Teisnach, picturesquely situated in the Bavarian Forest with a population of roughly 3,000, is one of the high-tech centres in the region. The Rohde & Schwarz technology group is one of the key contributors to this with its Teisnach plant. Since 1969, the plant has been responsible for the prefabrication of the global player’s products. Today, the company produces complex systems, numerous electromechanical assemblies and custom-made items. Last year, two Mitsubishi Electric EDM machines from the MP Connect series joined the precision production activities of the plant’s toolmaking department.

55 metres of grounded technology

Rohde & Schwarz transmitters and measuring techniques are used all over the world – as here on the Wendelstein in the Bavarian Alps.

With its industry-leading technological expertise, Rohde & Schwarz is working energetically on the future of communication, information and security.

The reference receiver for broadcast signal analysis is one of many Rohde & Schwarz products.

The independent group develops, manufactures and sells a wide range of electronic capital goods to industry, infrastructure operators and sovereign customers. The company is one of the technology or market leaders in all of its fields. Rohde & Schwarz concentrates on the areas of mobile radio and high-frequency measurement technology, and broadcasting and media technology. Air traffic control and radio communication, cyber security and network technology also enjoy high priority in the Group.

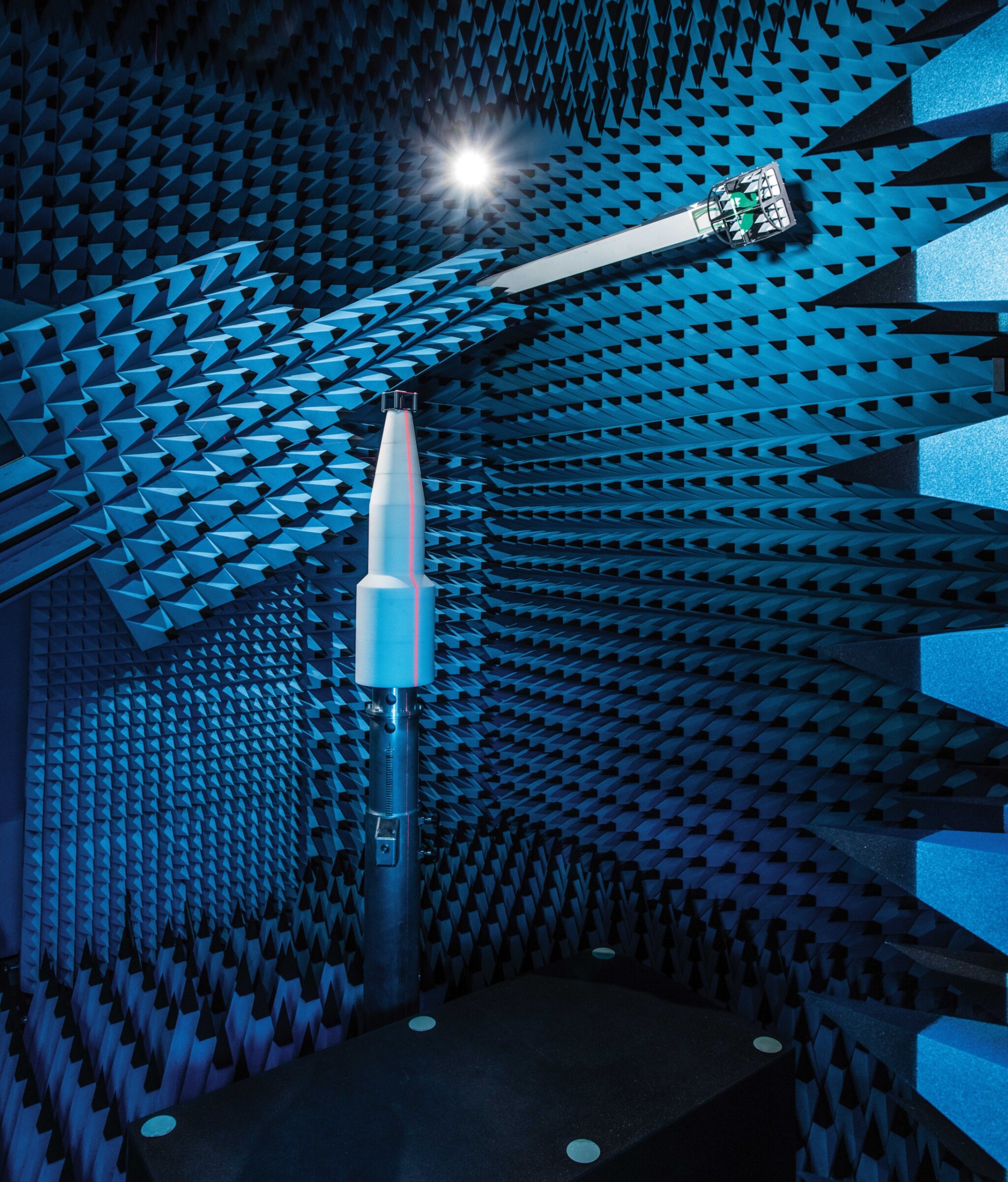

At Rohde & Schwarz, both large, wide-reach and small antennas are measured and tested in chambers such as these. The picture shows a small black specimen on a conical, white support.

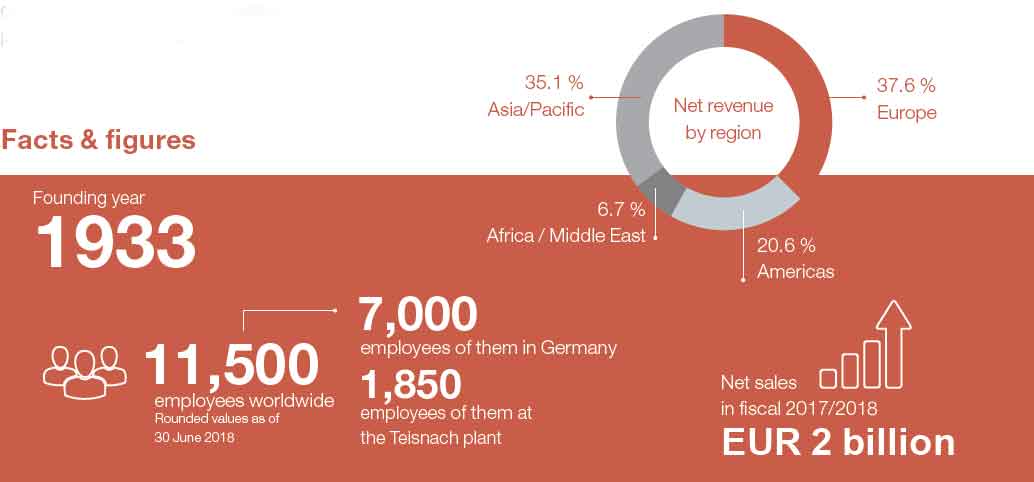

In fiscal 2017/2018, Rohde & Schwarz generated sales of EUR 2.04 billion. The company owes this success to its 11,500 highly skilled employees in over 70 countries. As the largest employer in the Teisnach region, the Group employs around 1850 skilled workers at its plant there and allocates more than 74,000 square metres to production.

Global player.

Since its foundation in 1969, the Teisnach plant has been responsible for the prefabrication of products. “In addition, we also manufacture among other things electromechanical assemblies, custom-made items and radio communication systems,” explains Andreas Bauer, head of toolmaking at Rohde & Schwarz in Teisnach. It is also home to the manufacture of radio and television transmitter systems, body scanners, micromechanical precision parts, antennas, printed circuit boards, housing parts and hollow waveguides.

The two Mitsubishi Electric machines in the EDM section of the toolshop

“Over the past five years, we have developed the Teisnach site into a contract manufacturer with expertise in the complete field of mechanical and electronic component production,” adds Christian Ebner from toolmaking in Teisnach. Since 1991, the plant has also been offering production services to external customers. Teisnach’s broad portfolio includes product development and design, software development, purchasing and logistics, and cutting and non-cutting machining as well as the assembly of mechanical assemblies, mechatronic systems and special machines. In addition, the specialists in Teisnach also perform high-quality surface finishing.

Technology and market leader.

“We have developed a comprehensive conception of quality. This also means that our quality testing accompanies all phases from procurement to production and documents them precisely,” says Bauer. This understanding of quality is also reflected in the company’s environmental policies. Water is not simply disposed of, but efficiently purified with a computer-aided water treatment system that guarantees the highest wastewater purity in every situation.

We have developed a comprehensive conception of quality. This also means that our quality testing accompanies all phases from procurement to production and documents them precisely.

Andreas Bauer, Head of toolmaking at Rohde & Schwarz in Teisnach

The company shows huge commitment in its training activities. More than 100 young people are currently undergoing training, primarily in technical professions such as industrial mechanic, electronics technician and electrician, or combined courses of theoretical study and work experience.

“The bulk of what we make is used in Rohde & Schwarz’s production activities, so we can only devote 20 to 30 per cent of our capacity to external orders,” Bauer explains. “But external customers are important to us. We always seek the challenge of the marketplace. Only then can we see whether we are competitive. And only then can we achieve the optimum for our company.”

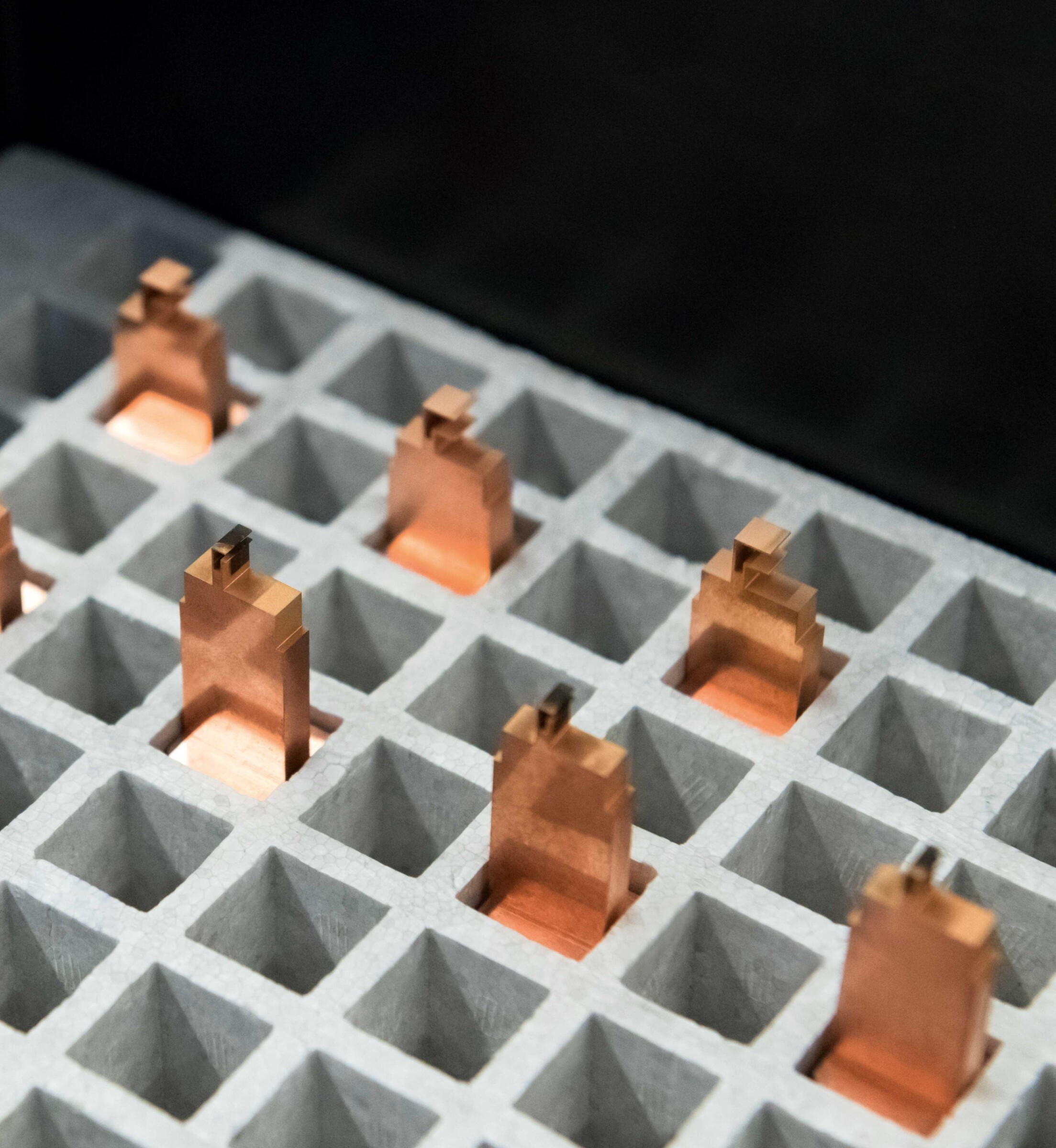

Body of an HF assembly – produced on the MP1200 from Mitsubishi Electric

Toolmaking enjoys high status at Rohde & Schwarz and is performed in several plants. Teisnach is a toolmaking centre. Of the approximately 100 toolmakers in the group, 50 work in Teisnach. “This is where most of the technologies are located,” Bauer reports. “It is important for our work that we can quickly serve the various departments within the Group. And this is why our department is equipped with a wide range of technologies.”

A number of Rohde & Schwarz products require very small and very precisely machined injection-moulded parts, which are developed and manufactured in the Teisnach plant. This also includes the fabrication of all the required injection moulds. “Since 2011, we have been involved in micro-injection moulding,” Bauer explains, “and have been working consistently in this area and built up extensive know-how. Most of the applications for these products at Rohde & Schwarz are in high-frequency technology. “The higher the frequencies, the smaller the components, and the smaller the components, the smaller the manufacturing tolerances,” Ebner notes. “Since we manufacture micro-injection moulds, we are also very heavily involved in the machining of high-precision moulds and tools and in the field of micro-erosion technology.

Comprehensive know-how.

One area firmly anchored at the Teisnach plant is the manufacture of punching and bending tools. The toolmakers specialise in machining sheet metal with a thickness of just a few tenths of a millimetre. “Forming processes for materials over a millimetre thick,” Bauer explains, “are the absolute exception in Teisnach.”

Vertical integration at Rohde & Schwarz is very high because the company prefers to have specialists in-house for special manufacturing processes. This way you always keep a check on costs. “Of course, we also attach importance to reacting quickly and flexibly internally,” Bauer continues.

With these two precision machines, we can operate with high process security in this area, and they give us the necessary flexibility.

Andreas Bauer,

Head of toolmaking at

Rohde & Schwarz in Teisnach

With 50 employees, the toolshop in Teisnach is of a manageable size. “To maintain a high degree of flexibility, we are constantly re-organising our operations. This is also one reason why we keep toolmaking here a little separate and autonomous.”

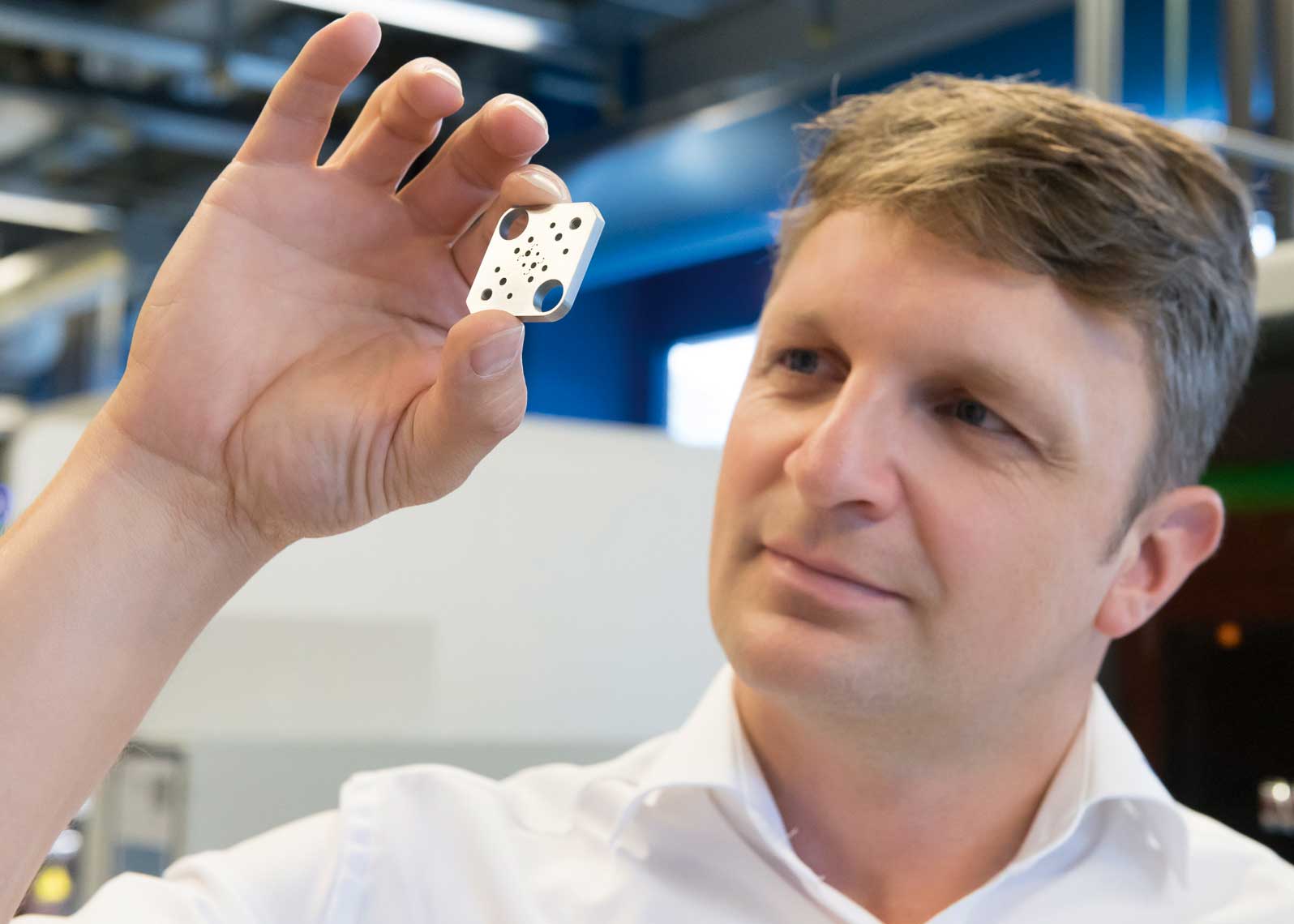

Andreas Bauer inspecting an intermediate ejector plate.

Five wire EDM machines are in operation in the toolshop in Teisnach, mainly in the production of punching, bending and extrusion tools. The two new Mitsubishi Electric MP1200 Connect and MP2400 Connect machines are mainly used for stamping and bending. “With these two precision machines, we can operate with high process security in this area, and they give us the necessary flexibility.”

“Last year we were faced with a change in our wire EDM machines. We took a close look at the main suppliers and drew up the requirements profile with our entire team,” Ebner reports. “It was important for us to make a joint decision in which all the pros and cons and the sustainability issues were examined. And the price-performance ratio was also of course a crucial factor. We paid visits to users and compared the technical data until we were convinced that Mitsubishi would be able to supply us with good and operational machines. Only then did we take the plunge. We’ve been using the two Mitsubishi machines in our toolshop for about a year, and we are still very happy with them and have no regrets.”

“We drafted our 2027 toolmaking strategy back in 2017, venturing a look ahead to 2027,” Bauer reports. “We coordinated our strategy with plant management. Last year we took the first big step and invested around EUR 2,000,000, among other things in two Mitsubishi systems. In doing so, we gave new impetus to micro-erosion, micro-milling and micro-drilling.

Precision and flexibility.

Another goal is efficient production planning, which will make our working methods more efficient. We also want to optimise our communication so that the right information is always available in the right place.”

Rohde & Schwarz is a high-tech company that thrives on innovation. The company has a tightly meshed sales and service network and is present in more than 70 countries, mainly through its own subsidiaries. Exports account for around 85 per cent of its sales. The company is headquartered in Munich and has strong regional offices in Asia and the USA.

Facts & figures

Name and place of company:

Rohde & Schwarz GmbH & Co. KG

Germany

Executive board:

Christian Leicher (President & CEO)

Peter Riedel (President & COO)

Employees:

11,500

Core business:

Rohde & Schwarz develops, manufactures and markets a wide range of electronic capital goods for industry, infrastructure operators and sovereign customers.

Rohde & Schwarz GmbH & Co. KG

Mühldorfstrasse 15

81671 München, Germany

Tel +49 89 4129 – 0

info@rohde-schwarz.com

www.rohde-schwarz.com

Toolmaking in Teisnach

Kaikenrieder Straße 27

94244 Teisnach, Germany

Head of toolmaking:

Andreas Bauer

Tel +49 9923 85-71885

andreas.bauer@rohde-schwarz.com

www.teisnach.rohde-schwarz.com

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com