From the research lab to industry – die-sinking is being investigated under this motto at Karlsruhe University of Applied Sciences. In its cooperation with Mitsubishi Electric, both sides benefit.

Close contacts with small and medium-size enterprises

Industry and higher education, Japan and Germany, global corporations and small and medium-sized enterprises (SMEs) – these apparent divides are overcome effortlessly at the Department of Manufacturing Engineering and Production (IFP) of the Institute of Materials and Process (IMP) at Karlsruhe University of Applied Sciences. Many manufacturing processes are brought together here, with the main focus being on machining, energy-efficient processes, ultrasonic lapping and electric discharge machining (EDM).

The IMP maintains close contacts with SMEs. “Tool- and mould-makers, classic users of EDM, tend to be pretty small-scale, and we have always had a keen ear for the issues facing SMEs,” says institute director Prof. Dr.-Ing. Rüdiger Haas.

Science and technology meet at Karlsruhe University. The joint project also extends to a ‘transparent laboratory’ in which innovative production methods are tested.

Since the founding of the IMP in 2009, about 27 research and development projects have been carried out in production under Haas’ direction. On his initiative, the Department of Knowledge and Technology Transfer (WTT) was also founded in 2016, which is responsible for accelerating the transfer of knowledge from the university to industry.

Excellent networking with users

Right now almost a dozen research projects are in progress. One of these research undertakings is concerned with technology transfer in the field of EDM, with both Mitsubishi Electric and the IMP benefiting from the existing partnership. Mitsubishi Electric Europe has been sponsoring the IMP’s research activities since 2009. The partnership started on the basis of a research project devoted to wire-cut EDM. At the time, the task was to increase the axes of a wire-cutting system from five to seven. Mitsubishi Electric made a standard FA20S wire-cutting system available, which was modified accordingly for use in this project. Several SMEs were also involved. “We have a good understanding of the needs and demands of SMEs and build bridges to these users. Networking is well-established, especially in southern Germany.”

Playful first steps – the Faculty of Mechanical Engineering and Mechatronics lectures, among other things, on interaction with robots.

One of the outcomes of the wire-cutting project is that today all Mitsubishi Electric wire-cutting systems are equipped with a control configuration permitting the use of 8 axes. Cooperation has continued to grow since this first project.

Research for new developments in robotics: mechatronics makes products intelligent and simple.

Lively contacts in the bid to boost machining performance

“Against a background of mutual trust, we profit from the mutual exchange of experience,” says Haas, describing the relationship between the university and Mitsubishi Electric. Both partnerships benefit from the exchange of theory and practice between IMP and Mitsubishi Electric, in terms of machine technology on the one hand and the user’s wishes regarding EDM. Mitsubishi Electric also supports research into EDM at Karlsruhe University in the context of a dedicated scholarship. This enables students to specialise in EDM and to finance their studies. For Mitsubishi Electric, these students are potential future employees with specific expertise in the field of EDM.

The MSc course in electrical engineering and IT takes one and a half years and covers in-depth training in scientific methodology.

The focus at present is on die sinking. A few years ago, the university purchased the EA8PV Advance die-sinking machine from Mitsubishi Electric. Current investigations are concerned with the performance of the sink erosion system when graphite is used as the electrode material. “To investigate the scope for improvements in processing performance, there is lively contact between the institute and Mitsubishi Electric,” explains Matthias Risto MSc, who is working on EDM production processes at the IMP. “In erosive production processes, account usually has to be taken of a large number of adjustment parameters. Since these are interrelated, they cannot be considered in isolation due to their in some cases conflicting effects on the target variables. This makes the production complex highly complex. In sinker EDM in particular, machining performance can vary greatly due to the variation in electrode geometry, “says Matthias Risto. Despite the complexity, if the aspect ratio is too large, EDM comes into its own.

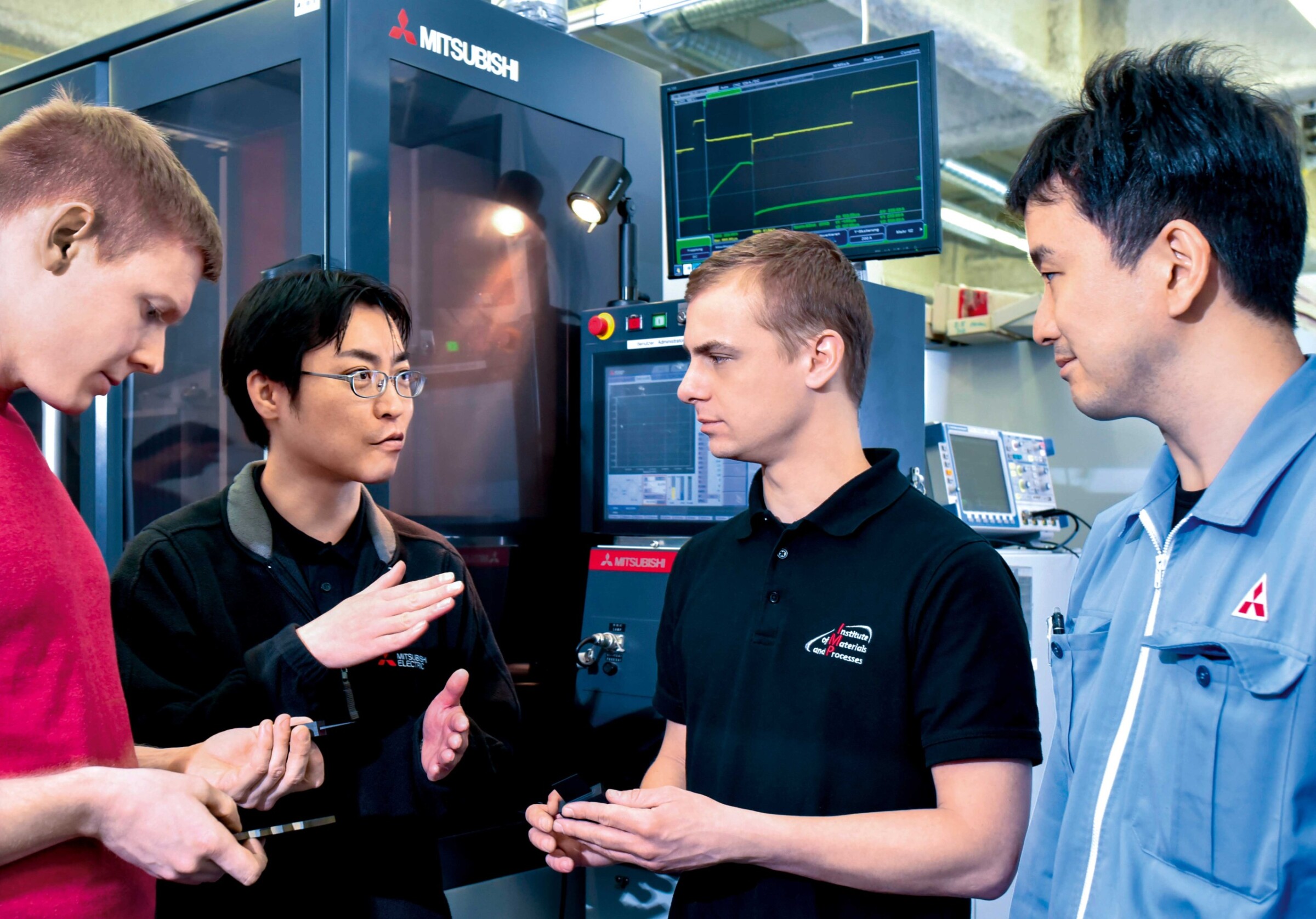

Briefing at the Mitsubishi Electric machine.

Profound insight into working methods and possibilities

“When conventional production processes (e.g. conventional machining) run up against their limits in terms of the aspect ratios or mechanical properties of the material being machined (e.g. hardness or toughness), there is no alternative to unconventional production methods such as spark erosion,” says Risto with conviction. His fascination for EDM technology has been reinforced further by cooperation with Mitsubishi Electric. “Through cooperation, I gain a deep insight into the workings and possibilities of Mitsubishi Electric’s die-sinking machine. The latest findings in EDM can be implemented with the help of Mitsubishi Electric‘s technologists, both from Ratingen and Nagoya, and examined on the existing machine for their feasibility in the production environment,” says Risto.

The team of Karlsruhe University is delighted with its outstanding position achieved in the Formula Student Germany 2016 design competition.

In his investigations, Risto always has the user’s needs in mind, although he is well aware that the technical practitioner is not interested in the technical niceties. “But the user benefits if, at the end of the day and thanks to our efforts, he can machine faster and minimise edge wear or requires less electrode material,” says an adamant Risto. In planned bilateral cooperation, the experience gained will contribute to the further development and evaluation of a new machine system for die sinking.

The machine is used not only for research purposes, but also for machining components associated with faculty contracts for project work, degree theses or third-party projects.

However, the machine is not only used for research purposes, but is also used for the production of components in connection with faculty contracts for project work, degree theses or third-party projects, e.g. shaft adapters for project work or mould cores for the internal structure of injection moulds. The High Speed Karlsruhe “Formula Student” team is also allowed to machine its components on it. In the university’s largest student project, 40–50 team members are building their own racing car as part of the “Formula Student” design contest. For this, Mitsubishi Electric’s EDM machines are also used in some cases, e.g. in the production of the steering knuckles and the anti-roll bar blades for the suspension system. Matthias Risto is still enthusiastic about the Mitsubishi Electric machine, attributing this also to his thorough knowledge of the machine. Moreover, he wouldn’t want to do without the many optional extras available for the EA8PV Advance. He still has his wishes however, and with regard to such current themes as Industry 4.0 and SmartFactory, Risto would like to show that the implementation of EDM has already come a very long way. The degree of automation is already very high, since electrodes can be produced automatically and can also be provided automatically in the die-sinking machine. The only thing that’s missing is a handling system that unites the various process steps in a single production cell. “In such a production cell, we would be able to show our students under ideal conditions how the entire process chain can be automated in industry with the aid of handling systems. This would be an excellent element of our ‘transparent laboratory’,” Risto concludes.

Under the direction of Prof. Dr.-Ing. Rüdiger Haas in cooperation with commercial companies, a production laboratory has been established at Karlsruhe University of Applied Sciences. The laboratory is available to scientists for their research projects and includes all modern production methods on the very latest machines on roughly 700 m² of space. Among them are numerous conventional machining systems, laser cutters, lapping machines, various test benches and extensive measuring equipment – and, of course, the two Mitsubishi Electric machines, the EA8PV Advance and the FA20S Advance.

What’s special about this is that students of the Karlsruhe University and neighbouring universities are given practical insight into the world of production technologies. In the ‘transparent laboratory’, knowledge of the various production methods is exchanged not only among employees, but also between the university, large corporations and SMEs.

Prof. Dr.-Ing. Rüdiger Haas

Name and place of company:

Karlsruhe University of Applied Sciences Institute of Materials and Processes

Germany

Founding year:

2009

Prorector:

Prof. Dr. Dieter Höpfel

Professors:

209

Students:

8,500 (Winter semester 2016/17)

Core activities:

Research institute specialising in numerical tool simulation, production engineering, production robotics, fluid mechanics, bionics and allied subjects

Karlsruhe University

of Applied Sciences

Institute of Materials and Processes

Moltkestr. 30

76133 Karlsruhe

Germany

Postal address:

Hochschule Karlsruhe –

Technik und Wirtschaft

Postfach 2440

76012 Karlsruhe, Germany

Tel +49(0)721 925-2395

Fax +49(0)721 925-2000

mailbox@hs-karlsruhe.de

www.hs-karlsruhe.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com