Despite being a relatively new company, Mold-tecnic R&D can boast many years of experience in the plastic injection-moulding, blow-moulding and thermoforming sectors. Their team includes professionals who have over 20 years of experience in mould production. They have equipment with the necessary technology to offer a complete service, from the design and adjustment of parts to achieve maximum quality, via the manufacture of prototype moulds, printed prototype parts or even printed prototype moulds, culminating in the final production mould. Ongoing technology development, continuous training of their teams and research into new technologies enable them to guarantee a first-class service to their customers.

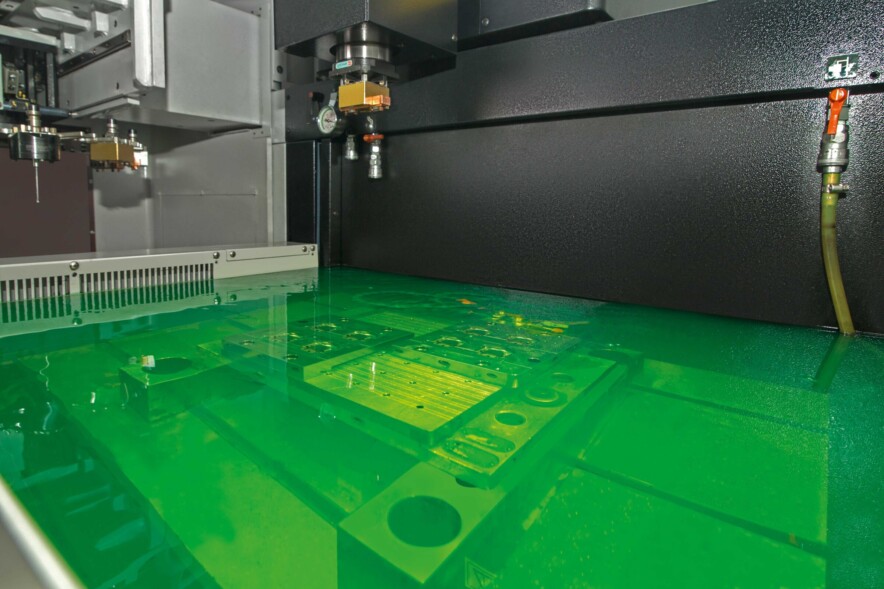

Good accessibility and user-friendliness thanks to the three-sided, lowerable work tank – for easy handling.

Most of Mold-tecnic’s activity is focused on the production of plastic injection moulds. A large proportion of these moulds are designed for the manufacture of vehicle interiors. As we all know, plastic injection moulding requires exceptional precision and the moulds must be able to withstand a large number of production runs. Mold-tecnic also manufacture dual-material moulds (double-shot moulds). These moulds allow the injection of two different materials, which gives the parts specific characteristics for their application. In the automotive sector, it is common to inject two materials with different degrees of hardness, so that composite parts can be manufactured in a single mould. This results in a large cost reduction and also avoids the need for assembly when the part is manufactured separately.

On the Natural User Interface (NUI), the touchscreen is similar to that of a tablet PC, which greatly simplifies navigation through the various functions.

For the design and creation of these moulds, they use software to design, virtually simulate and machine them, so that they are developed according to the customers’ requirements. With the aim of providing the best possible service, Mold-tecnic use the well-known TopSolid 7 software, using TopSolid Mold for the design of the moulds and TopSolid Cam for the machining. The superior production quality provided by Mold-tecnic enables suppliers to the automotive industry to produce thermoplastic components with very complex surface finishes. Today, Mold-tecnic manufactures high-quality, precision moulds for different industry sectors with the aid of Mitsubishi Electric EDM technology.

As we all know, plastic injection moulding requires exceptional precision and the moulds must be able to withstand a large number of production runs.

The decision to purchase the two Mitsubishi Electric EDM machines was driven by the need for a technology that would offer reliability, speed and precision mould manufacture. Previously, their EDM equipment was not fully reliable and did not offer sufficient performance for manufacturing high-quality and precision moulds. Therefore, in order to improve their processes and part quality, Mold-tecnic purchased an MV1200R Connect wire EDM machine and an SG12S die-sinking EDM machine from Mitsubishi Electric. This investment was due to a number of factors.

SG12S Mitsubishi Electric die-sinking EDM machine. Compact and user-friendly design.

SG12S

With its current range of wire EDM machines, Mitsubishi Electric is continuing its innovative and future-oriented approach, while retaining its tried-and-tested features. When we spoke to Rubén, he highlighted the many unique features of the Mitsubishi Electric machines compared to other EDM machines they had worked with up to that point. The MV1200R wire EDM machine stands out for its great flexibility of use.

MV1200R wire EDM and SG12S die-sinking EDM, the perfect duo for any workshop’s EDM section.

MV1200R Connect

Based on the first few months of using it in the workshop, the machine has proved to be extremely reliable. Thanks to this machine, they have been able to double their production and thus minimise their production costs. In addition, wire consumption has been visibly reduced. The MV1200R is designed for optimal wire consumption and perfect threading in even the most complicated situations. Other features include shorter machining times and more flexible processing. All this, combined with the machine’s high level of precision, has contributed to the choice of Mitsubishi Electric and COMHER.

With step-by-step guidance, less experienced users can navigate their way through complete process control. In addition, the intuitive hand control makes it easy to adjust the part in the machine.

As for the SG12S die-sinking EDM machine, Rubén pointed out that they have greatly reduced their electrode usage. “With the Mitsubishi SG12S, we have reduced electrode consumption by almost half compared to our old machine, which saves us a lot of time and expense in manufacturing the moulds.” The machine, equipped with an automatic 20-electrode changer, allows the process to be carried out hands-free. For die-sinking EDM, as for wire EDM, the programming and operation of Mitsubishi Electric’s fine-tuned control technology make the operator’s job much easier. This thus facilitates the production of high-quality moulds in a flexible and efficient way. In conclusion, Ruben credits both machines with the same strengths: reliable, precise, fast and user-friendly.

Erowa ITS pallet-mounted electrodes. The machine comes equipped with a C-axis head with the Erowa interface as standard.

The quality of the Mitsubishi Electric machines themselves was not their only requirement when purchasing them, but a quality after-sales service was also a determining factor. COMHER, the official distributor of Mitsubishi Electric EDM in Spain, has been offering the best industry solutions for more than 55 years. It was, therefore, no surprise that Mold-tecnic placed its trust in COMHER’s experience and technical team when deciding to purchase the machines. José Francisco Martínez, Product Manager for Mitsubishi Electric at COMHER, provided the necessary advice to Rubén and the Mold-tecnic team on the acquisition of this new equipment, helping them to significantly improve quality and production in their workshop. COMHER’s extensive experience in the machine tool sector, as well as having personnel with extensive knowledge and training in EDM, was a key factor behind the business relationship between the two companies.

High-quality precision tools.

Electrodes ready to enter the 20-position magazine.

The user-friendly nature of the machines and their exceptional operation meant that the start-up process was very simple. Mold-tecnic received training from COMHER’s technical staff on how to operate the machines, thereby enabling them to be used correctly and optimally for the mould production process.

This close relationship between the two companies continues on a daily basis. The COMHER team is at Mold-tecnic’s complete disposal to resolve any queries and provide technical assistance, offering an excellent after-sales service.

Name and place of company:

Mold-tecnic R&D

Spain

Core business:

Moulds and CNC Machinery

Director:

Rubén Pleguezuelos

Mold-tecnic R&D

Carrer Holanda, No. 2

08520, Les Franqueses del Valles (Barcelona)

Spain

Tel +34 667 648 628

comercial@mold-tecnic.com

www.mold-tecnic.com

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com