Boredom is practically unknown to Christian Casilda Weissen. The term “flexibility”, on the other hand, means more to him – for if it didn’t, he would hardly have become a service technician for Mitsubishi Electric.

Service – from eastern Westphalia to Mexico

The autumn sun bathes the surroundings in a warm light, but Christian Casilda Weissen has his eyes on other things at the moment. It’s early morning and he’s started work on annual preventive maintenance at A. & H. Meyer GmbH in Dörentrup, Ostwestfalen-Lippe. The internationally active company that develops customised and safe electrification strategies has signed a maintenance agreement with Mitsubishi Electric for its FX10-K Platin wire EDM machine.

The service technician replaces one of the threader’s deflection bearings.

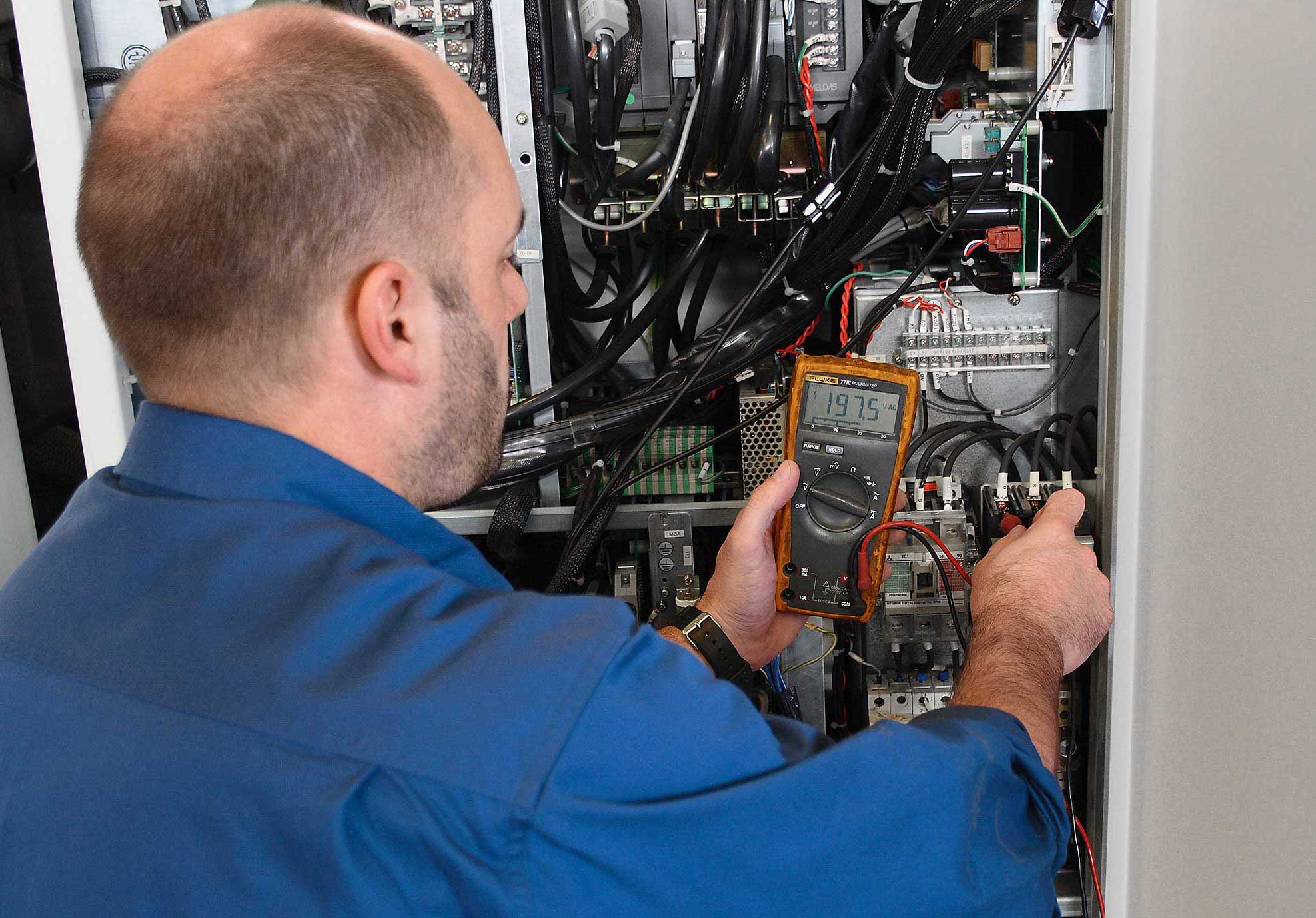

The service technician stands at the open switch cabinet of the machine control and measures its voltage. When he’s finished, he ticks the relevant inspection box on his maintenance checklist. “Doing this kind of work, it’s important to proceed systematically,” he stresses. “If the pump were faulty, for instance, I would first check the voltage.” Christian Casilda Weissen also checks the working of the fans responsible for cooling by illuminating them with a torch. In his checklist he notes that the customer uses an automatic fuse system instead of the usual, single fuses. Next in turn is the battery that goes into action when the mains power is off. During the previous year’s maintenance, the service technician replaced the battery because the software had to be reloaded after each machine use, which suggested that the battery was at fault.

Doing this kind of work, it’s important to proceed systematically.

Asked whether his working days are much the same, Christian Casilda Weissen shakes his head. “Since my daily routine is confined merely to basic tasks, a high degree of flexibility is indispensable. This applies as much to my daily tasks as to my mental approach. What’s more, no two machines are the same and the malfunctions are always different. It’s also essential to be open to the customer’s ad-hoc requests.” On top of this, there are the unscheduled maintenance and repairs. In these cases, the operator calls the hotline of the Mitsubishi Electric service centre in Ratingen. It’s from here that the assignments of the service technicians are coordinated, appointments made and any spare parts sent out in advance. If production stoppages are involved, there’s a high level of urgency.

The service technician replaces one of the threader’s deflection bearings.

The working day of a service technician usually lasts eight hours. Christian Casilda Weissen, who has been working for Mitsubishi Electric since 1998, mainly serves customers in eastern Westphalia and the Ruhr district. If required, his work may take him anywhere in Germany, and about five times per year abroad. Here, the focus is on Spain because he speaks the language fluently. “I’ve even been flown on a service assignment to Mexico,” he recalls. He has similarly fond memories of the butterflies in his stomach when he first glimpsed an FA50-S Advance. He was the first service technician to install the biggest Mitsubishi Electric EDM machine in Germany. However, his range of duties covers more than just maintenance, repairs and installation. His specialityis laser measurement, which he uses for checking machine geometries.

Against this background, the experienced service technician sees maintenance at A. & H. Meyer as anything but routine. Using the FX10-K Platin, a CNC submerged wire EDM machine with automatic threading and 5-axis CNC control, the customer machines components for injection moulds used in the production of plastic parts. With regular maintenance of the used machine bought in 2002, which had had a year’s service for demo purposes at Mitsubishi Electric’s Technology Center in Ratingen, he reduces the downstream costs. Apart from this, a machine stoppage would have knock-on effects on production.

Wadim Friesen thanks Christian Casilda Weissen for his professional maintenance.

Because Christian Casilda Weissen takes time for talks, he maintains close contacts with his customers. One of these is A. & H. Meyer, where he has good relations with Wadim Friesen, who is responsible at the company for machine tools and moulds and hence also for the Mitsubishi Electric EDM machine. Wadim Friesen suggests having the machine’s contacts cleaned. Then Christian Casilda Weissen inspects the sensor that measures the conductance of the dielectric fluid. He’s not surprised that its electrodes are clean. “Mr Friesen keeps his eye on the machine. Since he regularly cleans certain areas and components, like this conductance sensor, the machine is kept in an immaculate condition. This is an advantage that reduces the time spent on annual maintenance from about eight to six hours.”

Wadim Friesen tells the service technician about the uneven running of the wire in the machine, whereupon the service technician replaces one of the wire threader’s deflection bearings, a typical wearing part. “We’ve got good relations with the customer and cooperation is excellent. The customer handles the minor maintenance jobs himself and uses original parts from the Mitsubishi Electric consumables line for this.” In the last few years, A. & H. Meyer has mainly purchased bare brass wire of 0.2 and 0.3 millimetre diameter from this range. The consumables line also includes power feeds, filters, measuring instruments and clamping accessories.

Because Weissen takes time for talks, he maintains close contacts with his customers

The jobs during which Christian Casilda Weissen gets his hands dirty he reserves until the end. Today he has to dismantle and clean the pump because the machine fills its dielectric tank too slowly. His freshly washed shirt now also shows traces of his work. Maintenance sometimes calls for the use of his ears. “If the pump causes mechanical noises, it’ll soon break down and have to be replaced.”

Maintenance ends with function tests. After this, the service technician writes a final report, which he supplements, if necessary, with recommendations. He may, for example, draw attention to faulty parts that don’t yet affect the smooth running of the FX10-K Platin, but will still have to be replaced in the near future.

Christian Casilda Weissen packs his bag. “It would be great if things always went so smoothly. Some defects, however, are not always immediately identifiable. This depends often on the expanding use of electronics, which makes the machines and maintenance more complicated.” It occasionally also happens that a service technician is on site but the malfunction fails to occur the whole day long. Or the malfunction only arises in the afternoon. If the service technician doesn’t make progress with his work, he asks for support over the Mitsubishi Electric hotline. This may be necessary in the event of faults in the peripheral equipment or malfunctions that are new and with which there is no experience to fall back on. Finding solutions in such cases is ultimately again a question of flexibility.

Mitsubishi Electric offers maintenance agreements that cover annual machine maintenance and attractively priced replacement parts. If the customer chooses one of the three agreements available (Wire EDM Basic, Wire EDM Extended, Sinker EDM), all the relevant units of his machines are regularly looked at and checked. This way it is possible to spot malfunctions early on and prevent breakdowns. The customer benefits for many years from the high precision and availability of his machines and from the matching quality of his products. The Wire EDM Extended agreement covers the adjustment of the associated machine units in addition.

Maintenance made to measure

To back this up, Mitsubishi Electric has set up a free hotline, which is available from Monday to Friday, from 7:30 a.m. to 5 p.m. In addition, an on-call service has been established from Monday to Friday, 5 to 8 p.m., and on Saturday from 9 a.m. to 4 p.m. The fastest-possible support is thus assured in all cases. Sending out technicians to the customer is usually possible at one to two working days’ notice.

For customers who want to have their EDM systems under control at all times, Mitsubishi Electric has solutions available. This can mean giving the operator access to his machine functions from any location, having messages from his machine sent by text message to any compatible phones, and remote diagnosis or online support.

A. & H. Meyer GmbH with its parent plant in Dörentrup, Ostwestfalen-Lippe, is the market leader and trendsetter in customised electrification and cable management systems in the office sector. Suppliers of furniture and furnishing strategies to hotels, public buildings and shops are also resorting increasingly to the reliable plug connection technology and hence on the company’s almost fifty years of experience. Along with its leading position with electrification expertise, A. & H. Meyer is also noted for having one of the biggest ranges of neat multiple plug socket boxes and data sockets and for its international distribution network.

The electrification strategies for power, data and multimedia are organised on the “plug & play” principle. The range of switches and plug sockets is one of the world’s most comprehensive. The units are compatible with most international standards for power sockets and with many standards for data and telecommunication sockets. As the company also aspires to high standards of quality and safety for its products and services, they all comply with the international safety standards for electrical equipment and quality standard ISO 9001/2000ff.

Founded in 1961, the company specialising in connectors employs a workforce of over 100 in Germany. Another 50 employees work for A. & H. Meyer Sdn. Bhd. domiciled in Shah Alam, Malaysia, in which the company has an 80 per cent stake. While the base in Germany mainly serves Europe, the subsidiary in Malaysia works solely for the Asian market.

The customers include big-name manufacturers of furniture for a huge range of applications. In addition, A. & H. Meyer serves building equippers, hotel furnishers and large corporations such as Yahoo, Nokia, Google and Dell. These appreciate the high safety of the company’s electrification strategies as well as the extra efficiency of the installation process and minimised input of materials. Also worth stressing is the strong emphasis on design, enabling the cable and plug socket solutions and multimedia components to integrate smoothly and unobtrusively into the interior architecture.

No less important for A. & H. Meyer is sustainability in its environmental protection efforts united under the “meynature” banner. The emphasis here is on the use of environmentally compatible materials and on resource-conserving production processes and products. This aspect of company philosophy also finds expression in participation in environmental projects.

Name and place of company:

A. & H. Meyer GmbH

Germany

Founding year:

1961

Managing director:

Horst Meyer

Number of employees:

Germany: 100

Malaysia: 50

Core business:

Market leader with tailor-made electrification and cable management systems in the office sector

A. & H. Meyer GmbH

Leuchten und Büroelektrik

Fermke 8

32694 Dörentrup

Germany

Tel +49 .5265 .9488 0

Fax +49 . 5265 . 9488 11

info @ ah-meyer.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com