In the Stubai valley in Austria, the Stubai KSHB GmbH drop forge produces a wide range of high-grade steel and aluminium components for a variety of industries. The keys to its success are its high degree of vertical integration, employees acting on their own responsibility, a cooperative structure and its own toolmaking department.

Profitable production with creative strategies.

Stubai KSHB GmbH in Austria has developed very successfully in recent years as a competent supplier to industrial companies. The Tyrol company increased its sales from just under EUR 15 million in 2009 to EUR 41 million in 2018. Ernst Dummer, Managing Director in Fulpmes, reports that this extraordinary growth is based on a broad foundation. In his opinion, the company’s cooperative structure, for example, makes a significant contribution to the company’s success. Several cooperative companies in the Tyrol region assist each other, he continues, by offering a much broader range of services than any one company by itself. “Many of our customers appreciate the offer of a complete package of services from a single source. This gives them just a single contact person who can clarify all the details for them and supply a complete product,” says Dummer. In this way, the firm in the Stubai valley arranges to have its forged, thermally treated and machined components coated or painted by partner companies, for example.

Operator Sandro Dietl preparing the workpiece for machining

Benefit from high vertical integration.

Dummer mentions the special structures in his company as a further reason for being able to produce competitively in a high-cost region in the heart of Europe. This applies just as much to his commercial assessment of the business and as to his relations with employees. “As part of a cooperative, we’re not interested in maximising the dividend. We see our task as one of preserving and developing our businesses and the jobs associated with them over the long term.”

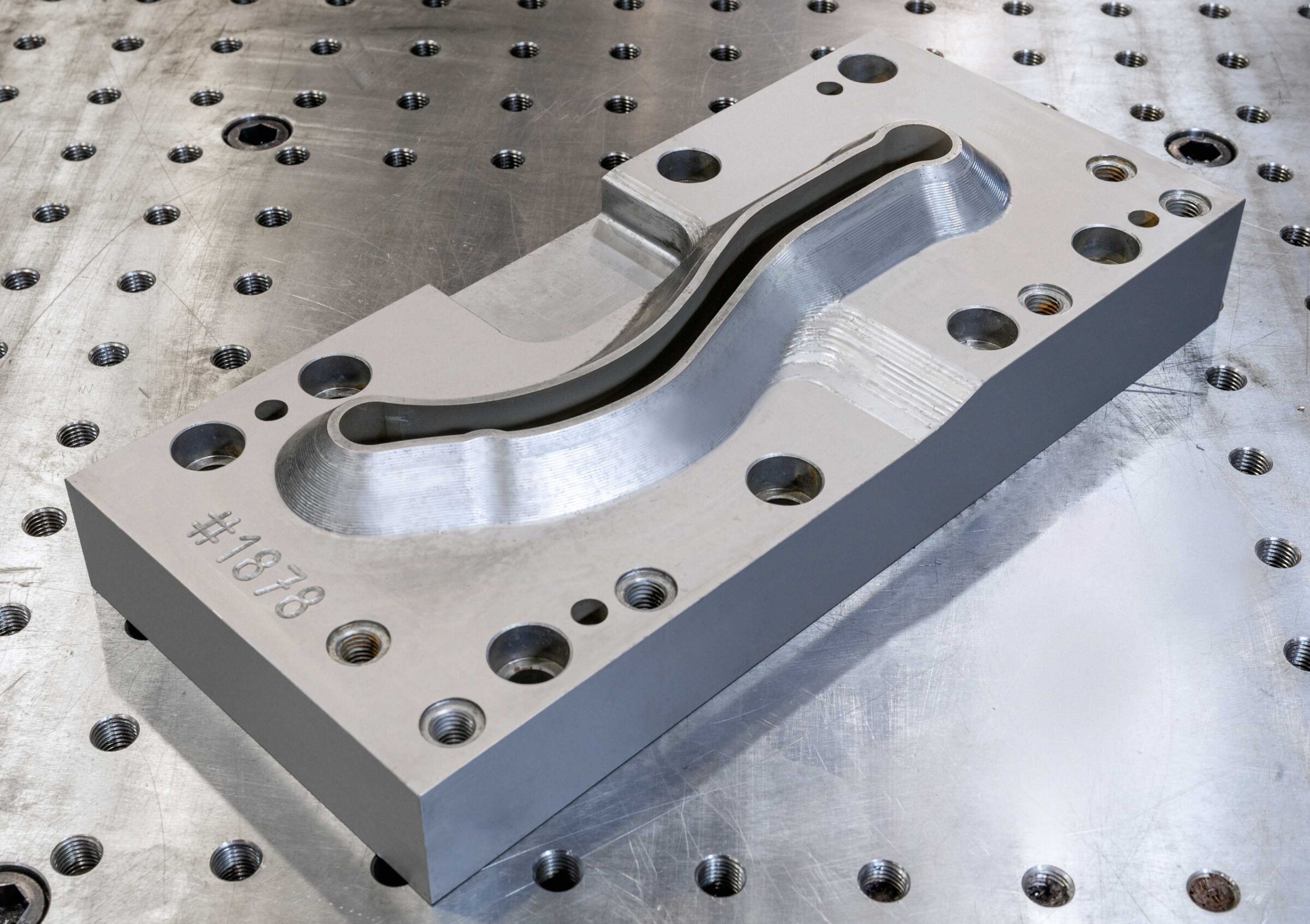

Wire-cut trimming dies made of hardened cold-work steel for the forging industry

The Tyrol firm has also optimised its internal processes over the past few years, implementing short information paths coupled with lean structures. This allows it to work highly flexibly and respond quickly to changing order situations.

In addition, the Stubai valley forge has high vertical integration. It is capable of thermally treating its forged workpieces, e.g. normalising and hardening them. In addition, it processes the components by drilling, turning, milling, grinding and deburring. The component suppliers in the Stubai valley also build ready-to-install assemblies in consultation with their customers. For this purpose, they have an internal toolmaking and equipment construction department at their disposal. As Dummer proudly reports, in this constellation he also sees his company excellently positioned beyond the immediate region. Stubai KSHB GmbH is the drop forge with the greatest vertical integration, he claims, when the large dimensions of the components produced here are taken into account. This also ensures a high degree of flexibility. “Our customers particularly appreciate flexibility. From us they can reliably expect even smaller series of ready-to-install components within the shortest delivery times.”

Outstanding technical advice and service.

In implementing such a corporate strategy, Dummer benefits from his excellent relations with his employees, always trusting in their expertise in their respective fields. He avoids giving direct instructions, he says, but assigns jobs to various units. “Freedom and responsibility instil the confidence on which employees can make the best-possible decisions for their particular unit and the company. Our experience with this has been excellent,” he adds.

With the remote maintenance mcAnywhere Control app, the operator has an overview of the entire machine at all times, regardless of location.

Services from a single source.

This applies in particular to internal toolmaking and fixture construction where the specialist staff mainly produce punching and cutting tools. These are mainly used for removing forging burrs from the workpieces. In addition, the toolmaking and fixture construction department in Fulpmes designs and builds complex systems for the automated production of components. These can be anything from special systems for transporting, inserting and removing forgings to fully automated robot cells. With the latter, the company automates, among other things, the loading and unloading of workpieces from lathes and milling machines and cleaning and measuring stations. In some production areas, fully automated, unmanned production has been achieved. Dummer says: “Our aim is to let the machines work productively for as long as possible unmanned. That’s why we’re automating many parts of our production.”

In the Stubai valley, this is primarily due to the high level of expertise of the employees in toolmaking and fixture construction. They also work largely on their own responsibility. In order to expand their capacity and improve their process reliability, toolshop manager Sandro Dietl’s employees decided to invest in an MV2400S NewGen wire EDM system from Mitsubishi Electric. This wire-cutting machine comes with a workspace working area sufficiently dimensioned for larger punching tools. In Dietl’s view, the outstanding technical advice and service provided by the manufacturer and its regional representative Büll & Strunz were particularly helpful and decisive for the decision in favour of the Mitsubishi Electric machine. If required, he adds, the manufacturer’s service staff can also be contacted quickly and reliably directly by telephone. The service staff are always competent and provide technically sound information, Dietl continues. As he further explains, wire EDM is indispensable especially for punching tool construction at the company. “However, our wire EDM machines have to be particularly reliable, as only then we can let the machines work in unmanned shifts. We need this to quickly and flexibly machine and rework the large number of punching tools and fixtures required at the forge,” he adds. He confirms that, on the basis of on initial experience, the MV2400S NewGen purchased in January 2019 has been operating reliably in every respect. The particularly dependable automatic wire threader has a major hand in this. The MV2400S NewGen in the company’s toolmaking and fixture construction department is also equipped with an extra wire station (20 kg) for sustained production operations.

The MV2400S NewGen always guarantees the rellable probing of a wide variety of workpiece.

Dietl and his staff are particularly proud of the mcAnywhere Control option, as this enables the machinists to display and operate the entire control terminal on their smartphone using an app. “This further improves flexibility when operating and monitoring the MV2400S NewGen wire EDM system. Wherever we are, we can quickly and easily check machine and process parameters and, if necessary, correct them,” Dietl adds. “This way we avoid unnecessary stoppages,” Dummer continues. “In addition, the wire eroding machine is capable of running completely unsupervised during evening and night shifts. This takes a lot of strain off our personnel, as they don’t have to work multiple shifts.” The MV2400S NewGen works more than 300 hours productively per month, i.e. about 12 hours per day, even though the toolmaking and fixture construction staff only work in single shifts. It thus goes a long way to ensuring that the company in the Stubai valley, a cost-intensive production location in the heart of Europe, can hold its own against fierce global competition.

Stubai KSHB GmbH

The wire eroding machine is capable of running completely unsupervised during evening and night shifts. This takes a lot of strain off our personnel, as they don’t have to work multiple shifts.

Ernst Dummer, Managing Director of Stubai KSHB GmbH

Name and place of company:

Stubai KSHB GmbH

Austria

Founding year:

1987

Managing Director:

Ernst Dummer

Employees:

200

Core business:

Forging, hardening and finishing of high-quality, heavy-duty components developed jointly with customers and the building of ready-to-install assemblies on a contract basis

Stubai KSHB GmbH

Industriezone A/1

6166 Fulpmes, Austria

Tel +43 5225 62239

Fax +43 5225 62239-300

www.kshb.at

office@kshb.stubai.com

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com