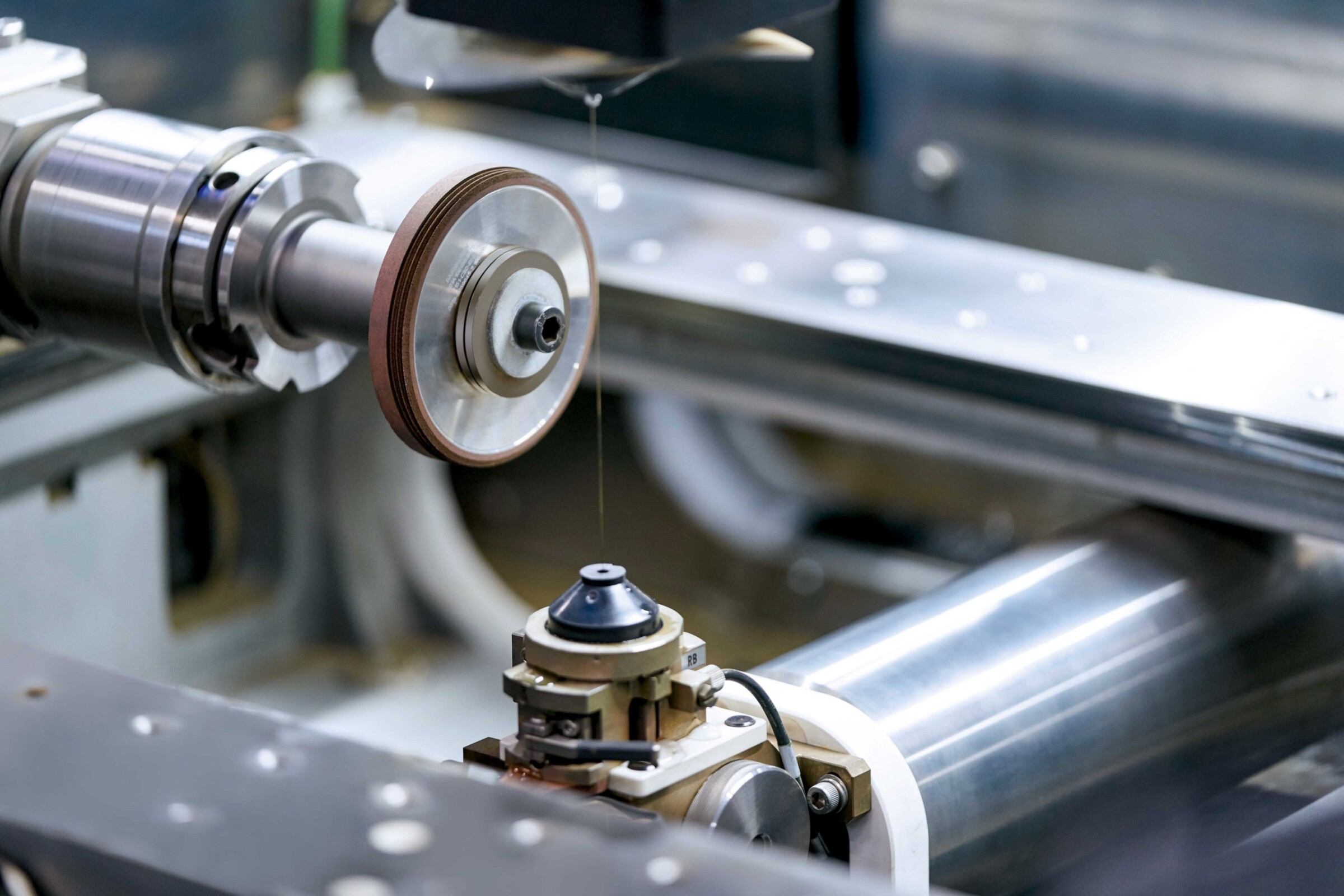

At the Institute of Precision Machining in Tuttlingen, Germany, scientists are developing process-safe methods for the wire-cutting of micro-profiles in metal- or resin-bond grinding wheels and pins with high repeat accuracy.

Opening up new fields of application.

Scientists at the institute in Tuttlingen have been working primarily on grinding processes since 1997. Prof. Dr.-Ing. Bahman Azarhoushang was appointed its head in 2013, expanding its fields of research and giving the institute its current name of Institute of Precision Machining. Since then, the now 14 scientific staff (including 8 doctoral postgraduates) and around 150 students in Tuttlingen have also been working on turning, milling, drilling and electrical discharge machining. However, the emphasis continues to be on grinding processes. The institute is supported by two work groups comprising 35 companies – mainly manufacturers of grinding machines and grinding tools and users. The scientists in Tuttlingen maintain their leading role beyond the region in their research into machining processes with special research focuses. As institute head Azarhoushang explains, these include above all processes for high-performance machining, micro-machining and non-conventional machining. The latter include laser- and vibration-assisted turning, micro-milling and micro-grinding. In conjunction with about 25 bachelors’ and masters’ theses, students and postgraduates develop and pilot innovative, application-driven manufacturing processes. To verify their theoretical predictions in practice, they have a lavishly equipped workshop comprising turning, milling, grinding and EDM machines, including, for roughly the last two years, a wire-eroding system from Mitsubishi Electric.

Prof. Dr.-Ing. Bahman Azarhoushang, Head of Institute of Precision Machining

Demand for sharp, micro-profiled grinding wheels

At the request of the automotive industry, toolmaking and medical technology, the scientists in Tuttlingen are currently working on special profiling and dressing processes for grinding wheels. Their aim is to create precise, intricate and difficult-to-produce geometries in grinding wheels. It is not yet possible, Azarhoushang explains, to realise concave micro-geometries in metal- or special resin-bond grinding wheels in particular.

Focus on grinding processes.

All currently familiar dressing and profiling processes have so far failed, be it with diamond, SiC or corundum dressing rolls or wheels. During dressing, either the bond of the grinding tools (diamond rolls) smears or the bond is reset by the process, causing individual abrasive grains to be torn out of the bond.

The result is a smooth and at the same time not precisely pre-determinable surface. Profile geometries smaller than the bonded grain size cannot be generated with contour accuracy. In addition, the bond of grinding tools made of hard cutting materials, such as diamond and high-strength bonded CBN in particular, cannot be reset in a controlled manner using conventional methods. However, this is absolutely necessary if the grinding wheels are to be resharpened again and again. Only then can they efficiently remove material from the surface of the workpieces being ground.

Dr Zahedi and Mr Khosravi (postgraduate) at work

First tests only a few years ago showed that it is possible to wire-cut even extra-hard grinding wheels. Azarhoushang explains: “We have taken up this approach at the institute and consistently pursued it further. The micro-profiling of high-strength grinding wheels can yield economic advantages particularly for regional industry.”

Wire-cut and ground

Economic benefits for regional industry.

Machining a much larger range of workpieces.

The institute has invested in a precision wire EDM system from Mitsubishi Electric. This make was chosen, Azarhoushang continues, because of the machine’s comprehensive equipment, the main reason being the integrated V350 generator, the heart of the wire EDM machine, which is particularly suited to machining diamond and CBN grinding wheels. He was also impressed by the sound advice and service he received. “We also have the impression that Mitsubishi Electric is particularly interested in innovations and forward-looking applications for its wire EDM technology.” He and his colleagues opted for the MP2400 Connect also because of its large workspace ideal for the processing of large grinding wheels. In addition, the wire EDM is equipped with a fine-finishing generator and a rotary axis. This enables the scientists to generate highly complex profile geometries on grinding wheels and pins.

Wire-cut

They have been running the machine for about five months now. Using HSK tool holders, they clamp the grinding wheels requiring processing on the machine. The parameters for wire eroding are first retrieved from the assistance system integrated in the controller. This considerably simplifies programming and operation, Azarhoushang says, especially for students and postgrads who usually work only briefly and occasionally at the machines. This also applies to the current control system with its large monitor and touch screen, which is operated using an app similar to those on smartphones.

Wire-cut

Reliable profiling of high-strength grinding wheels

In their research and development work to date, the specialists in Tuttlingen have already identified numerous parameters for the dressing of profiles and micro-profiles in extremely hard grinding wheels. Azarhoushang explains: “In wire EDM, the wire cuts the profile with precision. Only the bond of the grinding wheels is removed, causing abrasive grains outside the produced profile to drop out, with the abrasive grains left on the grinding wheel surface protruding in a perfectly sharp condition. This enables even small profiles to be produced with repeat accuracy, while the generated profiles are sharp as well. The grinding wheel is incisive and achieves high removal rates, removing material from the workpieces in a much more productive and, above all, precisely predictable manner. This proves to be highly beneficial for manufacturing companies. With grinding wheels dressed in this way, it is possible to produce workpiece geometries that were previously impossible. Profiling and dressing by wire erosion thus also open up totally new production applications.”

Prof. Dr.-Ing. Bahman Azarhoushang, Head of the Institute for Precision Machining

With grinding wheels dressed in this way, it is possible to produce workpiece geometries that were previously impossible. Profiling and dressing by wire erosion thus also open up totally new production applications.

Depending on the diameter of the cutting wire, wire EDM can also be used to reliably generate highly intricate profiles, such as tooth profiles only a few tenths of a millimetre high with almost any tooth flank contours. The innovative wire EDM dressing process is thus proving to be of great advantage to manufacturing companies. Numerous industrial users, especially in toolmaking, medical technology and microelectronics, Azarhoushang claims, are now interested in this technology. But he adds that for the application of the process in industrial series production, a large number of parameters and interrelationships between bonds, hard materials (grain size, concentration and grain type) and erosion parameters already work very well, although parameters optimised for special, newly developed bonds and hard materials still have to be determined. In his opinion, Mitsubishi Electric’s wire EDM machines at the institute in Tuttlingen are able to do this quickly, easily and above all reliably. Once parameters are considered optimal, they are simply stored in the database integrated in the CNC control.

Calculating parameters and simulating processes

In addition, the scientists are developing and refining suitable CAD/CAM software that makes the wire-cutting of profiled grinding wheels even easier to program and simulate than before. “With a sufficient bank of data, it will be possible in future to more precisely pre-determine the appropriate strategies and the machine and process parameters for the required accuracy and surface quality. In addition, it will also be possible to simulate the machining process as a means of detecting collisions and impracticable profile geometries in advance,” says Azarhoushang, looking ahead to the near future. At the research institute in Tuttlingen, wire EDM machines from Mitsubishi Electric are making a major contribution to enabling production businesses to process a much wider range of workpieces with much higher productivity by using precisely profiled, strong and extremely hard grinding wheels.

The Institute of Precision Machining is part of Furtwangen University (HFU), which in turn has evolved out of Furtwangen University of Applied Sciences. At the institute, scientists and students are concerned with the three production areas of grinding technology and precision machining, machining technology, and laser technology and EDM. Application-driven and in some cases on behalf of machine manufacturers, toolmakers and users, they research the machining of difficult-to-machine materials as well as innovative processes for non-conventional machining, such as hybrid machining and additive manufacturing. In doing so, they concentrate, among other things, on micro-structures and high-productivity processes such as high-performance and high-speed machining. They develop processes, tools and process monitoring. They also hold specialist conferences and workshops so that their specialist knowledge and the developed technologies can be transferred directly to production at toolmakers, machine and measuring instrument manufacturers, and users. They also assist interested parties individually with studies, research and plans for the launch of innovative manufacturing processes.

Name and place of company:

Furtwangen University

Institute of Precision Machining

Germany

Head:

Prof. Dr.-Ing. Bahman Azarhoushang

Employees:

14 research assistants including 8 doctoral postgraduates, and 150 students

Institute of Precision Machining

Katharinenstrasse 2

78532 Tuttlingen, Germany

Tel +49 7720 307 4328

ksfinfo@hs-furtwangen.de

www.ksf.hs-furtwangen.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com