Costs 45 per cent higher than EDM.

The question of the best manufacturing technology has been a matter of contentious debate for generations, in manufacturing on all levels, and from the shopfloor to the university chair. There probably never will be a universal answer.

Anyone attentively following the various articles and publications on this subject cannot help but notice a clear trend towards milling. In the field of hard machining in particular, there are repeated reports highlighting the possibility of replacing electrical discharge machining with hard milling. These articles suggest that EDM is on the retreat on the grounds that it doesn’t offer any scope for innovation. The reason for this is without doubt that technological advances extending to new spectacular materials and workpieces in the conventional machining sector are more memorable than incremental improvements in performance in the EDM sector.

Unlike conventional machining, the limits to the use of EDM are set by the physical properties of the workpiece and by the demanded level of productivity. When it comes to volume per unit of time, conventional machining is vastly superior to EDM. If, however, complex geometries are involved, EDM has more to offer. Deep holes, thin and deep slits and sharp edges are the domain of EDM. Thanks to the latest cutting materials and coatings, the workpiece is becoming an increasingly important factor in conventional machining as well. But there is no let-up in development in EDM, with advanced generator technologies and efficient electrode materials with optimized parameters achieving significantly improved erosion rates and better surface quality at the same time. Major progress has been made in the last few years, particularly in wire erosion.

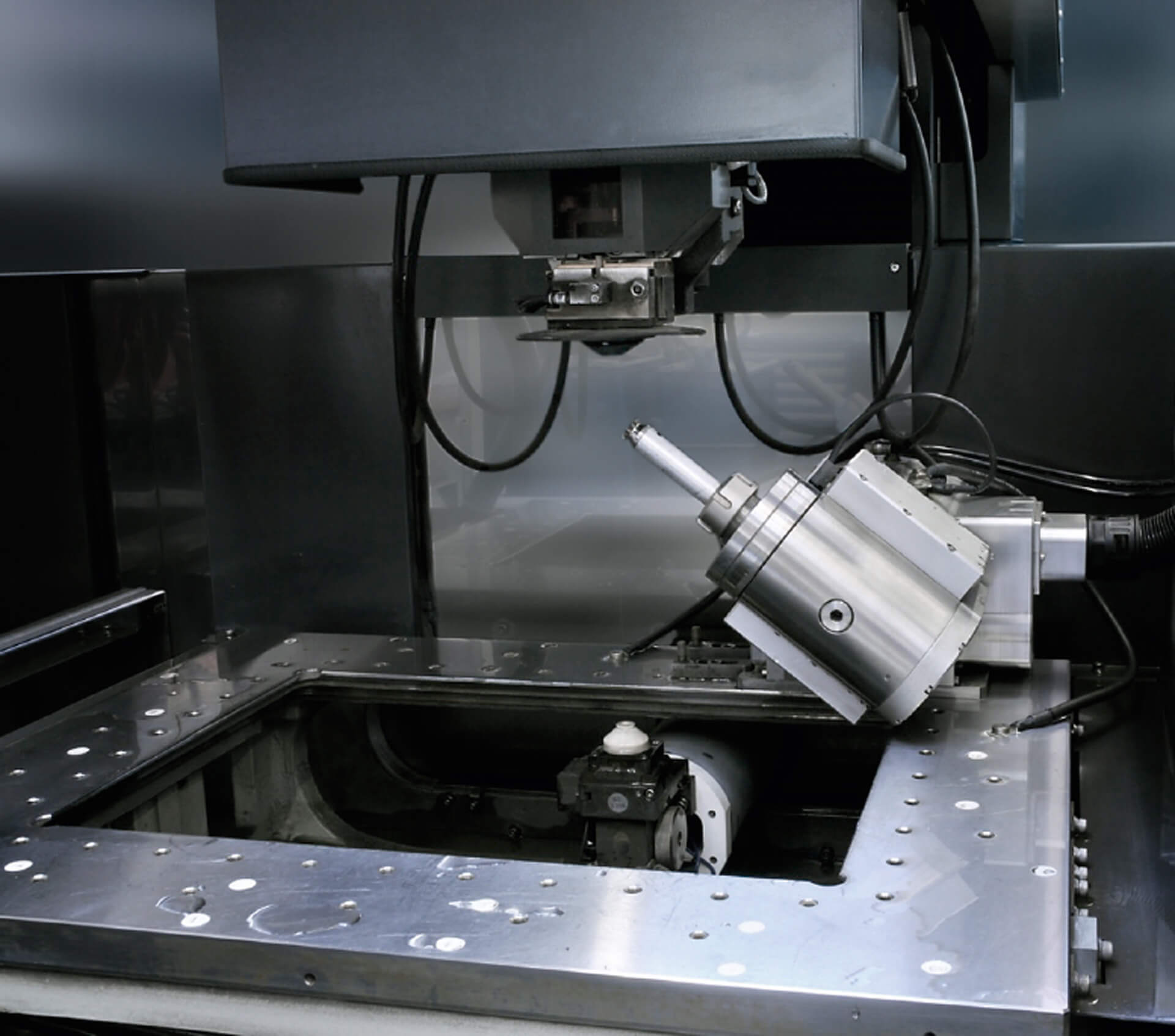

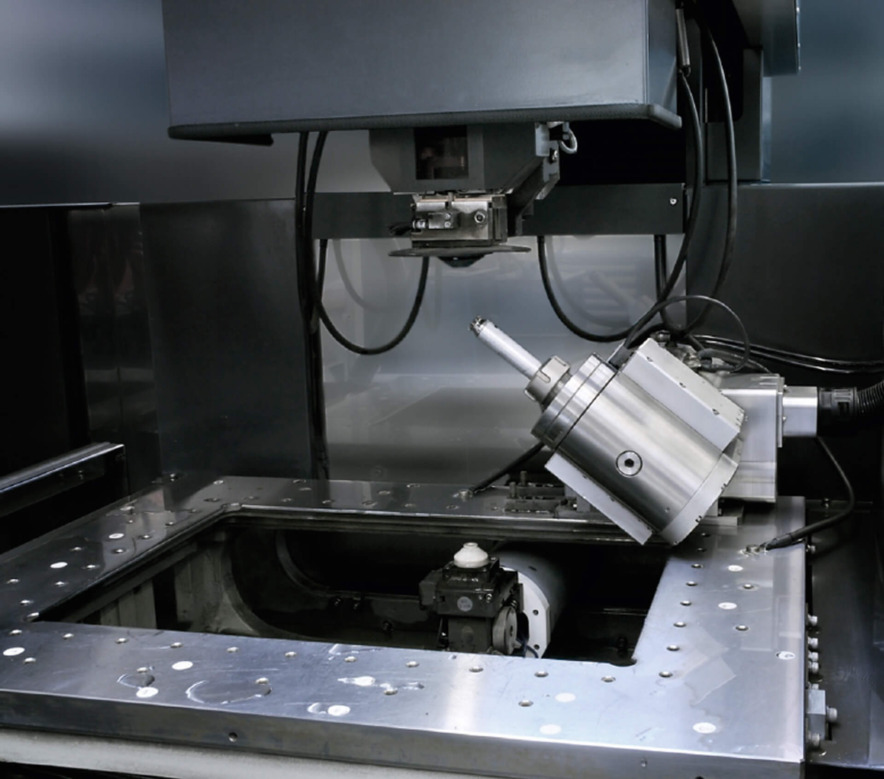

The Institute of Materials and Processes (IMP) of Karlsruhe University of Applied Sciences engages in the ongoing further development of manufacturing and production processes. In a research project funded by the German Ministry of Economics and Technology (BMWi), research and development activities are focused on wire erosion. Together with numerous partners in industry, the aim is to adapt wire erosion to highly complex component geometries – while sustaining high productivity. For this, a Mitsubishi FA20-S Advance wire-cut EDM system has been equipped with two extra rotational axes to facilitate the machining of metals in a complexity hitherto unachieved. By contrast with the current procedure, the components no longer have to be reclamped, thus permitting a further improvement in quality. These components are destined ultimately for use in the medical technology sector.

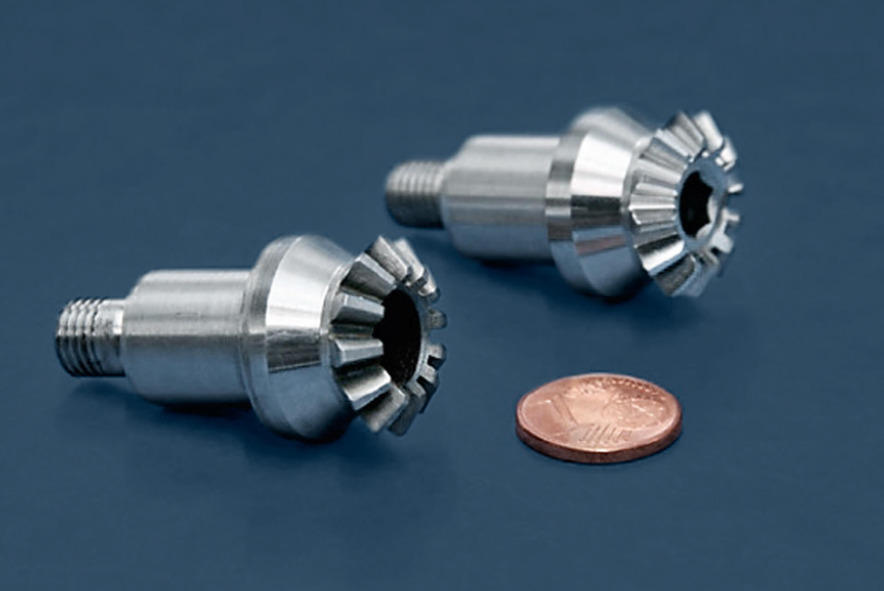

To illustrate the state of performance achieved in the project so far, a sample component, a bevel wheel gear made of steel, was produced at the IMP. The production of individual gears is a key activity in the drive sector in mechanical and plant engineering. The machining of individually adapted bevel wheels represents a special challenge in this connection. With the aid of this sample geometry, the IMP compared the production processes of high-speed cutting (HSC) and wire-cut EDM.

The two processes were demonstrated with modern machines; wire-cut EDM, as described, with the use of extra axes. The workpiece selected was a bevel wheel with a pitch circle diameter of 18 mm and 12 teeth. The dimensions of the bevel wheel make it relatively easy to produce, both on the milling machine and the wire erosion machine. The blank of 16MnCr5 (Mat. No. 1.7131) was prefabricated on a lathe.

Mitsubishi FA20-S Advance with rotational and swivel axes.

Before: Blank component.

After: finished component.

Milling was divided into roughing and smoothing processes. Milling tools with diameters of 0.8 and 1.0 mm were employed. Milling was performed with five axes.

For wire-cut EDM, an FA20-S Advance from Mitsubishi Electric was employed with a rotary/swivel table from JauchSchmider. This makes it possible to produce virtually any contour described by the straight line of the erosion wire. By using the rotational and swivel axes, further process improvements were realized with constant flushing conditions. These are the result of the vertical position of the wire during machining, accompanied by higher processing speed and precision. It is also possible to cut larger conical angles, even on workpieces of low height. A big advantage of the rotational and swivel axes is the reduction in reclamping frequency for the production of components with complex contours.

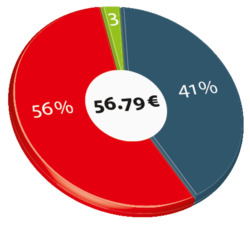

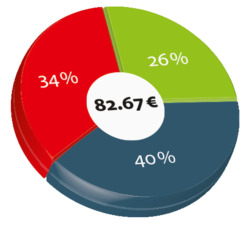

The criterion for the comparison of the techniques was cost-effectiveness. This encompasses both labour costs and machine and tool costs. Since production time has a direct effect on component cost, it is a crucial factor in this comparison. Also considered are the cost of tooling in the form of erosion wire and milling tools. The pie charts (below) show the breakdown of costs for the machining of the bevel wheel gear by HSC and wire-cut EDM.

Wire-cut EDM

HSC

Although machining by erosion took longer (34 minutes) than milling (30 minutes), the erosion process is clearly less expensive. This is due to the lower cost of machine purchase and the lower cost of consumables (wire) compared to the much higher equivalent figures for milling. Cost savings of about 30 per cent were facilitated by the use of additional axes on the wire-cut EDM machine for this sample geometry. The attainable surface quality and tolerances are the same as those for milling.

The tests have shown that wire-cut EDM has huge potential. In this example, it was possible to machine the gear at much lower cost. Highly intricate components ought therefore to be machined in future by wire erosion. It offers engineers in development departments totally new scope in component design. The productivity of wire erosion can also be significantly increased by reducing the frequency of reclamping. These issues will play a prominent role in the future of manufacturing engineering.

The Institute of Materials and Processes (IMP) at Karlsruhe University of Applied Sciences concentrates on the development of new modelling and simulation techniques for virtual design, on the optimization of processes in production and manufacturing and on applications in fluid dynamics. The three departments are organized in a matrix form and are supported by cross-sectional technologies in the chararacterization of materials.

Materials modelling, simulation of microstructure formations in multi-phase and polycrystalline grain structures, heat and mass diffusion in multi-component systems, elasticity, plasticity and magnetism

The production and manufacture department is concerned with the optimization and further development of conventional and nonconventional machining in production processes and particularly milling, turning, lasercutting and electrical discharge machining.

Focuses

The development and research activities take place in close cooperation with German and international industrial partners, mainly small and mediumsize enterprises. With its state-of-the-art machine and equipment park, it yields results relevant to modern processes and ensures a high quality of teaching.

Karlsruhe University of Applied Sciences

Institute of Materials and Processes (IMP)

Moltkestrasse 30

76133 Karlsruhe

Germany

Tel: +49 (0) 7 21 / 9 25-2395

Fax: +49 (0) 7 21 / 9 25-2348

sekretariat.imp@hs-karlsruhe.de

The Institute of Materials and Processes team – production and manufacture department

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com