For Alexander Wiegand, head of the WIKA Group, quality, dependability and proximity to the customer belong together. Founded in 1946, WIKA has steadily grown into a family company with over 9,300 employees, globally active in 75 countries.

Today, WIKA is the world market leader in pressure and temperature measurement and calibration instruments. The company also sets standards with the parameters of filling level, force and flow rate. To ensure efficient production, the production engineering specialists develop and produce an abundance of equipment for its plants.

When maximum safety counts and measuring components have to withstand tough conditions in the field, WIKA force measuring equipment comes into its own.

Quality, dependability and customer proximity have enjoyed high priority among staff at all levels since the company’s founding. The successful company history of WIKA Alexander Wiegand SE & Co. KG is built on this canon of values. WIKA is an internationally recognised supplier of and expert in pressure, temperature, level, flow and force measuring instruments. The requirements vary greatly and are challenging: each field of application has its own parameters, and each sector of industry, such as machine manufacture, HVAC and semiconductors, operates on the basis of its own guidelines and standards.

When things get tough, measuring equipment from WIKA reveals its strengths.

“To satisfy customer wishes, we have built up a broad product range that is constantly growing in accordance with market needs,” explains Ralf Bayer, group manager in production engineering at WIKA. In addition to standard products, the company also develops tailor-made solutions in cooperation with the customer. “Our expertise and high-tech production plant permit the production of high volumes – and at competitive prices and with short delivery times,” Bayer adds. “We produce much of our production machinery in our internal production engineering department.”

The company values its workforce, regarding it as is its biggest asset – a fact illustrated not only by the extra social benefits and by the working conditions in production and administration. WIKA differs strongly from other employers on a large number of counts. The reconcilability of work and family life is a central issue for many young employees. Is it possible to resume a job after maternity leave? What’s the best way for children to be cared for? And who takes parental leave when? These are the issues that young parents are faced with.

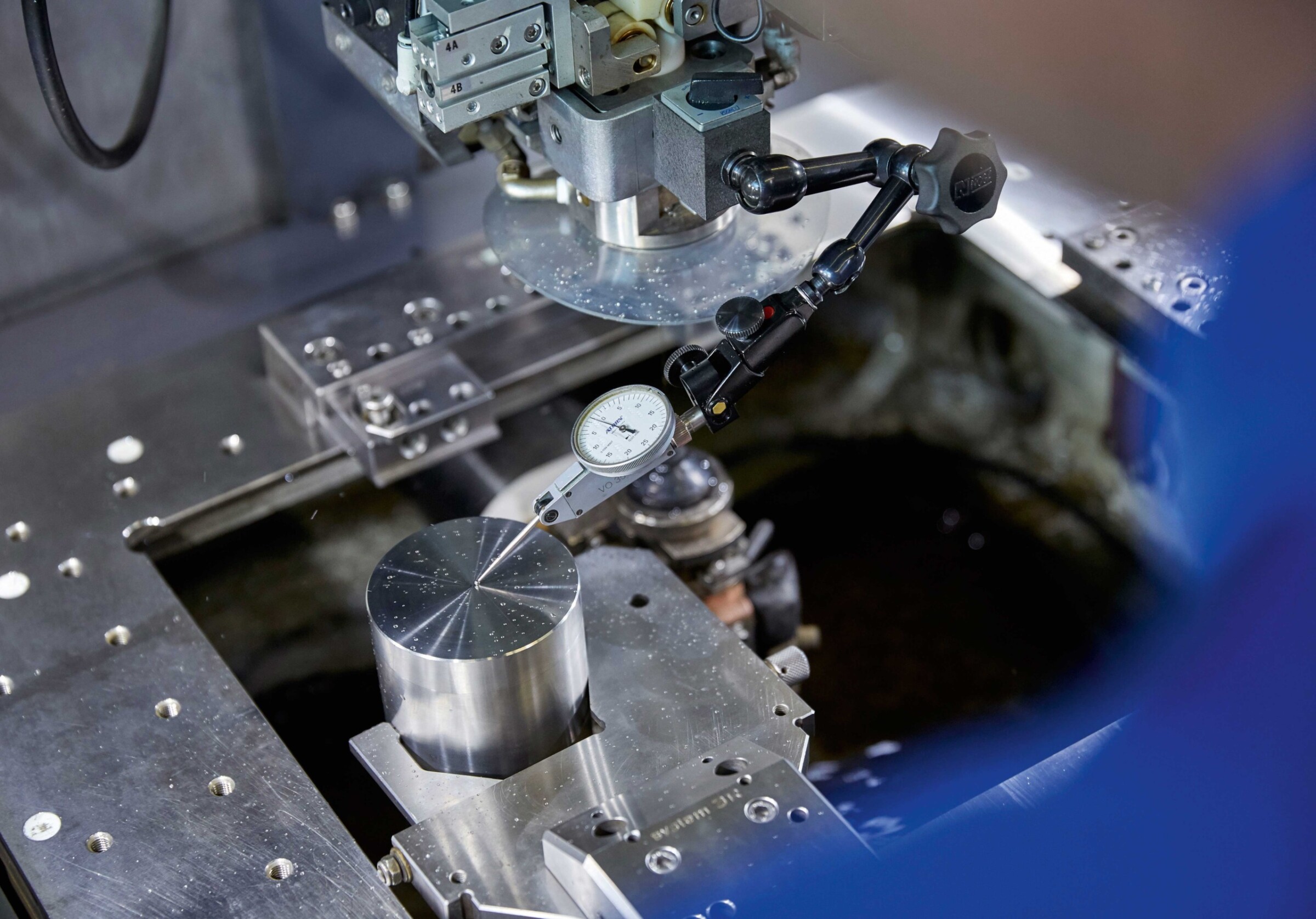

A Mitsubishi Electric MV1200R has been assisting the production equipment manufacturer since the end of 2016.

Quality, dependability and customer proximity.

Since 2009, WIKA has been running the WIKALINO day nursery in cooperation with the municipality of Klingenberg. Immediately opposite the company site, it provides places for 24 children. During holiday programmes lasting several weeks in the summer holidays, employees’ children are taken care of. To make it easier for young female employees to get back to work after a pregnancy, the company provides its own parent benefit. These are just three examples of the list of bonuses and incentives for staff.

For Karl Zimmermann (left) and Ralf Bayer it’s important to pool practical expertise in production equipment manufacture.

The performance data of the new MV1200R were just what we needed. In the last 20 years, our experience with Mitsubishi Electric has been very positive. The after-sales service with wear parts and consumables has always worked well in the past. The package is simply perfect.

Ralf Bayer

WIKA’s pressure, temperature and level measuring instruments often have to operate in extreme outdoor conditions, aggressive media or in areas exposed to explosion risk. In the overall chain of process engineering components, measuring equipment plays a crucial role. It supplies process-related information, thus making high-quality production possible. Measuring equipment improves safety for people, processes and the environment. “A lot depends on their dependable operation,” explains Karl Zimmermann of production engineering. “Our certified instruments comply with all relevant international guidelines, have been awarded global approvals and meet the highest standards of quality and safety.”

Production engineering with its 80 employees is certainly not the largest department at WIKA. But it is where the entire production expertise is pooled. “We develop, design and produce equipment for the WIKA plants worldwide as well as for external customers. It is still an advantage to have our own departments for instruments and tooling with highly skilled specialists. Our experts understand the needs of production,” explains Bayer. The internal production engineering department is in direct competition with external operators. But for equipment exploiting WIKA’s own expertise, there is a hard-and-fast policy of only producing it internally. The production engineering specialists are employed at the parent location in Klingenberg. The department includes not only design engineering, but also production and software development, control engineering, assembly and maintenance. And each step is subject to comprehensive quality assurance.

The highest standards of quality and safety.

The definition of production equipment at WIKA is straightforward and covers all machines, plant and tools that the company needs for its own production activities. These extend from tiny toggle presses to complex automatic assembly plant linked up with conveyors. So that each job can be completed in the agreed time, production engineering works on the project principle. Each job is a project with someone in charge who is responsible for all activities.

The first measurements are already underway on the machine.

“So that all the pending jobs can be completed on time, the department is adequately manned with specialists in mechanics, electrics and software and even has its own purchasing section and store. Everything we need for the construction of our plant and for maintenance is procured and warehoused largely independently by our department. Our customers, be they internal or external, receive everything from a single source. They are comprehensively served so that production is kept up and running,” Zimmermann elucidates.

In production engineering, it is electronics that dictates the pace. Electronic products offer genuine extra value in many cases and modern production equipment is incapable of doing its job without computers, actuators and sensors. “This transition is adding enormously to the complexity of our work,” says Bayer. “We’ve had to introduce new test technologies, as printed circuit boards and sensors are subject to entirely different requirements and standards. Electrostatic discharge is not an issue with mechanical measuring instruments, for example, while electronic instruments are very sensitive in that respect. We’ve had to thoroughly re-equip ourselves in many areas and have taken on new staff with the necessary expertise.”

Since all the departments in the company can basically decide for themselves whether to order their production equipment internally or externally, the production engineering department has to make efforts to stay competitive. “When we make internal estimates, they have to be tightly costed. We’re no exception in having to aim for a top-quality price-performance ratio,” says Bayer.

WIKA Alexander Wiegand SE & Co. KG

In addition to highly skilled employees with the necessary specialisations, a machine park equipped with the latest hardware is absolutely essential. WIKA is constantly investing in this area. Four years ago, for instance, in the course of the modernisation of the machine park, a new CAD/CAM system was introduced via which the design data can be transmitted straight to the machine. A Mitsubishi Electric MV1200R was also added to the production engineering machine park at the end of 2016. WIKA has been practising wire-cut EDM on Mitsubishi Electric machines since 1997. “The decision to buy the new MV1200R wasn’t difficult for those responsible,” Bayer stresses. “The performance data of the new MV were just what we needed. In the last 20 years, our experience with Mitsubishi Electric has been very positive. The after-sales service with wear parts and consumables has always worked well in the past. The package is simply perfect.”

20 years of experience with Mitsubishi Electric.

“We attach a lot of importance to working in partnership,” Zimmermann adds, “and it has paid off. It then means that some issues can be settled quickly over the phone and we can rely on the solution working. For an on-going, intricately timed process, this has a lot of benefits.”

Name and place of company:

WIKA Alexander Wiegand SE & Co. KG

Germany

Founding year:

1946

Management Board:

Alexander Wiegand

Employees:

9,300

Core business:

Equipment for pressure and temperature measurement and calibration

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Main, Germany

Tel +49 (0)9372 132-0

Fax +49 (0)9372 132-406

info@wika.de

www.wika.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com