The workshop of the Institute of Experimental Physics in Innsbruck is constantly being put to the test. For this is where individual items of highly complex laboratory equipment are designed and assembled that quantum physicists want to use in physics experiments to verify their theories. For this purpose, a large number of small and complex components made of exotic materials have to be fabricated in the workshop with high precision. In this endeavour, an MV2400R Connect wire EDM system from Mitsubishi Electric is proving particularly useful.

Machining the impossible.

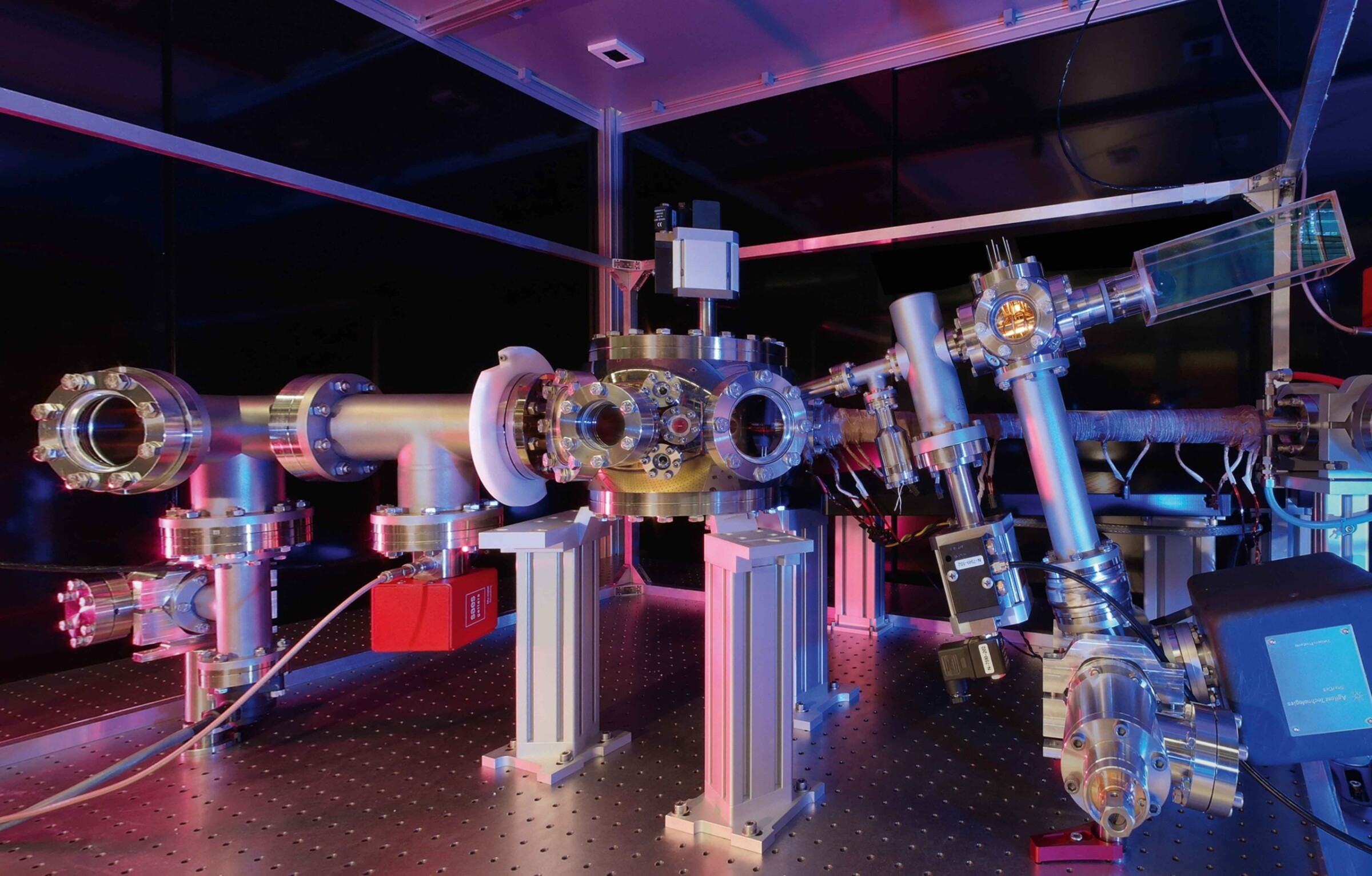

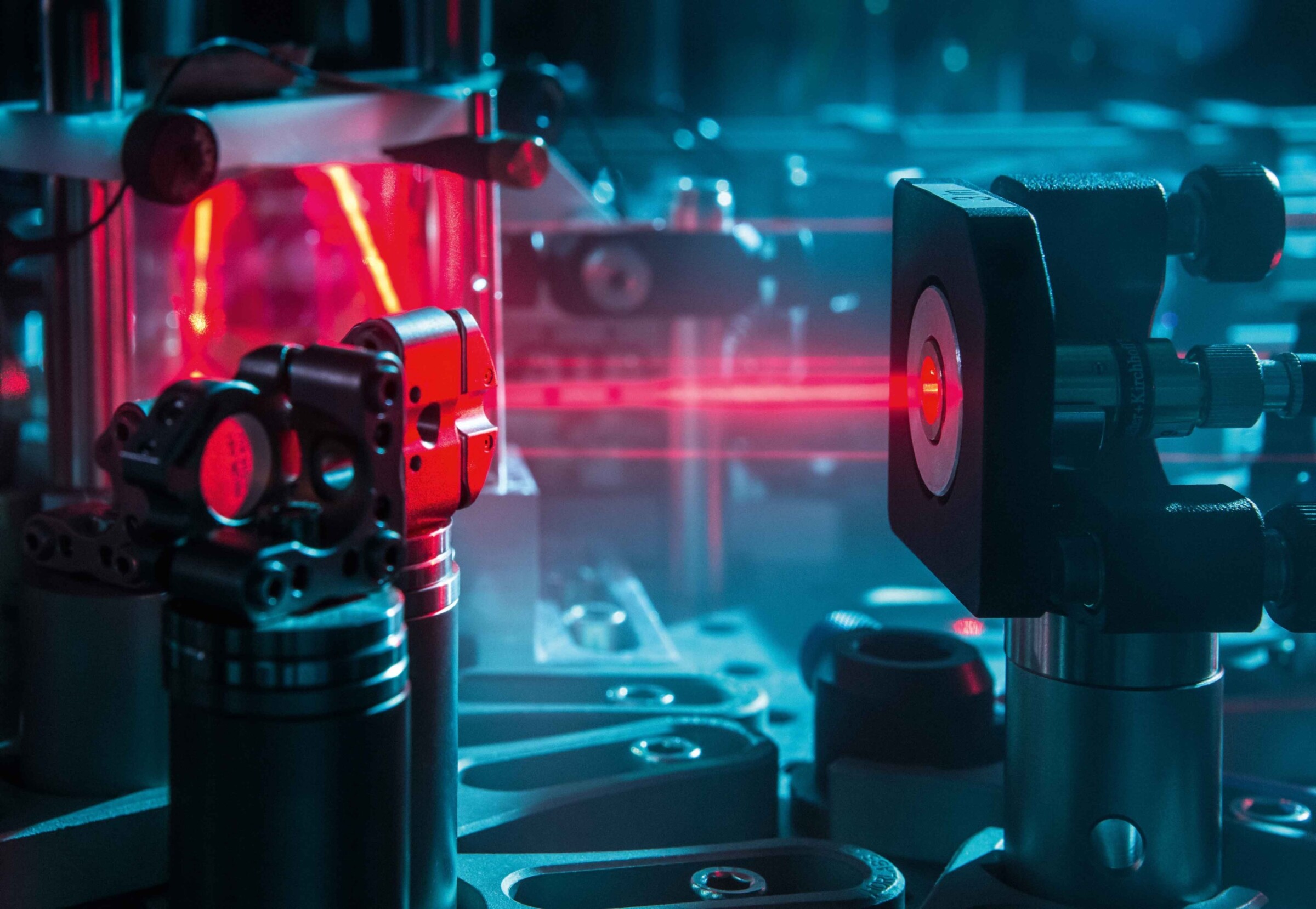

Special skills are demanded of the staff of the university workshop at the Institute of Experimental Physics in Innsbruck. For it is their job to design and build the best-possible laboratory equipment for the experiments that have been newly conceived. In Innsbruck specifically, this means elaborate apparatus – such as vacuum chambers, optical systems, measuring devices with high-resolution optics and other, highly sensitive sensors. To this end, housings, carrier elements, flaps and sealing discs, cooling bodies and tubes have to be produced, most of them made of exotic materials that are difficult to machine, such as titanium, titanium aluminide, corrosion-resistant steel alloys, and copper and aluminium alloys. As Armin Sailer, head of the mechanical workshop, reports, his employees use all the usual metalworking processes, ranging from filing and sawing to drilling, turning, milling, grinding and wire cutting. He also proudly mentions that his workshop is often even capable of machining the impossible with ingenuity and a great deal of skill.

According to Sailer, wire EDM is indispensable for hard materials that are difficult to machine and for the machining of tiny geometries. Milling simply takes too long and also runs up against its physical limits. This applies in particular to the production of narrow grooves and other openings with sharp corners or radii of less than a millimetre. For several years, he and his colleagues used to get a neighbouring institute to machine workpieces for them on its wire EDM system. But that proved to be inflexible and often held up the entire production process and delayed the completion of the required laboratory equipment. In addition, the working range of the other institute’s wire EDM machine was too small for an increasing number of workpieces. This is why, after almost five years of planning, the Institute of Experimental Physics invested in an MV2400R Connect wire EDM system from Mitsubishi Electric in 2018. An essential factor in the choice of this machine over a number of rival products was the extremely attractive ratio of investment cost to the machine’s range of functions.

Convenient operation with integrated axis crash protection on the MV2400R Connect.

As Sailer confirms, this choice has been fully vindicated. In his view, the good training, detailed consultation and expert after-sales service of the regional, exclusive specialist dealer Büll & Strunz contributed to this. As a further important factor he mentions the modern user interface of the MV2400R Connect controller. With its structure and pictograms similar to the apps on smartphones commonly used today, it is easy to grasp, especially for young technicians. In addition, the CNC control on the wire EDM machine can be operated and programmed via a touch screen. Thus he and his employees learned within a short time how to operate the wire EDM machine properly and productively, despite having had no previous training or experience of wire EDM. As Sailer further reports, the drawings for all workpieces are first produced on a Solidworks 3D CAD system in the institute’s workshop. The data are then transferred on data carriers to the CNC control where the machine parameters are set and the machining processes are programmed by the operator concerned.

Armin Sailer, head of the mechanical workshop

More than anything we were thoroughly impressed by the accuracy and surface quality of wire cutting on the MV2400R Connect.

On the basis of initial experience in the course of a year, the MV2400R Connect at the Institute of Experimental Physics has even exceeded expectations. Sailer: “More than anything we were thoroughly impressed by the accuracy and surface quality of wire cutting on the MV2400R Connect. For example, when wire eroding a tapered opening over 250 mm long, we achieve almost shiny, polished surfaces in the finishing process.” In addition, the cutting lines are exactly straight over the entire length to accuracies of less than 0.01 mm. When cutting even exotic materials such as hard and durable titanium aluminide, Sailer has always achieved impeccable results with the wire supplied by Mitsubishi Electric as an original accessory. He prefers uncoated wires as these in his view are particularly strong and heavy-duty. Automatic wire threading also works extremely reliably, not only with these wires. “We have been highly impressed by the threader. We can therefore process larger workpieces with a large number of cuts overnight without supervision. In doing so, we can always be sure that we will find the workpiece absolutely correctly and completely machined next morning,” Sailer stresses.

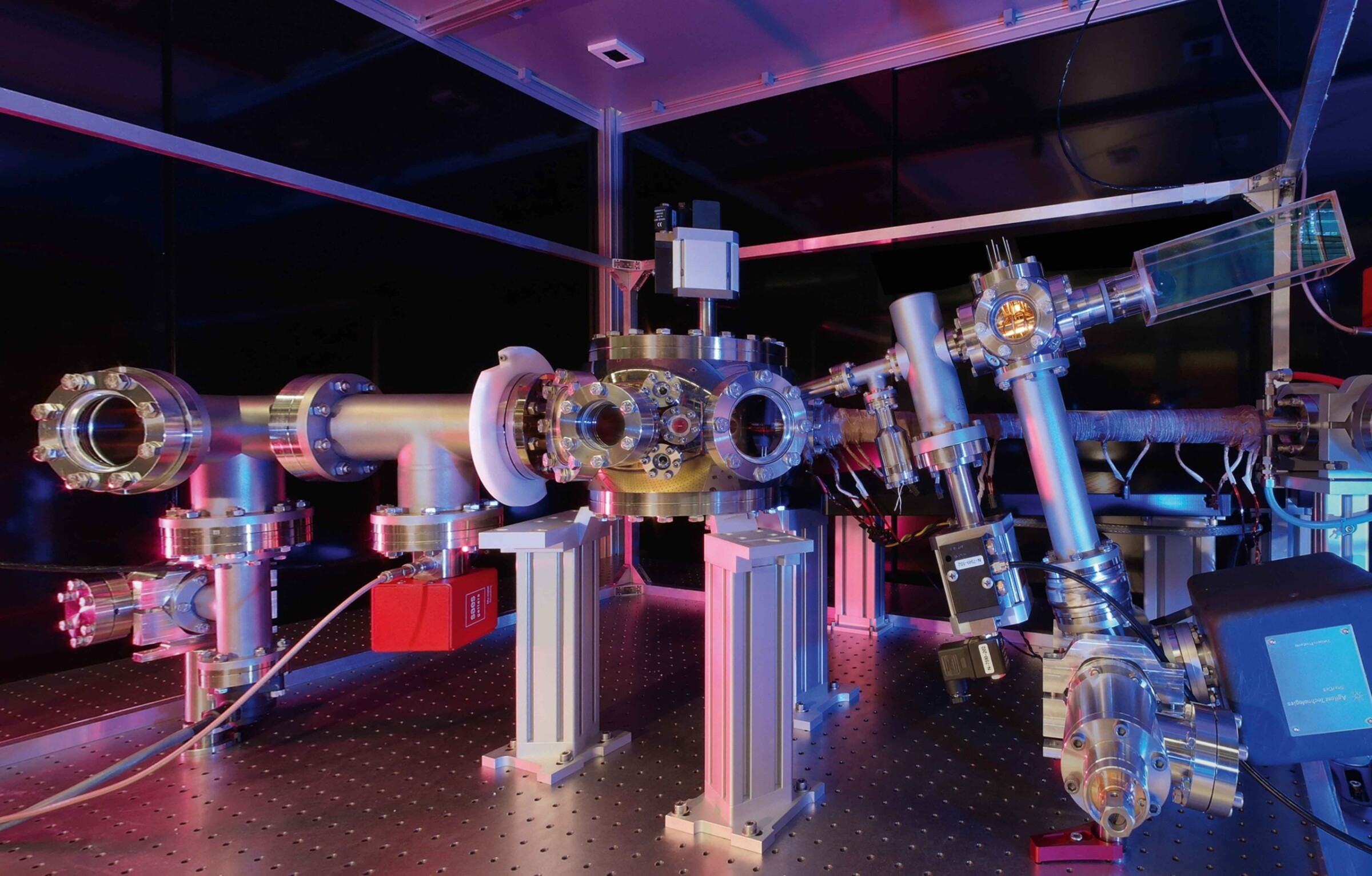

Some of the components eroded are made of high-alloy stainless steels for quantum mechanical experiments.

As a special feature, the MV2400R Connect in the institute workshop in Innsbruck has an NC rotary axis. Sailer explains: “We installed this optional item because we repeatedly have to machine some extremely complicated components. With the NC rotary axis, we are ready for any work that may be required. For example, we have already been able to put the optional equipment to good use several times in the high-precision machining in a single process of, for example, nozzle tubes with fanned grooves distributed evenly and unevenly over the diameter.” The NC rotary axis has a direct measuring system, which is why it works so precisely. The specialists in the workshop for experimental physics benefit from this when machining very small workpieces with a large number of grooves cut with high precision and openings around the workpiece circumference. In addition, they are capable of accurately cutting simultaneously interpolating conical contours and contours otherwise arranged at spatial angles.

Components made of exotic materials.

At the Leopold Franzens University of Innsbruck, the Institute of Experimental Physics is part of the Faculty of Mathematics, Computer Science and Physics. The experimental physics scientists conduct research in the fields of quantum information, spectroscopy, quantum optics, cold atoms, quantum gases, solid state physics, photonics and superconducting quantum circuits. Their research work and findings are recognised worldwide.

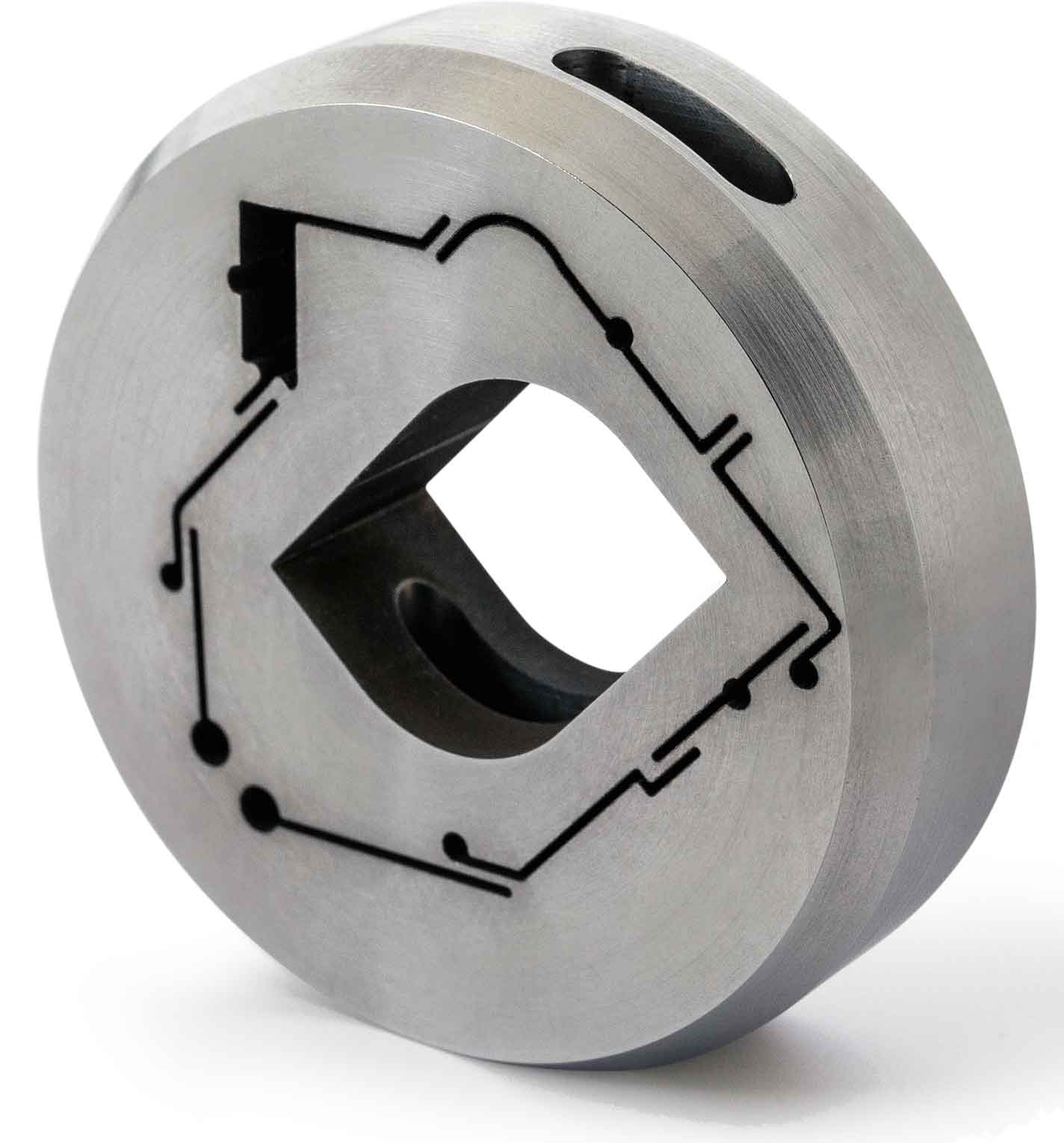

New technologies such as rotary eroding are also used in the workshop of the Institute for Experimental Physics in order to meet the ever tougher requirements in terms of component complexity.

Historically, the institute can be traced back to the year 1742. This was when a collection of physical instruments, the “Armarium”, was founded in Innsbruck. Many valuable devices have been preserved and can be seen today on the Internet in virtual museums. A special item is the astronomical clock that Empress Maria Theresa donated to the institute in 1776.

Exceeding expectations.

Larger workpieces are machined overnight.

In addition to research, the Institute of Experimental Physics is primarily responsible for experimental teaching and for internships in university education leading to BSc, MSc and doctoral degrees. For this purpose, the institute offers a wide range of courses and rooms for lectures and internships. In total, almost 40 top-level professors and internationally recognised scientific staff are active in research and teaching at the institute. They are supported by an equally large number of other scientific staff and about 35 non-scientific employees of the University of Innsbruck.

Name and place of company:

University of Innsbruck, Institute of Experimental Physics

Austria

University employees:

4,825

Founding year of the Department of Experimental Physics:

1742

Core business of the Department of Experimental Physics:

Research in the fields of quantum optics and spectroscopy, ultracold gases and quantum gases, photonics, superconducting circuits and the physics of porous and dense materials

Mechanical workshop employees:

3

Core business of the mechanical workshop:

Design and production of ingenious laboratory equipment for experimental physics and especially for investigating and verifying phenomena in quantum mechanics

University of Innsbruck, Institute of Experimental Physics

Technikerstr. 25/4. OG

6020 Innsbruck

Austria

Tel +43 512 507-52401

Fax +43 512 507-52499

leitung-experimentalphysik@uibk.ac.at

www.uibk.ac.at/exphys

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com