Wire eroder Bart Pinxten produces top-quality components. His customers are impressed by his attractive pricing and speed.

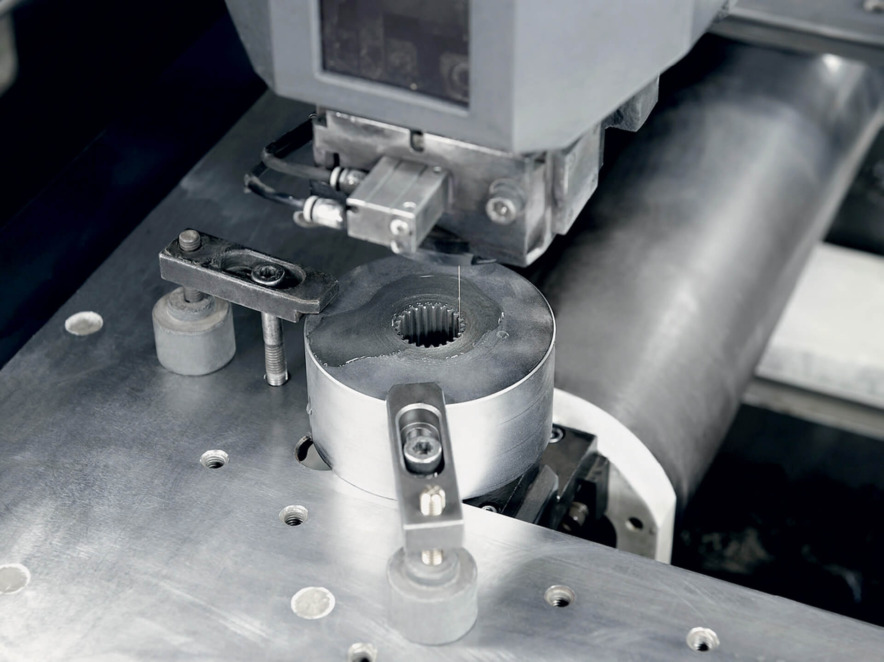

With his small business in Overpelt, Belgium, Bart Pinxten has been impressively demonstrating since 1999 that a one-man set-up can be successful with a high manufacturing depth. His work revolves around two wire-cut EDM machines from Mitsubishi Electric – an FA20-S Advance and an FA20-VS – together with a start hole drilling machine from the same manufacturer. Design and programming with CAD/CAM, surface treatment and comprehensive quality control are also covered by his range of activities.

“Tight delivery deadlines and increasingly sophisticated designs are the rule in my line of business,” says Bart Pinxten, describing the daily challenge of an EDM jobshop. The highly competitive market is also affected by a sustained squeeze on prices, as the experienced wire eroder adds: “I aim to undercut the prices of the competition without compromising on quality.”

The business run from home – the workshop is built onto his house – gives Bart Pinxten the necessary flexibility to check up on things in the evening or at weekends.

The product portfolio of Pinxten Bart Vonkverspaning is as varied as his customers’ target markets. All sectors – from the computer and automotive industries to mechanical engineering – are represented. “There are no limits. As long as the material is electrically conductive and the design will allow it, I can machine anything that comes along and is practicable,” Bart Pinxten sums up. However, he once had to turn down, with a smile, an inquiry about cutting a ceramic component.

Bart Pinxten has been relying on wire-cut EDM machines from Mitsubishi Electric in the pursuit of his goals since 2001. “Every few years I switch to a new generation,” the satisfied user explains. The reasons for this are increased speed and even greater precision, he says. “Keeping in line with the latest state of the art is essential, I believe, in order to stay competitive.” He has very straightforward reasons for staying faithful to the Japanese manufacturer: “Quality, reliability, an optimal price/performance ratio and good service.” Bart Pinxten will continue to closely follow further technological innovations in order to invest at the right moment.

Since starting his own business, Bart Pinxten has had four machines from Mitsubishi Electric in operation – all of them models of the FA series. The most recent, an FA20-S Advance, was installed at the beginning of this year. Bart Pinxten has benefited again and again from the improvements integrated in each new generation of machines. “Operation via the large touchscreen has become much more comfortable.” The speed and accuracy are also very impressive, he adds.

After a slight drop in business last year, Bart Pinxten has already noticed a significant recovery in workload: “I’m confident of getting back to 2008 order levels soon. ”The improved productivity of the FA20-S Advance is therefore all important for the wire eroder’s work.

Bart Pinxten runs a one-man business and has been relying on machines from Mitsubishi Electric since 2001.

“The new generator is so powerful that I can achieve the demanded quality with fewer downstream cuts,” Bart Pinxten continues. The FA20-S comes into its own particularly on large, long running components.

The current FA20-S Advance offers further advantages to jobbers like Bart Pinxten. Constantly changing materials and thus constantly new cutting parameters are part of the daily round. On the FA20-S Advance, many of these parameters are already stored in the system, a fact which simplifies programming and set-up enormously. “This reduces my workload even further compared to my previous machines,” says Bart Pinxten, satisfied with what the control has to offer.

Automatic wire threading, which all of his Mitsubishi Electric machines have been equipped with, is indispensable for Bart Pinxten. “Since the components are cut at night, it is important if the wire breaks that the machine continues to work automatically, i.e. that it can rethread the wire without my help,” says Bart Pinxten, explaining the importance of this machine feature.

„Mitsubishi Electric: Quality, dependability, optimal price/performance ratio and good service.“

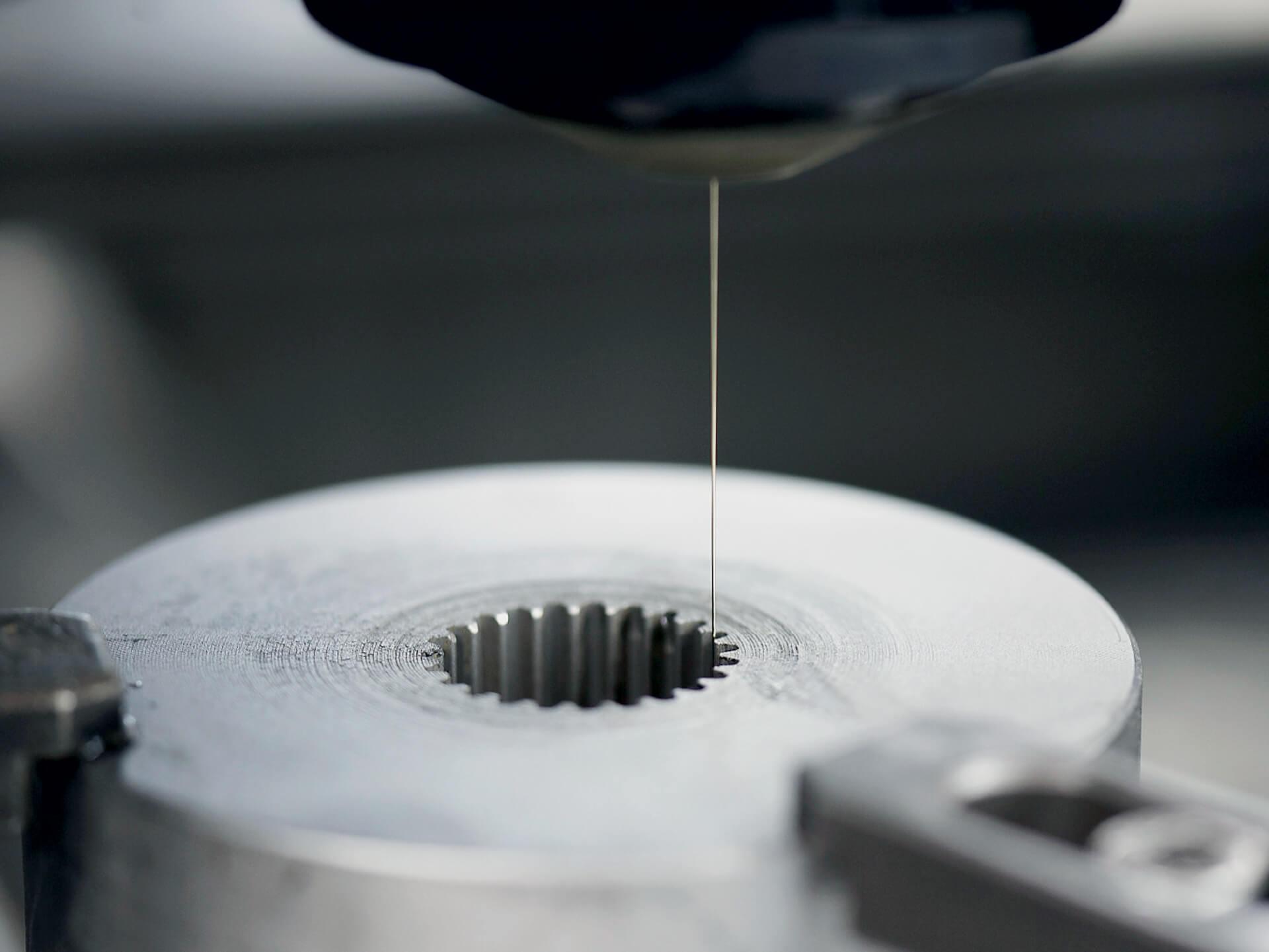

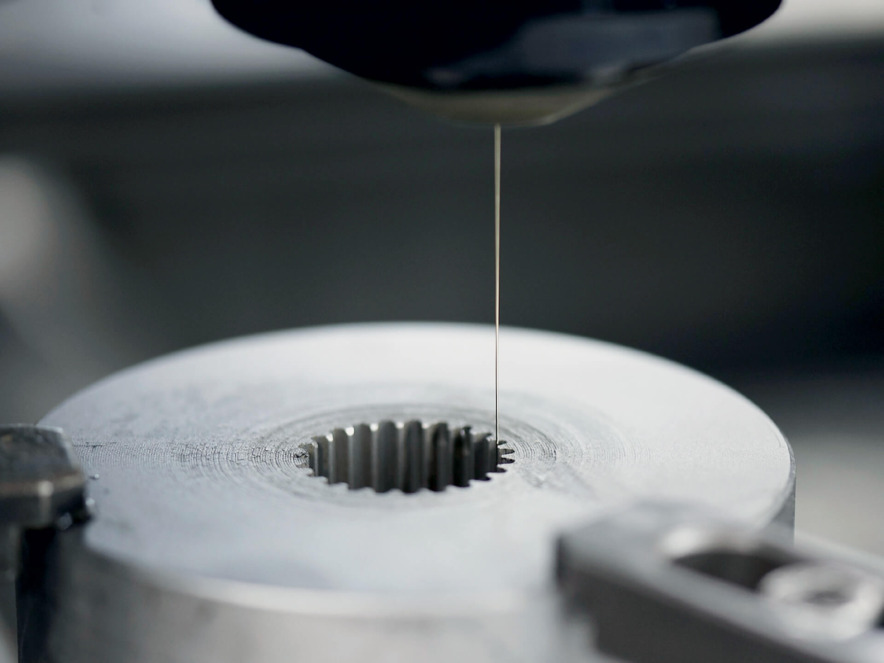

Pinxten also cuts fine gearing in components for the automotive industry.

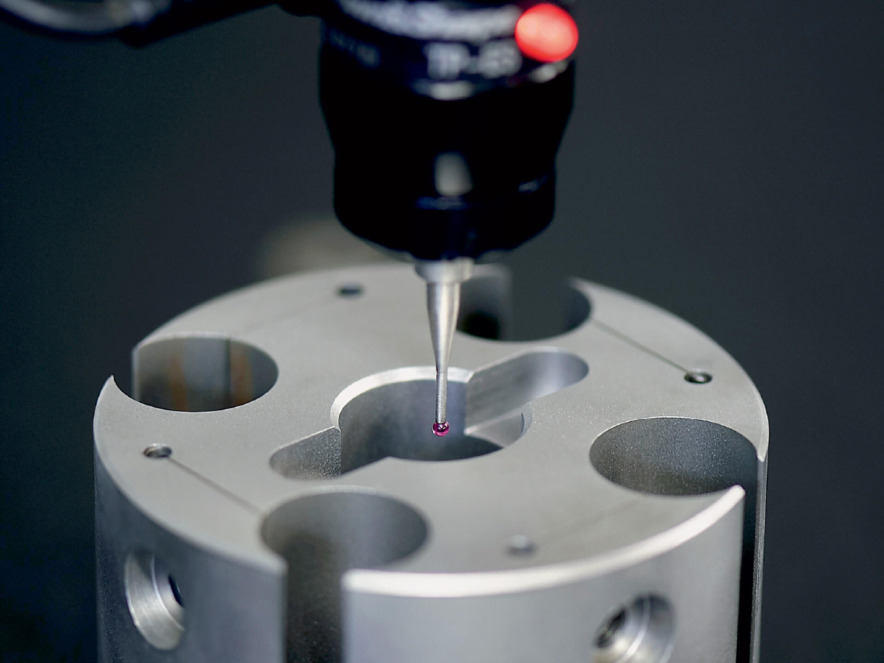

With the FA20-S Advance combined with the FA20-VS purchased in 2006, self-employed Bart Pinxten has everything he needs for flexible operations. His machine park also includes an FD20 start hole drilling machine, two precision measuring tools, a machine for the necessary surface treatment and an advanced CAD/CAM system. The purpose of this complete set of equipment for Bart Pinxten is obvious. “This means that I’m ready for any challenge and can supply my customers with finished end-products inclusive of the complete design and subsequent downstream treatment.

Absolute precision: Exact measurement of the components is essential.

Bart Pinxten wishes to continue the success of the first few years of his business. The family-minded man is interested not so much in expanding his capacity – because he feels perfectly happy with the small scale of his business run from home – as in continuing to be a skilled and reliable partner to his customers: “I’m happy when my customers are happy with my work and come back to me for their next component.”

Name and place of business:

Pinxten Bart Vonkverspaning, Overpelt (Belgien)

Founding year: 1999

Number of employees: 1

Manager:

Bart Pinxten

Core business: Wire erosion for a variety of sectors

Pinxten Bart Vonkverspaning

Heesakkerstraat 46

3900 Overpelt

Belgium

Tel: +32 (0) 11 / 64 31 07

pinxten.bart@telenet.be

Bart Pinxten, a wire eroder serving a broad range of sectors, lives and works in Overpelt, Belgium.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com