Complex stamping, cutting and follow-on composite tools plus automation processes for the machining of sheet and plate are the specialities of mödinger & hänle GmbH Automatisierungstechnik in Günzburg, Germany. 50 employees, 9 of them design engineers, devise the progressive and often unique tool solutions for customers in the automotive and capital goods industry. So that mödinger & hänle can sustain the demanded standard of quality, which has been constantly rising since the firm’s establishment in 1988, an FA30-S Advance V from Mitsubishi Electric was purchased in November 2009 – for better machining results in the first processing step.

mödinger & hänle engages in the fabrication of novel tools. The demanded quality and precision are achieved with hypermodern wire erosion.

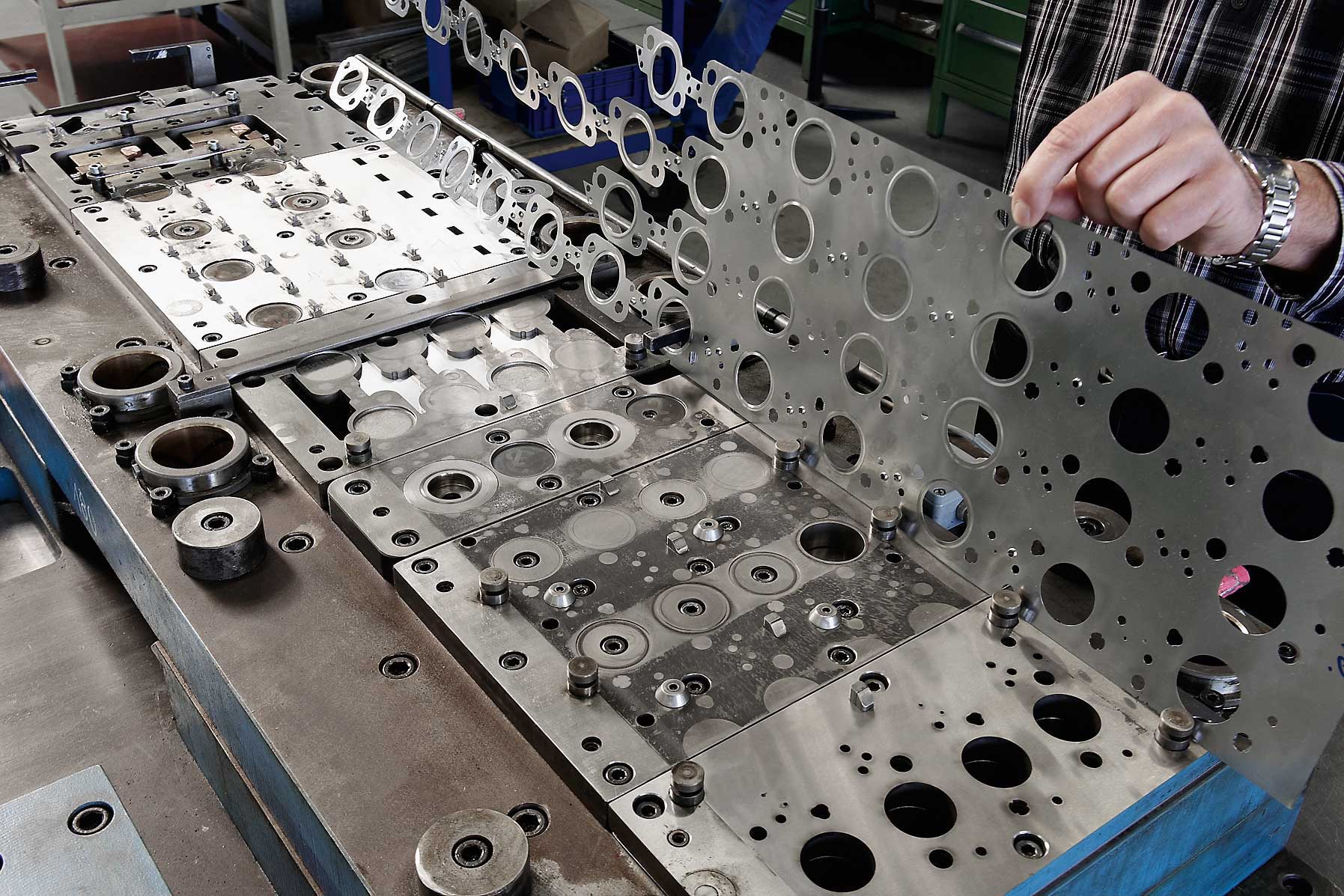

“It’s the unconventional tools that enable us to demonstrate to our customers that mödinger & hänle is a master of innovative solutions,” says Hermann Mödinger, managing director of the company. The graduate engineer has plenty of evidence to substantiate his claim. For the automotive industry, the company produces automated tools that are used in the manufacture of exhaust manifold seals, for example. The ingenious feature of these systems

is that two 0.2 mm thick sheets are cut, stamped and welded together inside the tool. “We are the first to have brought such a process to fruition,” says Hermann Mödinger.

We have the machine running around the clock – mostly unmanned – and make use of text message reporting.

It’s products like this tool that kept the mödinger & hänle order books full even during the global economic crisis. Hermann Mödinger has the reason: “These are niche products for which there is always demand. Per year, we develop about 150 new tools for our customers.” The high stands of quality and precision call not only for the expertise of the design engineers, but also for suitable production equipment. This is where wire erosion comes into play, as Herman Mödinger explains with reference to these seals: “The extremely thin sheet has to be very precisely cut. This is only possible with an equally precise tool, because we have such a narrow cutting groove.” The production of such tools is only feasible with the help of a wire EDM machine, he adds.

When mödinger & hänle purchased a new wire EDM machine for capacity reasons in November 2009, their tough requirement profile became the yardstick for comparison of the various offers. “A comparison of the machine quotations quickly showed that the FA30-S Advance V from Mitsubishi Electric fully satisfied our expectations, and the price/performance ratio couldn’t be better either,” says Berthold Sauter, senior craftsman in tooling, reviewing the relatively quick purchase process. The experts from mödinger & hänle were already impressed by the technical data. The large machining range of 1300 x 1000 x 405 mm provides sufficient space for generously dimensioned tool components, and the 0.2 mm wire delivers the precise cuts.

This tool cuts and stamps extra-thin sheet to produce seals for the engine compartment. Two sheets are welded together within the tool. The process is unparalleled worldwide.

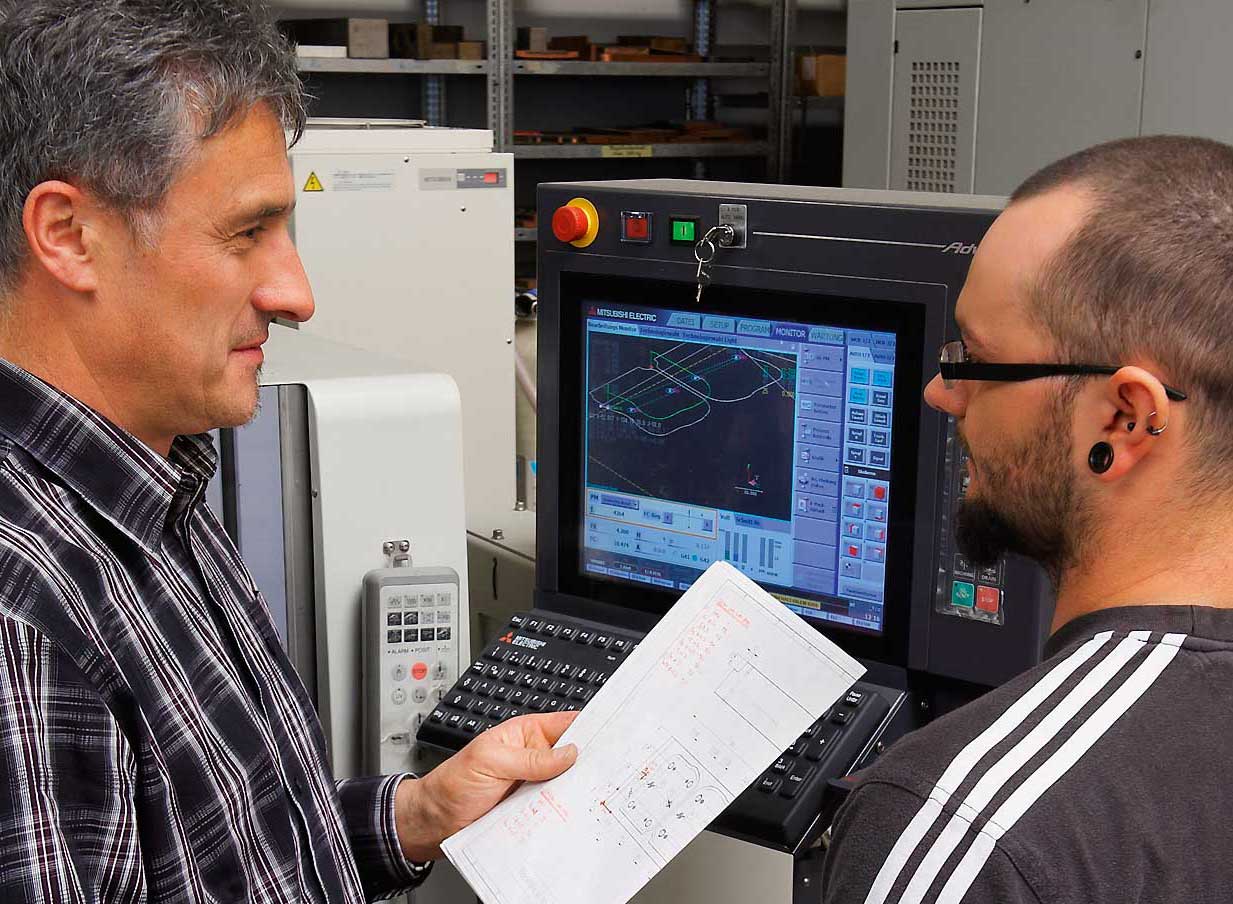

The changeover to a new control system was quickly accomplished by the wire eroders at mödinger & hänle. After two employees had attended the course given by Mitsubishi Electric, the FA30-S Advance V was fully ready for operation. In the programming sector, nothing has changed, Berthold Sauter tells us: “We are still supplied with the drawings and do the programming at the PC. A post-processor adapts everything so that the Mitsubishi Electric machine can process the program.” mödinger & hänle now fully exploits the scope offered by the machine, and this finds expression in longer machining times: “We have the machine running around the clock – mostly unmanned – and make use of text message reporting,” says Berthold Sauter, explaining the procedure. An employee is on standby on his days off to intervene if necessary.

Berthold Sauter, senior craftsman in tooling, and Tobias Meyer, eroder, planning the current component.

By investing in the high-performance wire EDM machine from Mitsubishi Electric, mödinger & hänle has paved the way for the development and fabrication of further high-grade and innovative tools, Hermann Mödinger believes. “Our technological capability has to be equal to our team’s energy

and innovative capacity – and the FA30-S Advance V fills the bill in every respect.” However, it is not only the company that benefits from advanced technology, the managing director adds: “We don’t work for ourselves but for our customers. Each job is only ever completed when the customer is satisfied.” This corporate philosophy also explains the close cooperation with each customer: “This is one of the reasons why we’re capable of creating such innovative tools.”

Graduate engineer Hermann Mödinger (right) founded the company in 1988. Berthold Sauter, senior craftsman in tooling, has been in charge of the EDM department for many years.

Success proves Hermann Mödinger right. In view of the full order books, he has every reason to look ahead with optimism. He aims to stick to the present strategy and tailor it even more closely to the customer: “We’ve intensified this policy in recent years and will seek even closer contacts with the customer in order to further enhance the quality of our products.”

Name and place of business:

mödinger & hänle GmbH Automatisierungstechnik

Germany

Founding year:

1988

Number of employees:

50

Managing director:

Hermann Mödinger, graduate engineer

Core business:

Stamping, cutting and follow-on composite tools

mödinger & hänle GmbH Automatisierungstechnik

Augsburger Strasse 50

89312 Günzburg

Germany

Tel: +49 (0) 82 21 / 20 45

Fax: +49 (0) 82 21 / 20 45-19

info @ moedinger-haenle.com

www.moedinger-haenle.de

We produce innovative and high-calibre stamping, cutting and follow-on composite tools.

With good ideas.

Our motivation is to develop new and improved tools that work well and satisfy the customer.

We’re more consistent in our response to customer needs.

We want to uphold our present high standards and, if possible, build on them. We also aim to expand our automotive activities and link toolmaking even more closely with automation.

The many years of cooperation with our biggest customer Schmitz-Cargobull where we have installed, among other things, a complete sheet/plate machining centre with presses and tools.

Going for a leisurely drive.

An open and honest approach is just as important to me as a high degree of activity and initiative.

There’s been lots of good advice.

We fabricate tools that automatically convert raw material into parts used in a wide range of sectors.

Managing director

mödinger & hänle GmbH Automatisierungstechnik

Hermann Mödinger

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com