Your holiday is booked, and the sun, the beach and relaxation are within reach. Time at last to unwind. Experienced EDM specialists who don’t want to plunge straight back into stress on their return from their well-earned break spare their machines a thought before they leave. By running through this brief checklist, you can ensure your machine gets off to a trouble-free start after a shutdown.

Service & support – holiday for your EDM.

Service – ready to help you.

Maintenance should always include regular air filter cleaning and replacement. Filters protect the electronics and cooler from unwanted contamination and ensure that the components always stay cool when the going gets hot. Original filters are precisely attuned to the needs of the machine and provide the necessary protection to keep the machine up and running. False economies by installing no-name filters have been known to cause cooler failure. Avoidable repair and downtime costs on the four-digit euro scale are the consequences.

Service Manager Martin Kuptz (centre) and the two “novices”, Christian Schneider (left) and Benjamin Werner (right)

When machines fail and replacement parts are needed for repairs, time is of the essence, because an unscheduled production stoppage means stress and expense. Mitsubishi Electric’s after-sales service provides express parts delivery. All parts orders received via the service hotline or by email by 3.30 pm are processed the same day and sent on their way. And, if desired, express-delivered the next day as well.

Martin Kuptz has been working for the service department for 18 years. As the Group Manager Wire-Cutting and Die-Sinking Machine Service, he is in charge of the assignments of technicians on site and for service hotline staff all over Europe. He is responsible for incoming orders and parts shipment, the organisation and planning of technician assignments and for the associated accounting. The service team supports customers locally with some 1,600 assignments. These are joined by some 20,000 inquiries by phone and email to the hotline, which are all handled by skilled staff. Via the hotline, Kuptz’s team can swiftly settle a good 85–90 % of all inquiries within an hour.

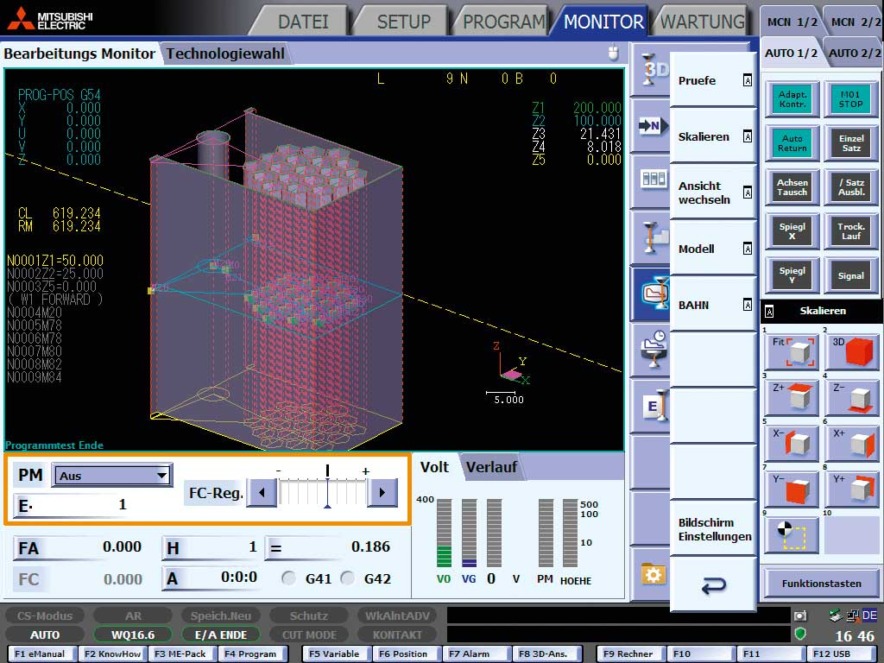

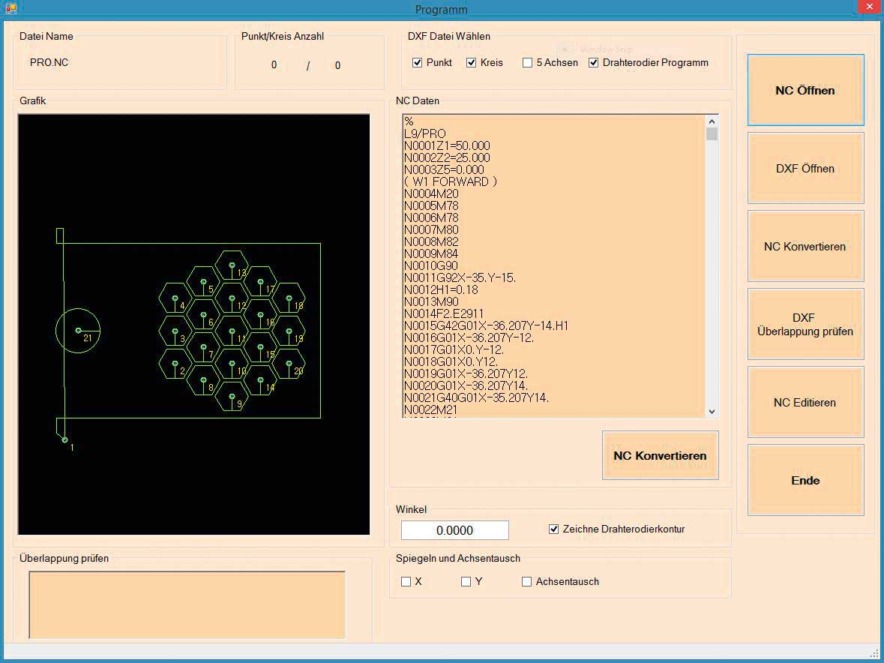

With just a few mouse clicks, it is possible to generate the exact positions of the start holes from the wire-cutting program. The process offers a rapid, visual control of the positions and error-free transmission of all start-hole data. An additional postprocessor is not necessary for the start-hole drilling machine. This how it works:

1. Switch on the start-hole drilling machine

2. Select the “Program” menu

3. Select the submenu “Indicate Wire Cutting Contour”

4. The drilling positions and wire contour are indicated

5. Check the start holes

6. Start the program

Service – ready to help you.

Service – ready to help you.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com