Chia-mo Srl has been designing and building accessories for machine tools for subtractive machining since 1972. The company whose headquarters is on the urban periphery of Bologna today produces an extensive range of accessories for machine tools and particularly for lathes: chucks, closure systems, lathe collets, tool holders, boring bar sleeves, manual tap holders, tailstocks, awls, spindles and other spare parts.

Thanks to its many years of market presence, Chia-mo Srl has acquired a wealth of experience in this field, enabling it to provide planning and design services for bespoke components that have to meet the customer’s specific requirements.

The company has been quality-certified for ten years and meticulously monitors the entire production process – from the materials and certified and tested heat treatments through to the application of SIT-certified measuring instruments for final control. All phases in planning, machining and testing are carried out internally, thus facilitating continuous control of all production processes. Chia-mo is also committed to the environment, having installed at its site a photovoltaic system that covers 50 per cent of the company’s energy needs.

The other strengths of the company in Bologna include rapid order processing, as Fabio Chiari, in charge of production, confirms: “We are constantly increasingly our product range. 95 per cent of our standard products are now stocked and we can send out the items on the same day as we receive the order. We design and machine many products. This applies, for example, to drilling tools that feature a special system making it easier to work with the tool and thus eliminate the strength- and centring-related problems that can occur on the machines. This product was the result of the requirements of customers who for the most part act as subcontractors and approach us with all kinds of inquiries calling for a high level of flexibility. This is a real test for us, as we are faced with every problem that can arise during machining. This experience is reflected in everything we produce.”

Chia-mo Srl’s extensive range of components for lathes and loaders includes collets, chucks, groove nuts, tool holders, sleeves, tailstocks and many other products.

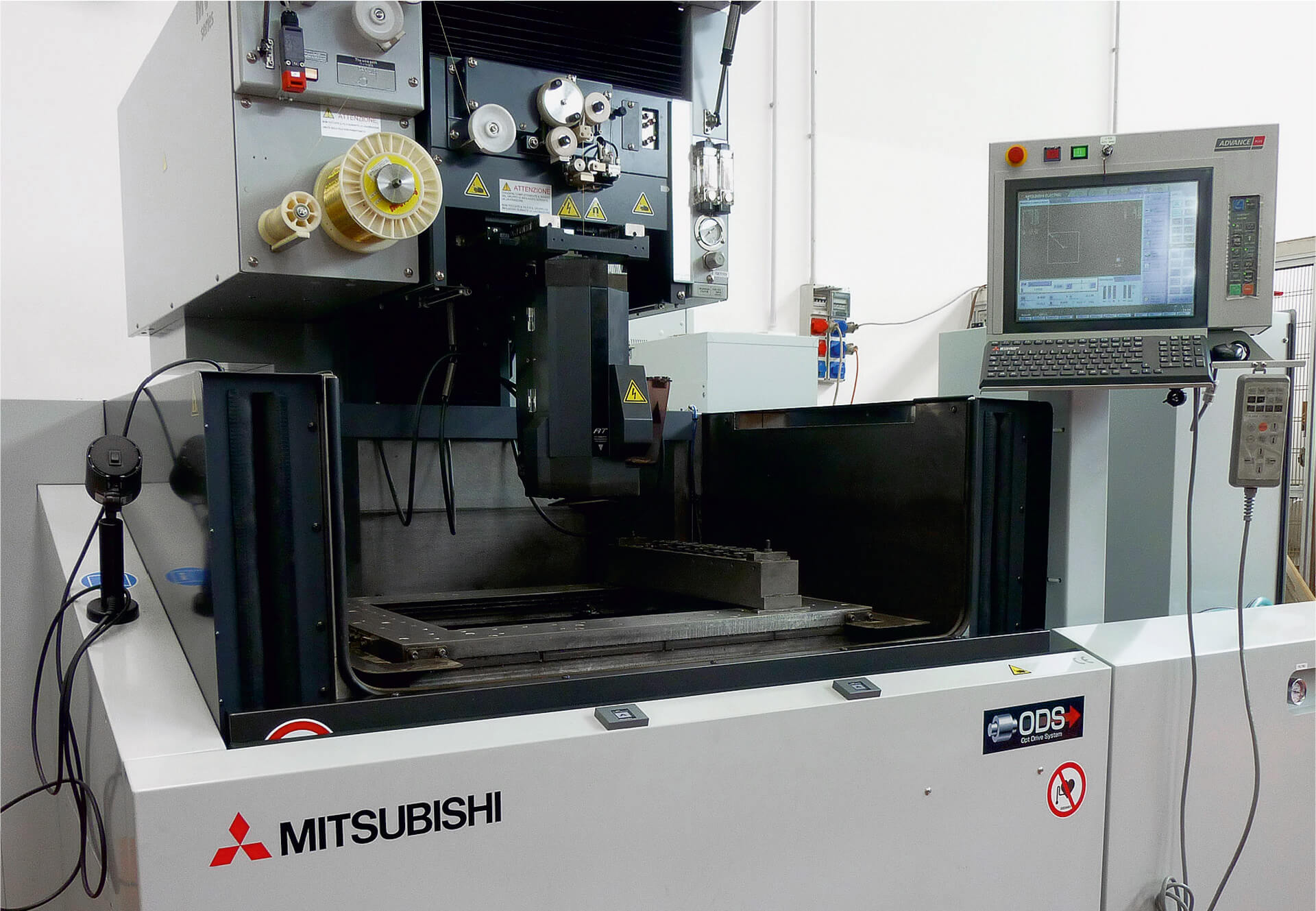

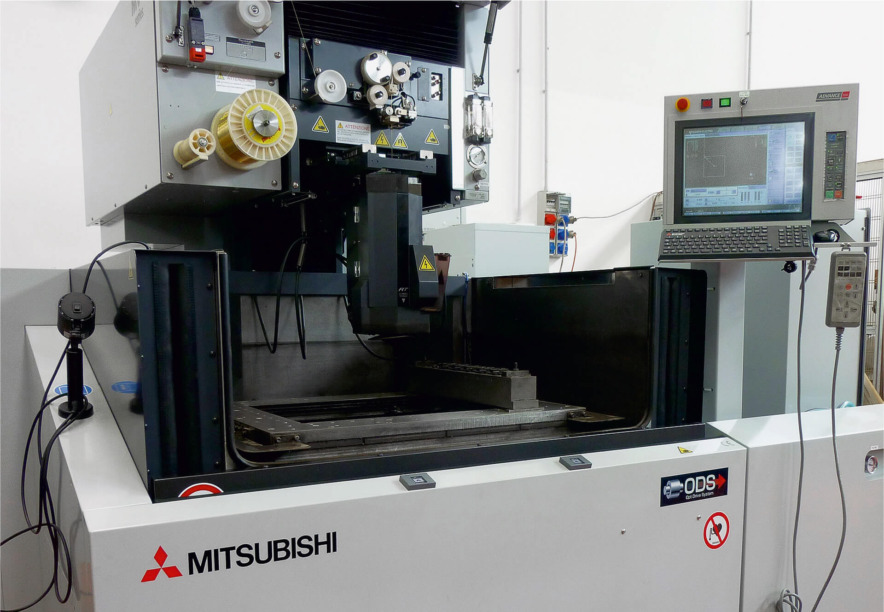

Most of Chia-mo’s customers are Italian, although the company has representatives and distributors for the most important European markets: Germany, France and Spain. Chia-mo has always attached huge importance to quality, which is reflected in its sales. Tested and certified raw materials, reputableand dependable suppliers, meticulous processes, and the application of the latest technology – all this contributes to the achievement of uncompromising quality. One of the most recent investments has been in an EDM machine, the new Mitsubishi Electric MV 2400 R.

“The Mitsubishi Electric machine was chosen to ensure a high degree of precision, quality, reliability and above all productivity.”

Even if the lion’s share of work is performed on lathes and milling machines at the Bologna plant, a not inconsiderable proportion calls for EDM. Particularly if subtractive machining is not possible – not least because they have to be carried out on already hardened material in order to ensure a high degree of precision.

It is a question of special shapes (square, hexagonal), geometrical sections with an extremely small radius, and interior areas that are inaccessible: “The Mitsubishi Electric machine was chosen to ensure a high degree of precision, quality, reliability and above all productivity. All this was guaranteed by our supplier Tecnomach. We trusted him – not least because of the many years of profitable cooperation that unites us – and took the plunge by purchasing it without having seen it in operation. We had clearly defined our requirements.”

The wire threader of the new Mitsubishi Electric MV 2400 R operates not only fully automatically, but also ensures a high degree of reliability and uniform results.

“The new MV 2400 R has demonstrated exceptional dependability – threading has been flawless without exception.”

The Bologna-based company has to machine numerous small-size workpieces and had long been considering benefiting from unmanned operation at night. This would mean that the machine is loaded in the evening and the workpieces are finished by the following morning.

However, for this to be possible, it was necessary above all that the wire-cutting machine was able to thread the wire automatically: “This feature has been available on the market for some time, but none of the machines we had previously tested proved to be absolutely reliable. The results were acceptable, as long as high standards of cleanliness were maintained.

However, it just took the tiniest contamination on the wire or a little dust, and there were problems. After a certain number of workpieces, rethreading failed to work properly, so the process had to be stopped.”

In addition, after the finished workpiece was removed from the water, rust developed on it after exposure to the air for just a few hours – only superficially and locally, but it was unacceptable for aesthetic reasons. It had to find an EDM machine that would solve all these problems: “At Mitsubishi Electric, we’ve found it. The new MV 2400 R has demonstrated exceptional dependability in the last few months – threading has been flawless without exception. Whenever I come into the workshop in the morning, all the work has been correctly performed – and with the previously set precision. Tecnomach also assured us that threading underwater would be performed with the same dependability. And so it was. This way we are able to solve the problem of rust, as we keep the workpieces immersed until the very last moment and thus prevent their coming into contact with the air. Then they are all dried collectively.”

Mitsubishi has designed an extremely efficient, innovative and revolutionary wire threading system. The wire is heated and stretched, which yields a barely perceptible but sufficient reduction in the diameter. Then a water jet is directed at the lower machine head (30 cm further down), which is only a few millimetres larger than the diameter of the wire and threads the wire. Digital motors feed the wire, with continuous monitoring of the process.

Semi-finished collet with a wire-cut pilot bore and overmeasure for skim cutting.

As for the programming of the machine, the Chai-mo technicians stress that the system for the simple and intuitive organisation of work processes, however complex, is mature and extremely user-friendly. “An external camera is practically unnecessary. The video graphics are self-explanatory. Communication with the machine takes place via masks and symbols that make programming much more straightforward.

Many parameters are automatically calculated by the machine. Other manufacturers adopt the same procedures, but in terms of precision we have found that this new model from Mitsubishi Electric sets the standard.”

The solution for the adapted movement of the axes is based on reluctance motors (tubular motors), which is why no further mechanical components are needed. Further advantages include energy savings and the optimisation of all operating parameters, starting with the speed of wire running through to the values for electrical discharge. The outcome is a considerable reduction in cycle time. Unlike other machines on which the number of successively settable operating coordinates is limited, the user is granted more freedom: “We can place a large number of workpieces on the table, each of which is accessible via its coordinates. The work program is capable of precisely positioning the machine head in the various positions and thus working automatically without the need for manual intervention.”

Wire-cut series parts: hexagonal tool holders for reamers.

“Since the installation of the new machine from Mitsubishi Electric, the productivity of Chia-mo Srl has improved considerably without compromising on quality.”

Since the installation of the new machine from Mitsubishi Electric, the productivity of Chia-mo Srl has improved considerably without compromising on quality: “We used to have to machine the workpieces one after another, empty the tank immediately to dry the components (before rust can form) and finally start the cycle from the beginning with a new workpiece. This resulted in waiting time that we wanted to eliminate at all costs. Now we can do all the work unmanned – the machine operates entirely by itself.”

Welcome to the home of tortellini, mortadella and other culinary delights. Bologna is the capital of the province of the same name and has a population of over 380,000. The area between the rivers Reno and Savena and the Appenine Mountains is also much loved by the students of the university city.

Bologna is the home of tortellini – ring-shaped pasta filled with minced meat that is usually served in a meat broth (“brodo”) or with “sugo bolognese” (made from minced meat and tomatoes), which is usually simply called “ragù”. In Bologna, the “sugo” is made not only with minced meat, but sometimes also with the addition of “salsiccia” (coarse raw Italian frying sausage). According to legend, tortellini are modelled on the navel of Venus, the Roman goddess of love.

Another speciality of Bologna is mortadella, a cooked pork sausage that is eaten cold, usually diced or finely sliced.

Bologna is also famed for its lasagne and yellow tagliatelle of egg pasta. According to another legend, the latter is said to have been invented by a cook who was ordered to create a dish for the wedding of Lucrezia Borgia to Alfonso I. d’Este, Duke of Ferrara, and found inspiration in the bride’s golden hair.

Name and place of company:

Chia-mo Srl, Bologna, Italy

Founding year:

1972

Managing Director:

Adalberto Chiari

Number of employees:

30

Core business:

Production of components for

machine tools

Chia-mo Srl

Via Caduti di Sabbiuno

40011 Anzola dell’Emilia

Bologna

Italy

Tel +39 . 051 . 734 153

Fax +39 . 051 . 734 958

info @ chiamo.it

www.chiamo.it

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com