To stay competitive on the international level, companies will have to make their production activities more flexible, faster and more efficient. To do this, however, they need greater transparency over the state of their equipment and much improved process security. The key to this is Industry 4.0.

On the way to digital networking.

For years now, the term “Industry 4.0” has been much in circulation in the industry. In this connection, some experts also refer to digitisation and the Internet of Things (IoT). What does all this mean? What is already reality and what is still fiction? An initial stocktake reveals that there are an abundance of pioneering approaches. One of these is Mitsubishi Electric’s

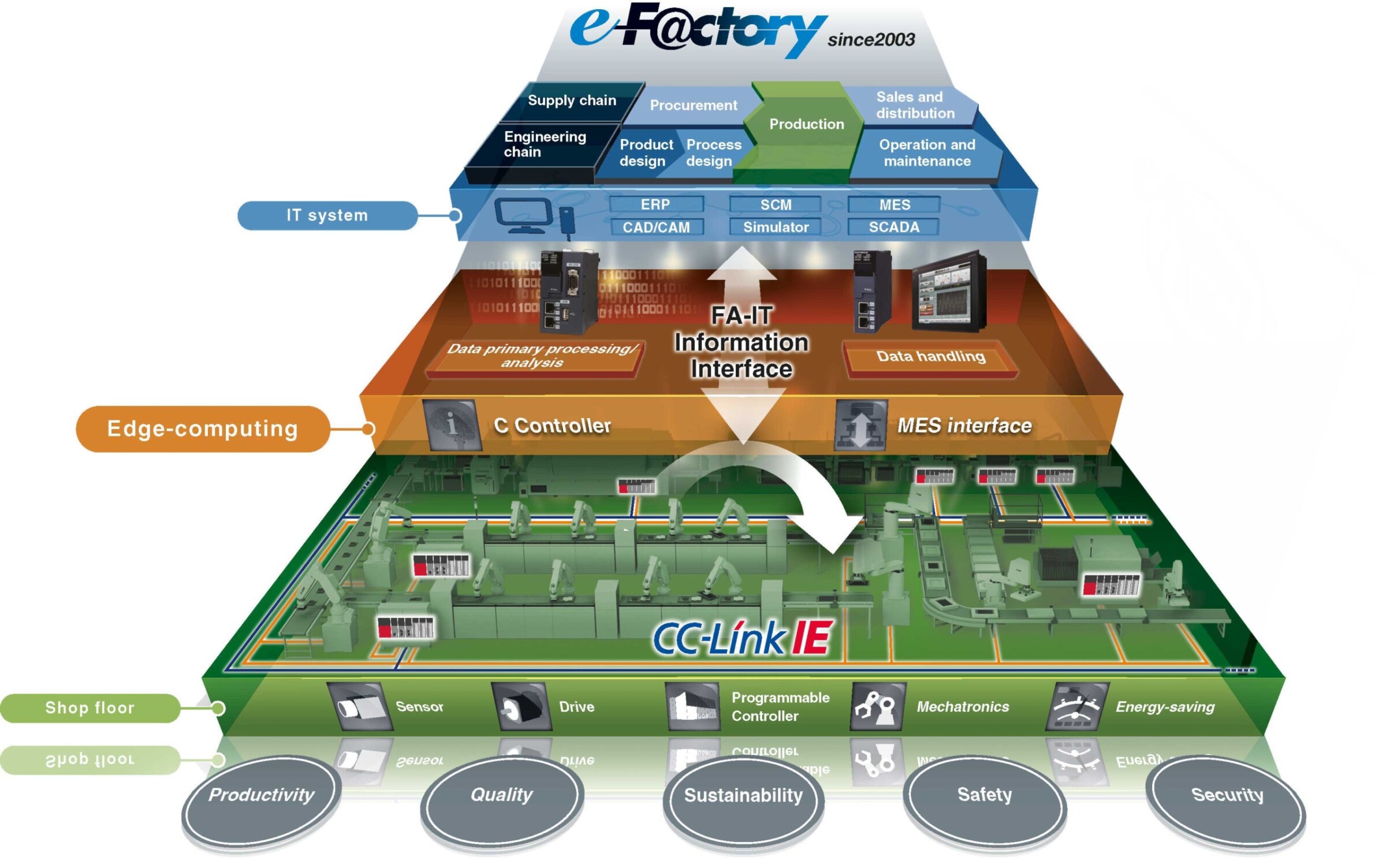

e-F@ctory Alliance. Under this umbrella over 300 companies in the fields of hardware, IT solutions and software have now come together worldwide. Together they devise solutions for customers who wish to exploit digitisation on the production level. The alliance is an integral part of the e-F@ctory strategy, which at Mitsubishi Electric stands for everything to do with digital transformation in production. This is where we support our customers with advice on the further development of their business projects in the field of industrial automation and information technology. The focus is currently on the digitisation of production, which, it is hoped, will improve transparency and go a long way towards boosting production and flexibility significantly.

Greater flexibility, speed and economy in production.

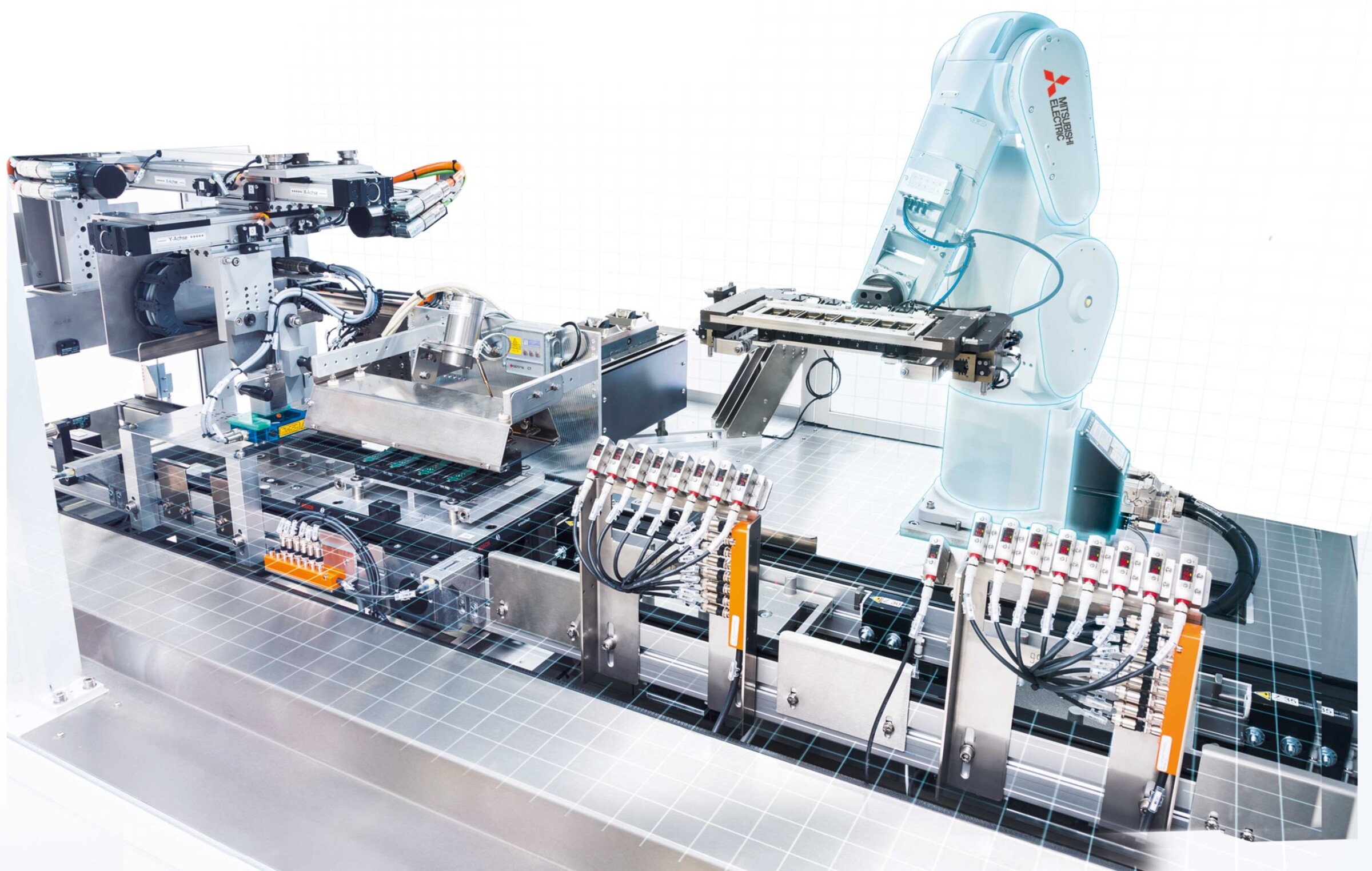

Mainly involved are manufacturers who produce, among other things, CNC controls, production machines, loading and unloading systems, robots, grippers, handling systems, sensors, optical and scanning measuring systems, HMI systems, hydraulic and pneumatic components, and electrical drive systems. In the building of production equipment, they coordinate their respective solutions in order to achieve the goal of Industry 4.0 – maximum transparency and the best-possible process security for more efficient and more flexible equipment operation.

Thanks to the cloud, production has continuous access to data in real time.

Back in 2005, Mitsubishi Electric established a model factory in Nagoya, Japan. This consistently pursues the e-F@ctory approach in which the achievable progress can be actually experienced. Top of the list of the goals to be achieved under the e-F@ctory approach is a boost in efficiency and flexibility by interconnecting all production processes with a link to higher-order planning and strategy systems. For maximum programming and operating comfort, modern visualisation and automation systems are to be integrated. The e-F@ctory initiative has a strong focus on building on existing structures and finding scalable solutions. The links in production processes must of course take place in real time. In addition, the large volumes of data injected and exchanged by all participating components have to be transferred and stored safely and reliably. In the e-F@ctory system, the companies involved resort to CC-Link data communication interfaces. Aspired to are globally standardised data interfaces on the OPC and OPC-UA principle.

Maximum transparency and process security.

In the production of servo drives at Mitsubishi Electric in Japan, the e-F@ctory strategy has demonstrated for the first time the huge potential of production optimisation through comprehensive digitisation. In the digital factory under the Industry 4.0 strategy, all the procedures and processes are geared to maximum flexibility and productivity. In addition, far-reaching control mechanisms have been introduced so that zero-error production can be largely realised. Production is linked to higher-order software solutions facilitating the analysis, planning and strategic control of company-wide processes at any time.

e-F@ctory interlinks the whole of production, from design through to the shop floor.

The e-f@ctory strategy.

With the same approaches and objectives, Mitsubishi Electric realised a trailblazing production strategy for its advanced motor contactors of the MS-T series in 2012. The goal was to create a highly flexible production system capable of responding to all customer needs. This called for the optimised interaction of assembly equipment, employees and ambient conditions. The outcome is several flexible production islands on each of which six robots working together with a single skilled operative produce theoretically up to 600 but in practice about 100 different variants of motor contactors in any desired sequence. The injection-moulded housings of the motor contactors are provided with a unique machine-readable code. This ensures that the various stations of a production island can obtain the instructions indicating which elements and components are to be installed in which order in the motor contactor in question. In addition, each station has the in each case appropriate control system for integrated QS. Data capture via the individual part code ensures complete traceability. This ensures that each produced motor contactor is 100 %-tested on leaving the production island. To back this up, all data from production are documented to make them available for analysis on the higher-order company level. From these, the production planners can, for example, derive intervals for predictive maintenance and servicing. In doing so, they can support basic components available in the system. These are continuously checked against current data from condition monitoring and the control mechanisms in production. All this goes a long way towards constantly improving the productivity, process security and efficiency of production equipment. As a result, production proceeds in regular steps towards the goal of flexibly manufacturing 100 % quality-assured products to customer needs with minimum effort and in the shortest time. All the approaches to Industry 4.0 focus solely on this goal.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com