With innovative technologies and a modern machine park, the two managers of Honex AG, Reto Christen and Edgar Blöchlinger, are keeping the company on track for success. Relaxed, with a cup of coffee in one hand and an intricate punched part in the other, Christen explains the philosophy of the specialists in punched and bent parts. For him, punching is more than simply perforating sheet metal. “With our machines,” he says, “we can conjure up contours, shape sheet metal, modify surfaces and fully machine sheet metal.” The punching and bending methods are very quick and efficient, offering vast scope for the processing of sheet.

Remote machine access opens up new opportunities

With its 25-strong workforce, Honex AG in Switzerland hasn’t committed itself to the mass production of series running into the millions. As a service provider in a high-price country with the associated wage levels and social standards, it has placed its focus on challenging punched and bent products. “We concentrate on products that call for a certain expertise, a high standard of production quality and exceptional precision,” Christen explains. These include complex, spring-hardened punched and bent parts as well as products with matt-finish punched edges or punched parts meeting special standards of accuracy and material hardness such as sheet metal of 100 % fine blanking quality.

Jonas Maier (left) and Reto Christen know that customers want precision components.

Focus on challenging punched and bent products

“We’ve developed a process for highly efficiently producing blanks with nothing but smooth edges, i.e. entirely without fractures,” the manager adds. Such edges are usually the preserve of fine blanking. The Honex method produces smooth edges that do not require any further working, which yields considerable cost advantages for the customer. This technology is much appreciated by the textile industry that requires particularly smooth edges.

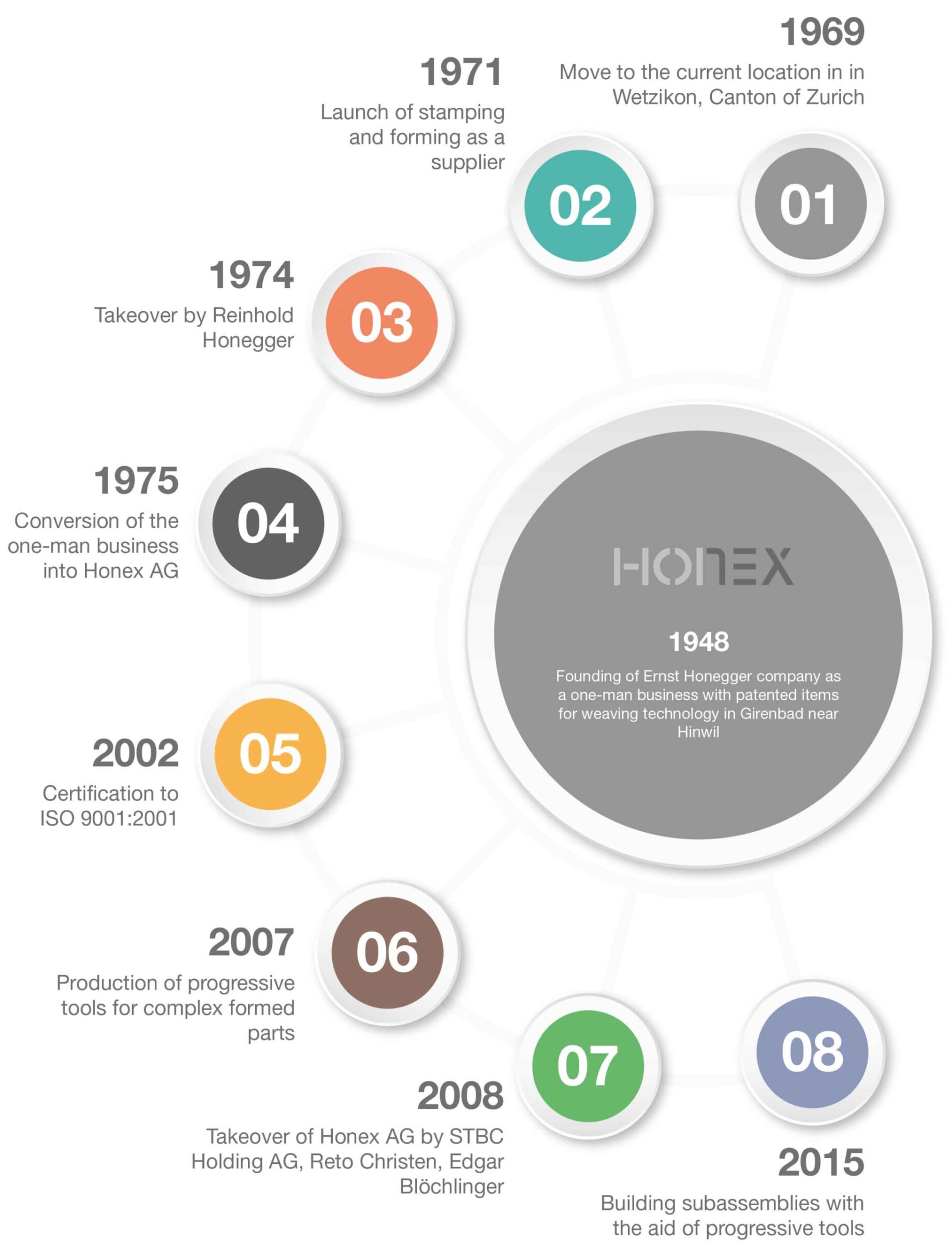

Chronicle of Honex AG

An important customer from this sector is a Swiss sewing machine specialist. For cost reasons, the company transferred parts of its production to Thailand a few years ago. But because of quality issues, the company brought the manufacture of core products back to Switzerland. For several years now, Honex has been producing parts meeting very high standards of quality and accuracy for the sewing machine manufacturer. These include a yarn brake satisfying levelness requirements of two hundreds of a millimetre over the entire surface.

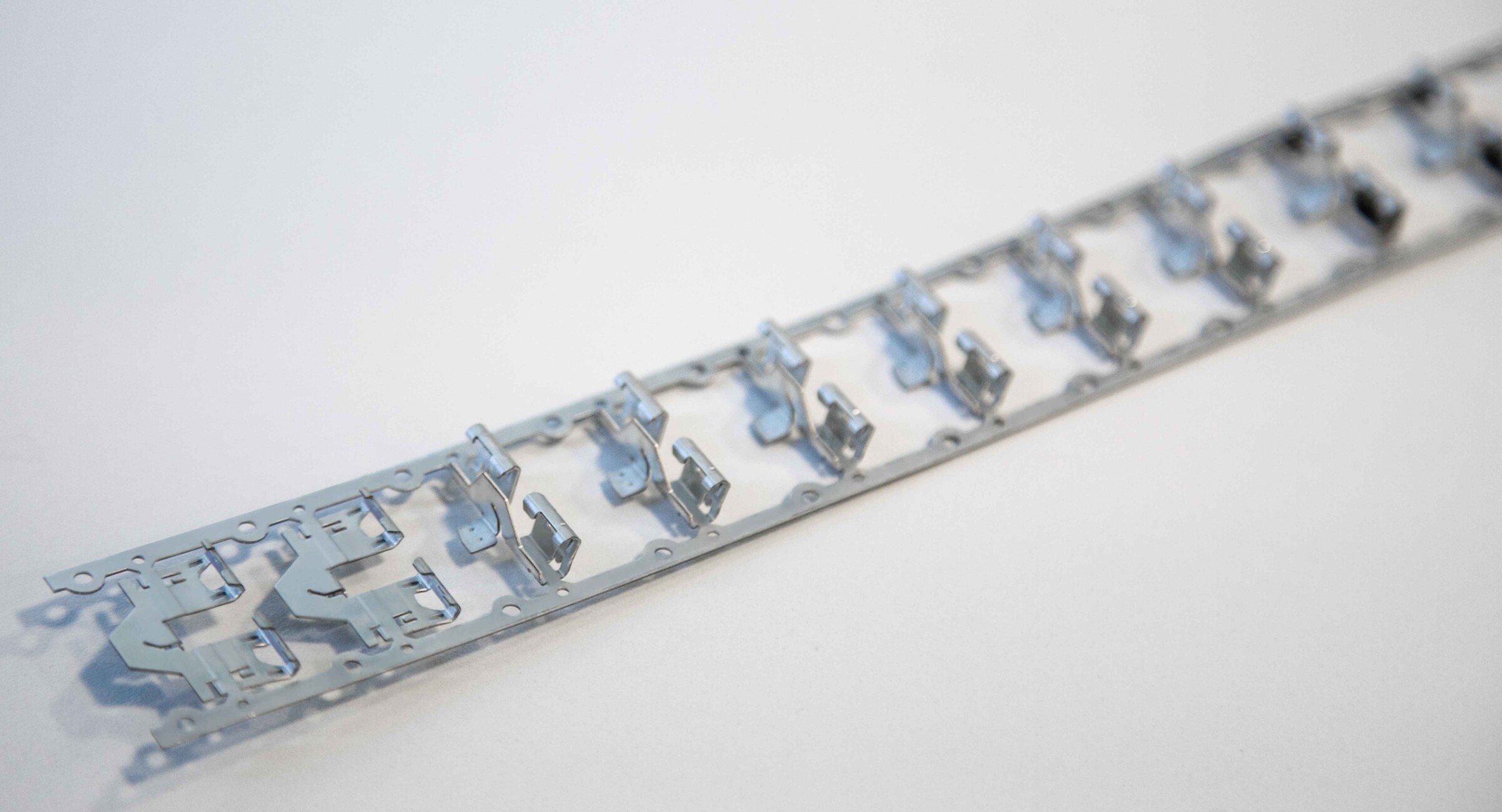

Complex formed parts meeting high standards of accuracy are a hallmark of Honex.

A specialist thanks to innovative technologies

Subassemblies for the electrical industry have so far been mainly produced with conventional cutting techniques. Parts are blanked and bent and then joined together by machine or by hand. “With our innovative method,” Christen explains, “we are able to feed different materials to our machines on three conveyor belts, process them with progressive tools and finally join them together into single units. This is how we produce clamping rings, for example, for the electrical industry.” Thanks to its innovative technologies, Honex is evolving from a company for punching and bending into a specialist in complex formed parts and subassemblies meeting high standards of function and dimensional accuracy. Christen sees materials that many companies avoid first and foremost as a challenge. Getting extra-hard and in some cases thick materials into shape arouses his sense of ambition. “We’ve built up a lot of expertise in this field and really get going when others have already given up.”

Jonas Maier appreciates the benefits of the Mitsubishi Electric MV2400R.

To meet the high expectations of quality, Honex produces all its punching tools in-house. Its toolmaking department is not particularly large, but it is manned by skilled specialists who are fully conversant with the entire production process. “Usually customers come to us with clearly defined tasks,” says Christen. “Honex is involved in product design at an early stage so that the production process for the parts can be optimised when it is a question, for instance, of joining two parts into one. Our development, toolmaking and production activities are closely dovetailed and integrated in planning early on so that all our experience is brought to bear. This is hugely beneficial.” The Swiss specialist attaches great importance to a modern machine park so that it can always offer its customers the best-possible quality and efficient production. A new wire-cutting machine was therefore on the investment agenda at the beginning of 2016. As with all newly purchased equipment, Honex launched a precise market analysis. It didn’t surprise the business owner that the closely examined machines were all highly efficient and differed relatively little in terms of precision and cutting speed. “But there are a number of definite advantages,” Christen reports, “that made their impression on us and swayed us in favour of a Mitsubishi Electric MV2400R.” Mitsubishi Electric scored above all with its new CoreHold function and the opportunities for remote machine access.

Almost unrestricted access to the machine from anywhere

Being able to access an EDM system from remote desktop or tablet computers or smartphones and reading off the operating status or fault messages is almost standard today. “But having full access to the machine,” Christen continues, “is new and a real advantage that pays off.” The goal of all businesses is to make optimum use of their machines – best of all around the clock. During the week, the employees’ working hours dictate the usage of machines that run for eight hours during a shift. If possible, long-running jobs are clamped on the machine for the night hours and weekends, always in the hope that everything goes smoothly and no hitches occur. This is usually the case, but not always. It’s the little things that cause stoppages every now and then.

Reto Christen Business Manager Honex AG

With our machines we can conjure up contours, shape sheet metal, modify surfaces and fully machine sheet metal.

The new Mitsubishi Electric software offering almost unrestricted access to the machine from anywhere supports Honex’s system of flexible working hours.

In a company with modest toolmaking activities and fixed working hours, employees are not constantly busy. “The idea for a new hours schedule came in good measure from the employees themselves. In consultation with them years back, we arrived at a flexible arrangement from which both sides benefit. It takes equal account of the interests of staff and of the company. A genuine win-win situation with greater responsibility and scope for decision-making.” In addition to a core period in which they are required to be at work, employees can now organise their duties and times of their own accord. They plan their work within the given time frame. The arrangement also entails that employees in certain cases have to bring their wishes into line with current workload. In the event of urgent jobs, it also envisages working into the late evening and at weekends.

Slashing machine running time

On the MV2400R the employee can see on his iPad which fault has occurred and intervene directly into the machine control and bring the machine to the next step. If, for instance, a problem crops up when machining a hole, the toolmaker is informed and can issue the necessary commands from his iPad, e.g. “Go to the next step”. “The machines competing with the Mitsubishi Electric MV2400R that we compared didn’t have this function,” says Christen. “Using this software means that at weekends we only have to be present on site to check up on things in emergencies – a real bonus for us.”

Honex stands for innovation in punching.

Plate from which many shapes have to be cut out used to require the toolmaker’s presence for several hours. The shape had to be cut out of the workpiece to leave a small web. The toolmaker then pressed out the web and removed the metal part from the dielectric. “On the new Mitsubishi Electric MV2400R, we can process such items as long-running jobs overnight or at the weekend without having to manually intervene,” says a gratified Christen. The CoreHold technology makes this possible.

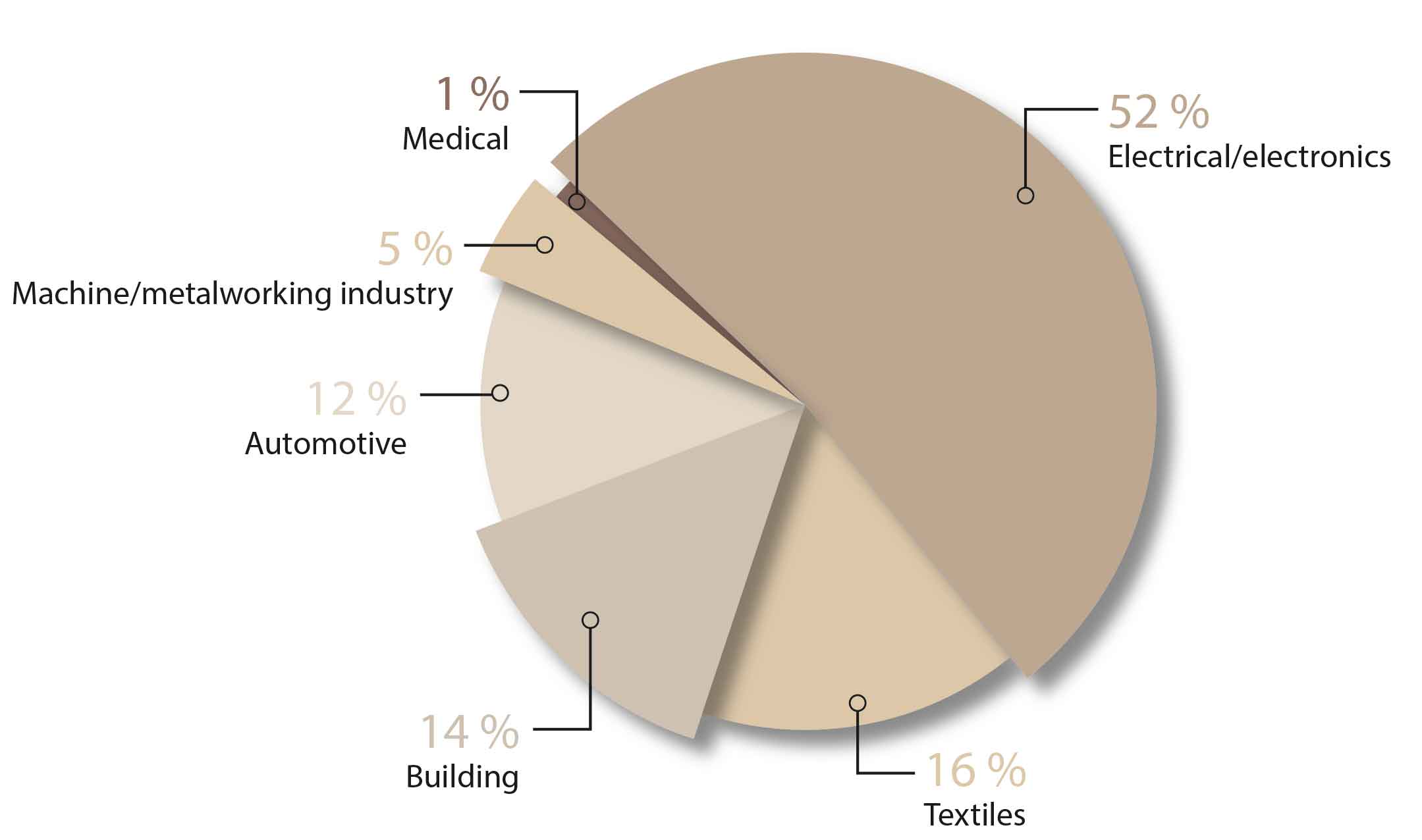

Shares of sales in 2015

At the roughing stage, the EDM system separates the part from the scrap but after cutting joins the two parts back together with one or more tiny dot welds. The scrap parts can then be removed from the workpiece and collected. “A work process that is completed in a matter of minutes,” Christen explains. After this, the machining program resumes. On long-running jobs with multiple openings, this shortens machine-running time considerably. So the purchase of the Mitsubishi Electric MV2400R has not only optimised the process and yielded cost reductions, but has also revolutionised working hour arrangements at Honex.

Name and place of company:

Honex AG

Switzerland

Founding year:

1948

Managing Directors:

Edgar Blöchlinger

Reto Christen

Number of employees:

25

Core business

Production of complex, spring-hardened punched and bent parts as well as products with matt-finish punched edges or punched parts meeting special requirements

Honex AG

Stanzerei Umformtechnologie

Hofstrasse 88

8620 Wetzikon, Switzerland

Tel +41 43 477 40-00

Fax +41 43 477 40-01

info@honex.ch

www.honex.ch

… a good network of personal contacts.

… luxury.

… a good network of personal contacts.

… I can’t think of any instances of bending the truth – sometimes I omit something, but lying really isn’t my thing.

… I achieve a goal that I’ve been working towards for a long time. That’s always a very emotional moment for me.

… injustice.

… the people around me.

… my motorbike’s petrol consumption.

Business Manager Technology/Sales

Honex AG

Reto Christen Business Manager Technology/Sales

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com