When jobs have to be accomplished quickly and flexibly, Jürgen Pirgl is always at the ready. His trusty sidekick is his Mitsubishi Electric machine of the MV Series on which he can always rely.

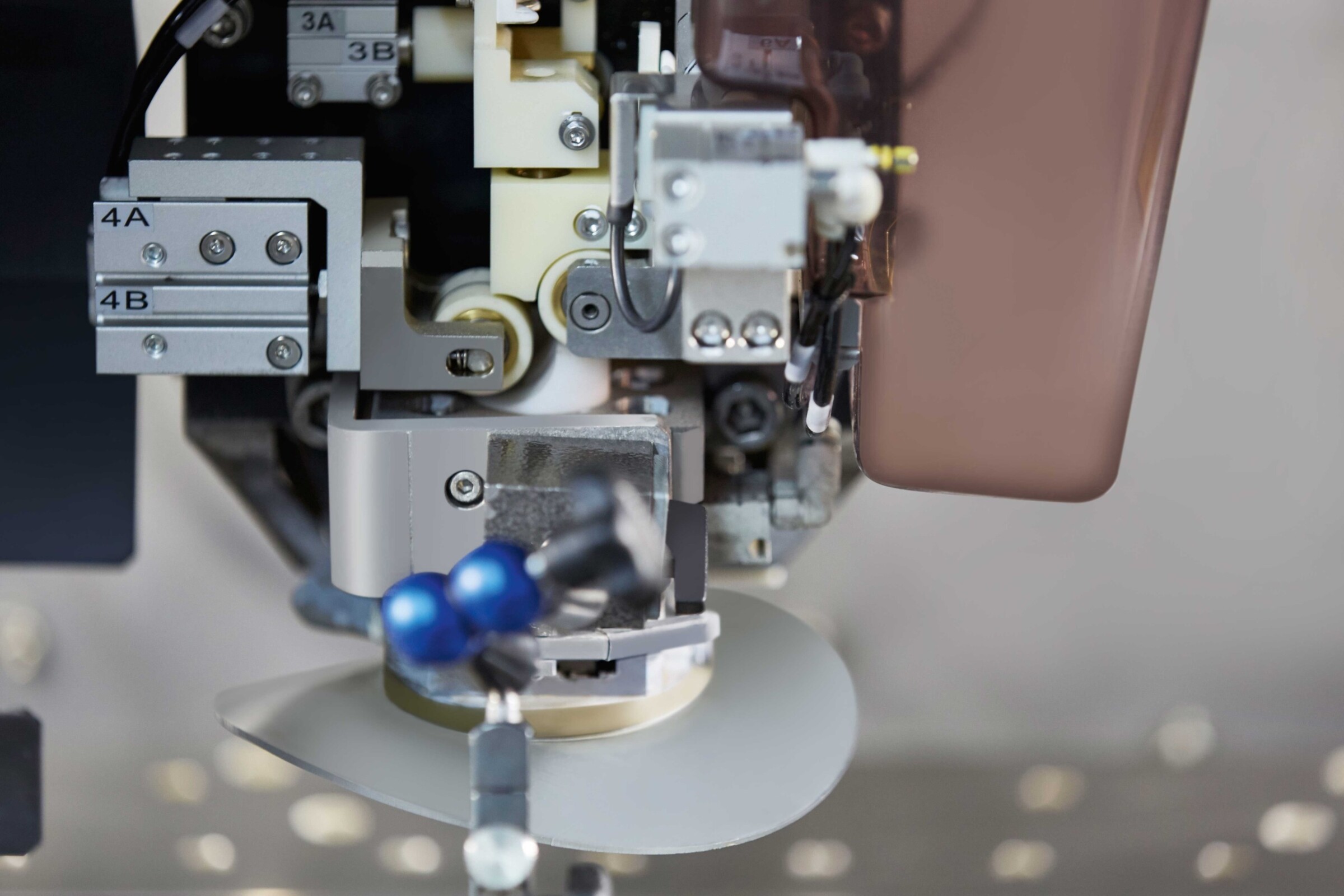

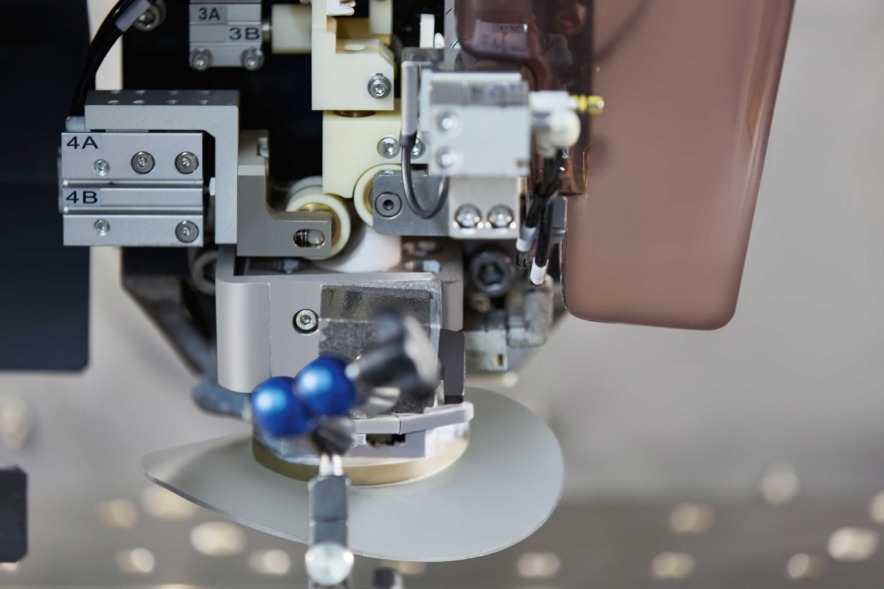

The automatic wire threader rethreads the wire trouble-free even after breakage in a 0.5 mm kerf.

The constant search for new challenges.

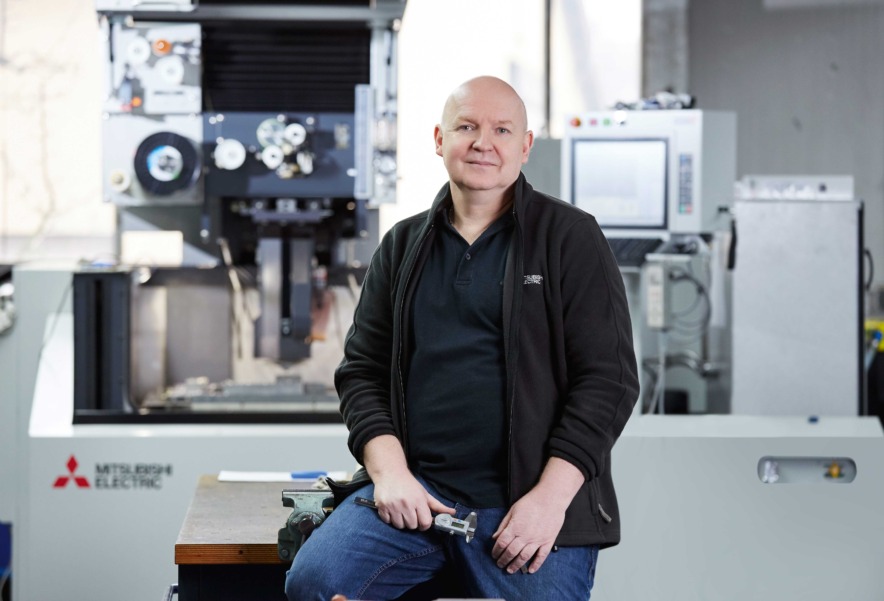

“When one door closes, another one opens,” or so the German saying goes. Anyone opening the door to JP Funkenerosion and entering the production shop cannot overlook the pride and joy of the one-man business in Erligheim: a new MV2400R. The wire-cutting machine from Mitsubishi Electric takes centre stage by the large windows of the company building, resplendent in the bright light. The unit joined the firm’s machine park at Christmas last year. The saying also applies admittedly in another respect. Because Pirgl is always on the lookout for new business challenges – and for new doors to open.

About 17 years ago, Pirgl started out electric discharge machining as a side line in a rented workshop. “I’d clamp workpieces on a die-sinking machine in the early morning and then go to work. And in the evening after work, I’d finish off the job,” the jobshop owner recalls. After about a year and a half, in which he was busy almost around the clock, Pirgl took the plunge in setting up his own business.

He then bought his first wire-cutting machine a year later, although this wasn’t planned at all. “My original idea was to concentrate on die sinking. But because customers kept on inquiring about special gearing, I seized the opportunity and bought a used Mitsubishi SX machine. This meant I could then handle these jobs as well,” Pirgl explains.

“For a successful jobshop, speed and flexibility are absolutely essential.” – Jürgen Pirgl

Over the years, he’s made steady progress and the company has successfully established itself on the market. The bulk of his work was originally from customers from the local area of Heilbronn and Stuttgart and came from a variety of industries. In the initial years, things were sometimes hectic, particularly when jobs for companies engaged in motor racing were concerned. “These customers were often very demanding, because they expected their components to be machined practically overnight,” says Pirgl. Although these customers are no longer his regulars, the business owner managed to gather a lot of valuable experience during this period from which he still benefits today. “Sudden urgent jobs I still handle at the drop of a hat. And my customers are very appreciative of this,” he adds with a smile.

Jürgen Pirgl

Successfully established on the market – step by step.

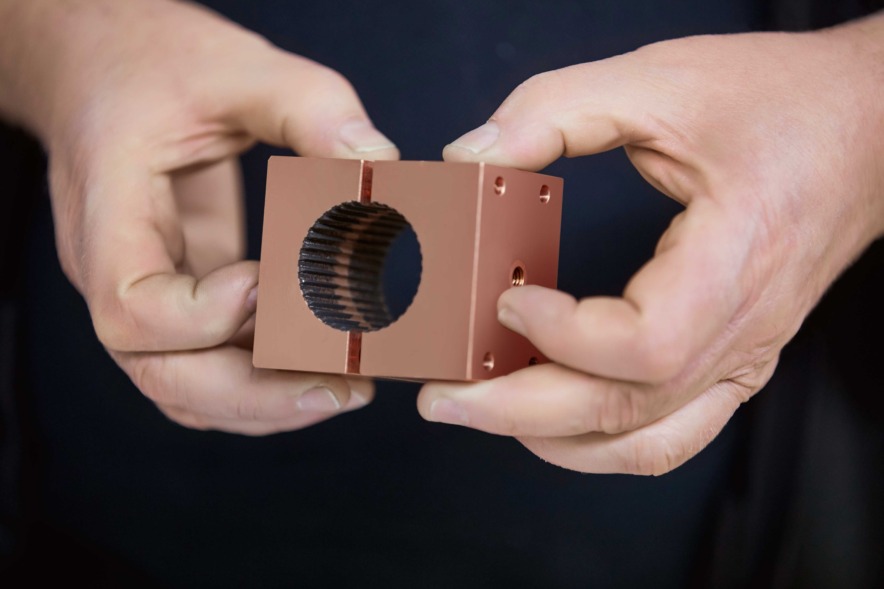

Today the company serves many machine manufacturers and component suppliers, and most of them are still located in the immediate surroundings. Wire-cutting accounts for about 70 per cent of the order volume. The jobs usually involve parts made of aluminium, copper, brass, steel or titanium, 0.5 to 300 mm thick, up to a size of 700 mm. Pirgl is extremely flexible and not so selective when it comes to taking on new orders. For his motto is: “If my machine can do it, I offer it”.

The used machine from Pirgl’s initial years has long gone. Today he works at the modern Mitsubishi Electric MV2400R. “I urgently needed a high-performance machine particularly for larger workpieces. A pleasant side-effect of any new investment is that it gives me a burst of new enthusiasm for my daily work,” Pirgl explains. The new machine was bought in part exchange for an older Mitsubishi Electric model. “The truck pulled up outside the firm at 8 o’clock in the morning, and the new wire-cutting machine was ready to operate after the lunch break,” says Pirgl describing the trouble-free delivery and installation of the machine. “The time taken to get used to the new machine was minimal, as I was already familiar with the user interfaces of the Mitsubishi machines. So I was able to get straight down to work.” So the seamless resumption of normal business was at no time at risk. “For a successful jobshop, speed and flexibility are absolutely essential. You can never rule out a customer ringing up on a Friday and expecting his parts to be machined at short notice by the following day. And without compromising on quality of course. So I’m always at the ready as far as new jobs are concerned,” says Pirgl.

Sudden urgent jobs I still handle at the drop of a hat.

A perfect fit – two components with gearing

Taking account of fluctuations in order volumes.

As a subcontractor, the cost-effective price per part is the decisive factor for survival on the market. Pirgl therefore needs a machine that operates economically. In view of this, the low wire consumption of the new MV Series has already had a positive impact in the brief time since commissioning. “I reckon a single wire spool now lasts about four hours longer than before,” says Pirgl reporting his experience. The jobber has also come to appreciate the other innovative features of the MV2400R. The automatic wire threader, which rethreads the wire trouble-free even after breakage in a 0.5 mm kerf, operates without a hitch. “You usually don’t even notice a wire breakage. All you see is a message on the display,” says Pirgl who wouldn’t want to do without this function.

Another important factor in subcontracting is machining speed. Time is a precious resource, and staying competitive means using it sparingly. Pirgl is therefore very happy with the markedly enhanced performance of his new system. Most important of all is the machine’s dependability. “What use is high cutting speed if the machine breaks down in the middle of the night?” says Pirgl. In his view, the MV2400R offers just the right blend of accuracy, dependability and economy. And competitively pricing.

Pirgl appreciates the rapid familiarisation and the accustomed user interfaces.

In Pirgl’s opinion, the competitive pressure has increased from year to year since he started his business. “It used to be easier to plan orders that would arrive in a steady volume. Today you have to react much faster and reckon with greater fluctuations in the order volume.” Pirgl regards this as a challenge and adapts flexibly to changing conditions. It is therefore all the more important for him to have a machine for his daily work that he can rely on 100 per cent.

Pirgl handles urgent jobs overnight.

In this connection, he has words of praise for Mitsubishi Electric’s after-sales service. Pirgl has occasionally carried out minor repairs himself. “It just took a phone call, and the replacement parts arrived the next day.” But this hasn’t been necessary yet on the new machine. However, Pirgl has no doubts that the Mitsubishi Electric service will quickly respond should the need arise and send a technician round swiftly.

For the go-it-alone businessman, one thing is already certain – that he will stay true to investment in machines of the Mitsubishi Electric brand. “Experience saves time” is how he puts it.

Name and place of company:

JP Funkenerosive Bearbeitung

Germany

Founding year:

1999

Owner:

Jürgen Pirgl

Core business:

Die-sinking/wire-cutting jobshop

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com