Electric is its excellent after-sales service. “Should a problem ever arise on a machine, it’s quickly solved. We’ve never had to wait for an answer longer than an hour. This is something I can always rely on,” says the business owner. “By contrast, I find annoying the tendency of other manufacturers to respond sluggishly. Sometimes there’s even a risk of a whole working day being wasted unproductively.” “We’ve come to appreciate that technical support is increasingly becoming a make-or-break factor. This is why we have redoubled our efforts in this area,” says Lutz Roger Neuendorf, the responsible Sales Manager, outlining the strategy of the leading EDM manufacturer. Service management has therefore been working even more closely with sales for some time now and has steadily adjusted manpower to the growing capacities of the sold units. In addition, Mitsubishi Electric mans its service hotline during the week until 8 pm and on Saturday even until 4 pm. “The better the service, the more satisfied the customer. And satisfied customers are loyal customers, as one can see from K-L Präzision,” Neuendorf affirms, bringing his constructive consultation with the customer to an end with a friendly smile.

K-L Präzision Falk Lange GmbH

Lutz-Roger Neuendorf, responsible Sales Manager: “I’ve been serving Mr Lange since he started his own business and am full of respect for how K-L Präzision has developed. This remarkable company has become established on a firm foundation and with a lot of hard work and technical expertise. Our contribution to this long-standing partnership is our support for K-L Präzision with suitable equipment and technologies in the EDM sector. I’ve always found this extremely harmonious business relationship to be down-to-earth and professional and also enjoyable.”

Name and place of company:

K-L Präzision Falk Lange GmbH

Germany

Founding year:

1998

Managing director:

Falk Lange

Number of employees:

9

Core business:

Everything from tool- and mouldmaking and precision part fabrication to small machine manufacture

K-L Präzision Falk Lange GmbH

Grünland 4

52385 Nideggen-Schmidt, Germany

Tel +49 (0) 2474 99779-0

Fax +49 (0) 2474 99779-29

falk-lange@online.de

www.k-l-praezision.de

We’re a company that operates on the principle of “A rolling stone gathers no moss”.

The principle of never resting on our laurels, but always staying one step ahead.

As a high-tech company that sets trends in the region.

Building up K-L Präzision Falk Lange with support from my family and my reliable workforce.

Hard work and honesty.

Managing Director and owner

K-L Präzision Falk Lange GmbH

Falk Lange

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com