Compared to the media stars of research such as medical technology, microprocessors and genetic engineering, the materials sciences are a rather unspectacular field of research. Their successes and breakthroughs attract far less attention in the media and among the general public than the cloned sheep Dolly or the latest mutations of the coronavirus. Nevertheless, science is conducted just as intensively and successfully here as in other research fields. The developments in materials science best-known to the general public include the lightweight and ultra-strong carbon fibres.

With the help of wire erosion, components produced by additive manufacturing are precisely detached from the building platform.

“Here at the Erich Schmid Institute for Materials Science, we conduct research into the high-tech materials of the future,” says Robin Neubauer, mechanical engineer and workshop manager at the Erich Schmid Institute for Materials Science in Leoben. The institute is one of a total of 25 of the Austrian Academy of Sciences. The latter institution, founded by scholars 175 years ago, today has over 760 members and around 1,800 employees. Its goal is to promote progress in science and in society as a whole.

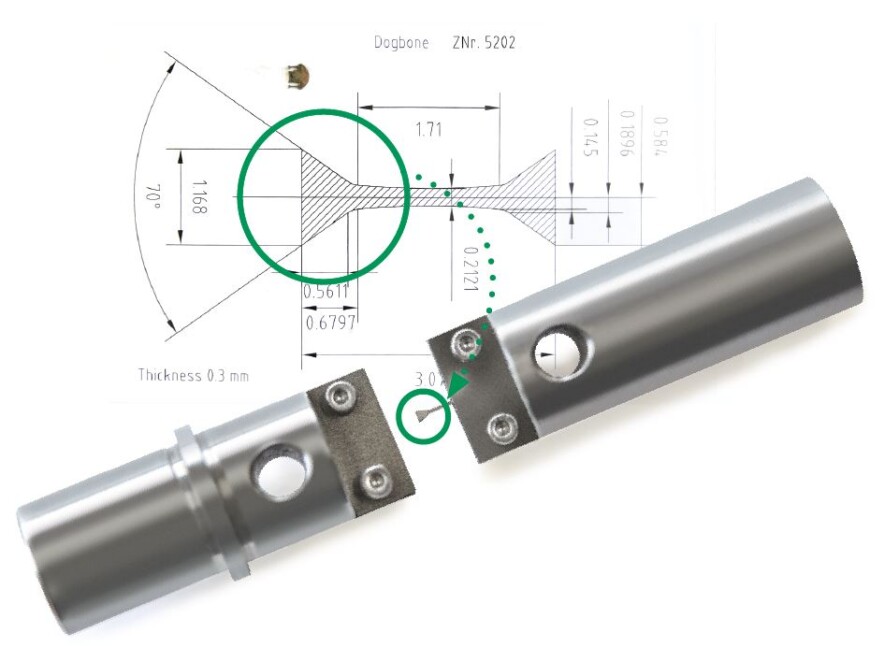

Tiny tensile specimens produced from an HPT blank (already clamped on one side in the holder for the experiment)

In close cooperation with the Chair of Materials Physics at Montanuniversität Leoben, the Erich Schmid Institute specialises in the study of microstructures as well as experiments on and the mathematical-physical modelling of metals, and also of biological materials and complex structures. Over and above the classic industrial metals, the institute often investigates special materials produced by unusual processes as well as novel nanocrystalline materials. Involved in the project led by Prof. Dr.-Ing. habil. Dr. h.c. Jürgen Eckert are some 95 employees, including senior academics, junior academics at all levels of education and numerous skilled employees from technical and administrative professions. The research partners include such numerous high-tech industries as aerospace, medical technology, machine manufacture and laboratory technology.

Electron microscopy allows researchers to study the internal structure of materials.

“We work with in some cases highly unusual materials produced in processes developed here, such as the High Pressure Torsion (HPT) forming process,” adds toolmaking technician Marco Reiter. His tasks include the design and realisation of the numerous special tools and devices needed for the production and testing of material specimens. Since there is practically nowhere where they can be purchased, they are fabricated in the institute’s own workshop.

This also includes the tools for synthesising the HPT material specimens produced at the institute. HPT specimens are made from in some cases quite exotic powder mixtures with the aid of solid round tools, between which the powder is compacted under extreme pressure by multiple rotational movements. Here, the powder particles, as a result of friction and pressure, fuse together into a solid body.

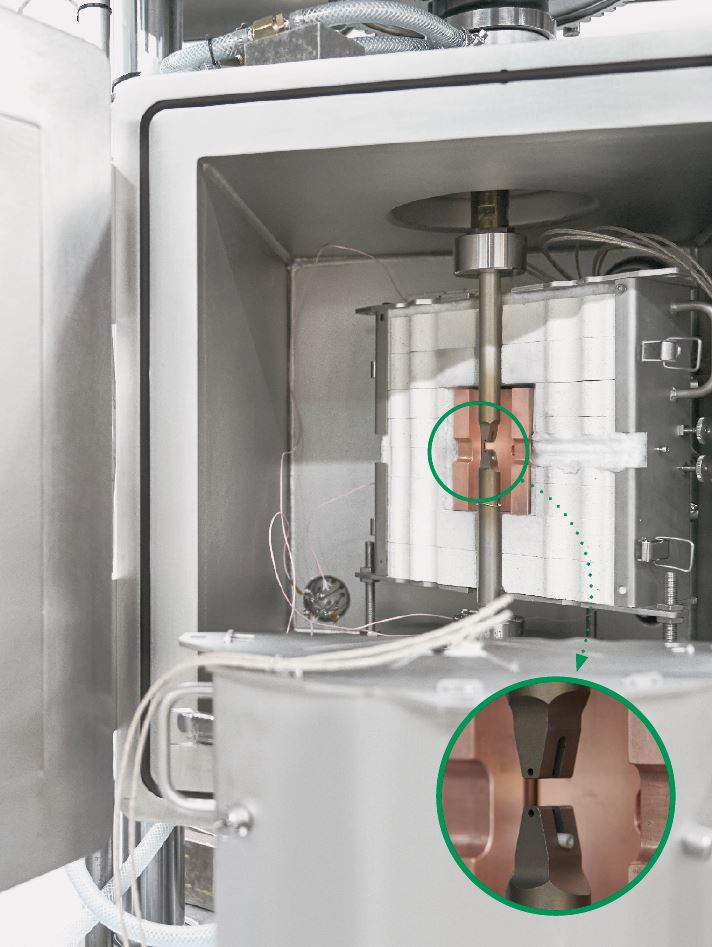

A clamped specimen in the installation space of the MV1200S shortly before the start of the process.

The specimens produced range from very tiny – much smaller than a 1 cent coin and only 0.3 mm thick – to the size of a men’s watch. To determine their mechanical properties, tiny tensile specimens must be obtained from them. This used to be done by milling, but this was extremely time-consuming and costly due to the specimens’ minuscule dimensions and the sensitivity of the extremely thin tools.

Specially fabricated fixtures for crack propagation testing. The fir tree structure is free to move laterally so that the specimen is not exposed to unwanted lateral force components.

“In 2017, we were then given a used wire-cut EDM machine, on which we were able to test the technology for the first time,” Neubauer recalls. Having appreciated the benefits of the technology, their appetite for more grew. As the existing system proved to be too antiquated and unreliable, the search for a modern alternative began in 2019. After reviewing several offers, they were impressed by the Mitsubishi Electric MV1200S wire EDM system, and not only because of its performance, but also because of its price-performance ratio and the good support provided by the Austrian technician Sebastian Ziegler. Deionised water is used as the electrolyte.

Installation took place in the second half of the year, but the agreed one-week training course was cancelled because of the COVID 19 restrictions. Thanks to a two-day brief introduction, the excellent documentation and the tireless efforts of the Mitsubishi Electric agent, who helped out repeatedly with brief visits and telephone support to answer queries or solve problems, familiarisation nevertheless went smoothly. In addition to specimens, the company now also builds in some cases highly sophisticated devices in-house, such as special test rigs for the performance of dynamic crack propagation.

The crack propagation tests are carried out in a furnace whose chamber can also be optionally placed under vacuum or inert gas.

Marco Reiter, toolmaking technician

“The MV1200S has meanwhile become an indispensable core item of our workshop equipment,” says Reiter. Some materials that are difficult to machine, such as tungsten- or nickel-based alloys and exotic materials like amorphous metal, can only be machined with wire erosion, as they are beyond the scope of conventional methods. In the meantime, the software link has been upgraded and CAD-CAM programs are used to feed the CNC data required for machining straight from the CAD designs into the machine control system. The importance of the wire EDM machine for the institute is demonstrated by the fact that its capacity utilisation is now at a roughly constant 75%. For a universal workshop like the one at the Erich Schmid Institute with its wide range of equipment and technologies, this value is exceptionally high.

The MV1200S has meanwhile become an indispensable core item of our

workshop equipment.

Specimen for dynamic crack propagation tests

Since commissioning, there have been no failures or malfunctions that can be directly attributed to the machine. However, new materials and tasks are constantly having to be processed. For many of these materials, some of them very exotic, there are no ready-made parameter sets in the control system database. In such cases, of course, one has to experiment more often in order to arrive at the ideal settings. In this context, the support provided by the Mitsubishi Electric agent should be highlighted, as he always helps out with advice and practical assistance when things get stuck.

Punch for the HPT process for the production of novel materials

Name and place of company:

Erich Schmid Institute of Materials Science of the Austrian Academy of Sciences

Austria

Employees:

Approx. 95

Founding year:

1971

Director:

Univ.-Prof. Dr.-Ing. habil.

Dr. h.c. Jürgen Eckert

Core business:

Investigation of microstructures and experiments on and the mathematical-physical modelling of metals, and also of biological materials

Erich Schmid Institute of Materials Science of the Austrian Academy of Sciences

Jahnstrasse 12

8700 Leoben

Austria

Secretary of the Austrian Academy of Sciences

Tel +43 3842 804 111

daniela.brunner@oeaw.ac.at

Mitsubishi Electric Agent

in Austria

Büll & Strunz Ges.m.b.H.

www.buellstrunz.at

vertrieb@buellstrunz.at

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com