Swiss watches are considered the epitome of precision, quality and dependability. Exceptional design and aesthetics make them stylish and prestigious timepieces as well. Only the best in the industry receive the much-coveted accolade of the Grand Prix D’Horlogerie de Genève. Inhotec SA in Le Locle (Switzerland) is a component supplier to such customers and decided to purchase a Mitsubishi Electric MX600 wire-cutting machine a year ago.

Perfection in function and aesthetics.

EDM in the unique world of Swiss clockmaking.

“You can gauge our status in the industry from the fact that several of our customers have been awarded the Grand Prix D’Horlogerie de Genève,” says Alexandre Eme, Director of Inhotec SA in Le Locle in Switzerland. With his roughly 50 employees, his company produces components and subassemblies for the Swiss clock industry. After serious crises, their business model is similar to that of the car industry where manufacturers rely to a greater or lesser extent on components from outside suppliers. Such small component suppliers can operate more flexibly and cheaply that the big names in the industry. Essential for such cooperation, however, is that the supplier works to the same high standards as the brand manufacturers and shares the same philosophy of quality.

Blank bronze platelets with their golden lustre

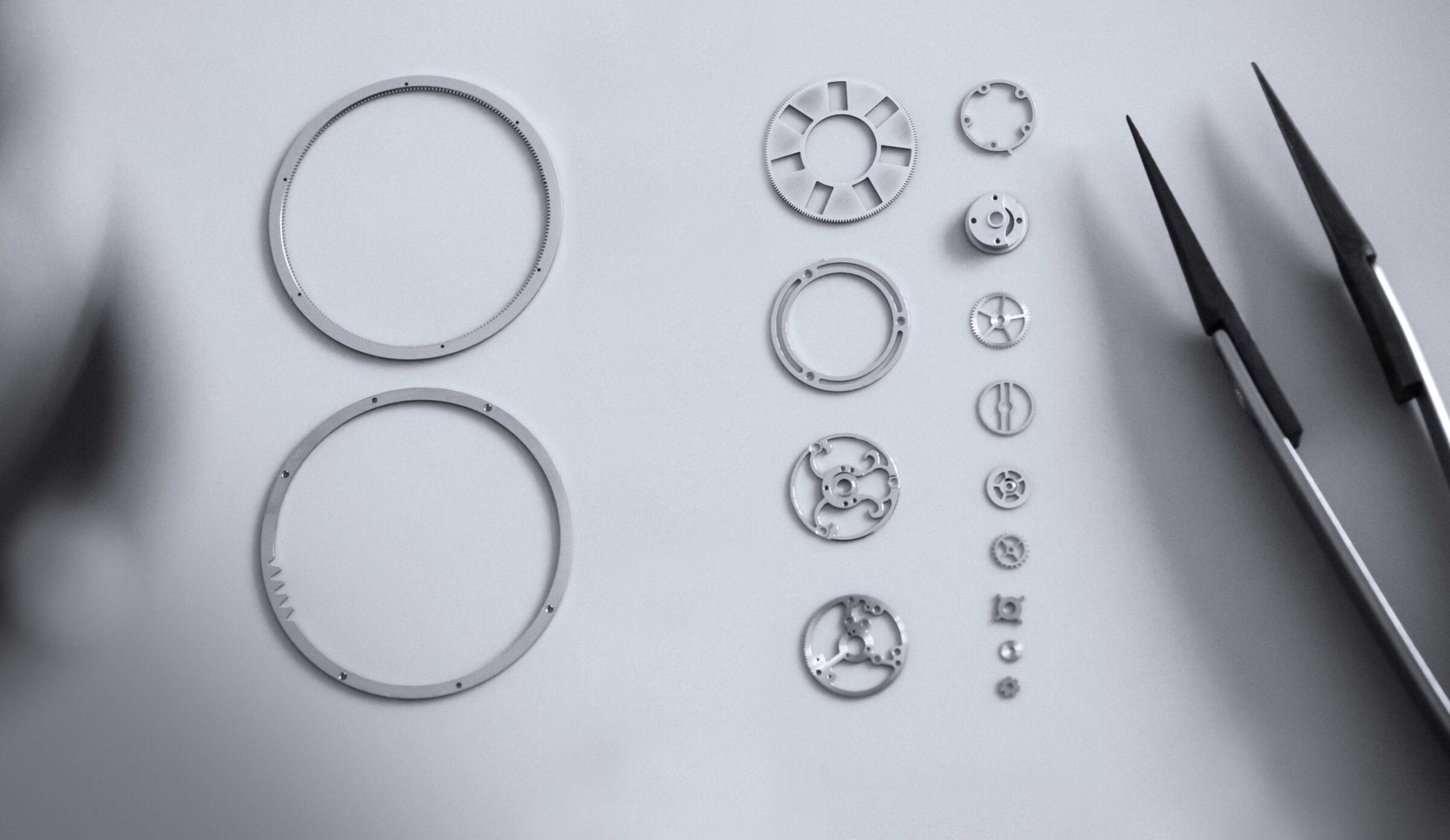

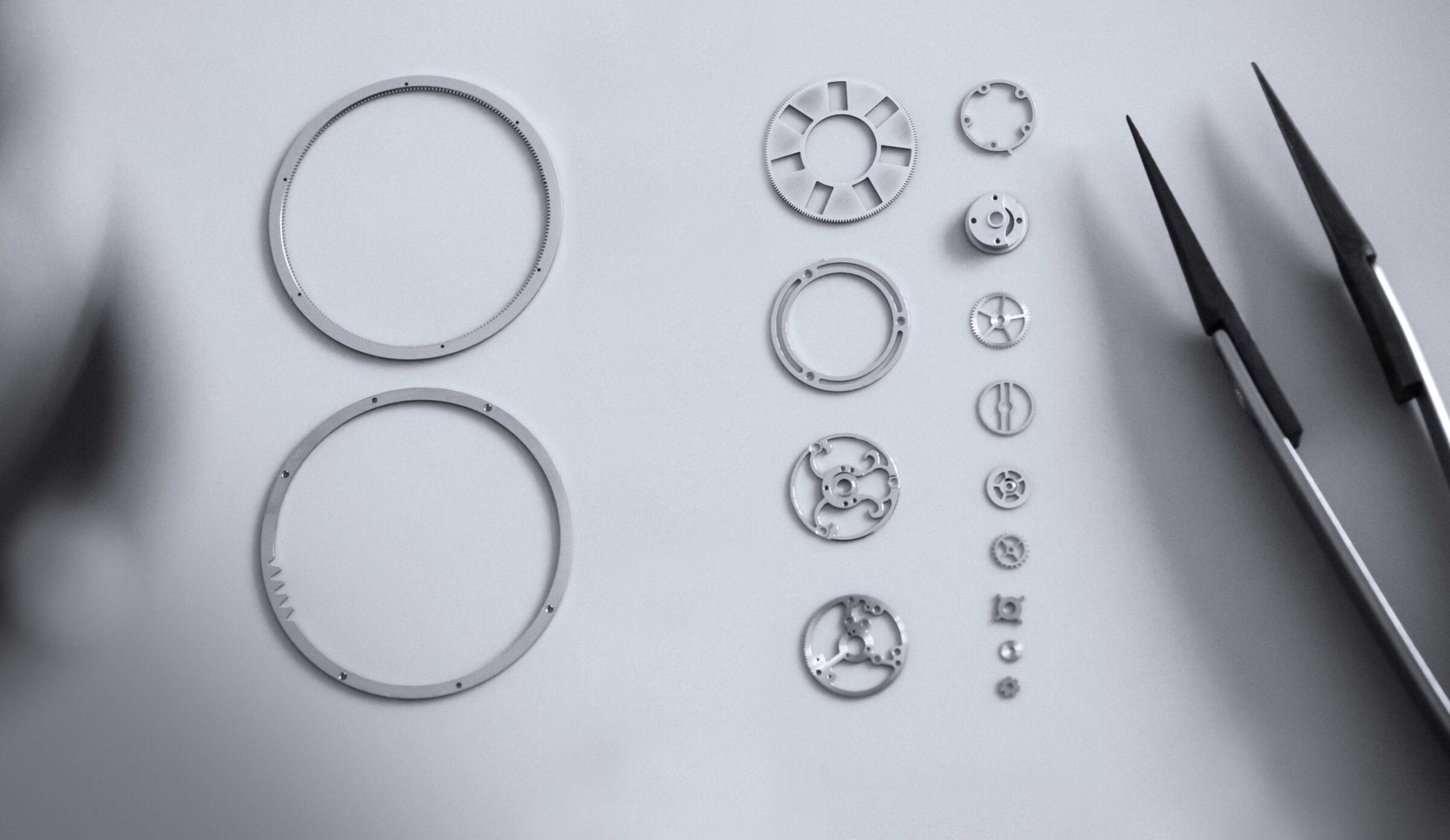

A characteristic feature of Swiss timepieces is their immaculate aesthetics outside and inside. The entire movement down to the tiniest components of the mechanism displays a quality of machining that is otherwise only found on high-grade jewellery. This starts with the materials, with classical steels typically playing second fiddle. The preferred materials include Durnico, a stainless maraging steel (X2NiCoMo18-9-5) with high nickel, cobalt and molybdenum contents that undergoes a special heat treatment to give it extreme hardness and strength. Plenty of brass and, in some cases, extra-light yet high-strength titanium are also processed. The demanded tolerances are also well within the ranges often expected in precision machining. ± 2 µm is typically required and in some cases ± 1 µm, and this calls for measuring equipment of especially high accuracy.

Decoratively machined pearl-effect platelet for a movement

All the same, precise compliance with the required dimensions is by no means everything in the world of Swiss clockmaking. Pretty well every component must also satisfy high standards of aesthetics. Burrs, coarse finishes and rough-cut edges are absolutely unacceptable, with great importance being attached to the quality of surface finish. During finishing, the parts are therefore subjected to numerous grinding, blasting and polishing processes. These are in many cases special versions of the systems otherwise commonly found in industry, adapted to the special needs of clockmaking. In addition, an exceptionally large number of steps are performed by hand, and hand lenses and stereomicroscopes are often employed. Hanging from a wire frame around Inhotec’s employees’ necks, the regularly used watchmaker’s loupe can be said to symbolise this philosophy of quality.

This decorative finish is known as “Côte de Genève”.

Extra-high accuracy is assumed.

The starting point in the process chain at Inhotec is a comprehensive stock of blanks. These are tiny, mostly rectangular platelets of the metals mentioned above, which are ordered in a variety of sizes and thicknesses. Keeping abundant stocks in hand is essential for the swift completion of orders from the moment they arrive. These platelets are machined either in their supplied state or after a prior grinding process on both sides to reduce the thickness or for surface preparation in the milling department. This is where numerous 3- or 5-axis milling centres are in use. In the course of this machining, the guide and fastening holes are given the desired size and are subsequently used for fixing stacks of platelets on the machine’s workspace for subsequent wire-cutting. The milling systems employed are of the highest quality and are always in line with the current state of technology.

We have been impressed not only by the excellent performance of the Mitsubishi Electric MX600, but also by the superior price/performance ratio and the rapid and efficient after-sales service by the Swiss agent.

In all aspects of the production of a component, we aspire to perfection. Such a philosophy of quality is essential in the manufacture of super high-quality timepieces.

The electrical discharge machining performed at Inhotec differs fundamentally from what is familiar from other fields of application, e.g. mould-making. In mould-making the emphasis is often on the cutting rate, while the roughness of the cut face is of secondary importance. Resort is made here to “thick” wire, high spark energy and deionised water as the dielectric.

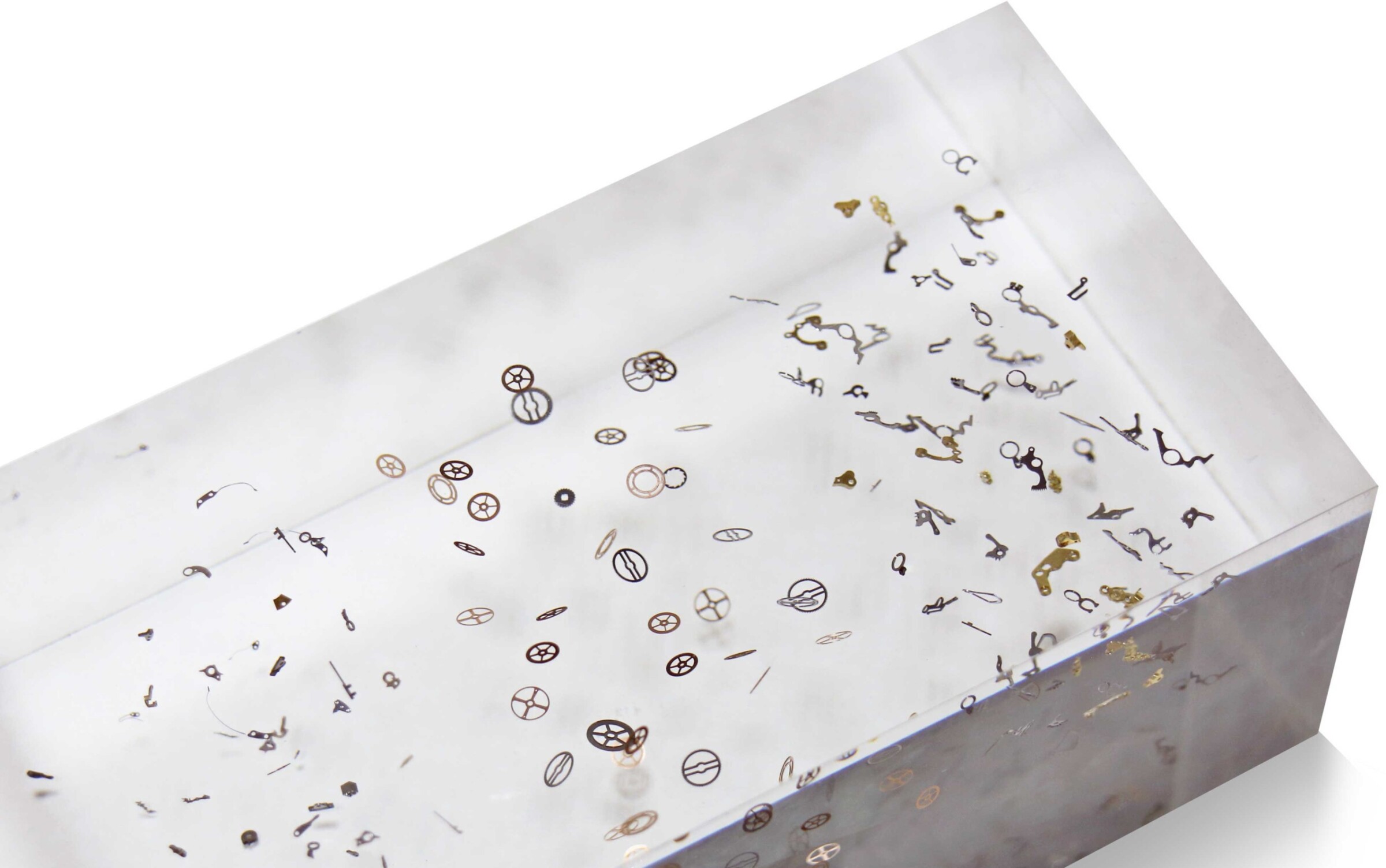

Frozen in a transparent block is a selection of watch components made by Inhotec.

The Mitsubishi Electric MX600 EDM system, which went into operation last year, operates entirely differently. On this system designed specifically for super-fine machining, oil is used as the dielectric. Although this is slower, it is much gentler on the material being machined. This is joined by electronics capable of generating an extremely smooth cut edge with sensitively dosed pulses lasting as little as a billionth of a second. At Inhotec, the cut edge after the first cutting cycle is typically processed seven to ten times more with ever decreasing feed rates and suitably reduced spark energy. The result is exceptionally smooth cut edges that meet even the exacting expectations of clock- and watchmakers.

Machine operation is easy to learn intuitively.

“We’re thoroughly content with the new system,” says Sylvain Jacquot, head of EDM at Inhotec, summing up. The Mitsubishi Electric MX600 runs with wire electrodes ranging in thickness from 0.2 down to 0.03 mm Ø and has been operating 24/7 since its commissioning a year ago. Thanks to its modern control with its high-resolution graphic display of processes, machine operation was easy to learn intuitively. The new machine surpasses the systems from a different manufacturer used to date in two ways, Jacquot stresses: with its good price/performance ratio and with the quick and efficient after-sales service provided by the Swiss agent, Binkert AG in Wallisellen.

Name and place of company:

Inhotec SA

Switzerland

Founding year:

2011

Managing Director:

Alexandre Eme

Employees:

50

Core business:

Supply of intricate mechanical components and complete subassemblies for high-grade Swiss clocks and watches, from the prototype through to series of several thousand pieces. All processes are handled so that the customer can use the parts directly in production. Along with meeting the highest quality standards, Inhotec aims for a fast response and flexibility in the performance of any special requests.

Inhotec SA

59, Rue de France

2400 Le Locle / Switzerland

Tel +41 32 9311800

Fax +41 32 9311801

info@inhotec.ch

www.inhotec.ch

Mitsubishi Electric agent in Switzerland

Josef Binkert AG

Grabenstrasse 1

8304 Wallisellen / Switzerland

Tel +41 44 832 55 55

Fax +41 44 832 55 66

info@binkertag.ch

www.binkertag.ch

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com