In the production of replacement parts and components for cutting and punching tools, USIMICRON in Besançon, France, is able to hold its own against East Asian and Indian competition thanks to the cost-effective and reliable wire-cut EDM systems from Mitsubishi Electric.

Staying competitive in Europe.

“We want to use EDM increasingly so that grinding becomes superfluous,” says Alain Perrenoud. He is the owner and Managing Director of today’s USIMICRON. A toolmaker by trade, he founded his own company in 1990. Specialising in individual components and replacement parts for cutting and punching tools, and particularly high-precision punches and dies, the production firm grew to 20 employees until the global financial crisis in 2009. Following the insolvency of the old USIMICRON firm, the owner continues to run the business under creditor protection. “I was fully convinced of what our firm was capable of. I also saw excellent opportunities for attracting customers with our outstanding quality and flexibility and thus continuing to gain valuable contracts from the region,” Perrenoud continues.

The success over the years since has confirmed his convictions at the time. Today, five skilled toolmakers machine precision parts in Besançon for other toolmakers. His customers include not only small and medium-size firms in the region, but also large companies and internationally active corporations. “We produce one-off parts and small series firstly for telecommunications and medical technology and secondly for automotive component suppliers,” Perrenoud confirms.

USIMICRON’s efficient toolmaking team in Besançon give precedence to wire-cut EDM.

Impressing with maximum quality and flexibility

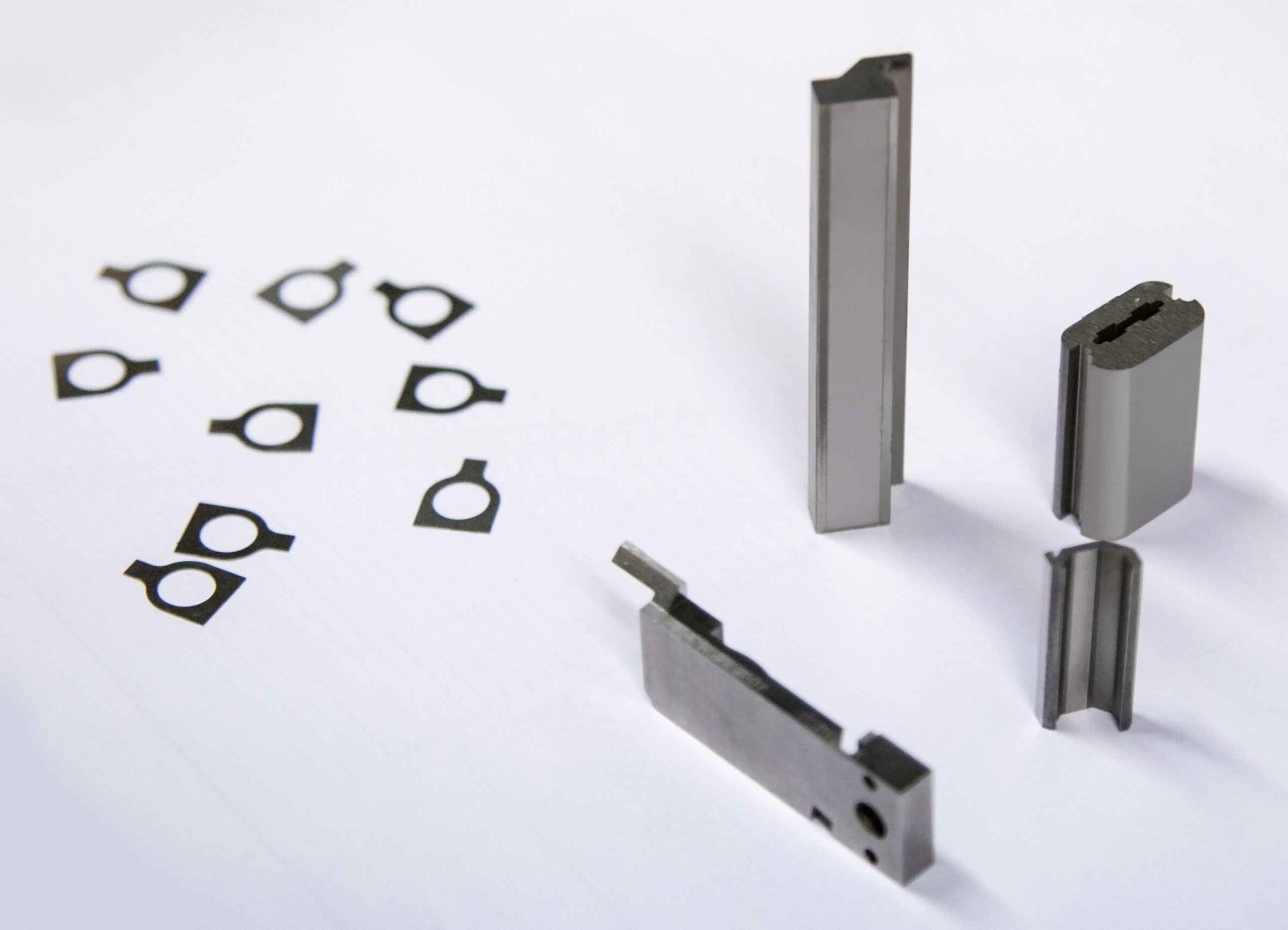

Working as a subcontractor, USIMICRON produces punches and dies for cutting and punching tools on the basis of drawings or samples. It is often a question of replacement parts for worn originals. And it is here in particular that the accuracy of the components determines how reliably they work. As replacement parts, they have to exactly fit the other components of the in most cases complex punching and cutting tools. Customers mainly demand accuracy of better than ± 2 µm, Perrenoud explains. Most of the punches and dies have challenging geometries and radii of less than a tenth of a millimetre often have to be machined. What’s more, the punches and dies are made of special steels and tungsten carbide. This applies, for example, to tool inserts for the punching and bending of small plug connectors or for the cutting of SIM cards for telecommunications equipment. Similar demands are associated with the production of tool inserts for cutting and punching tools in medical technology and automotive engineering. Since the replacement and one-off parts are used in toolmaking all over the world, USIMICRON obviously has to ensure their accuracy and quality. As Perrenoud reports, grinding used to be the only way of achieving the geometries on these workpieces. In his view, however, grinding is a time-consuming and labour-intensive method. “For two grinding machines, I need two experienced and highly skilled employees. These have to prepare the grinding process meticulously, set up the machines and then constantly monitor the grinding process,” Perrenoud continues. But this is extremely expensive. Jobshops in high-cost production locations in Europe have to compete with lower-price rivals in India and East Asia, for example. If they want to survive in the long term, they have to opt for more cost-effective and yet high-precision and dependable machining methods.

Sébastien Devernay: “The MV1200R is quick and easy to set up. This minimises unproductive time and ensures maximum flexibility.”

Component accuracy is all-important

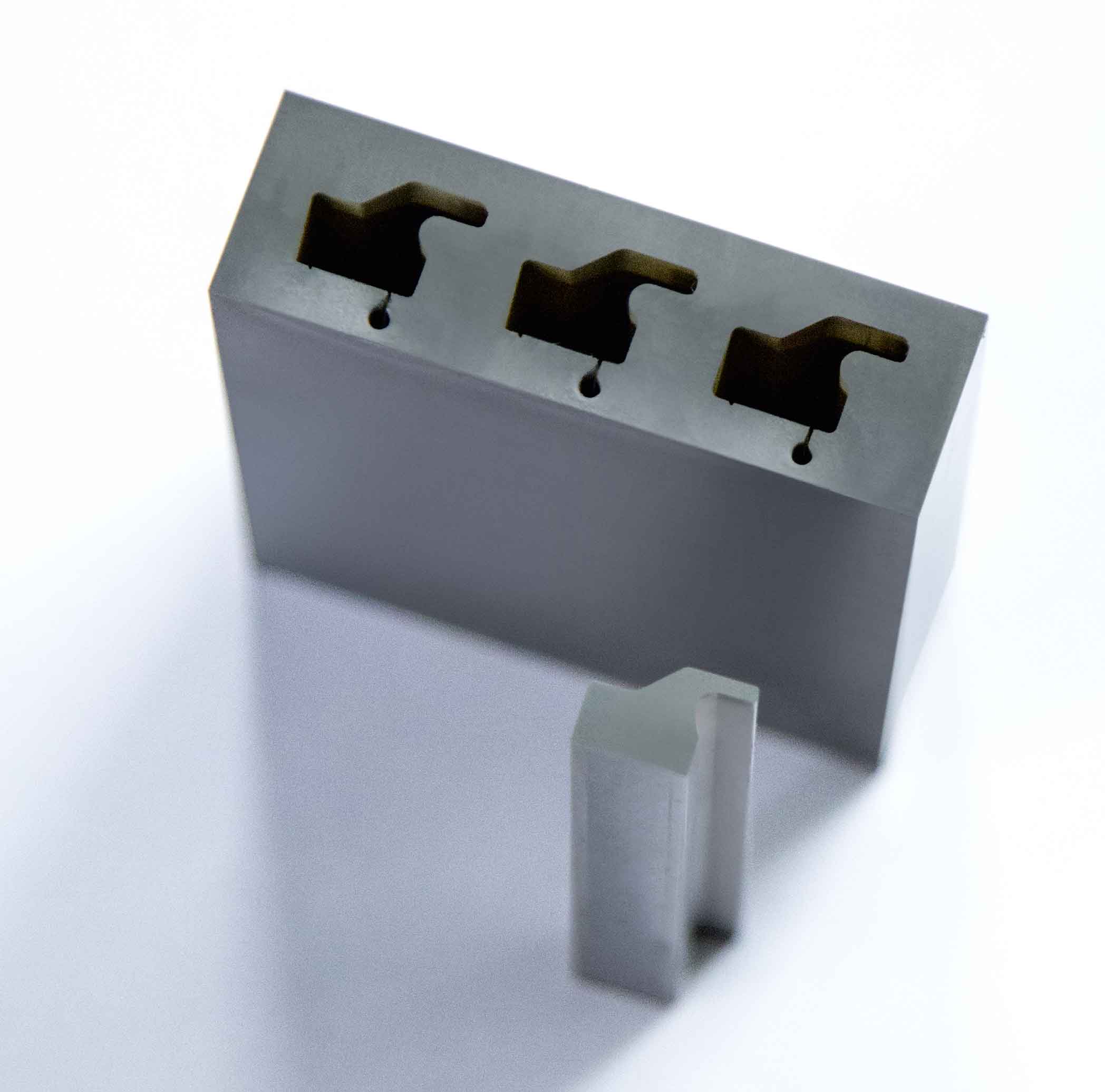

Several years ago, Perrenoud therefore started to wire-cut certain components. He chose wire EDMs from Mitsubishi Electric for a large number of reasons, he claims. From the exclusive dealer of the brand for France, Delta Machines, he was given a detailed technical briefing at short notice. He was able to fully rely on the service and skills of the employees of the dealership. In addition, he was impressed by the high-grade equipment and outstanding features of the wire-cutting machines – first and foremost of the recently additionally purchased MV1200R. The MV1200R with its DFS fine-finishing generator thus achieves surface quality down to Ra 0.1 µm. Accuracy of ≤ 2 µm coupled with high working speeds is ensured by the modern drive technology consisting of Tubular Shaft Motors in combination with the linear scales on all axes and rapid optical data transmission. Although wire-cutting is at first a time-consuming method, it has boosted the competitive standing of USIMICRON. For after set-up, the machine operates for many hours totally without supervision. Firstly, this reduces personnel costs, Perrenoud explains, and the firm, thanks to the machine’s dependable machining performance, can now exploit previously unproductive periods, e.g. night shifts. So that the machines can operate unmanned for as long as possible, the specialists at USIMICRON cut several punches and dies out of single blocks. In the case of dies with highly elaborate geometries, several penetrations and drilled holes, machining can take up to 48 hours. The MV1200R runs trouble-free without an operator for this period, in part because of the reliable wire threader. And seemingly little-noticed details, such as its ability to cut a multitude of materials with inexpensive uncoated brass wire, contribute to the cost-effectiveness of the wire-cutting machines from Mitsubishi Electric.

Alain Perrenoud, USIMICRON; Joël Martin, Product Manager for EDM systems from Mitsubishi Electric at exclusive dealer Delta Machines in France; Kersten Juhls, Regional Sales Manager for EDM systems at Mitsubishi Electric; and Sébastien Devernay, USIMICRON, have collectively chosen the MV1200R, the best-possible machining solution for USIMICRON.

USIMICRON generates the NC programs for wire EDM using drawings in DXF format at an external programming workplace. Because of the easy-to-grasp, ergonomically designed programming and control interface at the machine, the employees were very quickly familiar with the technology. This was largely made possible by the several days’ staff training by Delta Machines. The MV1200R can also be quickly and conveniently set up, thus keeping idle time short and boosting flexibility. USIMICRON benefits from this particularly when machining small components. Wire-cutting then usually calls for only two to four hours of pure machining time.

Maximum precision is called for in the machining of replacement parts for punching and cutting tools for the production of tiny components in medical technology and telecommunications.

Conversant with the technology in next to no time

Perrenoud is thoroughly impressed by the advantages of wire EDM on machines from Mitsubishi Electric, summing up his positive experience as follows: “Wire-cutting on the dependable and efficient machines from Mitsubishi Electric has had a large hand in our ability to stand our ground in the face of competition even from East Asia and India. With the MV1200R wire-cut EDM system, we are able to process our jobs inexpensively, flexibly and quickly. This way we can give ourselves that all-important competitive edge to keep us in business in France.”

USIMICRON uses wire-cutting to machine the tiniest radii and inner contours on tool inserts cost-effectively and with high precision.

Alain Perrenoud, owner and Managing Director of USIMICRON in Besançon, and Sébastien Devernay, toolmaker and EDM and grinding specialist, checking the quality of the wire-cut components

Name and place of company:

USIMICRON

France

Founding year:

1990

Managing Director:

Alain Perrenoud

Number of employees:

5

Core business:

One-off and replacement parts for cutting and punching tools for telecommunications, medical technology and automotive engineering

USIMICRON

Espace Industriel

2, Chemin de Palente

25000 Besançon, France

Tel +33 381 40 00-22

Fax +33 381 40 00-33

usimicron-sarl@wanadoo.fr

We produce difficult, highly accurate, individual shape-imparting parts for cutting and punching tools.

I trained as a cutting machine operator, lathe operator and toolmaker and worked in these areas until I founded USIMICRON in 1990.

I’m convinced that it is worth investing in new technologies. This is the only way that the company can flourish in the long term under difficult conditions.

Partly thanks to new technologies, we are much less expensive and more flexible today than several years ago. We have learnt many lessons and now go about our work with greater composure and confidence, even in a difficult business environment.

After the global financial crisis in 2009, we succeeded in regaining the confidence of the banks and regional customers and in keeping USIMICRON going as a business.

I do a lot of sport together with my wife Isabelle and attach great importance to high quality of life outside my work.

I produce replacement parts for tools that are used in the construction of cars and in the production of medical technology and telecommunications equipment.

Owner and Managing Director

USIMICRON

Alain Perrenoud Owner and Managing Director

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com