In the face of growing global competition, companies are investing in new technologies so they can maintain their leading positions. Alfred Jonscher GmbH, mouldmaker for injection and die-casting moulds, sees itself in this situation and is constantly modernising its machine park. The machines’ high performance and precision facilitate high accuracy, process security and cost-effective production. The company consistently focuses on the customer’s technological requirements, and wire-cut EDM has proven to be a key technology in this context. By installing an MV1200S, the company has added a new generation to the proven FA20-S Advance erosion machines from Mitsubishi Electric.

Playing safe – high-grade precision moulds make wire EDM indispensable.

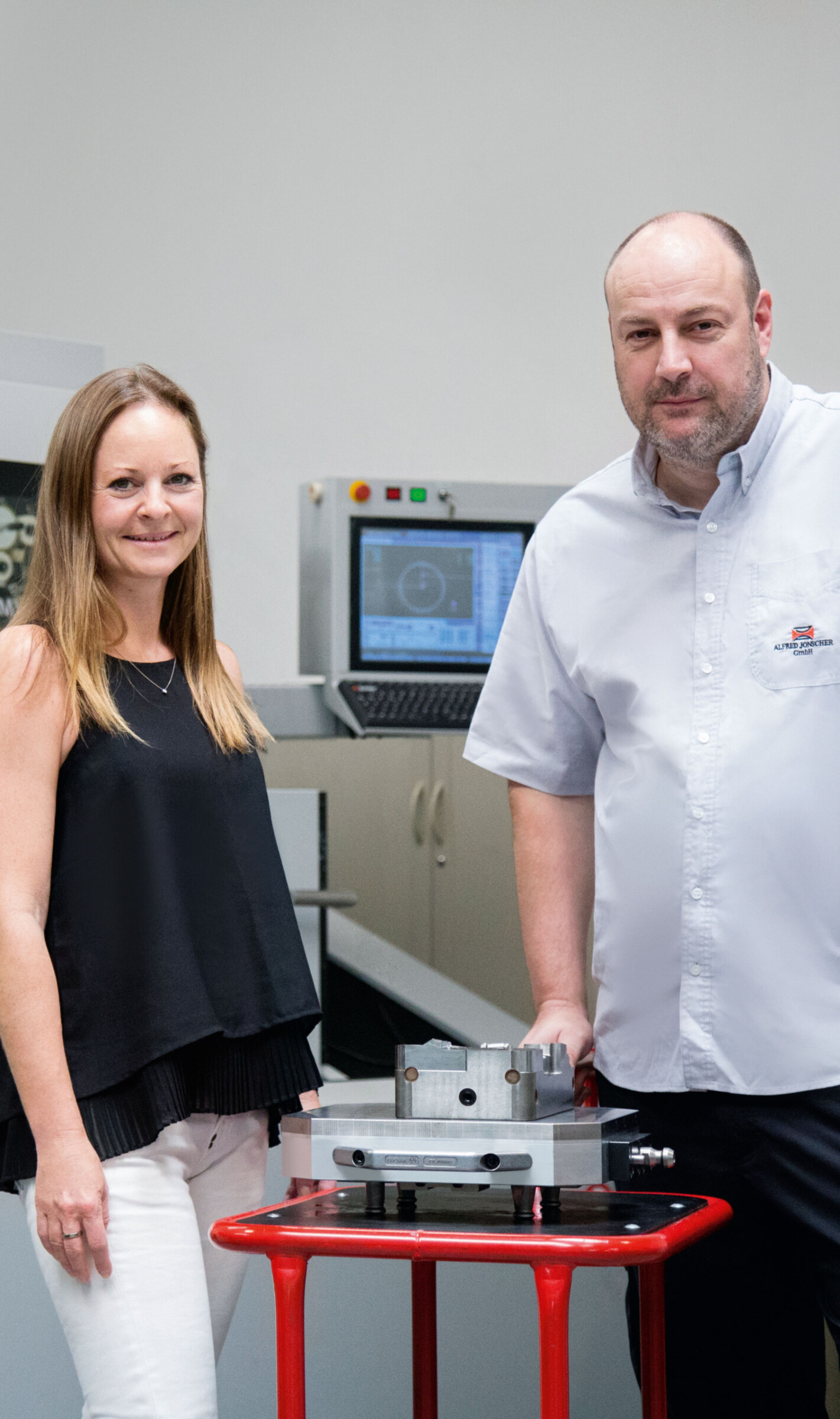

“Making moulds for injection moulding and die casting, we have been a reliable partner to our customers for over 45 years. These are complex, technically sophisticated products. To achieve superlative quality, we have to always strive to effectively coordinate our modern CNC-supported machine park with innovative technologies, our skilled workforce and our integrated IT system,” explains graduate business economist Natalie Pickshaus-Jonscher, Managing Director of Alfred Jonscher GmbH in Velbert, Germany. “In addition to a high degree of accuracy and quality of the finished product, it is important above all to maintain short cycle times and ensure long service life in production.

Precision and quality in the finished product.

Because then we can offer our customers moulds that achieve maximum productivity with minimum piece costs.”

Natalie Pickshaus-Jonscher and Sven Siegmund inspecting an injection mould.

The Jonscher company develops and produces high-grade precision moulds for plastics injection moulding and moulds for aluminium, zinc and magnesium die casting. The customers include big-name international firms in the automotive industry, telecommunications, household appliance sector, locks & fittings and the computer, electrical medical and toy industries. Jonscher thus possesses all the associated expertise for the production of such items as hot-runner moulds and moulds for thin-wall moulding and insert technology. These are joined by the production of elastomer moulds, moulds for two-component injection moulding and for vacuum-assisted die casting. The company also has a reputation for gas-assisted injection moulding and mono-sandwich technology. The produced moulds can be as much as 1,000 mm wide and 1,600 mm long. The weight of the relatively large moulds can be as much as 6 tonnes. The locking pressure can be as high as 1,000 tonnes for injection moulds and up to 800 tonnes for die-casting moulds. Jonscher’s range of services ranges from the design and production of moulds, both for prototypes and for mass production, through to the preparation of test reports on initial samples. It also extends to repairs, modifications, technical advice on feasibility, materials, product design and component optimisation. An integrated CAD CAM IT solution is essential for industrialised production processes. Thanks to its highly advanced machine park, the family company has a high degree of automation.

We now achieve rates of

capacity utilisation that we used to only dream of.

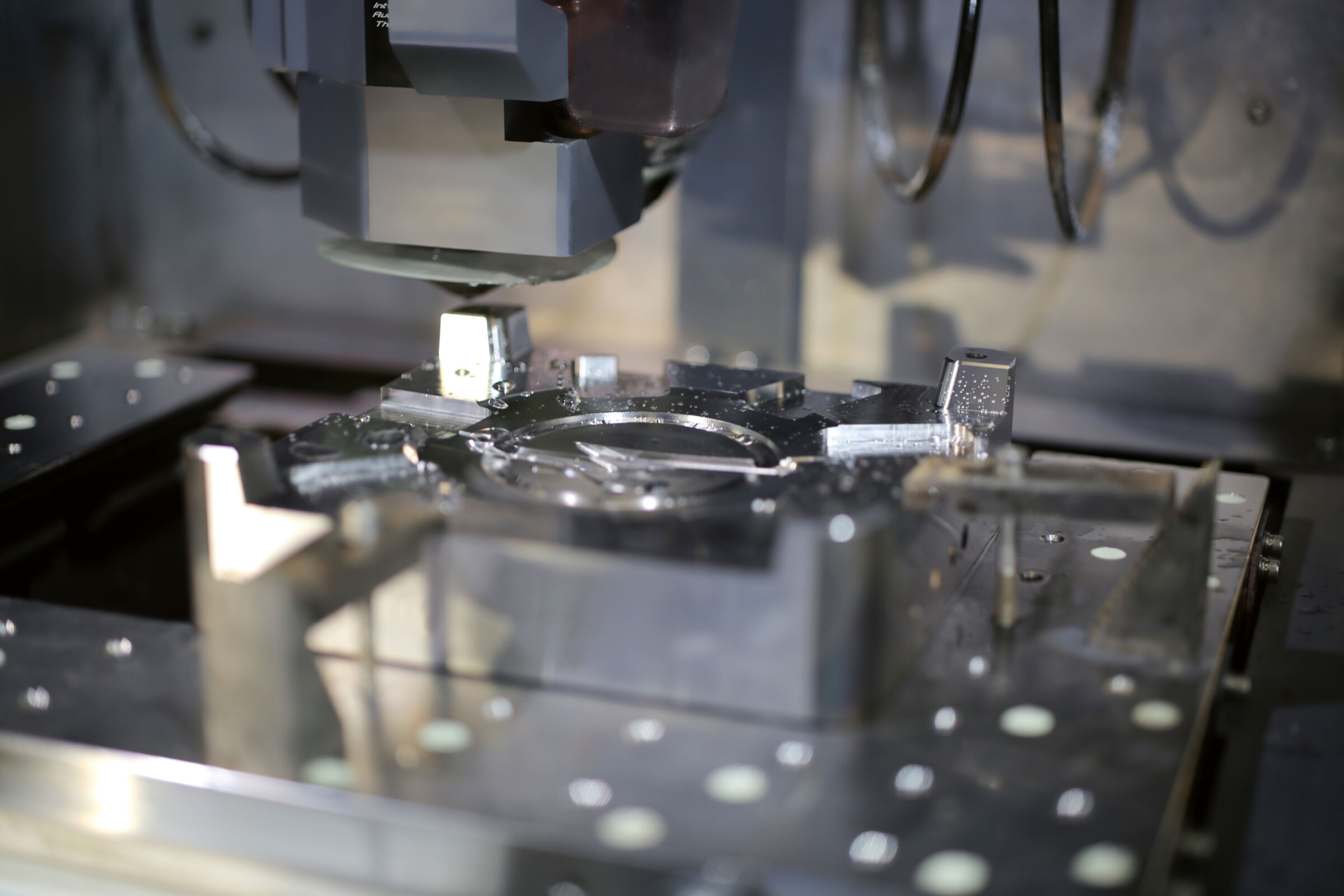

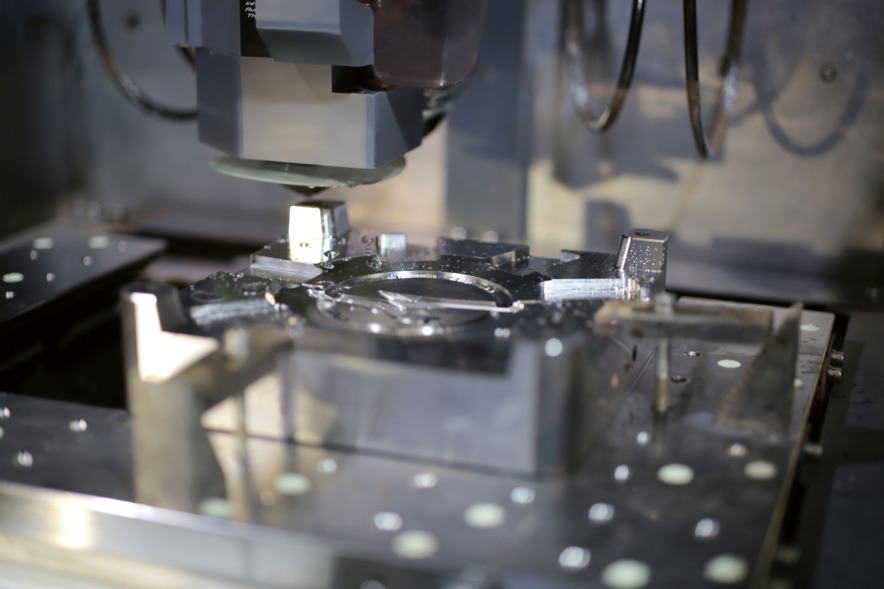

A modern production line with a linear robot for the fully automatic production with 5-axis HSC milling, die sinking and integrated 3D measurement has also been installed. “Automation has to be sensibly implemented so that processes can become more stable and faster while also remaining flexible. We now achieve rates of capacity utilisation that we used to only dream of,” says Pickshaus-Jonscher. The company constantly aspires to outstanding quality of workmanship and maximum precision throughout the process chain, which is why the production machines are accommodated together with the wire EDM machines in a fully air-conditioned production shop.

In 2012, the company was faced with an investment decision to integrate an innovative wire-cutting system in the machine park. “We were by no means dissatisfied with the three FA20 wire EDM machines from Mitsubishi Electric installed in 2001, as we achieve very good throughput rates and they have more than paid their way over the years. Wire threading on this machine generation was also pretty efficient. However, here at the company, we had taken a closer look at the new generation of wire-cut EDM machines,” says Sven Siegmund, responsible for wire erosion at Jonscher.

Meeting the growing aspirations of the market for quality production technologies also meant raising the bar for wire EDM machines. With their high performance, Jonscher wanted them to achieve greater precision, quality, functionality, flexibility and reliability coupled with savings potential. The company’s detailed wish list read as follows:

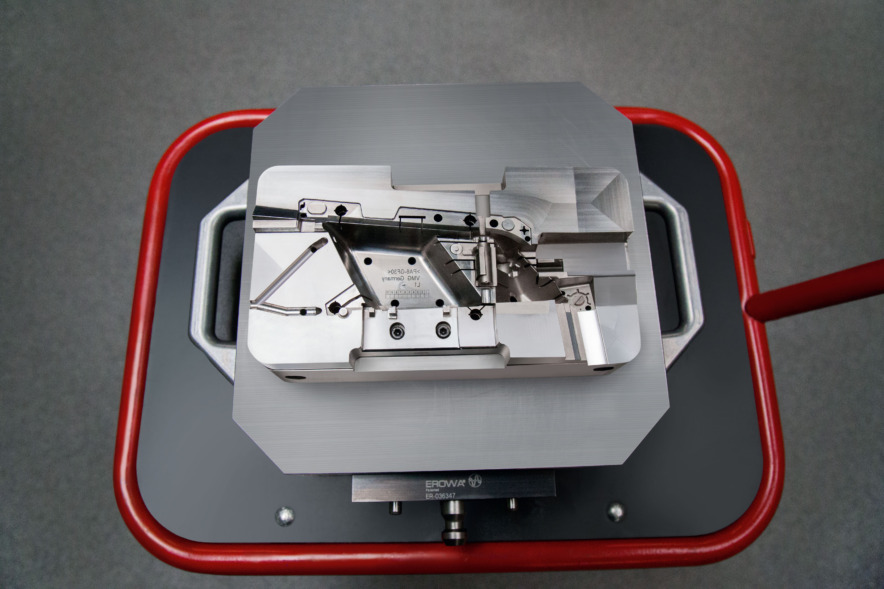

Insert for a 4-cavity mould (recessed grip)

By satisfying these requirements, the conditions would be created for boosting productivity, deadline compliance and competitiveness. “We tested a variety of makes and set benchmarks,” Pickshaus-Jonscher explains. “We compared them all to our FA20 machines and the MV1200S wire EDM from Mitsubishi Electric came out best. It has a higher cutting speed and 35 per cent lower throughput time. At the same time, it also produces a significantly better surface finish. This is where, for instance, the cogging suppression of the Tubular Direct Drive has a positive impact. In addition, the MV1200S displays further-enhanced stability during wire threading. In addition to these technical features, Mitsubishi Electric was the only company that rounds off its package with an environmental strategy in which ecological factors such as resource conservation find expression, which is something that I personally attach great importance to. Ultimately, it was the attractive price/performance ratio that pushed the balance of our decision in favour of Mitsubishi Electric.” So that the hypermodern machines and production technologies can be employed to best effect, the company in Velbert has its staff trained accordingly. This is the only way of achieving top-quality products for the market.

“As expected, we have managed to appreciably lower set-up times with the new zero-point clamping system. For this, the work table accessible from three sides (640 x 540 mm) is ergonomically aligned to the plane z = 0 so that workpieces can be optimally positioned even without clamping bars,” Sven Siegmund explains. “To machine contours, two to three recuts used to be necessary. Now we achieve one recut less on average per machining. Energy consumption is also markedly lower, as fewer power levels are required during machining. These benefits are attributable to the Precise Finish Cut technologies developed by Mitsubishi Electric for roughing, finishing and fine finishing in terms of parallelism, contour-trueness, radii and corners.

Trouble-free importation of NC programs.

On the MV1200S, the parameters for machining are assigned intuitively and with menu guidance. Operating comfort is assured by the proven and consistently refined human-machine communication of the FA Series. Intuitive operation is extremely straightforward for the operator using input masks and symbols. Available are a number of directly retrievable operating instructions, Windows-based user guidance and the automatic 3D workpiece position measurement.

Sven Siegmund after setting up the MV1200S

Precision, quality and throughput are boosted still further by activating the Power Master 3D that performs intelligent analyses and contributes optimum machining strategies. Malfunctions are practically eliminated. However, in the event of a fault, a message to this effect appears immediately on the screen. Via an additional window, the machine operator receives a problem analysis and suggestions for remedial action to be taken. “The entire documentation inclusive of the maintenance instructions can be accessed at the press of a button together with illustrations and 3D representations. Replacing the cutting wire, a filter or a power contact is now performed much faster and contributes to shorter set-up times,” Siegmund explains. “However, should a failure ever occur, the Mitsubishi Electric hotline provides quick and expert advice.”

“We have been particularly impressed by the further-developed automatic wire threader on the new machine. A suitable solution is always available for the particular threading situation. In the event of wire breakage, the wire is automatically re-inserted into the kerf even on tall and discontinuous workpieces. Time-consuming tracing back to the original position is no longer necessary,” says Siegmund. “The reliability of automatic wire threading makes it possible to load the machine during the day to make full use of it and let it run overnight, on public holidays and at weekends unmanned. This makes it easier for us to integrate urgent orders into our order processing system. With the optional mcAnywhere Contact remote access, we also have an excellent way of monitoring the current machine status or the state of order completion,” Pickshaus-Jonscher adds.

As a result of the optimised cutting behaviour of the MV1200S, appreciable savings of wire, filters and electricity have been achieved in addition to faster machining. “Against this background, we have been able to replace two of the FA20 machines with the new MV1200S wire-cut EDM. We now not only have more space, but have also reduced operating costs. For instance, we save electricity due to less cooling and ventilation. On top of this, the MV1200S is neither susceptible to failure nor maintenance-intensive, which was also our experience of the predecessor machines,” Pickshaus-Jonscher notes. The remaining FA20 is still working to full capacity, as it wire-cuts larger workpieces thanks to its extended machining range.

Precision, quality and productivity.

“If we do ever need Mitsubishi Electric’s after-sales service, the machine manufacturer is quick and proficient in keeping its machines up and running efficiently,” the Managing Director adds. “The change of generation with our wire EDM machines from Mitsubishi Electric has really paid off. The innovative technology goes a long way towards improving precision, quality and productivity. Thanks to their high process security, expenditure on maintenance, repairs and consumables has been reduced. Our expectations of performance, stability and competitiveness have been fully met,” Pickshaus-Jonscher continues. “The moulds we make put the customer in an ideal position to achieve extremely long service life on their production lines. We are proud of our expertise and are a reliable supplier to our customers.”

Name of company:

Alfred Jonscher GmbH

Founding year:

1968

Managing director:

Natalie Pickshaus-Jonscher

Number of employees:

20

Core business:

Mouldmaking for injection moulding and die casting, CAD, CAM, CNC milling, wire-cut/die-sinking EDM, sample mouldmaking

By passing an exam that I thought I’d failed and hence having a qualification in the bag much sooner than expected. I asked Dad to let me work for him as I was bored at home. Then I left the company for several years before coming back to my roots what is now 15 years ago.

With more advanced CAD/CAM systems and automated machining and measuring, we are capable of building more precise moulds – with shorter throughput times and less manual reworking. In addition, we also work entirely without drawings. A huge variety of computer solutions ensure greater transparency and scope for intervention in the processes. Such concepts as project time recording, planning, job scheduling, documentation and post-costing have become more important.

Vision, faith and a passion for what we do.

Achieving goals quickly and pragmatically with a slightly different approach.

With imagination, creativity, intelligence, a rapid grasp, a capacity to think things through, and by accepting responsibility.

Honesty, genuineness, loyalty, hard work, respect, helpfulness, politeness, initiative, optimism and modesty.

My children can always manage to conjure a smile onto my face.

By organising myself even better and working even faster [laughing].

Managing Director

Alfred Jonscher GmbH

Natalie Pickshaus-Jonscher Managing Director

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com