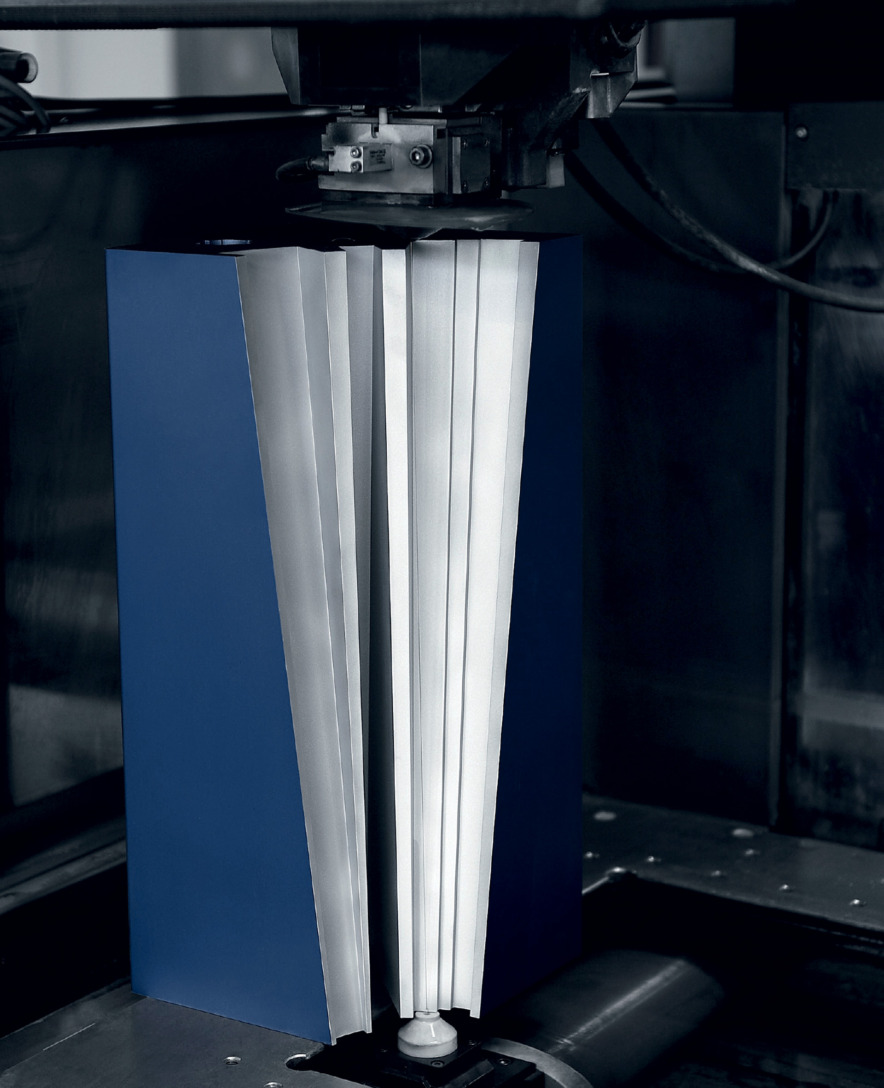

Thanks to an FA20-V Advance with a Z-axis extension, FEZ Mengemann now cuts tall

components – with great precision and high output.

Funken-Erosions-Zentrum Mengemann has its origins in a machining shop founded by Bernd Mengemann in Dresden in 1971. Having worked for State-owned enterprises for many years, the fine mechanical engineer and his brother Rolf were faced in 1990 with the challenge of piloting the firm safely through the initial difficult years after German reunification. The at the time astronomical investment in a new building and machines called for a good deal of staying power. But the effort has paid off. The busy jobshop now supplies high-grade components to customers throughout Germany and abroad.

After German reunification, Bernd Mengemann and his company were confronted like many other firms with the challenge of not only keeping the company afloat, but also of generating new business. “We had hardly any West German currency and our customers had fallen away from one day to the next,” the owner recalls. Bernd Mengemann was one of the first in his region to take the initiative and took out a loan for over a million German marks – a sum that he “could hardly grasp”. All the same, the sum was necessary for investing in the future in good time. Because only with new machines and suitable new premises was it possible to strengthen the company’s position in the long term.

The entrepreneurial responsibility was huge. In return for the government grant, Bernd Mengemann was committed to creating jobs and at the same time keeping the business going – with new customers and continuous production. To avoid the risk of production stoppages, he had the new premises built right next to the old shop. “This took a lot of persuasion, because the policy at the time was to locate businesses like ours exclusively in industrial estates,” Bernd Mengemann recollects.

With the Z-axis extension, FEZ Mengemann cuts workpieces up to 450 mm high.

“We wanted the FA20-S Advance V, of course, to boost our output and capacity. By selecting the ‘column-up’ option, we have been able to considerably extend our range of parts as well.”

When purchasing his machines, there was also another obstacle which the owner is keen to mention: “Mitsubishi Electric was one of the manufacturers banned from supplying goods to East Germany. However, totally incomprehensibly, this ban stayed in force after reunification.” It was not until the end of 1991 that they were able to install the first wire-cut EDM machine from the Japanese maker – a DWC 90C. The model was purchased through cover firms who were allowed to export to the East. “We finally enjoyed the freedom to buy and make what we wanted.” Thanks to higher productivity and increases in capacity, FEZ Mengemann went from strength to strength, thus necessitating further investment in manufacturing depth. “This is important so that we can supply our customers with complex components from a single source,” says Bernd Mengemann, explaining the investment.

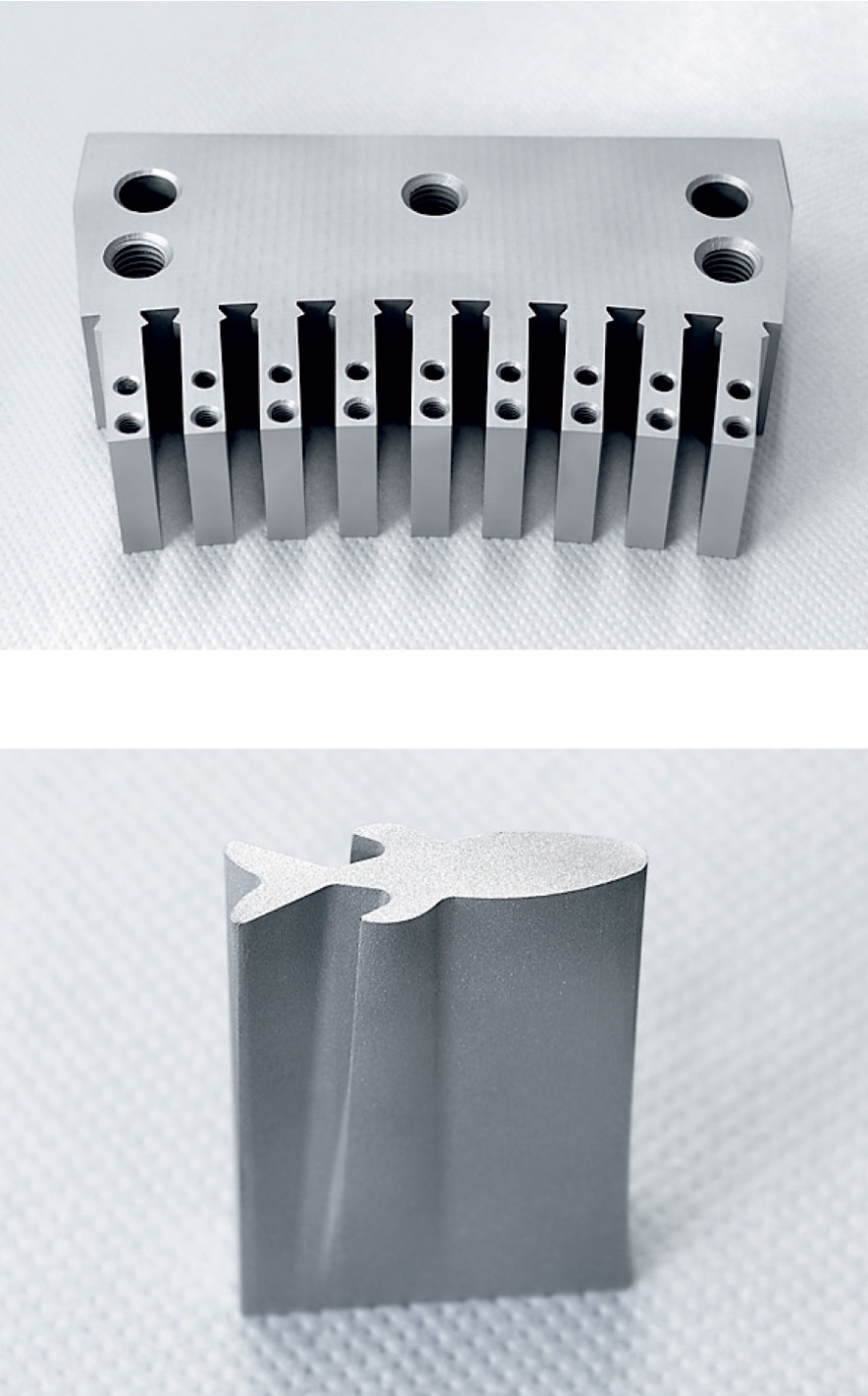

High precision and maximum surface accuracy – FEZ Mengemann machines components for a wide range of industries.

Wire erosion has since accounted for the lion’s share of sales, backed up by die-sink erosion and conventional metalworking. Bernd Mengemann and his staff were delighted with their experience of the first wire EDM machines from Mitsubishi Electric – the DWC 90C was followed by a DWC 90H: “Their performance was impressive even then, and choosing subsequent models was not therefore a difficult task.” The fact that they later bought two more machines from Mitsubishi Electric is also attributable to the supplier’s knowledgeable staff and their good advice. These were the FX20 in 1998 and a FA20-S Advance V in 2008 in a “column-up” version.

The Mengemann family focuses its attention on customer orders: Meeting on site at the machine.

The possibility of also being able to machine parts up to a height of 450 mm was a key factor for the jobshop, as Bernd Mengemann explains: “We wanted the FA20-S Advance V, of course, to boost our output and capacity. By selecting the ‘column-up’ option, we have been able to considerably extend our range of parts as well.” The accustomed high cutting rate is of benefit for tall components in particular, he adds.

Intricate designs and small series are all part of the daily round at FEZ Mengemann. A big help in the overall process, therefore, are the software and control of the wire-cut EDM machines from Mitsubishi Electric. “The menu guidance is clearly structured, and the functions also permit complex programming,” says Bernd Mengemann, citing angle compensation and virtual table rotation through 360° as examples.

The machine park with its diverse array of machinery gives FEZ Mengemann a good deal of flexibility in its operations. The beneficiaries of this are firstly the customer, because the company can respond quickly, and secondly the company itself: “We work in two shifts with all the machines running to full capacity. The long-running jobs are handled unsupervised overnight,” Bernd Mengemann adds. This is only possible because wire breakages are rare on the machine and the wire is in any case automatically rethreaded if a breakage ever does occur.

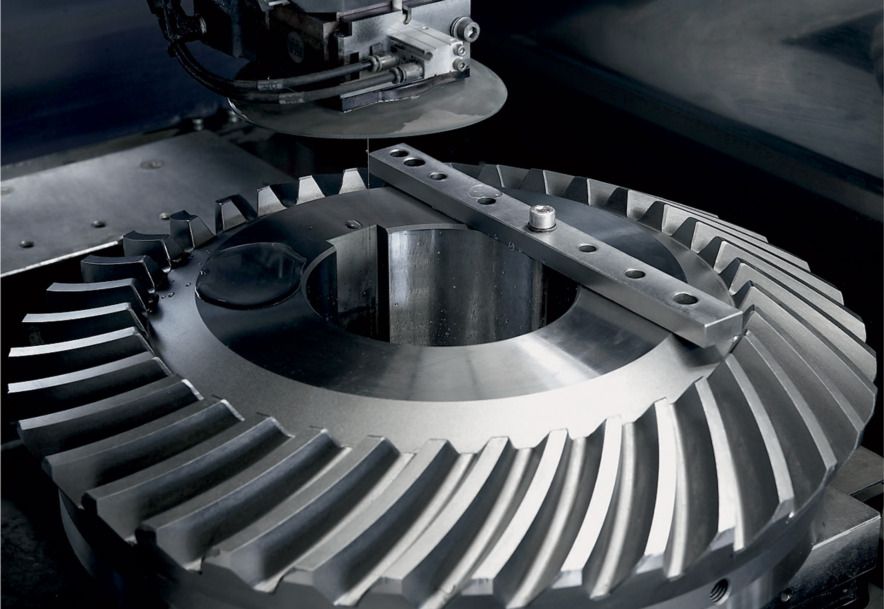

Precision cuts are carried out on large components like this gearwheel.

“You can tell that Mitsubishi and FEZ Mengemann share the same conceptions of dependability and service.”

The flexibility exhibited by FEZ Mengemann is matched by that of Mitsubishi Electric’s service, says the company owner: “The fitter may have finished work long ago, but still goes to the phone and helps us as best he can.” If hotline support isn’t enough, someone is sent round straightaway to keep loss of output to a minimum. Bernd Mengemann adds: “You can tell that Mitsubishi and FEZ Mengemann share the same conceptions of dependability and service.”

Despite everything the machines are capable of, skilled staff are still a big priority in the company. “We employ highly skilled workers and three engineers and offer long-term prospects so that we all benefit,” says Bernd Mengemann explaining the manpower structure. The shrewd choice of employees pays off: “The whole team shows total commitment – even when there’s more to do – and we can uphold an appropriate standard of quality.” This applies not only to production itself, but also to all the consultations relating to the component.

Quality, flexibility and customer orientation will continue to be the cornerstones of FEZ Mengemann. Rico Mengemann, the owner’s son, has already decided to follow in his father’s footsteps. He’s got plenty of ideas of his own: “We may well extend the portfolio to include fine cutting with thin wires or broaden the range of components with even larger machining ranges.”

The FEZ Mengemann production shop has plenty of space for the advanced machine park.

Name and place of business:

Funken-Erosions-Zentrum

Bernd Mengemann, Dresden, Germany

Founding year: 1971

Number of employees: 14

Managing director:

Rolf Mengemann

Owner:

Bernd Mengemann

Core business: EDM jobshop in the field of wire and die-sink erosion for a wide range of industries and applications, e.g. tool- and mouldmaking, research institutes, medical technology and aeronautics

Funken-Erosions-Zentrum

Bernd Mengemann

Schwarmweg 1 A

01156 Dresden

OT Unkersdorf

Germany

Tel: +49 (0) 3 52 04 / 7 86 95-0

Fax: +49 (0) 3 52 04 / 7 86 95-31

info@mengemann.de

www.mengemann.de

We’re an EDM jobshop, a service provider to our customers.

Harvesting potatoes as a child.

The pleasure of my profession.

I allow my work to benefit from the experience of the last five years.

Continuing to be a successful EDM jobshop.

The successful transition from the East German planned economy to the free market economy.

Walking in Saxon Switzerland.

Honesty and reliability.

“Anything that can go wrong, will go wrong.”

With electrically generated heat, we cut metal parts in a controlled fashion and thus change the workpiece contours and shape to precise specifications.

Owner

Funken-Erosions-Zentrum Bernd Mengemann

Bernd Mengemann (left) founded the company with his brother Rolf Mengemann (centre). His son Rico Mengemann (right) will one day take over the business.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com