The reason for Kuhn’s choice of a Mitsubishi Electric machine was the good reputation of the company’s technical service.

Whenever particularly complex tools have to be machined, the workforce of K+S GmbH Modell- und Formenbau is in its element. The reason for this is its vast expertise in terms of machining methods and materials and also in terms of modern machine tools. The latest addition to the machine park is the Mitsubishi Electric FA50-S Advance V that is now opening up new opportunities.

When you enter the premises of K+S Modell- und Formenbau, you can’t help being surprised. In the foyer of the modern industrial building stands a huge, round bathtub from Hansgrohe that you’re normally more likely to find in glossy brochures. Rudolf Kuhn, Managing Director of the company in Waghäusel, Baden, makes such flights of designer fantasy come true with the aid of down-to-earth machining methods. Previously, bathtubs of this size were simplytoo heavy (up to 600 kg) and didn’t sell well. The example in the foyer, on the other hand, weighs only 75 kg and sales have taken off. “We have always been in demand as a problem-solver. Having made little headway with conventional mineral casting methods, it only took us a year to come up with a special machining process, the tools and the associated surface treatment for this exclusive bathtub,” says Kuhn describing the process. However, the production of bathtubs and series of fittings is just one source of work of the medium-size enterprise. For over 20 years, it has been a dependable supplier to leading companies in the automotive component supply, aerospace and sanitary ware industry. The production range extends from CAD and NC programming via the production of a huge diversity of production tools and fixtures through to the production of prototypes and small and medium series using a variety of fabrication methods.

A factor for success has been the development of production methods that at first glance are not so easy to realise. Kuhn’s team concentrates on the development of tools and fixtures for prototypes, and pilot-series and series parts such as battery covers for electric vehicles, inner linings of aircraft, cabin roofs for combine harvesters and tractors, vehicle interior parts and engine compartment shielding.

The company first ventured into EDM four years ago with the development of a stamping press for the production of heat shields for underbody panels in cars. All vehicles have a variety of plastic trim linings that are reinforced in places with preshaped metal panels. This serves as a heat shield or is used for noise damping. “Technically speaking, these panels are very difficult to stamp, as they are very thin – usually 0.1 to 0.2 mm thick,” Kuhn explains. The production of a suitable press posed a special challenge. The rule of thumb in stamping is that the cut should not be wider than 10 per cent of the material’s thickness. This means a cut 1 to 2 hundreds of a millimetre wide. “First we tried milling the press. But as the material is hardened, this wasn’t so easy,” Kuhn recalls. To achieve the necessary accuracy, the presses were reluctantly sent to an EDM jobshop. This was an unaccustomed situation for the company, as it prefers to handle all the tasks itself.

As orders continued to grow, Kuhn was faced with a decision: “Should we invest in another 5-axis milling machine or in an EDM?” The decision went in favour of a wire-cut erosion machine, even though – as Kuhn frankly admits – they hadn’t had much experience with this technology. “It was ultimately our experience with the EDM jobshop that tipped the scales,” says Kuhn explaining his introduction of this form of machining. It had been difficult to find an EDM specialist who could meet the company’s quality standards and also operated machines with large workspaces. “In Germany we found just one – for milling work, there’s plenty of capacity, however,” says Kuhn.

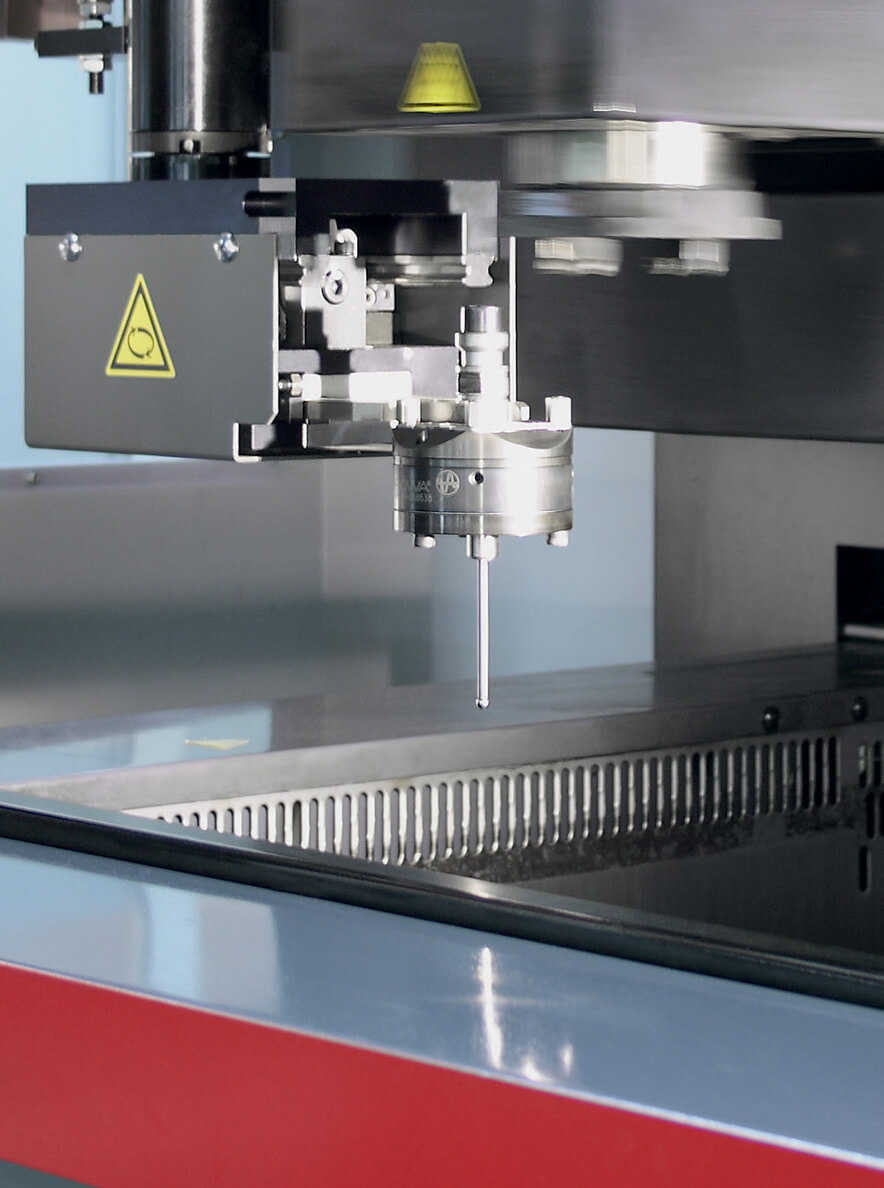

Kuhn then visited the EMO to find out about EDMs and chose the Mitsubishi Electric FA50-S Advance V. The reasons for this were not only the technology, but also the good reputation of the company’s technical service. “For me, this is almost more important than the running costs,” says Kuhn, who almost regrets not having put Mitsubishi Electric to the test in this area yet because he simply hasn’t needed to. Another positive feature is that attractive financing options are available from the KfW Bank because the FA50-S Advance V is so much more energy-efficient than its predecessor. The only drawback was having to wait six months for delivery even though they had already received their first order. The wait was bridged by Mitsubishi Electric with the provision of a slightly smaller replacement machine for this interim phase. The transition period was exploited for familiarising two employees. “The training was outstanding, so we were able to get down to work straightaway,” Kuhn explains. It was the experience during this period that vindicated their decision in favour of Mitsubishi Electric. The very first job involved a workpiece whose size pushed the smaller replacement machine to its limits. “I’d rather invest in a size bigger so I’m equipped for all eventualities than turn down a job,” Kuhn insists. With a machining range of 1,300 x 1,000 x 400 mm and maximum workpiece dimensions of 2,000 x 1,700 x 390 mm, the FA50-S Advance V is one of the biggest wire-cut EDMs currently on the market. The new machine was finally supplied after six months and installed on site within a week. The Mitsubishi Electric FA50-S Advance V wire erosion machine was ready to go. The device for large spools of wire and a telephone module were added as special equipment so that the responsible employee can be notified of a machine stoppage by text message. The machine has been in operation for a wide range of assignments since May 2014.

The new EDM is mainly used for the machining of stamping presses of high-alloy tool steel and has meanwhile almost replaced milling for this application. “We’re now able to produce the die geometries of the stamping presses in the µm range and with superlative surface finishes ourselves,” says Kuhn outlining the main task. “The dies cut on the machine are a 100 per cent fit. After milling, we’d often found during assembly that certain areas didn’t fit and had to be reworked.” The EDM is also used for producing test tools for these panels. “There really isn’t any good simulation tool for forming tests, particularly if the panels are domed and perforated to reduce noise. Any of these holes can later tear,” Kuhn stresses. Hot-sealing tools to connect the aluminium shielding panels to the plastic are already being produced on the new machine.

Kuhn is convinced that there is still plenty of unexplored potential in the new machine. In addition to the production of stamping tools, the company has now used the FA50-S Advance V for developing an RTM (Resin Transfer Moulding) mould which will later be instrumental in the production of carbon-fibre aircraft wheel rims. Another application is diamond blades for cutting concrete on which the teeth have broken off. To weld on new teeth, extremely flat surfaces are required – a task executed to perfection by the new FA50-S. “We can see on a daily basis the new tasks that we can handle with the machine. Jobs that used to be performed on the milling machine are now executed better on the EDM,” says a delighted Kuhn. With this experience under his belt, the company can now itself offer jobshop services. What he has discovered is that, with its own machine on its premises, he now has a better feel for the machining steps. Kuhn is now amazed that he used to mill the workpieces three-dimensionally before sending them to the EDM jobshop. After machining the same workpiece on his own machine, it quickly became obvious that it makes more sense to first wire-cut the material flat and then to mill it. “When you’ve got your own machine, you’re more flexible. You can modify the machining procedure and develop many new ideas – and that’s the recipe for success for a small business,” says Kuhn in conclusion.

The EA28-V Advance can automatically replace its starting electrode with up to 19 other electrodes and thus also operate unmanned.

According to Sogameca, a high-precision erosion machine is not enough. You need a skilled operator as well.

During his tour of the business, Lenoir stops at a FA30-S Advance, which is equipped as standard with a high-speed generator. The erosion machine cuts the material with 0.25 mm diameter wire and achieves parallelism and precision of less than 2 µm and surface quality of 0.4 to 0.8 µm Ra. “Here again, it’s all about speed,” says Lenoir, stressing an attribute shared with motor racing. “This is where we can really put our foot down. The operator can set up the machine more easily and faster because the door to the tank can be lowered and he has unrestricted access to the work space.

“The machines are simple to operate and offer easy access.”

In view of our workpieces with footprints ranging from 400 x 220 to 1300 x 1000 mm, we wouldn’t want to be without this feature.”

As can be seen from the example of the retractable door, Mitsubishi Electric takes account of the factor of time in the development of its EDM machines. This also applies to the automatic wire threader of the FA30-S Advance. Lenoir opens the machine’s side door and points to the 20 kilo wire spool. “With this in reserve and the automatic threader, which can be relied on to do its job in only 10 seconds, we can run the machines unmanned at night and at the weekends.”

Sogameca produces most parts by get- ting the desired workpiece into shape initially with die sinking and then cutting the material with wire EDM.

“A high-precision erosion machine is not enough. You need a skilled operator as well. And the service you provide also has to be good.”

On a wall board in the conference room, Lenoir sketches a die sinking process to illustrate what moved Sogameca to invest in two machines using different processes. “We produce most parts by getting the desired workpiece into shape initially with die sinking and then cutting the material with wire EDM. The EA28-V Advance can automatically replace its starting electrode with up to 19 other electrodes and thus also operate unmanned.”

Electrode replacement is indispensable for two reasons. Firstly, because the eroded surface of the workpiece has to be finished with a fresh electrode after the first machining step; and secondly, because of the wear that occurs on the electrode. Replacement is also executed smoothly in unmanned operation. As an electrode has a known service life, it is possible to program the replacement times. The user monitors these phases with the aid of Mitsubishi Electric’s intelligent remote contact function that enables the machines to send test messages to selected phone numbers. It is ultimately in these ghost assignments that the company builds up a strong lead, to borrow a phrase from motor racing.

Patrice Jacquelin, Production Manager at Sogameca, calls up a page of test results on his laptop. “The EDM machines from Mitsubishi Electric came off better than the machines from two rival manufacturers, as they meet our expectations in terms of quality, reproducibility and price/performance ratio. The precision with which the workpiece can be positioned on the clamping table also satisfies our requirements. In addition to all this, the machines are simple to operate and offer easy access.” The employees therefore soon got the hang of the control and user interface. The CAD data for wire EDM are produced by the company’s own design office. The operators then transfer the data from the company network straight onto the control of the FA30-S Advance. For the EA28-V Advance, the employee generates the CAD data himself.

Lionel Bézannier sees the machines as only one of the prerequisites for immaculate production results. “A high-precision erosion machine is not enough. You need a skilled operator as well. And the service you provide also has to be good.” Bézannier can rely on this, because when the machine comes off the production circuit for a ‘pit stop’, the service from Delta Machines fully meets the operator’s needs. This also applies to operator training, which is also performed by Delta Machines.

Serge Hessemans, Sogameca President, opens up a folder and shows us a document. “As soon as a job is completed, we ask the customer to rate his satisfaction. We’ve produced this document for this and appointed a quality officer.” The company evaluates each document and takes any appropriate remedial action. Ultimately, it’s a question of producing high-quality turnkey machines with a fully integrated strategy and getting them up and running smoothly. And, as in the 24 Hours of Le Mans, as quickly as possible.

K+S GmbH

Modell-und Formenbau

Industriestrasse 18

68753 Waghäusel, Germany

Tel +49 7254 95 882-0

Fax +49 7254 95 882-90

info@ks-modell-formenbau.de

www.ks-modell-formenbau.de

Managing Director

Rudolf Kuhn

Core business

Design and manufacture of a huge diversity of production tools and fixtures through to the production of prototypes and small and medium series using a variety of fabrication methods

Employees

15

Founding year

1990

Gérôme Lenoir: We’re on the fast track for high precision.

Lionel Bézannier: During a holiday job in a foundry.

Lionel Bézannier: Inquiries from customers.

Lionel Bézannier: With the aid of our customer satisfaction questionnaire, we give greater attention to new technologies for the customer’s benefit. And we’ve taken on an employee who’s concerned solely with research and development.

Lionel Bézannier: We’d like to make greater inroads into certain markets – in the health sector, food industry and aeronautics, for instance.

Gérôme Lenoir: With sport.

Lionel Bézannier: Honesty and professionalism.

Sogameca

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com